AEM_PDTG-TPD_BTV final version for production

advertisement

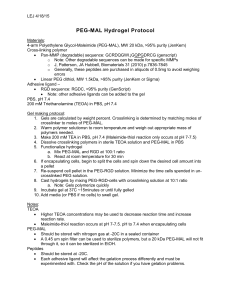

DOI: 10.1002/ ((please add manuscript number)) Article type: Full Paper Investigation of Radical and Cationic Crosslinking in High Efficiency, Low Band Gap Solar cell Polymers. By Chin Pang Yau†, Sarah Wang†, Neil D. Treat, Zhuping Fei, Bertrand J. Tremolet de Villers, Michael L. Chabinyc*, Martin Heeney* Dr Chin Pang Yau, Dr Zhuping Fei and Prof. Martin Heeney Department of Chemistry and Centre for Plastic Electronics Imperial College London Exhibition Road, South Kensington London SW7 2AY UK E-mail: m.heeney@imperial.ac.uk Sarah Wang, Dr Neil D. Treat, Dr Bertrand J. Tremolet de Villers and Prof Michael L. Chabinyc Materials Department Elings Hall Room 3219 University of California Santa Barbara CA 93106-5050 U. S. A. E-mail: mchabinyc@engineering.ucsb.edu †Both authors contributed equally. Keywords: Dithienogermole, Organic Solar Cell, conjugated polymer, Crosslinking Abstract We report the synthesis and characterization of dithienogermole-co-thieno[3,4c]pyrroledione (DTG-TPD) polymers incorporating chemically crosslinkable sidechains and compare their properties to a parent polymer with simple octyl sidechains. Two crosslinking groups and mechanisms are investigated, UV promoted radical crosslinking of an alkyl bromide crosslinker, and acid promoted cationic crosslinking of an oxetane crosslinker. We find that random co-polymers with a 20% incorporation of the crosslinker demonstrate a higher performance in bulk heterojunction solar cells than the parent polymer, whilst 100% 1 crosslinker incorporation results in deterioration in device efficiency. The use of 1,8diiodooctane (DIO) as a processing additive improved as-cast solar cell performance, but was found to have a significant deleterious performance on solar cell performance after UV exposure. The instability to UV could be overcome by the use of an alternative additive, 1chloronapthalene, which also promoted high device efficiency. Crosslinking of the polymer was investigated in the presence and absence of fullerene highlighting significant differences in behavior. Intractable films could not be obtained by radical crosslinking in the presence of fullerene, whereas cationic crosslinking was successful. 2 1. Introduction The surge of interest in organic photovoltaics over the last few years has resulted in a steady increase in device efficiencies, with values now approaching thresholds for commercialisation.1 Organic devices are typically comprised of a mixture of two components in a bulk heterojunction (BHJ), with the device performance crucially dependent on the complex nanostructure of this blend. This nanostructure is influenced by the miscibility of individual components, as well as their tendency to crystallise and phase separate.2 Desirable morphologies are thought to contain bicontinuous domains with sizes on the order of 10 nm for effective charge generation and separation.2-3 This morphology has been typically achieved by the manipulation of coating conditions, post processing thermal or solvent annealing and by the choice of solvent and processing additives.2-3 In many cases the nanostructure of the blend can be considered kinetically trapped rather than thermodynamically preferred.4 As such, the as-cast morphologies can change over time, because the fullerene in polymer:fullerene BHJs is able to diffuse within the amorphous regions of the polymer matrix.5 Therefore the lifetime of the device may be compromised by the reorganisation of fullerene and polymer to a more thermodynamically stable state over time. This change can be particularly relevant during device operation, in which relatively high temperatures can be reached. One possible approach to overcome this issue is to ‘lockin’ the optimum kinetically trapped morphology by some form of chemical crosslinking after the active layer has been formed. Crosslinking of donor polymers has been shown to stabilise the nanostructure in polymer:fullerene BHJs, principally by restricting the ability of PCBM, the most common fullerene acceptor, to crystallise or aggregate into large domains in thin films.6 Crosslinkable polymers also have other potential benefits, such as their use in bilayer devices where 3 deposition of the second layer can be facilitated by crosslinking of the first. For example some element of structural control over phase connectivity and length scale has been recently achieved by diffusion of fullerene derivatives into lightly cross-linked donor polymers during solution deposition.7 In these examples swelling of the polymer network by the solvent assisted the diffusion of fullerene into the film. Therefore, in general, polymer crosslinking may offer more flexibility in methods to form BHJs, as well as providing methods to control and stabilise the nanostructure in BHJs. Crosslinking groups have been incorporated onto the lateral sidechains of conjugated polymers to enable either thermal or photochemical crosslinking.6b Reactive groups such as alkyl bromide, oxetane, azide and alkenyl have been reported as effective crosslinkers. Many of these studies have used modified regioregular P3HT to demonstrate the proof of concept. 6a,8 However, there are relatively few examples in which low band gap donor-acceptor polymers, which provide higher power conversion efficiency, have been investigated.6c,9 Within the small class of low band gap polymers reported thus far, device efficiencies have been rather modest even before crosslinking. Furthermore there have been few studies examining the differences in performance for radical and cationic crosslinking groups. Two different reactive crosslinkers have previously demonstrated promising performance in semiconducting polymers, alkyl bromide groups as a radical crosslinkers and oxetanes as a cationic crosslinkers. Alkyl bromide functionalised sidechains have been demonstrated as a promising route to stabilise blend morphology in both P3HT functionalised polymers, and in low band gap benzodithiophene copolymers.6c,8c The process of crosslinking is believed to be a radical based mechanism, whereby direct exposure to 254 nm UV light causes homolytic cleavage of the carbon-bromine covalent bonds.10 Subsequent crosslinking likely occurs by abstraction of a proton by the bromine radical from the sidechains of adjacent 4 polymers, followed by coupling of the alkyl radicals. The crosslinking of oxetane groups has been widely investigated in OLED materials.11 Oxetane groups polymerise via a cationic ring opening mechanism also known as CROP.12 In comparing oxetane to other cationic crosslinking groups like epoxides, the oxetane functionality has the advantage of high stability to a variety of chemical conditions, facilitating the synthesis of oxetane containing materials. Furthermore unlike radical based crosslinking, which is sensitive to oxygen, cationic polymerisation can be performed in ambient atmosphere. In addition the cationic reactive center is generally less reactive and less prone to side reactions than highly reactive and nonselective radicals. The CROP mechanism typically requires small amounts of a photo-acid generator (PAG) to initiate the reaction. Following initiation, heat is generally applied in the form of a post-exposure bake in order to accelerate the crosslinking. Although several conjugated polymers incorporating oxetane functionality have been successfully crosslinked and photo-polymerised for OLED applications, at the outset of this work there were few examples in OPV.8a,13 In this paper we report the synthesis and characterisation of random alternating donoracceptor co-polymers incorporating either oxetane or alkyl bromide crosslinkers, and compare their optoelectronic properties to the parent alternating polymer. We focus on thieno[3,4c]pyrrole-4,6(5H)-dione (TPD) as a suitable readily functionalised electron poor co-monomer. TPD has been utilised in various high performing donor-acceptor co-polymers, and generally promotes high open circuit voltage and good photocurrent. 