MS Ranadive (MIE)

advertisement

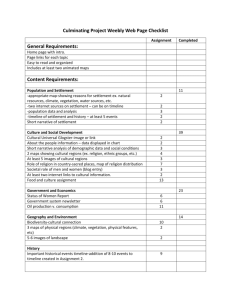

IMPROVEMENT IN BEARING CAPACITY OF SOIL BY GEOTEXTILES -AN EXPERIMENTAL APPROACH M. S. Ranadive (MIE) Assistant Professor Deptt. of Civil Engineering, Govt. College of Engineering, Pune (India). N. N. Jadhav Master of Engineering Research Scholar Deptt. of Civil Engineering, Govt. College of Engineering, Pune (India). ABSTRACT The construction of reinforced soil foundation to support a shallow spread footing has considerable potential as a cost-effective alternative to conventional methods of foundation support. In this technique one or more layers of geo-synthetic reinforcement are placed beneath the footing to create a composite material with improved performance characteristics. Most of the studies reported in literature by Andrawes and others (1989) and Fragaszy and others (1983), have been small-scale model tests to evaluate the potential benefits of a reinforced soil mass below shallow foundations. Since the ability of geotextile to reinforce such systems derives from friction at the soil-geotextile interface, the tests were conducted using sand as the fill material. Here an attempt is made to present the details of investigation on performance of geotextile reinforcement in soil other than sand. For this purpose, model strip footing load tests are conducted on soil with and without single and multi-layers of geotextile at different depths below the footing. The load settlement characteristic for each soilgeotextile configuration has been observed. The influence of various selected parameters on the load settlement behaviour are studied and critically appraised for their practical significance. MATERIAL PROPERTIES The material properties of soil and geotextile material used for the test are given below. a) Soil The optimum moisture content and maximum dry density by standard Proctor test was 17.7% and 1.652gm/cm3 respectively. The California Bearing Ratio (CBR) at 2.5mm penetration was 29.56%. b) Geotextile Non-woven geotextiles have high extensions, high creep and low strength, which make them unsuitable for application as soil reinforcements. Hence woven geotextiles are considered for the experiments. In woven geotextile the multifilament type was selected due to its high tensile strength. For experimental work the geotextile strips were made available from the local manufacturer, Garware Wall-Ropes Ltd., Pune. The properties of the geotextile are as given below. Type of geotextile: Multifilament Woven. Type of fiber : Polypropylene. Trade name : GWF (T) 52 – 240. Weight : 240 gm/ m2. Pore size : less than 75 microns. Maximum extension: 27 %. Tensile strength (Wide strip method) : Warp 55 KN/m :Weft 43 KN/m Bursting strength : 5500 Kpa. Permeability : 31 Lit/ m2/ sec . EXPERIMENTAL PROGRAM The aim of this experimental work was to study the influence of selected parameters on the behaviour of geotextile-reinforced soil supporting strip footing. The dimensionless parameters chosen for the purpose are as given below. 1) Number of reinforcing layers ‘N’ which varied from 1 to 4 (Fig. 4). Figures listed on page 8. 2) d/B ratio varied from 0.25 to1.0, where, d = depth of single reinforcing layer below footing, and B = width of footing. (Fig. 3). 3) S/B ratio varied from 0.25 to 1.0 where, S = spacing between subsequent geotextile reinforcing layers when depth of top layer below footing was kept constant equal to 0.25B. (Fig. 4). Table 1 gives details regarding number and spacing of geotextile reinforcement layers ‘d’ and ‘S’. Table 1: Details of Spacing of geotextile reinforcing layers No. of reinforcing Depth of top reinforcing Spacing of subsequent layers ‘N’ layer below footing ‘d’ reinforcing layer ‘S’ 1 0.25B, 0.5B, 0.75B,1.0B - 2 0.25B 0.25B, 0.5B, 0.75B,1.0B 3 0.25B 0.25B, 0.5B, 0.75B,1.0B 4 0.25B 0.25B, 0.5B, 0.75B,1.0B The test was conducted for following system of geotextile layers. a. Single layer test system. b. Two layer test system. c. Three layer test system. d. Four layer test system. A bearing capacity test on unreinforced soil for comparison of results was conducted. Load verses settlement curves are produced and presented for each test. The improvement in bearing capacity of soil due to introduction of geotextile is characterised by a dimensionless number called Bearing Capacity Ratio (BCR). BCR = Load taken by reinforced soil / Load taken by unreinforced soil The variation in BCR over increase in settlement is represented by BCR verses settlement curves. Experimental Set up The experimental set up was developed with reference to the model tests performed by Mandal and Manjunath (1990) on bearing capacity of single layer