Introduction

advertisement

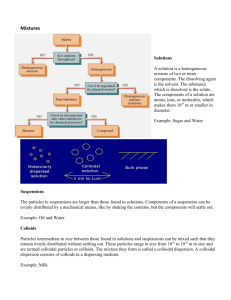

모세관을 이용한 콜로이드 자가조합체의 제조 문준혁, 이기라, 양승만 한국과학기술원 화학공학과 Preparation of macrocrystalline assemblies using an capillary tube Jun Hyuk Moon, Gi-Ra Yi, Seung-Man Yang Department of Chemical Engineering Korea Advanced Institute of Science and Technology, Taejon 305-701 Introduction Colloidal particles are interesting and versatile building block for twoand three-dimensional microstructures [1]. Well-controlled colloidal assemblies display a number of potentially applicable characteristics such as a photonic bandgap [2], high packing density, and high surface-tovolume ratio. For practical applications of these structures, they should be mounted or shaped into usable objects [3]. To address this problem, a number of methods have been exploited using colloidal crystallization in confined geometry, including gravity sedimentation on flat or periodically patterned substrates, flow of the colloids through micromachined channels or a smooth narrow pore membrane, and making use of capillary forces. One of approaches involves the use of a suspension droplet as a confined geometry. The crystallization of submicrometersized colloidal particles occurs inside the droplet, leading to a highly ordered colloidal assembly [4] In this work, we prepare the colloidal crystals using capillary as a confined geometry. Some report a mesoporous silica fiber with large pores using block copolymers [5]. This well-ordered colloidal rod or its replica has a potential as optical waveguides, macroporous membranes and catalytic supports. Experimental Non-crosslinked, monodisperse PS latex particles were synthesized by emulsifier-free emulsion polymerization, and micron-size PS latex particles were prepared by single stage polymerization process using a surfactant [6] and purchased from Polyscience. We used the capillary with various different diameters. Macrocrystalline colloidal rods were produced by PS latex particles and the capillary as templates. The solution contained with the PS particles put into the capillary through syringe pump. Colloidal assembly rod in the capillary was separated via HF treatments. The colloidal crystal rods were infused with in a metal alkoxide precursor solution such as titanium(IV) tetraisopropoxide (TTIP) and tetramethlorthosiilicate (TMOS). This process was conducted under moisture-free condition because of its high reactivity to water. Composite rods of crystalline PS latex particles and ceramic matrix were synthesized through sol-gel reaction. Finally, the rods constituting the composite colloidal crystals were removed by calcinations. Results Figure 1 shows the various colloidal rods. The drying condition determines the arrangement of colloidal assemblies, and the rod can’t be separated from the capillary at high drying rate. It is treated by HF solution, resulting in dissolving the capillary that is made of silica, and we can obtain the colloidal assembly rod. The capillary has an anion charge when it is exposed with an aqueous media, and an ionic surfactant, sodium dodecyl sulphate(SDS) is added to make the colloidal system stable by changing the surface properties of the particles and the capillary wall. The sodium ions gather around the capillary wall that possesses negative surface charges, and eventually change the strength of the zeta potential on the surface. The prepared crystalline rods were soaked into a solution of metal alkoxide precursor, which went through the interstices between the PS latex spheres by capillary force. The rod used as a template, resulting in the macroporous rod. The size of the air boids ranged from 100nm-1um, which depends on the size of PS particles (Figure 2). Conclusion We prepared the colloidal crystalline rod with PS latex suspension into the micron-sized capillary. The size and the length of the rod was obtaind, depending on the particle and capillary size. We also prepared the macroporous rods using the colloidal crystalline rod as a template. It has a potential as optical wave-guides, macroporous membranes and catalytic supports. Reference [1] Y. Xia, G. Bates, Y. Yin, Y. Lu, Adv. Mater, 2000, 12, 693 [2] B. Bates, S. H. Park, Y. Xia, Adv Mater. 2000, 12, 653 [3] van Blaaderan, R. Ruel, P. Wiltzius, Nature 1997, 385, 3210 [4] G.-R. Yi, J. H. Moon, S.-M. Yang, Adv. Mater. 2001, 13, 1185 [5] P. Yang, D. Zhao, B. F. Chmelka, G. D. Stucky, Chem. Mater. 1998, 10, 2033 [6] S. Gu, M. Konno, J. Chem. Eng. Japan 1997, 30, 742 Figure 1. Colloidal crystalline rods Figure 2. Cross section images of Macroporous rods