Cottage and Small Scale Industries

advertisement

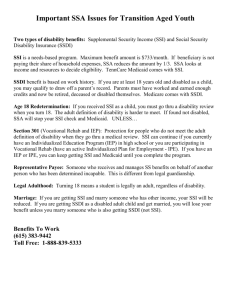

CHAPTER 6 Cottage and Small Scale Industries 6.1 During 2005-06, 5023 new units under the small-scale industries (SSI) sector commenced production out of which 3062 units are in the SSI sector and 1961 units are set up under the PMRY Scheme. In the current financial year (2006-07) the Directorate of Cottage and Small Scale Industries has a target of setting up 5000 new units. During 2006-07 (till September, 2006), 1501 numbers of new units were set up. A sum of Rs. 49.76 crore is invested in these units. Thus total investment in the sector has slightly decreased compared to previous years. 6.2 The registration of SSI units is not mandatory, but voluntary. The registered SSI units enjoy various types of benefits and assistance from the Government prompting such units to get themselves registered. There are two stages of registration: provisional and permanent. Provisional registration is granted in order to enable a unit to obtain all facilities and clearances required in the pre production stage, while the permanent registration is granted upon the start of production. Registration of SSI unit covers both SIDO and Non-SIDO units. SIDO units are those which come under the purview of the Industries (Development and Regulation ) Act,1951. On the other hand, the units, whose manufacturing activities fall under the purview of any statutory Board or Committee or Special Agencies like KVIC, Silk Board, Handicraft Board, Textile Commissioner, Handloom Board, Coir Board, etc. are termed as Non-SIDO industries. During 2002-03, there were 749 items reserved exclusively for SSI sector. During 2005-06, the number of items reduced to only 326. 6.3 During 2005-06,11194 SSI units were registered out of which 1356 units were permanently registered, while the remaining 9838 units were registered only provisionally. During 2006-07 (till September,2006), only 2767 units were registered (both SIDO & Non-SIDO) out of which only 352 SSI units were permanent in nature and had started production. 6.4 A large number of temporary/ provisional registrations indicate that the potentiality of investment in the small scale sector continues to be significant, although the actual number of SSI units in operation has declined sharply each year compared to those of the pre-liberalisation era. One of the reasons for the decline may be gradual de-reservation of industrial items from the exclusive domain of the small-scale sector. The other constraint, presumably, is lack of credit. Table 6.1 shows registration of SSI units in different districts of West Bengal during the year 2005-06. 160 Table 6.1 Registration of SSI Units in Different Districts of West Bengal in 2005-06 District/District Industry Centre Bankura Birbhum Burdwan Durgapur Kolkata Coochbehar Darjeeling Siliguri Uttar Dinajpur Hooghly Howrah Jalpaiguri Malda Midnapur Paschim Murshidabad Nadia South 24- Parganas Purulia North 24- Parganas Dakshin Dinajpur Midnapur Purba West Bengal (Number) Permanent Final Provisional Temporary Grand Total 33 5 281 81 400 11 16 145 34 206 54 18 446 87 605 83 3 244 2 332 191 34 1471 66 1762 36 18 206 18 278 2 10 9 11 32 20 22 62 5 109 12 1 81 12 106 47 13 253 11 324 154 19 866 56 1095 35 8 230 7 280 32 12 338 37 419 54 15 577 70 716 55 22 676 77 830 23 7 410 88 528 53 21 601 243 918 20 1 227 17 265 133 34 651 51 869 5 0 34 9 48 21 3 989 59 1072 1074 282 8797 1041 11194 Source: Department of Cottage and Small Scale Industries, Government of West Bengal. 6.5 It is evident from the above table that while the number of registration continued to be significant in and around Kolkata, districts like Burdwan, Murshidabad, Midnapur Paschim only had encouraging number of SSI registrations. Coochbehar, Bankura, Malda, Jalpaiguri and Malda are doing well. This indicates that opportunities have been created in such predominantly agricultural districts for the growth of economic activities in the secondary sector and, secondly, entrepreneurial talents are available to utilise such opportunities. However, the growth in registration of units over the years is not very encouraging(see Table 6.17 in Statistical Appendix).Disbursement of loans through West Bengal Financial Corporation over the years also shows a dismal picture. Percentage of total amount of loans disbursed by this agency to the SSI units have decreased over the recent years. 161 West Bengal Financial Corporation 6.6 In order to encourage investment in this small scale sector the Government of West Bengal has taken up a number of promotional activities and has continuously extended supports to set up new units. West Bengal Financial Corporation (WBFC) acts as the nodal agency for providing financial assistance to the small-scale sector. In the year 2005-06, WBFC sanctioned a sum of Rs.18996 lakh to 368 numbers of small and other ancillary units and actually disbursed an amount of Rs.11473 lakh. As compared to previous years the scenario has not improved much. Performance of the Corporation in respect of sanction and disbursement of term loans to various types of industries is furnished in Table 6.2. Table 6.2 Industry-wise Classification of Term Loan Sanctioned and Disbursed in 2005-06 Sl. Name of the industry No . 