of geosynthetic sand subgrade. The tests are performed in a mild steel rectangular box of size 60cm x 11cm in section and 50 cm deep (Fig. 1). The box was well stiffened by welding mild steel angles as stiffeners. The size of the footing under consideration was 10cm x10cm made of mild steel plate 6mm thick stiffened by another plate of width 8cm and thickness 6mm (Fig. 2). Testing was carried out on Universal Testing Machine. For accurate measurement of load, it was applied through a proving ring of capacity 25 KN with least count 12.5 N. Settlement was recorded using dial gauge of least count 0.1 mm. Experimental procedure The water content and dry density of soil was kept constant in all tests and equal to 15% and 1.50 gm/cm3 respectively. To achieve this, the existing water content of soil was determined before each test and the water content was adjusted accordingly. For uniform compaction of soil, it was filled in minimum three or more lifts depending on the spacing of geotextile. The weight of soil for each lift for desired dry density (1.50 gm/cm3) was worked out and that much quantity of soil was filled in the mould and lightly compacted to achieve desired height of the lift. Rectangular geotextile strips of length 60 cm and width 10.5 cm were cut and placed on compacted and leveled soil mass at the desired spacings. Thus the soil was filled upto height 45 cm in each test. Model strip footing was kept centrally on this mass and loaded. Loads required for settlements in the increments of 5 mm were recorded till the total settlement reaches to 50mm. INTERPRETATION OF RESULTS AND DISCUSSION Various useful graphs have been prepared based on the observations of the experiment. Following interpretations have been drawn. A) General 1. Graph of load verses settlement of unreinforced soil indicates failure of the soil for a settlement of 45mm (Fig. 9). 2. Improvement in bearing capacity of reinforced soil over that of unreinforced soil is observed for all positions of reinforcing layers in all tests. 3. The load settlement curves for reinforced soil in all tests continues to rise beyond the failure point of unreinforced soil at settlement of 45mm. This indicates the contribution of reinforcement in resisting bearing pressure. B) Layered System a) Single layer system 1. Improvement in bearing capacity was very low (BCR=1.20 at settlement 50mm) when the reinforcement was at depth d = 1.0B. The reason may be that reinforcement being comparatively at greater depth, shear failure of soil has occurred in the zone above the layer (Fig. 3). 2. Improvement in bearing capacity is maximum when the reinforcement is at depth 0.25B with BCR=1.39mm (Fig. 5). b) Two layered system 1. Maximum improvement in bearing capacity is observed for S/B ratio equal to 0.25 (BCR=1.53 at settlement 50mm) whereas, minimum improvement for S/B ratio equal to 1.0 with BCR=1.30 at settlement of 50mm (Fig. 6). c) Three layered system 1. Maximum improvement in bearing capacity is observed for spacing S/B ratio equal to 0.25 with BCR=1.58 at settlement 50mm (Fig. 7). 2. The differences in BCR of S/B=0.5 at settlement of 50mm (BCR=1.46) and BCR of S/B=0.75 at settlement of 50mm (BCR=1.42) is very low. d) Four layered system 1. Maximum improvement in bearing capacity is observed at S/B ratio equal to 0.25 (BCR=1.60 at settlement 50mm) whereas minimum improvement for S/B ratio equal to 1.0 with BCR=1.39 at settlement of 50mm (Fig. 8). C) BCR and Settlement 1. In general the BCR verses settlement graphs show linear variations. The graphs show increase in BCR during initial settlement but as the footing settles more (about 20-30mm) it declines. This may be due to non-development of proper friction mechanism between soil and reinforcement in the initial stages. As further settlement takes place, the soil gets consolidated and friction gets developed and the BCR starts increasing. Provision of end anchorage beyond the failure zone (at the end of reinforcing strips) or provision of geogrids suitably spaced and tied at the ends beyond the failure zone improves the bearing capacity. 2. In single layer system, the BCR verses settlement graph (Fig. 10) for D/B=1.0 is almost a straight line, which indicates the failure of soil in the zone above the layer of reinforcement. The increase in BCR is only due to the frictional resistance to shear displacement at the interface of soil and reinforcement. The reinforcement is not contributing any more in the improvement of BCR. Similar mechanism has been observed previously by Andrawes2. 