14 As an electron rich co-monomer, we investigated dithienogermole (DTG) due to the promising performance of the PDTG-TPD co-polymer previously reported, and our experience with this comonomer.15 We find that the incorporation of small amounts (20%) of crosslinkable monomer has a beneficial impact on overall device efficiency before crosslinking. The role of various processing additives is 5 investigated, and we find the that the use of 1,8-diiodoctane (DIO) causes unexpected stability issues when the films are irradiated with UV radiation. The use of chloronapthalene (CN) as an alternative additive circumvents these issues. Finally we compare and contrast radical and cationic crosslinking in blends with fullerene derivatives and demonstrate that the presence of fullerene in the blend reduces the efficacy of radical crosslinking. 2. Results and Discussion 2.1. Synthesis 4,4-Bis(2-ethylhexyl)-2,6-bis(trimethylstannyl)-4H-germolo[3,2-b:4,5-b']dithiophene16 DTGSn2) and 1,3-dibromo-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione6c (TPD) were synthesised by literature procedures. However, the purification of DTG-Sn2 was complicated due to its chemical instability towards column chromatography over silica. Therefore, purification was performed by preparative gel permeation chromatography (GPC) on a crosslinked polystyrene size exclusion column using hexane as the eluent. The TPD oxetane, bromide and octyl variants were synthesised according to a modification of literature procedure6c, as shown in Scheme 1a. Hence TPD was deprotonated with sodium hydride in DMF, and the appropriate alkylating agent was subsequently added. In the case of 1,6-dibromohexane, excess reagent was added in order to prevent the reaction of two TPDs with one 1,6-dibromohexane. Alternating co-polymers incorporating 100% of the crosslinking groups, as well as random co-polymers incorporating 20% of the crosslinker and 80% of an octyl substituted TPD comonomer (TPD-C8) were prepared, along with the parent PDTG-TPD-C8 co-polymer. Scheme 1b shows the nomenclature used to designate the percentage crosslinker in the polymer backbone. Percentages refer to the statistical amounts of co-monomers added at the beginning of the reaction, thus the 20% statistical co-polymers were synthesised using a 0.2 6 mol equivalence of the desired crosslinking TPD monomer (TPD-Ox or TPD-Br) with 0.8 mol equivalence of the TPD-C8. Five co-polymers, shown in Scheme 1c, were synthesised via a microwave assisted Stille coupling method in chlorobenzene.17 After precipitation, they were dissolved in chloroform then washed in sodium diethyldithiocarbamate trihydrate to extract any residual palladium before being precipitated into methanol.18 Soxhlet extraction was performed with methanol, acetone and hexane to remove catalyst residues and low weight oligomers. Finally, the remaining polymer was extracted into chloroform and the polymer was further fractionated by preparative GPC in hot chlorobenzene (80 °C). This method was used to modulate the molecular weights and narrow the polydispersity (PDI) for all five PDTG-TPD polymers. All polymers demonstrated reasonable solubility in common organic solvents like chloroform and chlorobenzene upon warming. The molecular weights were measured by GPC relative to polystyrene standards, as shown in Table 1, which shows the number average molecular weight (Mn), degree of polymerisation for Mn (DPn), weight average molecular weight (Mw), degree of polymerisation for Mn (DPw) and polydispersity (PD) of all five polymers. The molecular weight of PDTG-TPD-C8 was similar to that previously reported by Reynolds et al.,15b and both of the random co-polymers showed comparable molecular weights, with degrees of polymerisation around 60-70 for all polymers. For the PDTG-TPD-Ox100% and PDTG-TPD-Br100% copolymers, slightly lower Mn‘s were observed, with degrees of polymerisation around 35. The composition of the random co-polymers was confirmed by 1H NMR in CDCl3 (see Supporting Information). Although the aromatic protons and methylene groups close to the polymer backbone were rather broad and poorly resolved, likely due to restricted rotation, the peaks attributable to the alkyl bromide or oxetane were sharp. Integration of the aromatic 7 protons (8.60-7.30 ppm) and the oxetane proton environment (4.51 and 4.35 ppm) gave a ratio of 1:0.38, within the experimental error of the expected value of 1:0.4. Similarly, for PDTGTPD-Br20% the ratio was observed to be 1:1.1 (aromatic DTG proton environment (8.60-7.30 ppm):CH2 adjacent to the TPD nitrogen + CH2 adjacent to the bromine on TPD-Br (3.71-3.43 ppm)) which is in agreement with the theoretical reaction stoichiometry. Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) were performed under an inert atmosphere of nitrogen on all co-polymers. DSC measurements showed no obvious transitions from -20 °C to 330 °C for all co-polymers. TGA of PDTGTPD-C8, PDTG-TPD-Ox100% and PDTG-TPD-Br20% shows 5% mass loss at 431 °C to 433 °C, while PDTG-TPD-Ox20% shows a 5% mass loss at 450 °C and PDTG-TPD-Br100% at 385 °C (Figure S6). The TGA shows that there are no low temperature decompositions, and since the chemical composition of the backbone is similar for all polymers, it suggests that the 100% alkyl bromide incorporation may be the reason for the earlier decomposition temperature of PDTG-TPD-Br100%. The temperatures where decomposition occurs are much higher than any annealing temperatures used in the fabrication process for BHJs making these polymers highly stable for use in solar cells. 2.2. Optical and Electrochemical Properties The UV-Vis spectra were measured in chlorobenzene solution at room temperature and as thin films spin coated from a solution of chlorobenzene (5 mg/mL) (Figure 1). The long wavelength onset for all polymers is 730 nm, corresponding to an optical band gap (Eg) of 1.7 eV. All polymers exhibited similar shape spectra for both solution and film measurements, with a pronounced series of peaks with the most intense around 680 nm and 620 nm (Table 1), similar to that previously reported.15b This separation (~0.2 eV) is consistent with a vibronic progression as observed in many ordered semiconducting polymers. There was almost no change in the position of the absorption maxima (±2 nm shifts) upon 8 film formation suggesting aggregation in solution. Upon comparison of the five polymers, it is clear that the parent alkylated polymer (TPD-C8) and both polymers with 20% crosslinker groups show almost identical spectra, with very little difference in the relative heights of the two absorption peaks, both in solution and thin film. However, for the 100% oxetane and bromine containing polymers it can be seen there is a change in the relative peak amplitude of the two maxima, with the long wavelength peak reducing in relative absorption versus the shorter wavelength peak. Since the relative ratios of these two peaks are often related to coupling of the transition dipoles in the solid state, this suggests that high amounts of the relatively large crosslinking groups are influencing the intermolecular packing of the conjugated backbones. We do not believe this is related to the lower degree of polymerisation for both of the 100% polymers, because the MW should be sufficient to be above the effective conjugation length in both cases. Additionally, PCPTD-TPD-C8 of much lower weight (Mn 16.3 KDa) has been reported to have an identical UV spectra to that of the higher weight polymer.15e Therefore, we believe the origin is more likely related to the high percentage of crosslinking groups changing the interactions of the sidechains. The ionisation potential of polymer thin films was determined using photo-electron spectroscopy in air (PESA) and is shown in Table 1. The reduction potential (LUMO) was estimated by the addition of the optical Eg to the ionization potential. The ionization potentials are all in the range of 5.2 to 5.3 eV, and fall within the standard error of 0.05 eV associated with this particular measurement. These results support the fact that the 20% and non crosslinkable polymer are optically and electronically very similar. For both of the 100% crosslinkers (Br and Ox), a slightly lower HOMO of 5.3 eV was observed, which could be due to the crosslinker functionality disrupting the packing and backbone planarisation. 