1 Food Manufacturing except Rice Mill 2 Textiles 3 Paper & Paper Products 4 Manufacture of Rubber & Jute Products 5 Basic Metal Industries 6 Metal Products except Machinery & Transport 7 Chemicals and Chemical Products / Pharmaceuticals (Rs. in lakh) Sanctioned Disbursed SSI Total SSI Total No. Amount No. Amount Amount Amount 24 11 0 420 261 0 30 18 1 999 1724 470 233 237 0 422 587 0 5 0 250 0 6 0 376 0 48 0 48 0 2 245 17 4253 174 2659 7 201 8 581 187 187 0 0 0 0 8 Manufacture of Electrical Machinery except Electrical Machinery 0 0 9 Manufacture of Electrical Machinery Manufacture of 2 52 2 52 1 1 0 0 0 0 0 0 10 162 11 12 13 14 15 Transport Equipment Rice Mill Services Electricity Generation Gas & Steam Plastic Products Other Industries Total 5 76 0 212 1617 0 5 212 84 3297 1 250 425 1207 0 425 1737 0 33 137 846 2322 43 2058 153 4724 757 1568 1545 3862 302 6426 368 18996 4837 11473 Source: Annual Report and Accounts (2005-06) of West Bengal Financial Corporation. 6.7 Table 6.2 shows that in 2005-06 major thrust was given on manufacturing units like metal products except machinery and transport, food manufacturing, manufacturing of electrical machinery and service units like hotels, road transport, medical clinics/nursing homes, etc. Actual disbursement of loans was highest in service sector indicating a growth in this sector. 6.8 The State Government launched ‘Bangla Swanirbhar Karmasansthan Prakalpa’(BSKP) for promotion of self-employment. Under BSKP, a beneficiary has to bear only 10 per cent of the project cost. Out of the rest, subsidy of 20 per cent is provided by the State Government, while the remaining 70 per cent of the project cost is financed by credit from banks and other financial institutions. 6.9 Under National Equity Fund Scheme (NEFS) the Corporation sanctioned equity assistance amounting to Rs. 201 lakh to 97 small scale units in the year 2005-06. The Corporation also provides financial assistance under composite loan scheme in order to assist smaller units in SSI sector, artisans and other skilled persons. 6.10 WBFC assisted the units that undertake upgradation of technology under the technology upgradation fund scheme (TUFS) for textiles. Under equipment refinance scheme (ERS) the Corporation provides assistance for acquisition of equipment to small and medium scale units, which are in operation for at least four years and are earning profits with satisfactory track records. Under ERS and TUFS schemes the Corporation sanctioned a total amount of Rs. 4271 lakh to 46 units in the financial year 2005-06. 6.11 WBFC also provided financial assistance to the tune of Rs. 1209 lakh for setting up of 30 nursing homes and diagnostic centres with modern equipment in the financial year 2005-06. 6.12 The Corporation provides financial assistance – both term and working capital loans to selective SSI units with a view to helping the smaller ones of small scale sector to launch their projects quickly with assistance from a single 163 source. During 2005-06, the Corporation sanctioned Rs.412 lakh to 26 units as against Rs.459 lakh sanctioned to 28 units in the previous year. 6.13 During the financial year 2005-06 rate of growth in the area of recovery of loan from the assisted units by the Corporation has slowed down a little, total amount recovered being Rs.11824 lakh. Small Industries Development Agency 6.14 The Small Industries Development Agency(SIDA) provides single window services to SSI entrepreneurs. It provides escort services to investors with proposed investment in plant and machinery over Rs. 2 lakh. SIDA provides assistance/guidance in respect of (i) power connection from WBSEB/CESC, (ii) finance from banks/financial institutions, (iii) no objection certificate (NOC) for pollution from West Bengal Pollution Control Board (WBPCB) for registered SSI units falling under ‘red’ category, and (iv) one-time compromise settlement of SSI units with banks/financial institutions in case of sickness. 6.15 At first the activities of SIDA were confined mostly to the districts of Kolkata, North and South 24- Parganas, Howrah and Burdwan. Now SIDA settles unresolved cases that are referred to it by the respective District Industries Centres (DIC) all over West Bengal. Since inception till March 2006, SIDA sponsored 1067 numbers of SSI projects involving total investment of Rs. 249.408 crore. However, in recent time, inflow of new entrepreneurs at SIDA has slowed down due to stringency in bank finance and non-availability of Government land/shed in and around Kolkata and adjoining districts. Prime Minister’s Rojgar Yojana 6.16 The conditionality of Prime Minister’s Rojgar Yojana (PMRY) has been modified over the last few years. The upper limits of the project cost for the schemes under PMRY are Rs.1 lakh for business sector and Rs. 2 lakh for other activities. The educational qualification of the beneficiaries has been relaxed from matric appeared to class VIII passed. Preference is given to those who have been in the trade for at least six months. The age limit under the scheme is 18-35 years with a relaxation of 10 years for SC/ST, ex-servicemen, physically handicapped and women. In September, 2000, Government of India enhanced the family income ceiling under PMRY from Rs. 24000 to Rs. 40000 per annum. 