ELECTROCHEMICAL PULVERIZATION OF BULK METAL FOR

advertisement

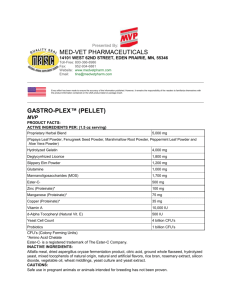

ELECTROCHEMICAL PULVERIZATION OF BULK METAL FOR PRODUCING FINE NIOBIUM POWDER Boyan Yuan1 and Toru H. Okabe2 1: Department of Materials Engineering, The University of Tokyo 2: Institute of Industrial Science, The University of Tokyo, Tokyo 153-8505, Japan The electrochemical pulverization (EP) of bulk niobium was investigated with the purpose of developing a new process for producing fine niobium powder for use in electronic devices. A niobium rod (anode) produced by aluminothermic reduction (ATR-Nb) was immersed in NaCl-KCl-MgCl2-DyCl2 molten salt at 1000 K, and it was electrochemically dissolved in the molten salt from the anode. The dissolved niobium ions were reduced in situ by Dy2+ ion in the molten salt, and fine niobium powder was successfully obtained. The Dy2+ ion in the molten salt, which acts as the reductant, was regenerated either by electrochemical reactions on the cathode or by magnesiothermic reduction. Niobium powder with an average particle size of approximately 1 m and a narrow particle size distribution (D10 = 1.0 m, D50 = 1.1 m, D90 = 1.2 m) was obtained under a specific condition. The electrochemical properties of the molten salt were studied, and the behavior of impurities during the electrochemical pulverization was analyzed. The optimum parameters for producing high-purity powder with a controlled morphology are currently under investigation. 1 Background The recent trend of increasing miniaturization of electronic devices has accelerated the demand for high-performance tantalum (Ta) capacitors. Fine, high-purity Ta powder is essential for such capacitors. Currently, it is produced by the sodiothermic reduction of potassium heptafluorotantalate (K2TaF7); this process is known as the Hunter process as illustrated in Fig. 1 (a). Limited resources and high cost of Ta powder have motivated significant attempts to commercialize new inexpensive capacitors that use niobium (Nb) instead of Ta. In recent years, research on Nb powder production processes, particularly direct oxide reduction processes, have attracted considerable interest (Fig. 1 (b-d)) for the development of Nb capacitors. However, only a few of these processes have gained practical industrial significance. Considering this situation, a new electrochemical pulverization (EP) technique of bulk Nb (Fig. 1 (e)) was developed with the objective of developing a new production process for Nb powder [1]. This process was proved to be feasible for producing fine and homogeneous powder. (a) Stirrer Liquid Na feeding port K2TaF7 powder feeding port (b) Current Nb2O5 monitor (cathode) A e- (c) Graphite (anode) Cl2(-COx) (g) e- [Ca2+] Na (l) Ta (s) [NaF] [K2TaF7] [O2-] Ta Reactor Electric powder furnace (d) Nb2O5 (s,l) Nb (s) Mg (g) MgO (s,l) C [Cl-] ([O2-]) [Ca2+] Nb2O5 powder Ca-X liquid alloy CaCl2 (-CaO) molten salt Mg shot Mg vapor Ar gas (e) Nb2O5 pellet (cathode) Graphite (anode) e- e- COx (g) C [O2-] Nb rod (anode) e- Molten salt containing Dy2+ ion [Nbn+] [Dy2+] Nb (s) [Dy3+] e- Mg-Ag liquid alloy (cathode) CaCl2-NaCl molten salt Mild steel reactor Nb powder Figure 1 Comparison of the new electrochemical pulverization (EP) technique with the Hunter process and other methods. (a) Sodiothermic reduction of K2TaF7 (the Hunter process); (b) Electronically mediated reaction/ molten salt electrolysis (EMR/MSE); (c) Magnesium vapor reduction; (d) Electrochemical de-oxidation; (e) Electrochemical pulverization (EP), (this study). 