Ohio Case Histories (Presentation Notes)

advertisement

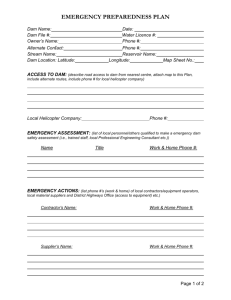

Presentation Notes Ohio Case Histories Mia Kannik, P.E., Project Engineer, Ohio Department of Natural Resources (ODNR), Dam Safety Engineering Program, Columbus, Ohio Slide 1 Good Afternoon. Today I will discuss a couple of case histories of dams that have had problems with filter and drain design. Slide 2 – The 1st dam I’d like to talk about is Salt Fork Salt Fork Lake Dam is located in the eastern part of Ohio about five miles north of the intersection of Interstate 70 and Interstate 77. Construction was completed in 1968. Homogeneous 61-high, 1500 feet long earthen embankment. The dam creates a beautiful 3010-acre lake in Ohio’s largest state park. Salt Fork Lake Dam is a Class I dam (high hazard) based on its height, storage volume, and potential downstream hazard. Interstate 77 is 2500 feet downstream, and approximately 500 residents are located between the dam and the USACOE flood control structure – Wills Creek Dam. Slide 3 - Aerial photo during construction of the dam The lake is on the right side Construction of I-77 downstream Slide 4 - Plan view: Right and left abutment Outlet works and Morning Glory spillway, note how it goes through the left abutment Toe Drain system and collection manhole – trench drain. The outlets exit into the principal spillway outlet channel Slide 5 - Cross section of the dam Blanket drain Toe drain Note the 8-inch drain pipe Slide 6 - Site Geology Glacial boundary map of Ohio – in unglaciated part of Ohio Blue indicates the buried valleys, Salt Fork Lake Dam located over one Bedrock is shale and sandstone 95-feet of silty sand, glacial meltwater at the ground surface is 10 to 15 feet of cohesive soil Slide 7 - Tuesday February 15, 2005 11:00 a.m. on Tuesday, February 15, 2005, Ohio’s Dam Safety Engineering Program (DSEP) received a call the maintenance manager for Salt Fork State Park Large seepage boil at the downstream toe 1 Received these photos from the park During the previous month, Salt Fork Lake had experienced high pool levels of about 8.5 feet above normal pool Backwater from Wills Creek Reservoir had inundated the toe of Salt Fork Lake Dam 8 to 10 feet up the slope. The toe was inundated for more than 3 weeks. Once the water receded, Park maintenance staff initiated brush removal from around the principal spillway stilling basin. They noted water at the toe of the dam; however, we were not notified until the damsafety-trained maintenance manager observed the boil Slide 8 – Close up It was 4 feet in diameter and 18 to 24 inches deep. The flow was somewhat cloudy and soil particles were moving at the bottom of the boil. On the upstream side of the boil, some evidence of a classic sand cone was present Slide 9 – Location Map of initial Boil Close to the center of the dam Slide 10 – Photo of ring levee DSEP staff arrived at the site, started constructing sandbag ring levee with v-notch weir to measure the flow. Slide 11 – Photo of small boil While constructing the sandbag ring levee, a second boil was noted adjacent and to the right of the original boil. This boil was about 6 inches in diameter and 18 inches deep. Slide 12 – Completed ring levees A second sandbag ring was placed around this boil. A v-notch weir was not added until the next morning, not a lot of flow Slide 13 - Seepage flow amounts: Initially 50 gpm 75 gpm by morning 130 gpm by afternoon 24-hour surveillance was initiated Slide 14 – Back in the office Gathering information about the dam turned up original construction photos From the photos it appears that the drainage material was very large. We had concerns that the embankment or foundation material had “piped” into the coarse aggregate. Slide 15 – Plan view of filter berm Decided that the best course of action was to open the lake drains and construct a weighted filter berm over the boil. 2 Slide 16 – Start of construction – Spreading material By Thursday February 17, 2005 a contractor mobilizing equipment immediately and started spreading material on the second day Slide 17 – Boil right before they covered it up. Slide 18 – Friday, February 18, 2005 Three small boils were found the next morning. The one closest one had a small sand cone already forming Slide 19 - Made berm larger - Completed berm. Slide 20 – The Department hired Gannett Fleming to investigate the cause of the boils. They put together a proposal to install some peizometer Slide 21 – Boils at the downstream toe They also dug test pits into the toe drain. The toe drain material consisted of a filter material the size of concrete sand with a lot of fines and a larger drainage material of gravel up to 8 