6.17 Table 6.3 shows the performance under PMRY. The achievement under the scheme is not very encouraging. Till 2000-01, disbursement of sanctioned cases showed a downward trend. Signs of improvement is being noticed in recent years. 164 Table 6.3 Performance under PMRY Year 2000-01 2001-02 2002-03 2003-04 2004-05 2005-06 2006-07(till Oct.,2006) No. of Cases No. of Cases Average sanctioned Sanctioned by Disbursed by project cost (Rs. in Banks Banks lakh) 2315 628 0.616 2647 852 0.609 2834 1174 0.635 3758 1956 0.629 5542 3661 0.661 5487 5032 0.679 1670 899 N.A. N. A. = Not available. Source : Department of Cottage and Small Scale Industries, Government of West Bengal. 6.18 If we analyze the above table, the average project cost comes out to the tune of Rs.60,900/- to Rs. 67,900/ -. It appears that schemes of higher project cost up to Rs.1 lakh for business sector and up to Rs.2 lakh for industry sector are not being selected or finally attracted. One of the reasons might be the low quantum of maximum admissible subsidy. Increase in the existing ceiling of subsidy(Rs.7500 per beneficiary) may change the present scenario of PMRY. Poor recovery of PMRY loan cases is one of the reasons behind this poor performance. Ancillarisation Programme 6.19 The Directorate has a programme of encouraging the small units to develop as ancillary to public sector undertakings. Under the programme, the units get marketing support from the big industries. Nearly 150 numbers of SSI units have been given ancillary status by large industries and plant level committees have been formed by 15 public sector undertakings to support/guide them. Moreover about 250 numbers of SSI units are registered as vendors by different public sector undertakings and a few private sector industries in Durgapur and Haldia and are getting orders regularly. Table 6.4 shows the offloading position of some of the public sector undertakings during the year 200405. 165 Table 6.4 Position of Off-loading of Some Public Sector Undertakings in 2004-05 Sl. No. Name of the PSUs Offloading to SSI Units (Rs.in lakh) Off-loading to Ancillary Units (Rs. in lakh) Total purchase of the PSUs (Rs. in lakh) 1 2 3 Durgapur Steel Plant Eastern Coal Fields Ltd. IOC(Haldia Refinery) 88.09 996.95 1000.00 1310.00 666.98 36.00 27741.00 11085.30 20000.00 % of offloading of SSI & ancillary units to total purchase of PSUs 5.00 15.01 5.20 Source : Department of Cottage and Small Scale Industries, Government of West Bengal. 6.20 The Eastern Coal Fields Ltd. purchases a major portion of its required manufactured products from outside and accordingly, the percentage of its offloading (to the SSI and ancillary units) to its total purchase is higher. 6.21 The commissioning of Haldia Petro Chemical Limited had opened new avenues setting up Petrochemicals downstream industries in the state. The Directorate has laid great emphasis on development on plastic processing units in the area. During the period 1998-99 to 2005-06 about 763 number of units have been set up and total investment in Plant and Machinery is Rs.78.78 crore. Technical Support 6.22 In order to meet the growing demand for tools and dies in the SSI sector and to provide specialized training for increasing the availability of skilled personnel, the State Government has decided to convert the existing tool room of Central Engineering Organisation(CEO), Dasnagar, Howrah into modern mini tool and training centre with the financial assistance from the Central Government. So far the Central Government has released Rs.413 lakh and the State Government has released about Rs.175 lakh till March’06. The State Government has sanctioned the money partly towards cost of machinery and partly towards working capital for the Central Tool Room Training Centre (CTRTC), Kolkata. CEO also provides marketing assistance to the SSI units affiliated to it. CEO obtains orders and farms it to the SSI units. It provides 80 per cent down payment to the SSI units against the supply of orders by them. CEO makes the balance payments when it receives payment from the customers. Only a nominal service charge at the rate of 5 per cent is deducted by CEO for its assistance. 166 6.23 The Electronic Test and Development Centre(ETDC), West Bengal, provides services among electrical/electronic industries for improvement of quality of their products and for conforming their products to national and international standards. The services provided by ETDC include calibration, test and evaluation of electric and electronic products and gadgets against national and international standards. ETDC is also equipped to test performance of electric and electronic products under different environmental stress and conditions. It also imparts training on quality control, electronics and computers and arranges seminar-cum-workshops at different DIC levels. It advises SSI units on quality upgradation of their products. The overall performance of ETDC is shown in Table 6.5. Table 6.5 Performance of ETDC Items Calibration (in no.) Tests (in no.) No. of industries served No. of persons