ABSTRACT

advertisement

ZIGBEE BASED WIRELESS WEATHER STATION

CHAPTER 1

In an industry during certain hazards is will be very difficult to monitor the

parameter through wires and analog devices such as transducers. To over come this

problem we use wireless device to monitor the parameters so that we can take certain

steps even in worst case. Few years back the use of wireless device was very less,

but due the rapid development is technology now a days we use maximum of our

data transfer through wireless like wi-fi,Bluetooth,wi max,etc.

In view of all this things, the design of wireless parameter progress helps in an

industry to monitor the parameter in real time with the use of zigbee, is an easy

installation platform, cost effective method for the low bit rate transmission, so with

the help of the ready zigbee platform by using the embedded c language we interface

the module with the pc by the help of visual basic we monitor the parameters in the

system.

The main use of this module helps in an industry during the worst cases as the

analog device may be damaged may be during the fire accidents,etc.But with the

wireless transmission we have not have an accurate data but when compared to the

analog failure the errors are very minimum so we use wireless to monitor the

parameter in an industry where their no means of human interface to monitor the

parameters

In this project we deal to monitor the parameter through wireless by using

zigbee ready platform which is based on the IEEE 802.15.4, 2.4 GHz, in this module

we use msp 430 for the voltage and other technical parameters, which has in build

RAM in it. The working of this module is simple in principle, the changes in certain

place is monitor in real time process which is very accurate in monitoring and their no

other interface and other disturbance in monitoring the parameter in this project we

monitor temperature and humidity with the help of respective sensors. The change in

the room temperature, humidity can be monitored like real time as the change is

displayed in respective interval in the visual basic screen.

This means of wireless end device is used to monitor the weather parameters

in an industry, which helps to monitor and have a clear thing to monitor it. The

1

sensors used in this module to monitor are Temperature sensor, humidity and rain fall

sensors Aare used.

MSP 430 used in the module of contains inbuilt RAM and flash memory and

also Zigbee module contains A/D converter, transmitter also.so, this can be widely

used for home automation, industrial application which helps for an easy wireless

communication for a low data rate transmission. In this following chapter we discuss

with zigbee and its importance and how it is used for the monitoring the parameters.

1.2 ZIGBEE:

ZigBee is the name of a specification for a suite of high level communication

protocols using small, low-power digital radios based on the IEEE 802.15.4 standard

for wireless personal area networks (WPANs), such as wireless headphones

connecting with cell phones via short-range radio. The technology is intended to be

simpler and cheaper than other WPANs, such as Bluetooth. ZigBee is targeted at

radio-frequency (RF) applications which require a low data rate, long battery life, and

secure networking

1.3

OVERVIEW:

ZigBee builds upon the physical layer and medium access control defined in

IEEE standard 802.15.4 (2003 version) for low-rate WPAN's. The specification goes

on to complete the standard by adding four main components: network layer,

application layer, ZigBee device objects (ZDO's) and manufacturer-defined

application objects which allow for customization and favor total integration.

Besides adding two high-level network layers to the underlying structure, the

most significant improvement is the introduction of ZDO's. These are responsible for a

number of tasks, which include keeping of device roles, management of requests to

join a network, device discovery and security.

2

(Fig 1:zigbee specifications)

At its core, ZigBee is a mesh network architecture. Its network layer natively supports

three types of topologies: both star and tree typical networks and generic mesh

networks. Every network must have one coordinator device, tasked with its creation,

the control of its parameters and basic maintenance. Within star networks, the

coordinator must be the central node. Both trees and meshes allow the use of ZigBee

routers to extend communication at the network level (they are not ZigBee

coordinators, but may act as 802.15.4 coordinators within their personal operating

space), but they differ in a few important details: communication within trees is

hierarchical and optionally utilizes frame beacons, whereas meshes allow generic

communication structures but no router beaconing.

The relationship between IEEE 802.15.4-2003 and ZigBee is similar to that

between IEEE 802.11 and the Wi-Fi Alliance. The ZigBee 1.0 specification was

ratified on December 14, 2004 and is available to members of the ZigBee Alliance. An

entry level membership called Adopter, in the ZigBee Alliance costs US$3500

annually and provides access to the specifications and permission to create products

for market using the specifications. For non-commercial purposes, the ZigBee

specification is available to the general public at the ZigBee Specification Download

Request. Most recently, the ZigBee 2006 specification was posted in December 2006.

3

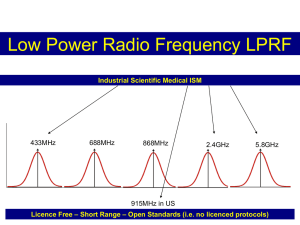

ZigBee operates in the industrial, scientific and medical (ISM) radio bands; 868

MHz in Europe, 915 MHz in countries such as USA and Australia, and 2.4 GHz in

most jurisdictions worldwide. The technology is intended to be simpler and cheaper

than other WPANs such as Bluetooth. The most capable ZigBee node type is said to

require only about 10% of the software of a typical Bluetooth or Wireless Internet

node, while the simplest nodes are about 2% However, actual code sizes are much

higher, closer to 50% of Bluetooth code size ZigBee chip vendors have announced

128-kilobyte devices.

