Biopharmaceutical Manufacturing - Bio-Link

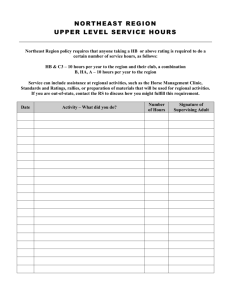

advertisement