inches in diameter. The larger drain material was clogged with sediment. Also video taped the toe drain pipe but was not able to make it very far since it was completely clogged with material Slide 22 – Gannett Fleming proposed a new toe drain Constructed downstream of the dam to avoid excavating into the embankment. Two conveyance pipes to the outlet channel Slide 23 – Typical cross section of the New Toe Drain Design Foundation materials Original drainage system - toe drain pipe was grouted shut and the blanket drain was still functional so it was connected to the new drain. Concrete sand and pea gravel and perforated 12’ diameter drain pipe Slide 24 –GF used NRCS-NEH, Chapter 26 “Gradation Design of Sand and Gravel Filters” to design the new toe drain materials – Skip over this one you have see enough filter bands for the design of the sand filter and gravel drain.. Slide 25 – Next look at the outlet of toe drain. Slide 26 – The toe drain outlet was design to be able to flush out the drain by opening this valve and during normal operation this valve is closed and the toe drain flow is measure through the v-notch weir. Slide 27 – Here is a picture of the completed toe drain outlet. Slide 28 – Another view. I’d like to point out the valve cover here which comes in to play later. 3 Slide 29 – Park’s annual inspection one year after the repairs were completed in the spring of 2007. The toe drain was flushed for the first time. Slide 30 – Prior to flushing the toe drains, small boils were noted at the end of the left toe drain headwall Slide 31 – Here is a video of the material piping. It was apparent that we should have paid closer attention to the backfill around the concrete headwall. We told Parks that they needed to make repairs; however, due to limited funds the park had to schedule this into their budget. Slide 32 – This is not the first time boils were discovered in the outlet channel. After the initial emergency back in 2005 with the boil at the downstream toe, the lake was drawndown several feet before repairs were make. Once this level was reached the lake drains were closed and the downstream outlet channel water level dropped several feet. Slide 33 – Photo of the sand boil at the bank Slide 34 – Here you can see the numerous boils in the channel and the sandbag ring levee around the one at the bank. Slide 35 – Plan of location of boils and piezometers Here is the approximate location of the boils. As part of Gannett Flemming’s investigation, they also placed several piezometers next to the channel and in the left valley slope. Slide 36 – Boils in the downstream channel. The piezometer data showed that the water level in the hillside was higher than the water in the reservoir. Therefore it was concluded that the boils in the outlet channel were a result of high ground water levels not seepage from the dam. Slide 37 – Photo taken during the 2010 periodic dam safety inspection. The park manager indicated that they finally had the repair money set aside in their budget and to start repairs later in the summer. Slide 38 – Close up view of the left toe drain outlet. Slide 39 – Sinkhole observed along the concrete side wall. Slide 40 – A couple of months after the inspection, a sinkhole was discovered next to the valve upstream of the toe drain outlet. Slide 41 – Here is a close up. Based on a survey taken at the time, the left headwall had settled 1.6 feet which most likely caused the outlet pipe to separate from the valve creating the sinkhole. Luckily the toe drain system has two outlets which allowed us to block the left outlet pipe and force all the flow out the right toe drain outlet until repairs can be made. 4 Slide 42 – 3 months later – Both sinkholes have gotten larger. Slide 43 – Another sinkhole photo. Slide 44 – This past year, plans were developed to repair the outlets. This is a plan view of the outlet area. This winter a contractor will installing vinyl sheet piling and concrete cap at the toe of the left outlet. Slide 45 – And they are planning on installing a new manhole and valve in the location of the original valve. This will allow for the change in pipe elevations. The fill around the concrete headwall will also be replaced with a properly designed filter. Slide 46 – Dam Safety Program Changes due to Lessons Learned from the original emergency. More critical of older high hazard dams Review original plans and photos if available. Require owners to investigate if there is uncertainty about the drain design. Also prioritized state-owned dams to assist Div. of Engineering with selection of capital improvement projects. Developed a departmental dam safety program for state-owned dams. Slide 47 – One of the state-owed dams that rose to the top of the rehabilitation list was Acton Lake Dam Dam is located in Hueston Woods State Park SW part of Ohio between Dayton and Cincinnati near the Indiana border. Dam construction completed in 1958. 