trained: i) Electronics ii) Computers iii) Others 2003-04 2004-05 2005-06 431 564 405 149 185 118 200 230 170 60 90 40 64 61 30 197 Source: Department of Cottage and Small Scale Industries, Government of West Bengal. Cluster Development 6.24 The State Government has a programme to develop SSI units that have come up in clusters and there are 19 major SSI clusters in the state. Under the cluster development programme, the Directorate has set up ferrous and nonferrous metal parts cluster in and around Bargachia of Howrah and surgical instruments cluster at Baruipur, South 24- Parganas district in order to provide better technical support to the small units. Under “National Programme for Rural Industrialisation”(NPRI) the Central Government renders assistance to the tune of 167 Rs.5 lakh maximum for development of rural clusters the District Level Implementation Committee(DLIC) of Hooghly and Howrah Districts have forwarded proposals for cluster development in some villages. In order to enhance productivity and competitiveness of Micro, Small and Medium enterprises in the cluster, Small Industries Cluster Development Programme(SICDP) was introduced. It is a centrally sponsored scheme and at present 92 clusters have been identified in different districts in West Bengal. However, 20 proposals have received approval. The total cost of cluster development programme in the state is estimated at Rs.2626.27 lakh of which Central assistance is Rs.2117.21 lakh and the balance fund will be shared between the State Government and the Implementing agency. . Entrepreneurial Development Programme 6.25 The dearth of properly trained and knowledgeable entrepreneurs among the beneficiaries under different self-employment programmes has been a constraint on the effective functioning of the SSI units. The State Government has accordingly undertaken the entrepreneurship development programme (EDP). Apart from hands on training in various vocational fields the entrepreneurs are given exposure to various aspects of running SSI units and business management techniques. During 2006-07, a great numbers of entrepreneurs are covered under six number of EDPs in the areas of cane and bamboo crafts and commercial paintings, automobiles and other traditional crafts. An expenditure of Rs.18.17 lakh was incurred for the purpose. Industrial Co-operatives 6.26 Any group of at least 10 artisans/ entrepreneurs/ workers forming a cooperative to establish a small scale unit for manufacturing and marketing of goods is given registration as an industrial co-operative society. The skilled workers/ employees of closed or sick industrial units, who form co-operatives to run such units are also registered as industrial cooperatives. During 2005-06, 15 number of co-operatives were allowed registration. During 2006-07(till October,2006), 3 numbers of co-operatives were registered in the trade of clay modeling, readymade garments and leather products. West Bengal Small Industries Development Corporation 6.27 The West Bengal Small Industries Development Corporation(WBSIDC) is a premier state level agency for promoting the small scale industries in the state. It constructs industrial estates, assists SSI units in marketing their products, arranges for the supply of scarce raw materials and provides various other services. 6.28 WBSIDC has so far developed 38 industrial and commercial estates. A joint sector company is being formed to develop a commercial estate at Kasba. Joint sector ventures are also being formed to develop and modernize existing estates and to develop new ones. Repair and maintenance of Kasba, Siliguri, 168 Dabgram industrial estates and Raiganj and Malda commercial estates are being carried out. WBSIDC has also taken up the projects like construction of various trade, commercial and office complexes. Apart from these, SSI units get marketing support from WBSIDC under a common brand name. It has also taken up two big projects for Rs.1.30 crore under RSVY in the district of Jalpaiguri. 6.29 During 2004-05, WBSIDC spent Rs.85 lakh on maintenance work for old industrial and commercial estates. These maintenance work is necessary in order to extend proper infrastructural facilities to SSI units. Promotional Activities of the Directorate of Cottage and Small Scale Industries 6.30 The DIC/Sub-DICs issue environmental clearance to SSI units. These clearances are in 3 categories, green, orange and red (ordinary). Green category units are permitted in any area of the state, orange category units are allowed in all municipalities except Kolkata and Howrah Municipal Corporation areas or within the industrial estates of these two cities. Red (ordinary) category units are not allowed in the municipal limits of Kolkata Metropolitan Area. In 2005-06 the total number of clearances issued by DICs/Sub-DICs are as follows: i) Consent to establish : Green: 3851, Orange: 3631, Red (ordinary):201, Total:7683. ii) Consent to operate : Green: 931. During the first two quarters of 2006-07 the clearances issued by DICs/Sub-DICs are as follows: i) Consent to establish: Green:1682, Orange:1793, Red (ordinary): 87,Total:3562 ii) Consent to operate : Green: 458. 