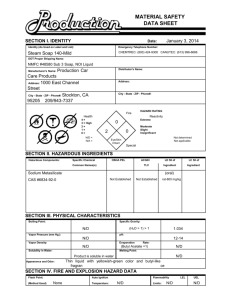

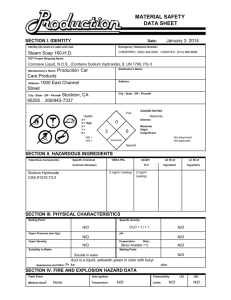

USDOT Hazardous Materials Transportation Placards

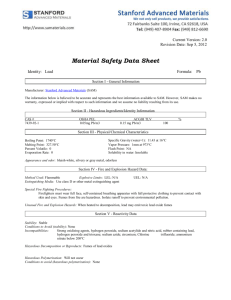

advertisement