9 2.3. Photovoltaic Properties The optoelectronic properties of these polymers were measured in BHJs using a glass|ITO|PEDOT:PSS|Polymer:Fullerene-Blend|LiF|Al device structure and their power conversion efficiency was measured under 100 mW cm2 AM 1.5 illumination. Polymer:fullerene BHJs were solution processed from chlorobenzene and due to the low band gap absorption of the polymer, PC70BM was used to complement and capture the low wavelength of the visible spectrum.19 All polymers were tested in 1:1, 1:2, 1:3 and 1:4 ratios against PC70BM. As shown in Table 2, the best performances were obtained in a 1:2 polymer:PC70BM weight ratio for all polymers. Average PCEs from as cast devices through the series are similar, around 1.6%, with the exception of PDTG-TPD-Ox100% which was below 0.5% Following literature by Reynolds, So and co-workers, further optimisation showed that the addition of 5 vol% 1,8-diiodooctane (DIO) increased the PCE of as-cast devices in all cases.15c Interestingly, both of the 20% co-polymers performed significantly better than the baseline polymer PDTG-TPD-C8, with the highest average efficiency of 7.35% for PDTG-TPD-Br20% (Table 2). Both of the alkyl bromide crosslinkers gave higher efficiencies compared to the analogous oxetanes. The 100% crosslinker polymers show a decrease in overall PCE compared to equivalent 20% and non-crosslinkable polymers. The limiting factor for both the PDTG-TPD-Ox100% and PDTG-TPD-Br100% is the fill factor, along with a small drop in current in comparison to the 20% crosslinkable polymers. The differences in performance may be due to changes in the blend microstructure from the addition of different functional groups at the solubilising chain end. Similar results have been seen from Bao and co-workers when altering the side groups with terminal siloxane groups.20 Our results further highlight the importance of solubilising chain effects on morphology and device performance. 10 In order to investigate the possible influence of the end group on polymer morphology, X-ray diffraction (XRD) using a lab source were obtained from drop cast films prepared from solutions of polymer dissolved in chlorobenzene (5 mg/mL). The XRD traces are shown in Figure S7. The polymers appear mostly disordered, with a lack of clearly resolved diffraction peaks. 2.4. Crosslinking Studies The different PDTG-TPD polymers allow an examination of the role of the cross-linking mechanism on the ability to form intractable films and on the efficiency of photovoltaic devices. The bromide and oxetane end groups crosslink by two different mechanisms, namely free radical and cationic.12b,21 Here we investigated the crosslinking of PDTG-TPD-Br20% and PDTG-TPD-Ox20% because they had the best performance in BHJs prior to crosslinking. To gauge the necessary amount of curing required for cross-linking, we studied the ability of crosslinked films to withstand solvent rinses using UV-Vis absorption spectra before and after washing (in chloroform) of the crosslinked films.6c,8c,9a For PDTG-TPD-Br20%, 15 mg/mL solutions were spin coated without any additional photoinitiator, and photo-crosslinking was performed in a nitrogen glove box. Varying times of deep-UV exposure from a 15 W UV lamp (254 nm) were used. As can be seen in Figure 2 the film without UV treatment shows complete solubility after washing. However, 20 min of UV exposure afforded 80% film retention and 30 min gave near 100% film retention. For the oxetane crosslinkers, photoacid generators (PAGs) are generally required to initiate the polymerisation.12 The use of both non-ionic and ionic PAGs was investigated, utilising N-hydroxynaphthalimide triflate and tris(4-tert-butylphenyl)sulfonium triflate PAGs. Preliminary attempts at crosslinking were investigated upon films prepared from 15 mg/mL solutions of PDTG-TPD-Ox20% containing 1 wt% of PAG. Films were exposed to UV light (365 nm) for 10 min, and followed by heating to 100 °C for 10 min. However, these initial 11 attempts proved unsuccessful, with no retention of the film after solvent rinsing. Increasing the PAG to 5 wt% was also unsuccessful at 100 °C, but did afford semi-intractable films when films were instead heated to 150 °C (note no cross-linking occurred in the absence of PAG under these conditions). However, the high concentration of PAG necessary caused significant issues with de-wetting of the polymer solution during spin-casting and in the formation of smooth and homogenous films. The difficulties may have been due to the low 20% oxetane density, which may have reduced the probability of oxetane groups being in close enough proximity to react, as well as reducing the ability of the catalytic species to migrate from oxetane to oxetane in the film. Because of difficulties with utilizing PAGs, we investigated the use of a volatile nonphotoactivated acid, trifluoroacetic acid (TFA), as a ring opening catalyst. TFA has a relatively non-nucleophilic counter ion, and its vapors can permeate through the film and initiate the CROP mechanism. The volatility also meant that the excess TFA could subsequently be removed by heating or vacuum treatment. Films of PDTG-TPD-Ox20% were spun as described in the method above and then exposed to TFA vapour for 5 minutes. Polymer thin films were placed in a glass petri dish containing a central shallow vial holding 0.5 mL of TFA. Warming to 100 °C on a hot plate created a sealed atmosphere containing TFA. Films were subsequently cooled, and the UV-Vis absorption measured before and after washing with chloroform. It can be seen from Figure 2, that 20 minutes at 100 °C resulted in approximately 75% film retention, but longer heating offered little improvement. Heating the films to higher temperatures did improve the retention, but was undesirable in terms of device fabrication, so 100°C was chosen as a good compromise. We believe the differences in film retention after solvent rinsing for the different crosslinkers are due to the different mechanisms of crosslinking. In the case of cationic 12 crosslinking, the films are only able to crosslink when one oxetane ring is in close enough proximity to another oxetane to react, so the difficulties may have been due to the relatively low 20% crosslink density, which reduces the probability of such close interactions, as well as reducing the ability of the catalytic species to migrate from oxetane to oxetane. In the case of the radical crosslinking of the alkyl bromide, the cleavage of the C-Br is expected to generate highly reactive alkyl and bromine radical species, which can react with a variety of species in close proximity – for example extraction of a proton from a neighbouring alkyl chain by the Br radical to generate HBr and another reactive alkyl radical. Dimerisation of these alkyl radicals would then cause crosslinks. Undoubtedly, there are competing reactions such as disproportionation, but the high reactivity and non-selective nature of the radicals generated ensures sufficient crosslinks are formed to generate intractable films, even at low loadings of the crosslinker. There was little change observed in the UV/Vis spectra before and after washing of the films in both cases, except for a slight decrease in the long wavelength peak of the spectra relative to the shorter wavelength shoulder. This may be expected due to the reordering necessary for the crosslinking process to occur, we note however this was a minor change and the absorption maxima did not shift suggesting that the crosslinking does not cause a significant perturbation of the chain packing. 