6.31 The West Bengal Incentive Scheme (WBIS) 2000 has been replaced by WBIS 2004 with effect from April 2004. During 2005-06, a sum of Rs. 3795.36 lakh was allotted to DICs/Sub-DICs and they utilized a sum of Rs. 3723.13 lakh on account of payment of pending subsidy claims. 553 number of units were benefited from the scheme. Under the scheme, certificates for waiver of electricity duty were issued to 46 eligible units. During the period certificates for availing concessional electricity charges were issued to 12 units. 6.32 The State Government extends marketing support to the SSI units and handicraft artisans through participation in different exhibitions and trade fairs at national, state and district levels. In 2005 the State Government spent Rs. 3.82 lakh to provide stalls/spaces to 56 units (against a nominal fee) in the India International Trade Fair at New Delhi. At the district level, DICs assisted SSI units to participate in a large number of fairs. 6.33 The national project on Biogas and Manure Management Programme is being implemented by West Bengal Renewable Energy Development Agency (WBREDA) as a nodal agency through the Directorate of Cottage and Small Scale Industries and some NGOs. During the year 2005-06, the Directorate of 169 C&SSI has set up 3000 number of Bio Gas Plants in different districts of West Bengal. BSAI Act Loan 6.34 The basic purpose of extending loans under Bengal State Aid to Industries Act, 1931 is to provide financial assistance especially to the different small handicraft units/ artisans by the Government through the General Managers of DICs of different districts. At present the limit of loan is Rs. 10,000/- per artisan and the sanctioned amount of loan is required to be repaid in equal annual installments not exceeding 15 commencing from the first anniversary of the drawal of loan. The rate of interest is 8 per cent per annum subject to a subsidy of 2.5 per cent per annum for timely and regular payment in all cases. During the current year the recovery position has improved considerably. In 2005-06, the Government disbursed Rs. 50.10 lakh for this purpose. 519 units have been benefited. The Government has also taken several steps to improve the recovery of loans. 6.35 The State Government has also taken initiative for repayment of outstanding loans. During 2005-06 an amount of Rs.19.50 lakh was realized. The State Government also provides grants towards salary, maintenance and capital assistance to the technical and industrial schools. Leather 6.36 West Bengal plays a vital role in the processing and manufacturing of leather and leather goods for the domestic market. The state contributes to 15 per cent of total export of leather goods from India during 2005-06. West Bengal has 538 tanneries. Table 6.6 presents the comparative position of the state in export of different types of leather products with respect to India. Table 6.6 Export of Different Leather and Leather Products from West Bengal and India Product Finished Leather Leather Foot-wear Foot- wear Components Leather Garments Leather Goods Saddlery and Harness Non Leather Foot-wear 2004-05 West India Bengal 145.585 2730.625 18.226 2955.518 5.731 805.212 60.927 1480.227 1563.998 2631.713 1.791 277.265 5.254 331.504 170 (Rs. in crore) 2005-06 West Bengal India 134.092 17.446 1.580 64.354 1596.172 0.777 3.814 2683.226 3483.282 792.667 1454.133 2873.966 338.260 304.360 Total of Leather and Leather Products 1801.512 11212.064 (16.07%) 1818.235 11929.894 (15.24%) Source: Council of Leather Export. 6.37 The Government has an elaborate training infrastructure for upgrading the knowledge and skill of the artisans and small entrepreneurs. Training programmes on footwear and leather goods production are organised by the DICs in their respective districts. Training programmes for women entrepreneurs on the production of fancy leather goods are organised at Kolkata. In collaboration with the Central Foot-wear Training Institute, Agra a footwear project has been started in Bankura district under which training is given to the artisans and owners of small units for upgrading skill in footwear production. The State Government provides assistance to the small scale leather units/artisans through participation in fairs like LEXPO, EXPO, IITF (New Delhi), etc. The West Bengal State Leather Industries Development Corporation Ltd. provides marketing facilities to the small scale units by selling their products through its retail outlets. WBSLIDC also collects orders from various Government organizations and the orders are executed by procuring finished products from the small leather good manufacturing units. Handicrafts Sector 6.38 West Bengal has a large number of artisans skilled in the production of various handicraft products. The Government has wide ranging programmes for promotion of handicraft industries in the state. The creation of new design and arrangement of training programmes for artisans are important functions of the Experimental Workshop-cum-Research Institute situated at Baruipur in the district of South 24- Parganas. During the financial year 2005-06, 38 handicrafts artisans were imparted advance training for different trades like batik print, soft dolls, dry flowers, hand embroidery, fabric printing, etc. at the state level. DICs also organize various training programmes for the development of skill and design in different handicraft activities. 