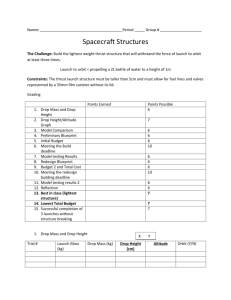

Results

advertisement

Introduction NASA Glenn Research Center (NGRC), our sponsor, has asked us to use design, build, optimize, verify, and document the thrust of a pulsejet; to do so, we used a steel shroud, or ejector, placed behind the pulsejet. The results from our experiment can be used for the study of the more expensive and complex Pulse Detonation Engine (PDE) Propulsion. We have completed our study of the pulsejet, and found that the thrust does, in fact, increase with the use of an ejector. The purpose of this report is to provide a complete documentation of our study. Details and History of Project Currently, NGRC is researching the PDE system. The PDE system works by mixing the fuel with air. Once the detonation is initiated, it moves through the fuel/air mix. This results in high pressure gas filling the detonation chamber. The detonation wave exits the engine and air is drawn in by the reduction in pressure restarting the cycle. There are many benefits of using the PDE. They include a reduced cost compared to regular turbojets, a high efficiency at higher speeds, a greater reliability than other systems, and a potential to reduce hazardous emissions. The pulsejet is used to model the PDE because the operation of the pulsejet is very similar to the pulse detonation of the PDE. Because it has a more simple design and is less expensive, the pulsejet is easier to test. The pulsejet system works by injecting fuel into the combustion chamber with air from the mouth of the engine. Increased pressure in the combustion chamber closes the valve at the mouth of the engine and forces the products out the rear end producing thrust. After the products leave and the pressure in the chamber returns to its normal state, the engine repeats the process by opening the valve and taking in more fuel. The exhaust from the pulsejet then enters the ejector with additional outside air. This results in increased mass flow, which causes an increase in the thrust. The pulsejet and ejector system are shown in figure 1. Figure 1: Pulsejet and Ejector System Setup In the past, groups have performed tests using various ejectors, but have not produced good results. The past experiments have also not been well documented. There has been a problem with the fuel system of the pulsejet. At speeds of approximately eighty miles per hour, the fuel line would kink and no fuel could reach the pulsejet. Another group has fixed the fuel system problem this semester, and we were able to run the pulsejet at high speeds with no problems. In our study of the pulsejet, we constructed three (3) steel ejectors of various lengths. We then tested each ejector with the pulsejet in the five-by-seven foot wind tunnel, and also obtained the thrust of the pulsejet alone. Finally, we analyzed the data and determined whether the use of an ejector does, in fact, increase the thrust of a pulsejet. Method The thrust of a pulsejet can be increased with the use of an ejector of the right design. The purpose of the ejector is to increase the mass flow rate which then increases the thrust. The exhaust gases from the pulsejet enter the ejector with additional outside air. This causes an increase in the mass flow. The thrust from the ejector can be maximized from the position and the design of the ejector. We were only able to examine the design of the ejector, but not the position behind the pulsejet. We used a design for the pulsejet that has been used by previous groups. We made three (3) conical ejectors of various lengths: six, eight, and ten inches. We used an inlet produced by a previous group and constructed the three conical shrouds. For the testing, we attached the inlet to each of the ejectors with magnets. Each of the ejectors was made of steel, as was the inlet. We chose this material because it is inexpensive and is able to withstand high temperatures without melting. To construct each ejector, we started with a sheet of twenty-two (22) gauge sheet metal. Using the pattern shown in figure 2, we cut the metal, and then rolled the sheet into a cone. The ends were then welded together to keep the cone shape. Using the remaining sheet metal, we constructed stands for each of the three ejectors to be attached to the pulsejet test stand. Figure 2: Sample plans for 8" ejector After each of the ejectors was constructed, we tested the ejector and the pulsejet in the five-byseven foot wind tunnel for three days. We used the six-component balance in the wind tunnel. This balance measures the drag, lift, and side forces as well as the pitch, roll, and yaw moments. The balance uses six transducers to measure these forces and moments; the signals from the transducers are sent to a data acquisition system that translates the voltage of the transducers into forces and moments. We spent most of the first day of testing calibrating the balance in the wind tunnel to determine any error in the balance. To do this, we applied a known force to the pulsejet setup in