2.5. Crosslinking of Solar Cell Devices prepared from 5 vol% DIO Additive To study the impact of crosslinking on PCE, we fabricated crosslinked devices using the optimal device parameters for uncrosslinked layers with 5 vol% DIO. PDTG-TPDBr20%:PC70BM films were spun cast in a nitrogen atmosphere, and crosslinked before vacuum deposition of the LiF/Al contacts. Crosslinking was performed using the optimised conditions for film retention by 30 min of exposure to 254 nm light. Upon irradiation the OPV performance of the completed device suffered a very significant 99-100% drop in 13 performance (Figure 3), with very low Jsc and PCE. Surprisingly reducing the UV exposure time to only 5 minutes still caused a very large degradation in device performance. Our initial hypothesis was that the degradation upon UV exposure was caused by residues from the crosslinking of the alkyl bromide in the polymer film (for example HBr or bromine). To test this hypothesis, films of PDTG-TPD-Ox20%, cast from identical solvent and DIO mixtures were also exposed to 254 nm UV (note we did not expect this to crosslink the film). Interestingly this polymer which contains no alkyl bromide, showed an identical degradation in performance (Figure 3), ruling out the possibility that the effect was due to formation of HBr or molecular bromine. An alternative explanation may be that the polymer backbone was degraded. However, no change to the film UV-Vis absorption was noted, and in addition the literature has also shown many studies in which UV crosslinking is demonstrated without backbone degradation.6c,8c Therefore we suspected that reaction of the residual DIO in the films could be the cause, despite the high vacuum treatment (1×10-7-1×109 mbar) before electrode deposition which was expected to remove DIO traces.22 Other reports have noted that DIO or high boiling additives can be retained in thin films after spin coating23, and that its presence can cause films to crosslink when heated to 300ºC.24 In our case, exposure of any residual DIO to UV could likely trigger the homolytic fission of the carboniodine bond (similar to the alkyl bromide in the polymer), and the resulting alkyl and iodine radicals may subsequently react in the film, either with each other, the polymer or the fullerene.25 Figure 3 shows the degradation effects to the J-V curves of a) PDTG-TPDBr20%:PC70BM and b) PDTG-TPD-Ox20%:PC70BM. A similar reduction in performance occurred for both polymers, which may be attributed to the same volumetric qualities of DIO (5 vol%) used in the solution before spinning the films. Carbon-iodine bonds are known to be 14 even more prone to homolytic fission of the bond than carbon-bromine because of the weaker covalent bond,26 making it highly labile to deep-UV exposure. We attempted to remove residual DIO by prolonged vacuum treatment (1×10-2 mbar) for 2 or 24 hours, before subsequent UV exposure. Two hours was found to be insufficient and resulted in similar effects to the freshly spun devices. However after 24 h, although a reduction in Jsc and FF was still observed, this was similar to that seen for UV crosslinking in the absence of DIO (see section 2.6) suggesting most of the DIO was removed. Surprisingly we can find no reports on the effects of UV exposure to residual DIO in the literature. It is likely that such effects have not been observed previously due to the minimal UV exposure during routine testing of BHJs under simulated solar illumination. However we believe this result is significant because with such labile carbon-iodine bonds, the use of DIO may not be suitable for OPV applications where the long term exposure of sunlight may result in similar degradation in situ.27 These results suggest that the use of DIO as an additive should be avoided to achieve high PCE over long lifetimes, particularly since prolonged high vacuum treatment is not viable for large scale printing. 2.6. Investigating Chloronaphthalene as an Alternative Additive Due to the stability problems associated with the films cast with DIO, alternative additives were investigated, which could still afford high efficiency devices but demonstrate improved UV stability. Chloronaphthalene (CN) has been much investigated as a high boiling point additive,28 and unlike the alkyl iodide, the aromatic carbon-chlorine bond is stronger and stable towards UV light. Different concentrations of CN (3, 4, 5 and 6 vol%) were first screened in the same device structure as reported earlier. The optimum performance was achieved with 4 vol% of CN with both PDTG-TPD-Br20% and PDTG-TPD-Ox20%. As shown in figure 4 and Table 3, the use of CN boosted FF, Jsc and overall PCE for all polymers by approximately 1% compared to the use of DIO. CN has previously been suggested to promote 15 phase segregation of PCBM in P3HT:PCBM cells,29 affording higher degrees of polymer crystallinity when compared to neat polymer film without PCBM, which was ascribed to the slower evaporation rate of the high boiling additive. This gives rise to a super saturated regime allowing more time for the alkyl chains to self-organise. In our case, similar effects may help to explain the increase in Jsc and FF by improved thin film morphology and thus better charge extraction in the active layer. The improvement of photocurrent and fill factor suggest an improvement in exciton harvesting and charge extraction, which may indicate an increase in donor-acceptor interfacial area and improved ordering of the polymer films upon spin coating. The best performing device was again PDTG-TPD-Br20% with an average PCE of 7.88%, followed by PDTG-TPD-Ox20% with an average PCE of 7.05%. Interestingly the performance of both of the 100% polymers also improved as can be seen in table 4. It should also be noted that these efficiencies, which have been measured in a normal device architecture, are on par to those reported for the best inverted device structure by Reynolds and co-workers.15b 2.7. Crosslinking of Solar Cell Devices prepared from 5 vol% CN Additive Having substituted DIO for CN, further crosslinking studies with PDTG-TPD-Br20% were performed using the same crosslink parameters. Gratifyingly, the results showed a significant improvement to the previous study using DIO, although a deterioration in performance was still observed upon crosslinking (Figure 5 and Table 4), mainly as a result of a reduction in Jsc and FF. Exposing the film after crosslinking to further thermal annealing (120 °C and 150 °C for 5 minutes), or to high vacuum to remove possible breakdown residues did not improve performance. We also investigated the crosslinking of the PDTG-TPD-Ox20%/PC70BM blend with 4 vol% CN. In this case, crosslinking was initiated by exposing the films to TFA vapour in a nitrogen atmosphere for 30 min, followed by a thermal bake at 100 °C. Following the deposition of the 16 cathode, the device performance is shown in Figure 5 and summarised in Table 4. Interestingly, we find that the photocurrent increased after crosslinking, from 10.5 to 12.7 mA/cm2, although the fill factor reduced from 0.66 to 0.46 resulting in an overall reduction of PCE from 5.79 to 5.02% in this batch of devices. The increase in photocurrent may indicate that a change in morphology has occurred during the crosslinking process. 2.8. Differences in Crosslinking behaviour between pristine Polymer and Polymer:PC70BM Films. The changes in device behaviour post crosslinking prompted us to investigate the effectiveness of crosslinking in a blend film with fullerene present. Having established that crosslinking can be performed without causing significant device degradation, further film retention studies were performed using blend films on Glass|ITO|PEDOT:PSS in order to best simulate device conditions and reaffirm the films solvent resistance. Many papers have used the pure polymer films to exemplify crosslinking, but crosslinking studies of a blend with fullerene have rarely been reported.6c,8c,21 Films were deposited using the same methodology as for OPV fabrication with the 4 vol% CN additive. The films were then crosslinked with varying amounts of time, either with UV (254 nm) exposure (for PDTG-TPD-Br20%) or heated to 100 °C under a TFA vapour atmosphere (for PDTG-TPD-Ox20%). As before, film retention was determined by a normalised loss in absorption at the UV maxima. The results of PDTG-TPD-Br20%:PC70BM (1:2) demonstrated that even exposure to 254 nm UV for 60 minutes did not result in the formation of an intractable film. In all cases, the film was removed completely upon insertion into a chloroform bath. Previous reports have also reported a reduction in crosslinking efficacy upon the inclusion of fullerene to the blend, which was rationalized on the basis that the fullerene acts as a UV screening layer, absorbing most of the UV light and reducing crosslinking efficiency.21 However given the long exposure