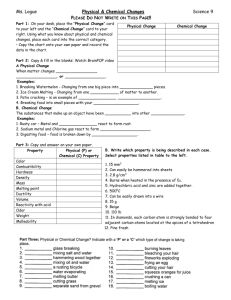

1-141

advertisement

MATHEMATICAL MODELING OF FERRO-ALLOY FUSION IN FE-C MELT Zhuchkov V.I., Lozovaya E.Y. Institute of Metallurgy of Urals Division of RAS One of the main factors that greatly influence the way the components are assimilated and distributed in carbon-ferrous melt is the period of alloy smelting. The study of smelting period turns out to be highly actual when the problems of new ferroalloy grades are concerned: their development, methods and parameters of their application. The research of ferroalloy smelting period, its mathematical modeling and technological parameters of powder ferroalloys injection are an important part of theory of metallurgy and industrial applications. Among the examined chemicophysical and thermophysical characteristics of ferroalloys are the melting temperature (Tm), density (ρ), specific heat capacity (C), the ratio of heat conductivity (λ), the ratio of termal diffusivity (a), the period of smelting (τ). The number of lump ferroalloys smelting models is extensive, being constantly developed and complicated. All the calculations in our model involve the solution of Fourier differential equation. The model consists of thermophysical and hydrodynamical parts. The accordance of the model with the real conditions is rather difficult to establish if we deal with ferroalloys. So, the experiments were carried out with water as the liquid phase, and with ice balls as the solid phase. In static conditions the experiments were carried out with balls of 28, 40 and 50 mm in diameter, the initial water temperature within 10-50 °C (Fig. 1). Fig. 1. The effect of ice lump size on its melting period (water temperature 10 °C). 1calculated values, 2- experimental values. In dynamic conditions experiments were carried out with balls of 40 mm in diameter and water temperature of 23 °C at different movement rates (Fig. 2). 1-141 melting period, sec As the experimental results show, the calculated and experimental values of melting period stand quite close together, the difference getting up to 8%. The calculations were proved by X-ray TV unit experiments. For the experiments we used casting pig-iron as melting base and ferrosilicon FeSi45. The results were in a good agreement with calculations and the difference between calculated and the experimental values being 5%. Fig. 2. The effect of movement rate on melting period for ice balls of 40 mm in diameter. (water temperature 23 °C). 1- calculated values, 2- experimental values. Thus, the mathematical model has proved to be widely applicable (can be used for calculating melting periods of various substances) and calculations are in agreement with real melting process of ferro-alloys in the liquid metal volume. The model was applied for the study of kinetics of ferrosilicon melting process (for FeSi25, FeSi45, FeSi75 with silicon content 25, 45, 75% correspondingly) and silicocalcium melting process (for SiCa10, SiCa 20, SiCa 30 with calcium content 10, 20 and 30% correspondingly) in static state relatively to the liquid metal volume. The calculations were made for steel temperature of 1600°C and the temperature of initial crystallization 1500 C°. Ferroalloy melting runs at three stages: 1) ferroalloy heating up to the temperature of its melting and crust formation; 2) melting of the core and the crust; 3) final core melting. Kinetics of melting for ferrosilicon FeSi75 is shown at the Fig. 3. The results of melting period calculations for ferroalloys with different silicon content are shown at the Fig. 4. The contribution of some ferroalloy and liquid melt parameters to the ferroalloy melting period is studied. Parameters include granulometric of ferroalloy, temperature of ferroalloy pre-heating prior to its placing into the liquid metal volume, density, melting temperature, specific melting heat, heat capacity, heat conductivity ratio and temperature of the melt. The contribution of different factors to the melting period of ferrosilicon FeSi75 is calculated regarding lump movement rate 0 – 1 m/sec. The increase of FeSi75 lump movement rate in iron-carbon melt volume leads to decreasing of density and specific melting heat influence on melting period of 1-142 temperature, °С Core and crust size, mm ferro-alloy. Also it leads to increase of influence on melting period of such factors as iron-carbon melt temperature, heat capacity, heat conductivity ratio and lump grade. melting period, sec Fig. 3. Kinetics of melting for a FeSi75 lump with 20 mm radius. 1- temperature of the ferroalloy surface; 2 – radius of the core; 3 – thickness of the solid steel crust. Fig. 4. The effect of silicon content on ferrosilicon melting period. Among the factors, the most effect is produced by temperature of the ironcarbon melt, granulometric of ferroalloy, heat conductivity ratio and ferroalloy density. The effect of ferroalloy movement rate in the iron-carbon melt is studied for ferrosilicon FeSi75 and silicocalcium SiCa10 on melting period. It was established that ferroalloy lump movement rate increasing up to 1 m/sec reduces ferrosilicon FeSi75 melting period by 59% and silicocalcium SiCa10 melting 1-143 melting period, sec period by 54,5% (Fig. 5). To explain the effect of ferroalloy relative movement rate on its melting period the kinetics of ferroalloy melting is studied. For our calculations it is assumed that there is no direct interaction between ferroalloy and iron-carbon melt, hence the amount of heat in chemical reaction (oxidation) is negligible and its effect in calculations can be left out. We also studied the effect of ferroalloy granulometric on the height of particles floating till final fusion. For particles 0,4 mm diameter the ferroalloy type, its movement rate and depth of input have very little effect on the floating-up height (particles melt down in the place of intrusion into melt). If granules of ferrosilicon FeSi75 6 mm diameter are injected at the rate of 25 m/sec, they float up to 2 meters. Silicocalcium SiCa10 granule 6 mm diameter melts down with floating-up height of 0,7 m. Fig. 5. Effect of relative movement rate of ferroalloy lump 0,04 m diameter in ironcarbon melt at 1600 °C on melting period. 1 - FeSi75; 2 - SiCa10. The present research includes study of the effect of the melt temperature on melting period of a silicocalcium SiCa10 granule. It decreases by 25-48% (0,0540,83 sec) at melt temperature falling down from 1600 to 1500 °C for granules 2-6 mm. For particles size less than 2 mm the effect of melt temperature on the melting period is insignificant because it amounts to fractions of a second. The gas jet ferroalloys injection into iron-carbon melt in manufacturing environment leads to temperature decrease by 20 °C (approximately 2-3 °C/min), so that melting period of particles <6 mm size increases by 5%. As a result, the total effect of metal temperature falling during the injection process on the melting period can be neglected. Thus, different factors effecting melting period of lump and powder ferroalloys (granulometric composition, chemic-physical and thermo-physical characteristics of ferroalloys, iron-carbon melt, hydrodynamic input characteristics) have been studied in this research. As a result of the revealed effects, some important practical recommendations have been developed to improve the ferroalloys injection process into liquid metal. 1-144