each direction separately. For example, we first applied a known drag force to the pulsejet and measured the voltage output by the transducers. We then used the same procedure for each of the other forces. We found that all of the forces and moments were linearly related to the voltage output from the transducers. After calibrating the balance in the wind tunnel, we first tested the pulsejet without any ejector on the stand to produce baseline data. We used the data produced from this test to compare to the data from the tests with the ejectors on the stand. To examine the thrust of the pulsejet, we only needed to study the change in the drag component of the balance. We first took samples with the pulsejet not running using the data acquisition system; then, we started the pulsejet and took multiple samples of the thrust at thirty feet per second (30 ft/sec) and sixty feet per second (60 ft/sec). We chose these values for the speed of the wind tunnel because the fuel system was still unreliable at high speeds. Also, because the fuel tank can only hold a limited amount of fuel, we were only able to run the pulsejet for a maximum of ten minutes. It takes the wind tunnel longer to get up to higher speeds which would reduce the amount of time to take samples of the thrust. Once we obtained our baseline data from the pulsejet alone, we tested each of the three ejectors the last two days of testing. We placed each ejector approximately one and a half inches behind the pulsejet. We then used the same procedure that we used for the pulsejet alone. We first took samples with the pulsejet not running. Then, we ran the pulsejet and acquired samples at the two velocities. To reduce error, we not only obtained samples with increasing velocity; once we reached sixty feet per second, we decreased the velocity and took samples as the velocity of the wind tunnel went down. Problems Encountered As with any project, we encountered a few problems while testing the different ejectors with the pulsejet. Our main problem was caused by the exhaust of the pulsejet. The fumes from the pulsejet can be very dangerous if exposed to them for extended amounts of time. During our entire time testing in the wind tunnel, the air was constantly being tested by OSHA (Occupational Safety and Health Administration). After running the pulsejet for an average of five minutes, we were required to wait forty-five minutes before entering the wind tunnel again to change the setup. At one point, we ran the pulsejet for ten minutes, and we had to wait over two hours before the levels of dangerous gases dropped to the acceptable level of five (5) parts per million. Because we were required to wait an extended amount of time before entering the wind tunnel, the amount of tests we could perform was limited. If we were able to start the pulsejet, but for some reason it shut off in the middle of testing, we had to wait forty-five minutes until we could try the test again. Another problem we encountered is that the inlet was not secure on the ejectors when we started testing. We first tested the six inch ejector in the wind tunnel with the inlet only pushed on to the front of the ejector. When we were starting the pulsejet for the test, the suction produced by the pulsejet pulled the inlet off of the ejector. To fix this problem, we used two very strong magnets. The magnets were placed behind the inlet to attach onto each ejector, so it wouldn't affect the flow of air over the ejector. After the one incident, the inlet was secure for the rest of the tests. The pulsejet is very difficult to start in cold weather. During our testing, the average temperature inside the wind tunnel was about fifty degree Fahrenheit. Even at this temperature, the pulsejet needed to be heated with a heating gun before starting it. If the pulsejet was left sitting too long before starting, it would not start because it would be too cold. The pulsejet was also very temperamental when starting. This caused us to not obtain as many samples as we had originally planned. Yet another problem we encountered was that the pulsejet would cease functioning during a run for no apparent reason. After disassembling the pulsejet we would discover that the reed used in the combustion chamber had broken and pieces of the reed were gone. You can see the missing sections of the reed in FIGURE BLAH, in addition we noticed that the ends of some flanges would chip after the pulsejet had run for an extended time. The chipping may have resulted in changing the performance of the pulsejet. Figure BLAH: The Two Reeds After Running in the Pulsejet and Closeup of Reed Two (right) The last major problem we found was the variance in the wind tunnel velocity. With each test, we obtained data at different speeds because the wind tunnel velocity is difficult to control. Because of the variations in the speed, it was more difficult to analyze the data produced by our tests. In some tests, we were able to obtain thrust samples at thirty and sixty feet per second. However, in other tests, the speed varied as much as ten feet per second. Results Based on the data from our wind tunnel testing, the overall resulting thrust increased significantly compared to the thrust produced only by the pulsejet itself. As we expected, the ejectors increased the overall thrust and worked well with the non-steady thrust engine. Referring to Figure # generated from the raw wind tunnel data, we could see a general trend of increasing thrust with the ejectors. We obtained a thrust of as much as 43% better than the pulsejet with no ejector. 