time in the present case we believe that this is unlikely to be the only 17 explanation. Another possibility is that cleavage of the C-Br is occurring, but the resultant radicals are preferentially reacting with fullerene, rather than cross-linking with another chain. The well-known ability of fullerenes to act as radical scavengers suggests this may be a possibility.30 However we were unsuccessful in attempts to directly detect any polymer with bound fullerene by techniques such as MALDI or NMR (of the washed films). These results suggest that, despite several reports of the efficacy of alkylbromides as useful crosslinkers, caution must be exercised particularly in the presence of high loadings of fullerene. In contrast, the cationic crosslinking of blends of 1:2 PDTG-TPD-Ox20%:PC70BM with 4 vol% CN in TFA vapour proved to be much more effective (Figure 6). Although longer exposure times were needed than for the pristine polymer film, almost complete retention of the polymer film could be obtained after 60 min of exposure to TFA at 100 °C. The longer reaction times are probably a result of the dilution of the polymer by the fullerene in the thin film. Interestingly examination of the UV spectra before and after washing (Figure 6), shows that a 70% reduction in intensity is seen in the peak at 450 nm after washing in chloroform whilst the polymer peak at 680 nm is barely affected. We attribute the drop in the short wavelength to a reduction in PC70BM content after washing. One explanation for the loss of PC70BM may have been due to the swelling of the crosslinked polymer in chloroform, thus allowing for the release of PC70BM. This suggests that even though the polymer was intractable, the fullerene which was blended into the film was not. Interestingly, with the removal of PC70BM it is clear that the absorption spectra closely resembles that of the pure polymer thin film, further suggesting that the polymer has not degraded during the crosslinking process. Although this shows that PC70BM is able to freely move in a solvent swollen film, crosslinking may still help to slow detrimental aging of the blend film particularly as it has recently been shown that the formation of an electron blocking polymer 18 rich capping layer next to the cathode is one reason for reduced device efficiency upon aging.31 In addition, it may be possible to pattern and crosslink the pure polymer film, before subsequent solvent swelling in the presence of fullerenes to allow the laterally patterned blend films. However, in order to form fully intractable blend films, it may be necessary that both the polymer and fullerene contain crosslinkable functionalities. We further investigated the stability of both sets of cross-linked devices, PDTG-TPDBr20%:PC70BM and PDTG-TPD-Ox20%:PC70BM (1:2) blends, with 4 vol% CN, under accelerated aging conditions – namely thermal annealing. Devices were annealed at 120 °C over a period of 5, 10 and 30 min. Although devices are not expected to reach this temperature during actual operation, this temperature was chosen since any issues regarding blend stability (for example detrimental large scale phase separation) were likely to happen more rapidly at this temperature. Thus devices were fabricated as reported above, and then annealed for the appropriate time and temperature within a glove box, before measurement at room temperature. The results are shown in Table S1 and Figure 7. In the case of PDTG-TPD-Ox20% using the optimal blend crosslinking procedure resulted in a drop in overall efficiency, which we attribute to the extended baking time. Exposure of the control non-crosslinked film to the same heating profile but without TFA present also resulted in a similar reduction of efficiency. The two devices demonstrated significant differences in the subsequent heating of the devices to 120 °C. The noncrosslinked devices exhibited a large initial drop in performance after just 5 min heating, followed by a small improvement over time due to an increasing photocurrent. The improvement of the control over time was surprising, but it may perhaps be related to crosslinking of the film at 120 °C by acid present in the PEDOT:PSS.32 Previous reports have shown that PEDOT:PSS can initate a surface initiated crosslinking upon heating. 12b 19 Morphology changes caused by such crosslinking could help explain the increased photocurrent, similar to the increase in photocurrent observed for TFA exposed devices. In contrast the cross-linked blend did not show the rapid reduction in performance upon annealing at 120 °C, but rather a gradual decrease in efficiency over time, such that both sets of material show similar performance after 30 min cumulative annealing. In conclusion it seems that the crosslinking does not result in a clear improvement of device stability for the oxetane polymer, although it does improve film intractability which may be beneficial for multi-layer solution processing. For PDTG-TPD-Br20% although UV crosslinking did not form intractable films, this did appear to reduce device stability. On the contrary annealing at 120 °C resulted in a small improvement in device efficiency, whereas the non-crosslinked polymer reduced in performance. Subsequent thermal annealing of both films did not result in any further significant changes of device efficiency. In order to probe the origin of the differences in behavior for the oxetane polymers, atomic force microscopy (AFM) topography was used to probe the surface of the 1:2 PDTGTPD-Ox20%:PC70BM film with (Figure S8) and without crosslinking (Figure S9). The images of all films appear very similar, and no obvious change occurs to the morphology of either the crosslinked or the non-crosslinked films during thermal annealing, despite the reduction in solar cell performance. Certainly there appears to be no growth of large domains during the annealing process, as has been seen in other reports. Indeed the surface morphology for all films appears to show good intermixing of the two materials, with no large features observed, in agreement with the high device efficiencies observed. RMS values shown in Table S2 demonstrate the smoothness of each film. The lack of any obvious difference in film morphology over time and with post heating (at both 120 °C and 180 °C) with or without 20 crosslinking may indicate that the degradation in device performance is due to other factors apart from morphology changes, or perhaps more simply that the effects are more subtle than can be observed by AFM, which is only probing the surface morphology. Further investigations into the thin film morphology and long term stability are required. 3. Conclusion In conclusion, four novel crosslinkable polymers were synthesised based upon PDTGTPD with different ratios of crosslinker, and their optoelectronic properties and device characteristics in OPVs were measured. Polymers with high degrees of crosslinking group showed a reduction in solar cell performance compared to the parent polymer, whereas those with 20% crosslinker demonstrated an improved overall PCE by increasing Jsc and FF. Comparisons of two crosslinking methods, both radical and cationic, were performed for pure polymer films as well as blends of polymer:fullerene, highlighting significant differences in behaviour. We also demonstrated that the choice of processing additive is very important when crosslinking devices with UV light. The use of diiodooctane resulted in a significant reduction in device performance upon UV exposure suggesting that DIO may be a problematic additive for BHJs with long lifetime under sunlight. We further demonstrated that the oxetane containing PDTG-TPD-Ox20% could be readily crosslinked by exposure to a saturated TFA vapour environment. Crosslinking by this route was successful for both pure polymer as well as blends with fullerene. In contrast, although the pure alkyl bromide containing PDTG-TPD-Br20% films could be crosslinked by exposure to 254 nm UV light, this was unsuccessful for blend films containing fullerene. For blend devices, UV crosslinking of the alkyl bromide containing polymers was shown to have a detrimental effect on performance, whereas acid catalyzed crosslinking of the oxetane polymer resulted in a small increase in device performance. 