6.39 The State Government organizes district level competitions in order to encourage the handicraft artisans for creation of better and innovative handicraft products. During 2005-06, 252 artisans were given district awards and 75 artisans state awards. The Directorate also encourages artisans to participate in a number of fairs and exhibitions thereby providing marketing assistance to the handicraft artisans. Besides, the Government also provides financial assistance in the form of grant of reimbursement of travel costs to the poor handicraft artisans for participation in different exhibitions and fairs. 6.40 As per existing scheme of payment of pension of old age handicrafts artisans, eligible artisans above the age of 60 and having no other source of income are granted pension at the rate of Rs. 400 per month. In 2005-06, the 171 Government disbursed an amount of Rs.45.52 lakh among 876 artisans towards old age pension through the DICs. Coir Industry Development Scheme 6.41 There is sufficient potential for development of coir industry in the state. It is the 5th largest state in production of coconut. The Government of West Bengal has set up two training cum servicing centres for the coir industry, one at Uluberia in Howrah and the other at Dhancheberia in South 24- Parganas. During 2005-06 training programme for manufacture of coir yarn and coir products are organized at Dhancheberia under ‘Mahila Coir Yojana’ of the Coir Board, where 40 women were trained up. Machines for the said training were provided by the Coir Board. Demonstration programme on preparation of coir pith manure and on quality improvement of coir products have been organized in different areas of Howrah and South 24- Parganas. Lac Development Scheme 6.42 The State Government has implemented a number of schemes to develop lac industry in the state. The basic raw material is cultivated in the mono-crop drought prone areas of Purulia, Bankura, Midnapur , Murshidabad and Malda. The processing units are mainly in Purulia district. During 2005-06, the state produced only 90kg. of stick-lac, which cannot meet even 10 per cent of its requirement. 6.43 During 2004-05 backward districts like Bankura and Purulia have come under a new scheme called Rastriya Sam Vikash Yojana (RSVY).Both the districts have prepared plans for implementation of different projects for lac development under this new scheme. 6.44 The State Government has set up 23 brood lac farms in order to meet the need for quality brood-lac of the farmers. Brood-lac produced in the state are distributed free of cost to the lac cultivators as per recommendation of the panchayats. During 2006-07(till December ,2006), 5240 kg. of brood-lac was produced and 4465 kg. of brood-lac was distributed among 900 beneficiaries. Sericulture 6.45 Sericulture is a labour intensive major agro-based cottage industry in the state of West Bengal. It produces all the four commercially exported varieties of silk. In this sector, the State Government aims at improving the production, productivity and product quality in the pre-cocoon as well as post-cocoon stages by transferring the new technologies developed by the Central Silk Board to the sericulturists in the state. The Directorate of Sericulture has undertaken a number of programmes for overall development of sericulture activities of the state. The major objectives are as follows: To replace local variety of mulberry with HYV mulberry ensuring that loss to farmers in the process is compensated. 172 To supply rearing inputs/appliances to the beneficiaries at free of cost or at subsidized rates under special schemes and to supply planting materials at subsidized rates. Maintenance and multiplication of basic silkworm seeds. To promote post cocoon sector through development of reeling/twisting technology for silk yarn. To encourage cultivation of eri and muga in the district of Jalpaiguri and Coochbehar respectively by providing necessary infrastructural assistance to the tribals engaged in these activities. To impart improved technological training to the officials, farmers, reelers and private seed producers. In addition, the State Government also aims at providing financial support and necessary marketing support to the producers. 6.46 Apart from these normal routine activities, the Directorate has implemented certain new schemes. Catalytic Development Programme: A cluster of schemes was launched in the year 1998-99 and the expenditure of the same is being co-shared by the State Government and Central Silk Board. Major emphasis is given on areas like construction of rearing houses for both mulberry and eri farmers, construction of grainage building, supply of equipment to muga producers, augmentation of area under eri culture, coverage of insurance for silkworm seeds in mulberry, tasar and muga sector, supply of rearing equipments to the people in both mulberry and non-mulberry sectors, providing working capital assistance to silk co-operatives and strengthening of post cocoon areas through supply of reeling/spinning machines to the beneficiaries in both mulberry and non-mulberry sectors. Seri -2000: This programme was launched in 1998-99, but it was stopped in the midway in July,2003. However, some of the major achievements of the programme are 1) training of 112 reelers on improved reeling machine, 2) establishment of 62 number of Quality clubs, 3) training of 173 licensed Seed Preparers (LSP) at Silkworm Silk Technological Laboratory (SSTL), Bangalore under Central Silk Board, 4) replacement of 945 acres of land having local variety of mulberry. 