11400 - Nycsca.org

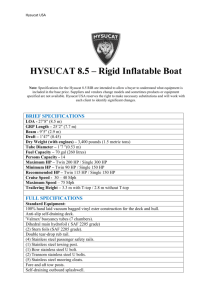

advertisement