21 4. Experimental All reactions were treated as air and light sensitive and performed under argon and in the dark. All glassware used were washed using teepol surfactant, rinsing with excess water, acetone and dichloromethane and dried in an oven at 120 °C. All solvents and reagents were sourced commercially from Aldrich. 4,4-Bis(2-ethylhexyl)-2,6-bis(trimethylstannyl)-4Hgermolo[3,2-b:4,5-b']dithiophene16 and 1,3-dibromo-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione6c were synthesised as previously reported. 1H and 13C NMR spectra were recorded on a Bruker AV-400 (400 MHz for 1H and 100 MHz for 13 C) unless otherwise stated, using the residual solvent resonance of CDCl3 as an internal reference. Number-average (Mn) and weight-average (Mw) molecular weight were determined by Agilent Technologies 1200 series GPC running in chlorobenzene at 80 °C, using two PL mixed columns in series and calibrated against narrow polydispersity polystyrene standards. Electrospray mass spectrometry was performed with a Thermo Electron Corporation DSQII mass spectrometer. UV-Vis spectra were recorded on a UV-1601 Shimadzu UV-Vis spectrometer. Flash chromatography was performed on silica gel (Merck Kieselgel 60 F254 230–400 mesh). A custom build Shimadzu recSEC system was used to fractionate the polymers (chlorobenzene at 80 °C) and purify the tin monomer (hexane at 40 °C). The system comprises of a DGU20A3 degasser, a LC-20A pump, a CTO-20A column oven, an Agilent PLgel 10 μm MIXEDD column and a SPD-20A UV detector. Photo electron spectroscopy in air (PESA) measurements were recorded with a Riken Keiki AC-2 PESA spectrometer with a power setting of 5 nW and a power number of 0.5. Samples for PESA were prepared on glass substrates by spin coating. Data reported is the average of 2 separate thin film measurements for pristine samples, and 2 films for blend samples. X-ray diffraction (XRD) measurements were performed on the PANALYTICAL X′ PERT-PRO MRD diffractometer equipped with 22 nickel-filtered Cu K1 beam and X′ CELERATOR detector, using current I = 40 mA and accelerating voltage V = 40 kV. Samples were prepared by drop casting. The conventional devices were fabricated using the structure of Glass/ITO/PEDOT:PSS (30-40 nm)/active layer (80-90 nm)/LiF (1 nm)/Al (100 nm). For inverted device architecture it was Glass/ITO/ZnO (~30 nm)/active layer (80-90 nm)/MoO3 (10 nm)/Ag (100 nm). Indium tin oxide (ITO) coated glass was first cleaned using via sequential sonication in detergent (Mucasol), water (DI), acetone, isopropanol and then dried using nitrogen and finally plasma cleaned (228 mtorr 2 min). 30-40 nm of poly(ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS, Baytron P TP AI 4083, Bayer AG) was then deposited via spin coating and dried at 150 ˚C for 20 min. Additives and n-type material (PC70BM purchased from nano-c) were added to a 12 mg mL-1 polymer solution and stirred overnight. The following blend solution was then spin coated to a thickness of approximately 80-90 nm. LiF (1 nm) was then thermally deposited followed by Al (120 nm) under high vacuum (1×10-6 mbar). The device area was 0.045 cm2 in both cases. OPVs were characterized using a Xenon lamp at AM1.5 solar illumination (Oriel 300 W solar simulator). Incident photon conversion efficiency (IPCE) measurements were made using a 100 W tungsten halogen lamp (Bentham IL1 with Bentham 605 stabilized current power supply) coupled to a monochromator and a computer-controlled stepper motor (Bentham M300, 300 mm focal length, slit width 3.7 nm, 1800 lines/m grating). The photon flux of light incident to the samples was calibrated using a UV-enhanced silicon photodiode. A 590 nm long-pass glass filter was inserted into the beam at illumination wavelengths longer than 620 nm to remove light from second-order diffraction. Photocurrent was measured using a Keithley 2400 source meter; Measurement duration for a given wavelength was sufficient to ensure the current had stabilized (up to around 5 s under low or zero bias light conditions). All 23 electrical measurements of OPVs were executed in the inert N2 purged devices chamber. For crosslinking with TFA, films were placed on the base of a glass petri dish, and an open glass vial containing 0.5 ml of TFA was placed adjacent to the film. The petri dish was covered, and the whole ensemble was heated on a hot plate at 100C for the indicated time in a fume cupboard. Films were then dried under vacuum before further fabrication. 1,3-Dibromo-5-(6-((3-methyloxetan-3-yl)methoxy)hexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)dione (TPD-Ox) A solution of 1,3-dibromo-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (2 g, 6.43 mmol) in dry DMF (12 mL) and added dropwise to NaH (60% mineral oil, 0.353 g, 8.36 mmol) at RT. After which the reaction was left to stir for 1 hr at RT. The resulting solution was added dropwise to a separate solution of 3-methyl-3-[(6-bromohexoxy)methyl]-oxetane (2.05 g, 7.72 mmol) in dry DMF (20 mL) and stirred overnight at RT. The reaction was diluted with diethyl ether (~100 mL) and washed with water (3×50mL) and brine (3×50mL), dried (MgSO4), filtered and concentrated under reduced pressure. The residue was purified by column chromatography over silica (eluent: ethyl acetate:hexane, (1:1)) and recrystallised in aqueous ethanol (ethanol:water, (4:1)) to afford light yellow crystals (1.34 g, 2.71 mmol, 42% yield). Mp 92.3-92.8 °C; 1H NMR (400 MHz, CDCl3) δ 4.51 (d, J = 5.7, 2H), 4.36 (d, J = 5.7, 2H), 3.61 (t, J = 7.4, 2H), 3.52 – 3.41 (m, 4H), 1.70 – 1.55 (m, 4H), 1.48 – 1.34 (m, 4H), 1.32 (s, 3H); 13 C NMR (100 MHz, CDCl3) δ 160.38, 134.79, 112.99, 80.25, 76.08, 71.40, 39.91, 38.71, 29.34, 28.22, 26.61, 25.72, 21.39. HRMS (ESI) m/z: [M + H]+ calcd for C17H22NO4SBr2, 493.9636; found, 493.9641. 24 1,3-Dibromo-5-(6-bromohexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (TPD-Br) A solution of 1,3-dibromo-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (2 g, 6.43 mmol) was dissolved in dry DMF (12 mL) and added dropwise to NaH (60% mineral oil, 0.353 g, 8.36 mmol) at RT. After which the reaction was left to stir for 1 hr at RT. The resulting solution was added dropwise to a separate solution of 1,6-dibromohexane (4.71 g, 19.3 mmol) in dry DMF (20 mL) and stirred overnight at RT. The reaction was diluted with diethyl ether (~100 mL) and washed with water (3×50mL) and brine (3×50mL), dried (MgSO4), filtered and concentrated under reduced pressure. The residue was purified by column chromatography over silica (eluent: chloroform:hexane, (4:1)) and recrystallised in aqueous ethanol (ethanol:water, (4:1)) to afford light yellow crystals (1.05 g, 2.215 mmol, 34% yield). Mp 104.4-105.0 °C; 1H NMR (400 MHz, CDCl3) δ 3.63 (t, J = 7.2, 2H), 3.42 (t, J = 6.8, 2H), 1.93 – 1.83 (m, 2H), 1.73 – 1.63 (m, 2H), 1.54 – 1.45 (m, 2H), 1.43 – 1.32 (m, 2H); 13C NMR (100 MHz, CDCl3) δ 160.39, 134.75, 113.09, 38.59, 33.68, 32.54, 28.08, 27.67, 25.96; HRMS (ESI) m/z: [M + H]+ calcd for C12H12NO2SBr3, 470.8139; found, 470.8130. Poly[(4,4-bis(2-ethylhexyl)-4H-germolo[3,2-b:4,5-b']dithiophen-2-yl)-(5-octyl-4Hthieno[3,4-c]pyrrole-4,6(5H)-dione)] (PDTG-TPD-C8) 4,4-Bis(2-ethylhexyl)-2,6-bis(trimethylstannyl)-4H-germolo[3,2-b:4,5-b']dithiophene (304.9 mg, 0.386 mmol) was weighed into a pre-dried microwave vial. 1,3-Dibromo-5-octyl-4Hthieno[3,4-c]pyrrole-4,6(5H)-dione (164.0 mg, 0.386 mmol), Pd2dba3 (7.1 mg, 7.73 μmol) and P(o-tol)3 (9.4 mg 0.031 mmol) were added. The microwave vial was capped and degassed with argon and vacuum (×3). o-Xylene (2 mL) was added and the mixture further degassed with stirring for 30 min. The resulting solution was then heated in the microwave reactor (constant heating mode) at 100°C (2 min), 120°C (5 min), 140°C (5 min), 160°C (5 min) and 180°C (40 min). The reaction was cooled to 50 °C and then precipitated into methanol before 25 bring filtered into a cellulose thimble. Lower molecular weight fractions were removed via Soxhlet extraction with methanol (1 day), acetone (1 day) and hexane (1 day). The remaining polymer was then extracted in chloroform (3 hr), concentrated and dried under vacuum. The polymer was then fractionated using preparative GPC (eluent: chlorobenzene). High molecular weight fractions were combined, concentrated under reduced pressure and precipitated into methanol to produce a black solid (21.3 mg, 8% yield). 