6.47 Extra Departmental Schemes: The Directorate receives fund from different sources under various programmes like RSVY, SGSY, SGRY, BCWD, etc. Different schemes under RSVY are being implemented for development of Mulberry,Tasar, Eri culture in the districts of Uttar Dinajpur, Dakshin Dinajpur, Midnapur, Birbhum, Bankura, Purulia and Jalpaiguri. 6.48 The status of sericulture sector as on March,2006 is shown in Table 6.7. Table 6.7 Status of sericulture in West Bengal as on 31.03.06 173 Sl. No. 1. 2. 3. 4. 5. 6. Item Mulberry Tasar Eri Muga Plantation (acre) No.of farmers (families) DFL consumption (lakh) Cocoon production 34892 108000 481.72 14961MT 524 780 0.57 1552.48 512.00 12823 9000 6.63 22339 kahan 26.63 14.35 3.65 - 795 700 0.53 9.54 (lakh nos.) 0.20 0.10 2.80 0.26 0.01 0.015 62 16 4 59 12 2 2 5 12 8 1 1 1 - 2 1 - Silk production (MT) Silk waste production (MT) 7. Employment generation (lakh nos.) 8. Government Infrastructure: i) Farms ii) Grainage iii) Cold storage iv) T.S.C.* v) Cocoon market vi) Filature vii) Twisting Plants viii) Reeling Training Centers ix) Sericulture Training Institute** 9 Infrastucture at private level i) Reeling Units: Ghosh Basin Charka Cottage Basin ii) Drying Chamber iii) Powerlooms iv) Handlooms v) Weavers vi) Matka spinners(Women) 4.57MT (pierced) 2 2965 4248 264 110 128 18621 30000 35760 (Takli) 870 (improved) 174 207 46 (improved) (improved) 1180 3800 230 (improved) 112 160 (takli) 147 (improve d) 24 29 (improved) vii) Dyeing units and printing 200 *TSC covers for both Mulberry and Non-mulberry sector. **Training Institute imparts training in Mulberry and Non-mulberry sector. Source : Directorate of Sericulture, Government of West Bengal. 6.49 As compared to previous year the total area under plantation of each of four variety has marginally increased. However, additional 1332.91 acres of land was brought under new mulberry plantation and additional 919.73 acres, 161.40 acres and 207.10 acres of land were brought under Tasar, Muga and Eri plantation respectively during 2005-06. 6.50 In 2005-06, 1552.48 MT mulberry raw silk and 26.63 MT of tasar raw silk was produced. Also, 3.65MT of eri spun yarn and 0.20MT of muga raw silk were produced. Production of all the varieties have thus increased marginally compared to previous year. 6.51 Under the Project for Development of Mulberry Production, 2802 farmers were benefited. Among them, 571 belonged to scheduled castes and 104 to scheduled tribes. Under the project for Institutional Finance for Development of Sericulture, a sum of Rs. 1.86 lakh was utilized for providing subsidy to only 40 number of rearers. Under the Human Resource Development Project, a sum of Rs. 4.96 lakh was utilized in order to impart training to 1982 sericulturists. 6.52 A number of special schemes were also implemented in the year 200506. A sum of Rs. 42.65 lakh was incurred for the execution of various maintenance works at various Government farms. A sum of Rs.7.62 lakh was utilized to purchase tasar and muga seeds. 193 SC and 466 ST sericulturists were benefited by the scheme. 6.53 Apart from the normal schemes, a few need-based schemes were implemented for improving the quality and quantity of production. During 200506, assistance was provided to 47 rearers for adopting shelf- rearing, 390 rearers for remodeling of their rearing houses. 6.54 Under catalytic Development Project, 888 rearing houses were built in the Mulberry Sector. Cost of Rs. 7.80 lakh mulberry saplings was reimbursed benefiting 831 number of sericulturists. In the Tasar sector, assistance was provided to 464 Tasar rearers for development of chawki rearing and maintenance of host plants. Assistance was also provided to 190 Tasar rearers for purchasing rearing equipment. In the eri sector, assistance was provided for augmentation of eri host plant in 75 units. 15 eri rearers were assisted to construct rearing housescum-grainage building. In the Muga sector, assistance was provided for augmentation of muga host plant on 125 acres of land and 142 muga rearers were assisted to procure start up tools. In post cocoon sector, assistance was provided to 159 spinners and 25 reelers to procure improved spinning wheel and reeling devices. 175 Handloom 6.55 The handloom industry is the largest cottage industry, which provides widest avenue of employment. There are about 351 thousand handlooms in the state providing full time and part time employment to about 667 thousand handloom weavers. 