62-feet high, 1100 feet long zoned-earth embankment 560 acre lake at normal pool Class I (High Hazard) dam – immediately downstream of the dam is rural with scattered homes but several miles downstream is the City of Hamilton. Similar foundation condition as Salt Fork Lake Dam – deep alluvial valley with a thin cohesive layer on top Slide 48 – here is a plan view of the dam The spillway is cut into the rock in the left abutment with a concrete weir with a side drop outlet channel. The lake drain goes through the left end of the dam and outlets into the spillway outlet channel. The original design called for a rock toe drain along the entire length of the downstream toe. Slide 49 – However, during construction the drain design was changed to include 51 – 6” perforated corrugated metal pipe extending 80’ perpendicular from the downstream toe. The cross section shows the pipe extending below the downstream shell. The drains outlet into a ditch at the toe. Slide 50 –Here are a couple of construction photos from June 1955. This is looking across the valley to the right abutment. The lake drain pipe and tower are in the foreground. You can see the new embankment drain system being installed in the distance. 5 Slide 51 – Here you can see the 6” perforated CMP lying in a trench filled with 1” sized gravel. Slide 52 – The size of the gravel indicates that proper filter criteria was not provided between the embankment soil and the gravel drain. In addition this type of drain does not address the foundation conditions at the site. Slide 53 – In 1956 during first filling of the reservoir, boils were noted at the downstream toe. Arrow points to the dry drain outlet. They stopped filling the dam and closely monitored the situation but it appears that they continued filling the reservoir with not additional remediation. The file for this period is incomplete. Slide 54 –May 1958 Slide 55 – May 1958 Slide 56 – May 1958 - Phase 1 and Phase 2 reports were generated in the late 1970’s and early 1980’s that reveled that the dam was stable at normal pool; however at higher pools the exit gradients became very high. Remediation was recommended. Slide 57 – This is what the downstream area looks like today. For some reason, the dam was not formally inspected by Ohio Dam Safety in the 1990’s. A cursory inspection was performed in 2000 but it was not until the inspection in 2006 that all the issue with the dam came to light. Last year, the Department hired DLZ to investigate the dam. Slide 58 – Current Investigation and Repair Installed piezometers Video inspection of drain pipes Preliminary analysis confirmed what the Phase II Report had indicated. Preparing design alternatives Construction tentatively scheduled for 2014 Slide 59 – Dow Lake Dam Dow Lake Dam is located in Strouds Run State Park in SE Ohio very close the Ohio University in Athens. Dam construction completed in 1959. 66-feet high, 775 feet long homogenous earth embankment 290 acre lake at normal pool Class I (High Hazard) dam – based on height and downstream hazard. There are several small towns before reaching the Ohio River 30 feet of clay and sand layers over a shale bedrock foundation Slide 60 – Plan view of the dam Principal spillway inlet and outlet Blanket drain and toe drain. Toe drain outlets through a concrete headwall into the original stream channel. 6 Slide 61 – Typical cross section of the dam Here you can see the extent of the blanket drain under the downstream slope. Slide 62 – Close up of the toe drain Here is the blanket drain 8-inch perforated CMP surrounded by stone and 12 inches of sand filter. Slide 63 – Photo from the original construction. The stone in the toe drain looks very large. Slide 64 – During our 2001 inspection we discovered a shallow slide on the downstream side of the embankment – left of the original stream channel. Slide 65 – This is what the toe drain outlets looked like at the time. They could not be observed. Slide 66 – In 2009 the Park cleaned out the downstream channel to lower the grade of the tailwater and cleaned out around the concrete headwall exposing the toe drain outlets. Slide 67 – Got a call at the end of January from the Park indicating that the side was continuing to move. Slide 68 – The department has hired S&ME and they are in the process of taking borings and installing piezometers. They have not excavated in the toe drain material so that question still remains to be answered. Slide 69 – Questions? 7