1 2 Electrochemical pulverization of a Nb rod for producing fine Nb powder The experimental apparatus for the EP technique is shown in Fig. 2 (a). Cyclic voltammetry (CV) measurement was conducted using the electrodes, e.g., the glassy carbon electrodes, which were immersed in the preliminary molten salt (NaCl-32 mol%KCl-11 mol%MgCl2). After the CV measurement, a stainless steel holder containing Dy metal and Ag shot was immersed into the molten salt, and Dy2+ ion was generated in situ according to the following reaction: MgCl2 + Dy + Ag → Mg-Ag + DyCl2, and was supplied to the preliminary molten salt. After confirming the Dy2+ ion generation and Mg-Ag liquid alloy synthesis by CV analysis, a constant current of 2 A was applied between the Nb rod (anode) and Mg-Ag alloy (cathode) to feed Nbn+ ions into the molten salt. Cyclic voltammograms of the molten salt containing Dy2+ ion (NaCl-32 mol%KCl-10 mol%MgCl2-1 mol%DyCl2), shown in Fig. 3, indicate that the peak couple A/A’ is due to the reactions of deposition and dissolution of Mg, peak B is caused by the reaction of chlorine evolution, and the redox peak couples C/C’ and D/D’ can be attributed to the redox reactions of Dyn+ ions because these peaks are not detected by CV using the same electrodes in the molten salt before Dy2+ ion addition. The electrochemically dissolved Nbn+ ions were reduced in situ by the Dy2+ ion in the molten salt, and fine Nb powder was recovered in the collecting dish (see Fig. 2 (b)). Pure Nb powder was obtained after removing the salt by leaching with acid followed by rinsing with water and acetone. 0.8 e- A Electrochemical interface Thermocouple Ar gas inlet Stainless steel tube current lead Rubber plug Glassy carbon electrode (WE, or CE) 0.4 0 D’ C’ -0.4 A’ -0.8 Nb rod (anode) A 0.4 D C 0 -0.4 A’ C’ D’ -0.8 -0.4 -0.2 0 0.2 0.4 Potential, E / V vs.Mg-Ag liquid alloy 0 1 2 Potential, E / V vs. Mg-Ag liquid alloy Ni electrode (RE) 3 Figure 3 Cyclic votammograms of glassy carbon electrode in the molten salt: NaCl-32 mol%KCl-10 mol%MgCl2-1 mol%DyCl2. Counter electrode: graphite. Scanning rate: 20 mV / s. Mg-Ag liquid alloy (RE, or cathode) ➾ Dissolved part of Nb rod Molten salt: NaCl-32 mol%KCl-10 mol%MgCl2-1 mol%DyCl2 B D C Current, i / A‧cm-2 Ni wire potential lead Current, i / A‧cm-2 e- ➾ ➾ (a) (a) Stainless steel powder collecting dish Ceramic insulator (b) Figure 2 (a) Schematic illustration of the experimental apparatus for carrying out the electrochemical pulverization (EP) technique. (b) Representative image of the powder collecting dish after experiment. (c) Frequency, F (%) 10 mm 10 8 6 4 2 0 0.1 Intensity, I (a.u.) (b) 1 10 Particle size, d / m 100 80 60 40 20 0 100 Cumulative percentage, C (%) 1 m Niobium powder deposit with salt : Fig. 4 shows the scanning electron micrograph, particle size distribution profile and X-ray diffraction pattern of the Nb powder obtained in this study. Nb 20 40 60 80 100 Angle, 2 (deg.) powder with an average particle size of approximately Figure 4 Characterization results of the niobium powder produced by the electrochemical 1 m with a narrow particle size distribution (D 10 = pulverization (EP) technique. (a) XRD pattern, (b) SEM image, (c) particle size distribution profile. 1.0 m, D50 = 1.1 m, D90 = 1.2 m) was successfully obtained using the electrochemical method. These results demonstrate that the electrochemical pulverization technique is effective in producing fine and homogeneous Nb powder directly from bulk metal. Nb JCPDS #34-0370 Reference [1] Boyan Yuan and Toru H. Okabe: Proceedings of First Asian and Ninth China-Japan Bilateral Conference on Molten Salt Chemistry and Technology, Wuhu, Anhui, China, (2005), 129–132. 2