1H NMR (500 MHz, CDCl3, 40 °C) δ 8.59 – 7.31 (m, 2H), 3.70 (s, 2H), 2.16 – 0.68 (m, 49H); UV/Vis (Chlorobenzene, 10-5 M) λmax (log ε) 618 (4.71), 679 (4.83) nm. GPC: (chlorobenzene, 80 °C) Mn = 49,000 g/mol, Mw = 62,000 g/mol and PD = 1.27. Poly[((4,4-bis(2-ethylhexyl)-4H-germolo[3,2-b:4,5-b']dithiophen-2-yl)-(5-octyl-4Hthieno[3,4-c]pyrrole-4,6(5H)-dione))0.8-stat-((4,4-bis(2-ethylhexyl)-4H-germolo[3,2-b:4,5b']dithiophen-2-yl)-(5-(6-((3-methyloxetan-3-yl)methoxy)hexyl)-4H-thieno[3,4-c]pyrrole4,6(5H)-dione))0.2] (PDTG-TPD-Ox20%) Following a similar method reported for PDTG-TPD-C8, 4,4-bis(2-ethylhexyl)-2,6bis(trimethylstannyl)-4H-germolo[3,2-b:4,5-b']dithiophene (179.1 mg, 0.227 mmol), 1,3dibromo-5-octyl-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (77.0 mg, 0.182 mmol), 1,3dibromo-5-(6-((3-methyloxetan-3-yl)methoxy)hexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (22.5 mg, 0.045 mmol), Pd2dba3 (4.2 mg, 4.54 μmol), P(o-tol)3 (5.5 mg, 0.018 mmol) and oxylene (2 mL) were reacted together. Following the workup and extraction the crude polymer was then fractionated using preparative GPC (eluent: chlorobenzene), high molecular weight fractions were combined, concentrated under reduced pressure and precipitated into methanol to afford a black solid (76.3 mg, 45% yield). 1H NMR (500 MHz, CDCl3, 40 °C) δ 8.60 – 7.30 (m, 2H), 4.51 (s, 0.4H), 4.35 (s, 0.4H), 3.94 – 3.29 (m, 2.8H), 2.23 – 0.67 (m, 48.2H); GPC: (chlorobenzene, 80 °C) Mn = 39,000 g/mol, Mw = 72,000 g/mol and PD = 1.86. 26 Poly[(4,4-bis(2-ethylhexyl)-4H-germolo[3,2-b:4,5-b']dithiophen-2-yl)-(5-(6-((3methyloxetan-3-yl)methoxy)hexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione)] (PDTG-TPDOx100%) Following a similar method reported for PDTG-TPD-C8, 4,4-bis(2-ethylhexyl)-2,6bis(trimethylstannyl)-4H-germolo[3,2-b:4,5-b']dithiophene (209.6 mg, 0.266 mmol), 1,3dibromo-5-(6-((3-methyloxetan-3-yl)methoxy)hexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (132.0 mg, 0.266 mmol), Pd2dba3 (4.9 mg, 5.31 μmol) , P(o-tol)3 (6.5 mg, 0.021 mmol) and oxylene (2 mL) were reacted together. Following the workup and extraction the crude polymer was then fractionated using preparative GPC (eluent: chlorobenzene), high molecular weight fractions were combined, concentrated under reduced pressure and precipitated into methanol to afford a black solid (28.6 mg, 13% yield). 1H NMR (500 MHz, CDCl3, 40 °C) δ 8.54 – 7.33 (m, 2H), 4.51 (s, 2H), 4.34 (s, 2H), 3.89 – 3.18 (m, 6H), 2.13 – 0.71 (m, 45H); GPC: (chlorobenzene, 80 °C) Mn = 29,000 g/mol, Mw = 42,000 g/mol and PD = 1.46. Poly[((4,4-bis(2-ethylhexyl)-4H-germolo[3,2-b:4,5-b']dithiophen-2-yl)-(5-octyl-4Hthieno[3,4-c]pyrrole-4,6(5H)-dione))0.8-stat-((4,4-bis(2-ethylhexyl)-4H-germolo[3,2-b:4,5b']dithiophen-2-yl)-(5-(6-bromohexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione))0.2] (PDTGTPD-Br20%) Following a similar method reported for PDTG-TPD-C8, 4,4-bis(2-ethylhexyl)-2,6bis(trimethylstannyl)-4H-germolo[3,2-b:4,5-b']dithiophene (171.2 mg, 0.217 mmol), 1,3dibromo-5-octyl-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (73.4 mg, 0.174 mmol), 1,3dibromo-5-(6-bromohexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (20.6 mg, 0.043 mmol), Pd2dba3 (4.0 mg, 4.34 μmol), P(o-tol)3 (5.3 mg, 0.017 mmol) and o-xylene (2 mL) were reacted together. Following the workup and extraction the crude polymer was then fractionated using preparative GPC (eluent: chlorobenzene), high molecular weight fractions 27 were combined, concentrated under reduced pressure and precipitated into methanol to afford a black solid (53.6 mg, 34% yield). 1H NMR (500 MHz, CDCl3, 40 °C) δ 8.62 – 7.33 (m, 2H), 3.92 – 3.27 (m, 2.2H), 2.14 – 0.60 (m, 47.8H); GPC: (chlorobenzene, 80 °C) Mn = 44,000 g/mol, Mw = 71,000 g/mol and PD = 1.63. Poly[(4,4-bis(2-ethylhexyl)-4H-germolo[3,2-b:4,5-b']dithiophen-2-yl)-(5-(6-bromohexyl)-4Hthieno[3,4-c]pyrrole-4,6(5H)-dione)] (PDTG-TPD-Br100%) Following a similar method reported for PDTG-TPD-C8, 4,4-bis(2-ethylhexyl)-2,6bis(trimethylstannyl)-4H-germolo[3,2-b:4,5-b']dithiophene (199.0 mg, 0.252 mmol), 1,3dibromo-5-(6-bromohexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione (120.0 mg, 0.252 mmol), Pd2dba3 (4.6 mg 5.04 μmol), P(o-tol)3 (6.14 mg, 0.02 mmol) and o-xylene (2 mL) were reacted together. Following the workup and extraction the crude polymer was then fractionated using preparative GPC (eluent: chlorobenzene), high molecular weight fractions were combined, concentrated under reduced pressure and precipitated into methanol to afford a black solid (26.5 mg, 14% yield). 1H NMR (500 MHz, CDCl3, 40 °C) δ 8.61 – 7.33 (m, 2H), 3.90 – 3.28 (m, 4H), 2.20 – 0.62 (m, 42H); GPC: (chlorobenzene, 80 °C) Mn = 25,000 g/mol, Mw = 35,000 g/mol and PD = 1.41. Supporting Information Supporting Information is available from the Wiley Online Library or from the author. Acknowledgements This work was supported by EPSRC grants EP/G060738/1 and EP/I002936/1, and NSF grant 1026664. We would like to thank Dr Ester Buchaca-Domingo (Imperial College London) for performing the WAXS experiments, and Scott E. Watkins, (CSIRO Melbourne) for the PESA measurements. 28 References (1) (a) Duan, C.; Huang, F.; Cao, Y. J. Mater. Chem. 2012, 22, 10416; (b) Son, H. J.; Carsten, B.; Jung, I. H.; Yu, L. Energy Environ. Sci. 2012, 5, 8158; (c) Ameri, T.; Li, N.; Brabec, C. J. Energy Environ. Sci. 2013, 6, 2390. (2) Wang, T.; Pearson, A. J.; Lidzey, D. G. J. Mater. Chem. C 2013, 1, 7266. (3) Rivnay, J.; Mannsfeld, S. C. B.; Miller, C. E.; Salleo, A.; Toney, M. F. Chem. Rev. 2012, 112, 5488. (4) Treat, N. D.; Chabinyc, M. L. Annual Review of Physical Chemistry 2014, 65, 59. (5) (a) Treat, N. D.; Brady, M. A.; Smith, G.; Toney, M. F.; Kramer, E. J.; Hawker, C. J.; Chabinyc, M. L. Adv. Energ. Mater. 2011, 1, 82; (b) Treat, N. D.; Mates, T. E.; Hawker, C. J.; Kramer, E. J.; Chabinyc, M. L. Macromolecules 2013, 46, 1002; (c) Lee, K. H.; Zhang, Y.; Burn, P. L.; Gentle, I. R.; James, M.; Nelson, A.; Meredith, P. J. Mater. Chem. C 2013, 1, 2593. (6) (a) Miyanishi, S.; Tajima, K.; Hashimoto, K. Macromolecules 2009, 42, 1610; (b) Wantz, G.; Derue, L.; Dautel, O.; Rivaton, A.; Hudhomme, P.; Dagron-Lartigua, C. Polym. Int. 2014, 63, 1346; (c) Griffini, G.; Douglas, J. D.; Piliego, C.; Holcombe, T. W.; Turri, S.; Frechet, J. M. J.; Mynar, J. L. Adv. Mater. 2011, 23, 1660; (d) Png, R. Q.; Chia, P. J.; Tang, J. C.; Liu, B.; Sivaramakrishnan, S.; Zhou, M.; Khong, S. H.; Chan, H. S. O.; Burroughes, J. H.; Chua, L. L.; Friend, R. H.; Ho, P. K. H. Nat. Mater. 2010, 9, 152. (7) (a) Liu, B.; Png, R. Q.; Zhao, L. H.; Chua, L. L.; Friend, R. H.; Ho, P. K. H. Nat. Commun. 2012, 3, 1321; (b) Tao, C.; Aljada, M.; Shaw, P. E.; Lee, K. H.; Cavaye, H.; Balfour, M. N.; Borthwick, R. J.; James, M.; Burn, P. L.; Gentle, I. R.; Meredith, P. Advanced Energy Materials 2013, 3, 105. (8) (a) Brotas, G.; Farinhas, J.; Ferreira, Q.; Rodrigues, R.; Martins, I. L.; Morgado, J.; Charas, A. J. Polym. Sci. Part A Polym. Chem 2014, 52, 652; (b) Nam, C.-Y.; Qin, Y.; Park, Y. S.; Hlaing, H.; Lu, X.; Ocko, B. M.; Black, C. T.; Grubbs, R. B. Macromolecules 2012, 45, 2338; (c) Kim, B. J.; Miyamoto, Y.; Ma, B.; Fréchet, J. M. J. Adv. Funct. Mater. 2009, 19, 2273. (9) (a) Qian, D.; Xu, Q.; Hou, X.; Wang, F.; Hou, J.; Tan, Z. a. J. Pol. Sci. A. Poly. Chem. 2013, 51, 3123; (b) Chen, X.; Chen, L.; Chen, Y. J. Pol. Sci. A. Poly. Chem. 2013, 51, 4156. (10) Tang, Y.; Ji, L.; Zhu, R.; Wei, Z.; Zhang, B. J. Phys. Chem. A 2005, 109, 11123. (11) (a) Zuniga, C. A.; Barlow, S.; Marder, S. R. Chem. Mater. 2011, 23, 658; (b) Müller, D. C.; Falcou, A.; Reckefuss, N.; Rojahn, M.; Wiederhirn, V.; Rudati, P.; Frohne, H.; Nuyken, O.; Becker, H.; Meerholz, K. Nature 2003, 421, 829; (c) Zacharias, P.; Gather, M. C.; Köhnen, A.; Rehmann, N.; Meerholz, K. Angew. Chem. Int. Ed. 2009, 48, 4038; (d) Jungermann, S.; Riegel, N.; Müller, D.; Meerholz, K.; Oskar, N. Macromolecules 2006, 39, 8911. (12) (a) Feser, S.; Meerholz, K. Chem. Mater. 