6.56 The strategy of the Government in the handloom sector is to form cooperatives of poor handloom weavers and to assist these co-operative with inputs, marketing assistance, etc. The State Government encourages the co-operatives to produce fabric according to market demand. Every effort is made by the Government to provide the handloom sector with information about current fashion, designs, colour combinations, etc. 6.57 At the end of 2005-06 as many as 298228 handloom weavers have been brought effectively under 613 active co-operatives till date. 6.58 Total production of handloom cloth has remained almost stagnant as compared to previous year. In the year 2005-06 total production of this sector was to the tune of 1080.00 million metres. The State Government supplies yarn to the handloom co-operatives and other poor handloom weavers through Tantuja (apex Soceity) and Tantusree. The yarn is produced by six spinning mills under the control of the State Government. The State Government had set up a monitoring committee to oversee the operation of the mills. It also provides sufficient fund to the spinning mills in order to improve their working efficiency through upgradation and modernization of their manufacturing facilities. The annual export of handloom products from this sector is about Rs.12.00 crore. 6.59 The six spinning mills now functioning under the direct control of the C&SSI department are: West Bengal Co-operative Spinning Mills Ltd., Tamralipta Spinning Mill, Kangsabati Spinning Mill, Kalayni Spinning Mill, West Dinajpur Spinning Mills Ltd., Mayurakshi Cotton Mills Ltd. Kangsabati Spinning Mills is producing acrylic and synthetic yarn and other mills are producing only cotton yarn. Yarn produced by these mills are marketed through Tantuja , Tantusree and West Bengal Handloom & Powerloom Development Corporation (WBHPDC). In the year 2004-05, the total turnover of West Bengal State Handloom Weavers Co-operative Society Ltd. was Rs. 28.35 crore and that of WBHPDC was Rs. 10.85 crore. Entire requirement of cotton for the six mills is purchased from Cotton Corporation of India under the supervision of the monitoring committee of the State Government. The State Government also provides financial assistance to these mills for their renovation and modernisation. However, as compared to previous year total turnover has fallen with the fall in total production. 6.60 In view of globalisation of market leading to the change of taste of modern consumers for fashion fabrics, the sustenance of handloom industry is 176 now solely dependent on the production of value added products through development in designs and improvement in finishing quality and colour. The production of high quality fabric with new designs is being promoted by schemes like Din Dayal Hathkargha Protsahan Yojana (DDHPY) and development of exportable products and their marketing (DEPM), etc. In 2005-06 one CAD/CAM centre for design development was to be set up at Samudragarh near Burdwan. 6.61 The State Government also formulated a number of welfare schemes for the poor handloom weavers in the state. Weavers are covered under provident fund/thrift fund and during 2005-06 there was a budget provision of Rs. 10 lakh for 4200 number of weavers. So far 6905 weavers have been covered under a workshed-cum housing scheme. Apart from these the Directorate has also introduced old age pension scheme for weavers under co-operatives and health insurance schemes. Powerloom Sector 6.62 At present there are about 6089 powerlooms in West Bengal and 40 powerloom co-operatives, out of which only 18 co-operatives are working. Only 658 powerlooms are working under co-operative societies. Annual production of this sector is estimated to be 152.90 million metres. These looms mostly produce coarse /medium count dhuti, saree, markin, long cloth, tikkin cloth, etc. Some of these looms also produce polyester blended fabrics. Most of these looms are running on job work basis for paucity of working capital and adequate marketing facilities. Hosiery 6.63 There are about 17900 hosiery units in the state. These units are located mainly in Kolkata and Howrah and there are nine registered co-operative societies out of which only four units are active. These units are engaged in activities like knitting, processing, cutting and stitching. The annual production of this sector is estimated to be 1600 million square metres approximately. The State Government provides financial assistance to the co-operatives under the state plan schemes. It also encourages the entrepreneurs to set up new hosiery units by providing assistance in the formulation of bankable schemes. Readymade Garments 6.64 There are 699 licensed readymade garment units in the state, located mostly in Metiabruz, Gardenreach, Santoshpur, Bankra and Jagdishpur. Most of these units are tiny units and operate with outdated machinery and technology. There are 71 registered readymade garment co-operative societies of which only 10 societies are active. The annual production of this sector was estimated to be Rs.10340 crore. The State Government arranges training programmes in tailoring institutes located in Kolkata, Malda and Coochbehar. The Government is also considering a proposal for setting up of an apparel park at Uluberia, Howrah. The 177 Government encourages entrepreneurs in various ways for setting up modern readymade garment manufacturing units. 178