5.8 Thrust (lb) 5.3 10 inch 4.8 8 inch 6 inch 4.3 No Ejector 3.8 3.3 20 30 40 50 60 Tunnel Veocity (ft/sec) Figure Something: Due to the frequent turning on and off of the wind tunnel, the raw data fluctuates greatly, as shown in figure ### above. The fluctuations are the greatest with the six inch ejector. The vibrations in the ejector due to a weak upright support and unsteady thrust also caused the variations in the data from pulsejet. We were not able analyze how the resulting thrust generated is a function of the ejector length and wind speed. Thus, we compiled the raw data and produced figures showing the resulting thrust with the ejector length and wind tunnel speed inputs. Thrust vs Ejector length 6 Pulsejet system thrust 5 4 30 ft/sec 3 60 ft/sec 2 1 0 0 2 4 6 8 10 12 Ejector Length Figure #@: Figure ### shows an overall increase in thrust from the pulsejet with no ejector to the pulsejet with the eight (8) inch ejector. It decreases from the eight inch ejector to the ten inch ejector. As shown in figure ####, the thrust increases from less than four (4) pounds to as high as five (5) pounds with the ejectors. The optimal ejector length for generating maximum thrust is somewhere between eight and ten inches. This applies for both speeds of thirty (30) feet per second and sixty (60) feet per second. Thrust vs Windspeed 6 Thrust (lbs) 5 4 6 inch ejector 8 inch ejector 3 10 inch ejector No Ejector 2 1 0 20 30 40 50 Wind Speed (ft/sec) Figure*&: 60 70 Figure ### shows the eight inch ejector had a slightly higher thrust than the ten inch ejector at low speeds up to forty-four (44) feet per second. At higher speeds, the ten inch ejector had the best performance. We observed a trend of decreasing thrust as the tunnel velocity increased. As shown in figure ###, the thrust produced with the ejectors decreased over time while the thrust produced without the ejectors stayed constant. This shows that the ejectors became more inefficient as the wind tunnel speed increased. Eventually, if the wind tunnel speed was increased greatly, the ejectors may not have increased the thrust at all. Overall, the ejectors were shown to be very effective in generating extra thrust from the pulsejet at low velocities. The optimal length of the ejector is between eight and ten inches. The ejectors were reliable in increasing the thrust of the pulsejet despite the unsteady thrust of the pulsejet and the change in the wind tunnel velocity. Reducing the vibrations in the ejector by making the upright support stronger would make the resulting thrust more stable. Timeline Figure (*%): Costs Overall, the pulsejet project was not very expensive as shown in figure #####. However, we did spend more than we had originally planned. When we started, we had planned to spend $ 6,524.75. Because of the extended time we spent in the wind tunnel, our cost increased about $ 1,000. The only cost to the group included the four (4) sheets of 22-gauge sheet metal, a digital video tape to document our tests, the transparencies, and the poster for the final presentation. We used the steel inlet used by previous groups, so we did not have to pay for one ourselves. We also used the fuel system and fuel used by the pulsejet fuel delivery system group. Unit Cost Quantity $130.00/hr $50.00 9.6 1 Ejector Steel Plate Steel Inlet $ 4.00 $15.00 4 1 $ 16.00 $ 15.00 Supplies Fuel Cost $25.00/gal 1 $ 25.00 Labor Machinist Technicians Engineering $65.00/hr $65.00/hr $50.00/hr 2 15 100 $ 130.00 $ 975.00 $ 5000.00 $30.00 $0.75 $30.00 2 25 1 $ 60.00 $ 18.75 $ 30.00 Facilities Wind Tunnel Test Stand Documentation Final Report Transparencies Poster Total Cost $ 1248.00 $ 50.00 $ 7,567.75 Total Figure ####: Cost Diagram of the Pulsejet Project Further Research There are many things that can be done for further study of the pulsejet. The most relevant to our study would be to build more ejectors of lengths between those we tested and get even more resolution in the data. Another area for further study would be to design and build a mechanism to change the separation between the ejector and the pulsejet. Building a mechanism to remotely change the separation is necessary due to the limitations on entering the wind tunnel. In addition, a new data acquisition system could be used to find time dependant values of the pulsejet. Finally, to simplify the testing, a different test stand should be designed and built that is specifically for thrust measurements.