2011, 23, 5001; (b) Köhnen, A.; Brücher, M.; Reckmann, A.; Klesper, H.; von Bohlen, A.; Wagner, R.; Herdt, A.; Lützenkirchen-Hecht, D.; Hergenröder, R.; Meerholz, K. Macromolecules 2012, 45, 3487. (13) (a) Farinhas, J.; Ferreira, Q.; Di Paolo, R. E.; Alcacer, L.; Morgado, J.; Charas, A. J. Mater. Chem. 2011, 21, 12511; (b) Brotas, G.; Farinhas, J.; Ferreira, Q.; Morgado, J.; Charas, A. Synth. Met. 2012, 162, 2052. (14) (a) Chu, T.-Y.; Lu, J.; Beaupré, S.; Zhang, Y.; Pouliot, J.-R. m.; Wakim, S.; Zhou, J.; Leclerc, M.; Li, Z.; Ding, J.; Tao, Y. J. Am. Chem. Soc. 2011, 133, 4250; (b) Guo, X.; Xin, H.; Kim, F. S.; Liyanage, A. D. T.; Jenekhe, S. A.; Watson, M. D. Macromolecules 2010, 44, 269; (c) Li, Z.; Tsang, S.-W.; Du, X.; Scoles, L.; Robertson, G.; Zhang, Y.; Toll, F.; Tao, Y.; Lu, J.; Ding, J. Adv. Funct. Mater, 2011, 21, 3331; (d) Piliego, C.; Holcombe, T. W.; Douglas, J. D.; Woo, C. H.; Beaujuge, P. M.; Fréchet, J. M. J. J. Am. Chem. Soc. 2010, 132, 29 7595; (e) Warnan, J.; Cabanetos, C.; Labban, A. E.; Hansen, M. R.; Tassone, C.; Toney, M. F.; Beaujuge, P. M. Adv. Mater. 2014, 26, 4357; (f) Guo, X.; Zhou, N.; Lou, S. J.; Hennek, J. W.; Ponce Ortiz, R.; Butler, M. R.; Boudreault, P.-L. T.; Strzalka, J.; Morin, P.-O.; Leclerc, M.; López Navarrete, J. T.; Ratner, M. A.; Chen, L. X.; Chang, R. P. H.; Facchetti, A.; Marks, T. J. J. Am. Chem. Soc. 2012, 134, 18427. (15) (a) Kesava, S. V.; Fei, Z.; Rimshaw, A. D.; Wang, C.; Hexemer, A.; Asbury, J. B.; Heeney, M.; Gomez, E. D. Advanced Energy Materials 2014, n/a; (b) Amb, C. M.; Chen, S.; Graham, K. R.; Subbiah, J.; Small, C. E.; So, F.; Reynolds, J. R. J. Am. Chem. Soc. 2011, 133, 10062; (c) Small, C. E.; Chen, S.; Subbiah, J.; Amb, C. M.; Tsang, S.-W.; Lai, T.-H.; Reynolds, J. R.; So, F. Nat. Photonics 2012, 6, 115; (d) Small, C. E.; Tsang, S.-W.; Chen, S.; Baek, S.; Amb, C. M.; Subbiah, J.; Reynolds, J. R.; So, F. Adv. Energ. Mater. 2013, 3, 909; (e) Gendron, D.; Morin, P.-O.; Berrouard, P.; Allard, N.; Aïch, B. R.; Garon, C. N.; Tao, Y.; Leclerc, M. Macromolecules 2011, 44, 7188; (f) Fei, Z. P.; Shahid, M.; Yaacobi-Gross, N.; Rossbauer, S.; Zhong, H. L.; Watkins, S. E.; Anthopoulos, T. D.; Heeney, M. Chem. Commun. 2012, 48, 11130; (g) Yau, C. P.; Fei, Z.; Ashraf, R. S.; Shahid, M.; Watkins, S. E.; Pattanasattayavong, P.; Anthopoulos, T. D.; Gregoriou, V. G.; Chochos, C. L.; Heeney, M. Adv. Funct. Mater. 2014, 24, 678. (16) Fei, Z.; Kim, J. S.; Smith, J.; Domingo, E. B.; Anthopoulos, T. D.; Stingelin, N.; Watkins, S. E.; Kim, J.-S.; Heeney, M. J. Mater. Chem. 2011, 21, 16257. (17) Tierney, S.; Heeney, M.; McCulloch, I. Synth. Met. 2005, 148, 195. (18) Nielsen, K. T.; Bechgaard, K.; Krebs, F. C. Macromolecules 2005, 38, 658. (19) Wienk, M. M.; Kroon, J. M.; Verhees, W. J. H.; Knol, J.; Hummelen, J. C.; van Hal, P. A.; Janssen, R. A. J. Angew. Chem. Int. Ed. 2003, 42, 3371. (20) (a) Kim, D. H.; Ayzner, A. L.; Appleton, A. L.; Schmidt, K.; Mei, J.; Toney, M. F.; Bao, Z. Chem. Mater. 2013, 25, 431; (b) Mei, J.; Bao, Z. Chem. Mater. 2014, 26, 604. (21) Carlé, J. E.; Andreasen, B.; Tromholt, T.; Madsen, M. V.; Norrman, K.; Jørgensen, M.; Krebs, F. C. J. Mater. Chem. 2012, 22, 24417. (22) Lee, J. K.; Ma, W. L.; Brabec, C. J.; Yuen, J.; Moon, J. S.; Kim, J. Y.; Lee, K.; Bazan, G. C.; Heeger, A. J. J. Am. Chem. Soc. 2008, 130, 3619. (23) (a) Ye, L.; Jing, Y.; Guo, X.; Sun, H.; Zhang, S.; Zhang, M.; Huo, L.; Hou, J. J. Phys. Chem. C 2013, 117, 14920; (b) Chang, L.; Lademann, H. W. A.; Bonekamp, J.-B.; Meerholz, K.; Moulé, A. J. Adv. Funct. Mater. 2011, 21, 1779. (24) Chang, L.; Jacobs, I. E.; Augustine, M. P.; Moulé, A. J. Org. Elect. 2013, 14, 2431. (25) Miranda, M. A.; Pérez-Prieto, J.; Font-Sanchis, E.; Scaiano, J. C. Prop. React. Kinect. Mech. 2001, 26, 139. (26) Bernardes, C. E. S.; M. E. Minas da Piedade, M. E.; Amaral, L. M. P. F.; Ferreira, A. I. M. C. L.; Ribeiro da Silva, M. A. V.; Diogo, H. P.; Costa Cabral, B. J. J. Phys. Chem. A 2007, 111, 1713. (27) Jørgensen, M.; Norrman, K.; Gevorgyan, S. A.; Tromholt, T.; Andreasen, B.; Krebs, F. C. Adv. Mater. 2012, 24, 580. (28) (a) Chen, F.-C.; Tseng, H.-C.; Ko, C.-J. Appl. Phys. Lett. 2008, 92, 103316; (b) Guo, X.; Cui, C.; Zhang, M.; Huo, L.; Huang, Y.; Hou, J.; Li, Y. Energy Environ. Sci. 2012, 5, 7943; (c) Moon, J. S.; Takacs, C. J.; Cho, S.; Coffin, R. C.; Kim, H.; Bazan, G. C.; Heeger, A. J. Nano Letters 2010, 10, 4005. (29) Shin, N.; Richter, L. J.; Herzing, A. A.; Kline, R. J.; DeLongchamp, D. M. Adv. Energ. Mater. 2013, 3, 938. 30 (30) Hoke, E. T.; Sachs-Quintana, I. T.; Lloyd, M. T.; Kauvar, I.; Mateker, W. R.; Nardes, A. M.; Peters, C. H.; Nopidakis, N.; McGehee, M. D. Adv. Energ. Mater. 2012, 2, 1351. (31) Sachs-Quintana, I. T.; Heumüller, T.; Mateker, W. R.; Orozco, D. E.; Cheacharoen, R.; Sweetnam, S.; Brabec, C. J.; McGehee, M. D. Adv. Funct. Mater. 2014, 24, 3978. (32) Köhnen, A.; Riegel, N.; Kremer, J. H.-W. M.; Lademann, H.; Müller, D. C.; Meerholz, K. Adv. Mater. 2009, 21, 879. 31 Scheme 1. a) Synthetic route for monomer, b) Nomenclature of polymers, c) general synthetic route for polymer synthesis. b) Normalised Absorbance (a.u.) Normalised Absorbance (a.u.) a) 1.0 Solution PDTG-TPD-C8 PDTG-TPD-Ox20% PDTG-TPD-Ox100% PDTG-TPD-Br20% 0.5 PDTG-TPD-Br100% 1.0 Film PDTG-TPD-C8 PDTG-TPD-Ox20% PDTG-TPD-Ox100% PDTG-TPD-Br20% 0.5 PDTG-TPD-Br100% 0.0 0.0 400 600 400 800 600 800 Wavelength (nm) Wavelength (nm) Figure 1. UV-Vis spectra of all polymers: a) solution (CB) at room temperature and b) thin films (spin coated from CB). 32 Figure 2. Percentage retention after chloroform washing against crosslinking time for: a) PDTG-TPD-Br20% with 254 nm UV light and b) PDTG-TPD-Ox20% with TFA vapour. Figure 3. Degradation of photovoltaic performance upon exposure to 254 nm UV light from a) PDTG-TPD-Br20% and b) PDTG-TPD-Ox20% with 5 vol% DIO additive. 33 Figure 4. As cast polymer:PC70BM (1:2) devices with 4 vol% CN. Figure 5. Initial non-crosslinked (solid) and crosslinked (dashed) devices of PDTG-TPDBr20% and PDTG-TPD-Ox20% with 4 vol% CN. 34 Figure 6. a) Retention of TFA vapour crosslinked films of PDTG-TPD-Ox20%:PC70BM (1:2) blend with 4 vol% CN after solvent rinsing. b) UV-Vis spectra of crosslinked (in TFA vapour/100 °C/60 min) glass|ITO|PEDOT|PDTG-TPD-Ox20%:PC70BM (1:2) with 4 vol% CN, before and after washing. Figure 7. Device performance of PDTG-TPD-Ox20% and PDTG-TPD-Br20%, crosslinked and non crosslinked at 120 °C overtime. 35 Table 1. Molecular weight, degree of polymerisation and optoelectronic properties of all five co-polymers. Polymers Mn (kDa) DPn Mw (kDa) DPw PD λmax (sol) (nm) λmax (film) (nm) I.P.a (eV) Egb (eV) LUMOc (eV) PDTG-TPD-C8 49 68 62 86 1.27 679, 618 681, 620 5.2 1.7 -3.5 PDTG-TPD-Br20% 44 60 71 97 1.63 679, 618 681, 620 5.2 1.7 -3.5 PDTG-TPD-Br100% 25 32 35 45 1.41 675, 617 678, 619 5.3 1.7 -3.6 PDTG-TPD-Ox20% 39 53 72 98 1.86 679, 618 681, 620 5.2 1.7 -3.5 PDTG-TPD-Ox100% 29 36 42 56 1.46 675, 617 678, 619 5.3 1.7 -3.6 a) Ionisation potential was measured using photo electron spectroscopy in air, b)Band gap extrapolated from the onset of optical absorption, c)LUMO estimated from I.P. and Eg Table 2. Table of photovoltaic properties of all five PDTG-TPD co-polymers in a polymer:fullerene ratio of 1:2, averaged over 5 devices, as cast and with 5 vol% DIO additive. As Cast DIO 5 vol% Voc (V) Jsc (mA/cm2) FF PCE (%) Voc (V) Jsc (mA/cm2) FF PCE (%) PDTG-TPD-C8 0.85 3.2 0.59 1.61 0.81 10.40 0.58 4.88 PDTG-TPD-Ox20% 0.86 3.8 0.49 1.63 0.79 12.2 0.62 6.00 PDTG-TPD-Ox100% 0.80 2.4 0.24 0.48 0.83 6.7 0.37 2.09 PDTG-TPD-Br20% 0.86 3.8 0.52 1.70 0.86 14.3 0.60 7.35 PDTG-TPD-Br100% 0.89 6.1 0.34 1.85 0.89 9.6 0.40 3.44 Table 3. OPV performance of polymer:PC70BM (1:2) blend (CB) with 4 vol% CN averaged over five devices. Polymer:PC70BM + CN 4 vol% Voc (V) Jsc (mA/cm2) FF PCE (%) PDTG-TPD-C8 0.81 11.6 0.62 5.79 PDTG-TPD-Ox20% 0.84 13.2 0.63 7.05 PDTG-TPD-Ox100% 0.82 9.8 0.41 3.29 PDTG-TPD-Br20% 0.84 15.1 0.63 7.88 PDTG-TPD-Br100% 0.84 11.0 0.44 4.07 Table 4. OPV properties of crosslinked devices of PDTG-TPD-Br20% and PDTG-TPD-Ox20% with 4 vol% CN. Polymer:PC70BM + CN 4 vol% Voc (V) JSC (mA/cm2) FF PCE (%) PDTG-TPD-Br20% 0.82 13.1 0.66 7.11 PDTG-TPD-Br20% crosslinked 0.84 10.7 0.52 4.65 PDTG-TPD-Ox20% 0.83 10.5 0.66 5.79 PDTG-TPD-Ox20% crosslinked 0.86 12.7 0.46 5.02 36