3. In two layer system, all the BCR verses settlement curves starts declining after settlement of 20mm (Fig. 11). This is due to slippage of upper reinforcing layer. The curves again start rising after some settlement because of consolidation of soil or increase in stresses mobilize the friction and both the reinforcing layers gets activated. For S/B =1, as the second layer is far below, its activation needs more settlement, hence the graph continues to decline upto settlement of 40mm and then rises. 4. In four layer system, the BCR verses settlement graph shows a declining trend due to more number of closely spaced layers affecting the homogeneity of soil mass and ultimately the bond between soil and reinforcement (Fig. 13). Hence the provision of 4 or more number of layers could not be justified. CONCLUSIONS 1. Improvement in bearing capacity was observed considerable in reinforced soil over the unreinforced soil. For single layer system, BCR for depth of layer below footing equal to 0.25B is maximum and BCR decreases as the depth of layer increases. 2. For multilayer system, BCR for a constant d/B ratio and S/B ratio increases with increasing the number of reinforcing layer. The BCR is maximum for N=4 but the percentage increase in BCR for N=4 over BCR for N=3 is very low. Thus N=3 is recommended as optimum value. 3. For constant number of layers, and constant S/B ratio, BCR decreases with increase in spacing of layers. Maximum BCR is observed at spacing of 0.25B. If the spacing of layers is more than 0.1B, the lower layer does not contribute more in improving the bearing capacity. Because the lower layers are out of tension zone and carry only compression hence do not serve the function of reinforcement. 4. In multi-layer reinforcing system, if the subsequent layers below top layer are provided at greater distance (greater than 2/3B), their contribution in improvement of bearing capacity reduces significantly. At spacing of 0.25B maximum improvement in bearing capacity was observed. 5. More number of closely spaced layers affect the homogeneity of soil mass and ultimately the bond between the soil and reinforcement. This results in decreasing the rate of improvement of bearing capacity. The test was conducted for 4 layers and optimum value of number of layers observed was 3. REFERENCES 1. Adams, M.T. and Collin J.G. (1997), “Large Model Spread Footing Load Tests on Geosynthetics”, Geo-environmental Engineering, January 1997, pp 66-72. 2. Andrawes, K.Z., McGown, A and Wilson-Fahmy, R.F. (1989), “The Behaviour of a Geotextile Reinforced Sand Loaded by Strip Footing”, Proceeding of the 8th European conference on Soil Mechanics and Foundation Engineering, Helsinki, pp 329-334. 3. Ayyar, T.S.R., Krishnaswamy, N.R. and Viswanadham, B.V.S. (1989), “Geosynthetics for Foundations on Swelling Clay”, Proceedings of the International Workshop on Geotextiles, Nov.1989, Bangalore, pp 176-180. 4. Ayyar, T.S.R., Krishnaswamy, N.R., Ravishankar, S and Parashar, S.P. (1990), “Bearing Capacity of Kaolinitic Clay Reinforced with Geosynthetics”, Proceedings of the Indian Geotechnical Conference, Mumbai, pp 11-14. 5. Fragaszy, R., Lawton, E. and Asgharzadeh-Fozi, Z. (1983), “Bearing Capacity of Reinforced Sand”, Proceeding of the 8th European conference on Soil Mechanics and Foundation Engineering, Helsinki, pp 357--360. 6. Guido, V.A., Biesiadecki, G.L. and others (1989), “Behaviour of Geosynthetically Reinforced Earth Slabs”, Proceeding of the International Workshop on Geotextiles, Nov. 1989, Bangalore, pp 170-175. 7. Mandal, J.N. and Manjunath, V.R. (1990), “Bearing Capacity of Single Layer of Geosynthetic Sand Subgrade”, Proceedings of the Indian Geotechnical Conference, Mumbai, pp 7-10. 11 0m m m 600 500mm m M.S. ANGLE STIFFNERS 6mm FIG.1: MILD STEEL MOULD 100mm 6mm 80mm FIG.2: MODEL STRIP FOOTING LOAD d PROVING RING B GEOTEXTILE LAYER 'd' VARIED FROM 0.25B TO 1.0B FIG.3: SINGLE LAYERED TEST SERIES LOAD PROVING RING S S d B GEOTEXTILE LAYERS 'd' KEPT CONSTANT IN ALL TESTS = 0.25B 'N' VARIED FROM 2 TO 4 'S' VARIED FROM 0.25B TO 1.0B FIG.4: MULTI-LAYERED REINFORCEMENT TEST SERIES 1.4 BCR 1.3 1.2 FOR D/B =0.25 1.1 FOR D/B =0.50 SETTLEMENT (mm) 1 0 10 20 30 FOR D/B =0.75 40 FIG.10 BCR VS SETTLEMENT FOR SINGLE LAYER SYSTEM 50 FOR D/B =1.0 60 1.52 1.47 BCR 1.42 1.37 1.32 FOR S/B =0.25 1.27 FOR S/B =0.50 FOR S/B =0.75 SETTLEMENT (mm) 1.22 0 5 10 15 20 25 30 35 40 45 50 55 FOR =1.0 60 S/B 65 FIG.11: BCR VS SETTLEMENT FOR TWO LAYER SYSTEM 1.6 1.55 BCR 1.5 1.45 FOR S/B =0.25 1.4 FOR S/B =0.50 1.35 FOR S/B =0.75 1.3 FOR S/B =1.0 SETTLEMENT (mm) 1.25 0 10 20 30 40 50 60 FIG.12: BCR VS SETTLEMENT FOR THREE LAYER SYSTEM 1.65 BCR 1.55 1.45 FOR S/B =0.25 FOR S/B =0.50 1.35 FOR S/B =0.75 SETTLEMENT (mm) 1.25 0 10 20 30 40 FOR S/B =1.0 50 FIG.13: BCR VS SETTLEMENT FOR FOUR LAYER SYSTEM 60