As of 2006, the retail price of a Zigbee-compliant transceiver is approaching

$1, and the price for one radio, processor, and memory package is about $3.

Comparatively, before Bluetooth was launched (1998) it had a projected price, in high

volumes, of $4 - $6; the price of consumer-grade Bluetooth chips is now under $3.

First stack release is now called "Zigbee 2004". The 2nd stack release is called

2006, and mainly replaces the MSG/KVP structure used in 2004 with a "cluster

library". The 2004 stack is now more or less obsolete. The ZigBee Alliance has

started work on ZigBee 2007, looking to extend the ZigBee 2006 specification

capabilities; the main enhancements are optimizing certain network level functionality

(such as data aggregation). There are also some new application profiles like

Automatic Meter Reading, Commercial building automation and home automation

based on the "cluster library principle".

Zigbee 2007, now the current stack release, is sometimes called "Pro", but pro

is a stack profile, which defines certain stack settings and mandatory features.

ZigBee 2007 at the network level is not backwards-compatible with ZigBee

2004/2006, although a ZigBee 2004/2006 RFD node can join a 2007 network, and

vice-versa. It's not possible to mix 2004/2006 routers with 2007 routers/coordinator.

1.4

NETWORK LAYERS:

The main functions of the network layer are to enable the correct use of the

MAC sublayer and provide a suitable interface for use by the next upper layer, namely

4

the application layer. Its capabilities and structure are those typically associated to

such network layers, including routing.

On the one hand, the data entity creates and manages network layer data units from

the payload of the application layer and performs routing according to the current

topology. On the other hand, there is the layer control, which is used to handle

configuration of new devices and establish new networks: it can determine whether a

neighboring device belongs to the network and discovers new neighbors and routers.

The control can also detect the presence of a receiver, which allows direct

communication and MAC synchronization.

1.5

APPLICATION LAYER:

The application layer is the highest-level layer defined by the specification, and is

the effective interface of the ZigBee system to its end users. It comprises the majority

of components added by the ZigBee specification: both ZDO and its management

procedures, together with application objects defined by the manufacturer, are

considered part of this layer.

1.5.1 Main Components:

The ZDO is responsible for defining the role of a device as either coordinator or

end device, as mentioned above, but also for the discovery of new (one-hop) devices

on the network and the identification of their offered services. It may then go on to

establish secure links with external devices and reply to binding requests accordingly.

The application support sublayer (APS) is the other main standard component

of the layer, and as such it offers a well-defined interface and control services. It

works as a bridge between the network layer and the other components of the

application layer: it keeps up-to-date binding tables in the form of a database, which

can be used to find appropriate devices depending on the services that are needed

and those the different devices offer. As the union between both specified layers, it

also routes messages across the layers of the protocol stack.

5

1.5.2 Communication models:

An application may consist of communicating objects which cooperate to carry

out the desired tasks. The focus of ZigBee is to distribute work among many different

devices which reside within individual ZigBee nodes which in turn form a network

(said work will typically be largely local to each device, for instance the control of each

individual household appliance).

The collections of objects that form the network communicate using the

facilities provided by APS, supervised by ZDO interfaces. The application layer data

service follows a typical request-confirm/indication-response structure. Within a single

device, up to 240 application objects can exist, numbered in the range 1-240. 0 is

reserved for the ZDO data interface and 255 for broadcast; the 241-254 range is not

currently in use but may be in the future.

(Fig 2 :ZigBee high-level communication model)

There are two services available for application objects to use (in ZigBee 1.0):

i)the key-value pair service (KPV) is meant for configuration purposes. It enables

description, request and modification of object attributes through a simple interface

based on get/set and event primitives, some allowing a request for response.

Configuration uses compressed XML (full XML can be used) to provide an adaptable

and elegant solution.

6

ii)the message service is designed to offer a general approach to information

treatment, avoiding the necessity to adapt application protocols and potential

overhead incurred on by KPV. It allows arbitrary payloads to be transmitted over APS

frames.

Addressing is also part of the application layer. A network node consists of an

802.15.4-conformant radio transceiver and one or more device descriptions (basically

collections of attributes which can be polled or set, or which can be monitored through

events). The transceiver is the base for addressing, and devices within a node are

specified by an endpoint identifier in the range 1-240.

1.5.3 Communication and device Discovery:

In order for applications to communicate, their comprising devices must use a

common application protocol (types of messages, formats and so on); these sets of

conventions are grouped in profiles. Furthermore, binding is decided upon by

matching input and output cluster identifiers, unique within the context of a given

profile and associated to an incoming our outgoing data flow in a device. Binding

tables contain source and destination pairs.

Depending on the available information, device discovery may follow different

methods. When the network address is known, the IEEE address can be requested

using unicast communication. When it is not, petitions are broadcast (the IEEE

address being part of the response payload). End devices will simply respond with the

requested address, while a network coordinator or a router will also send the

addresses of all the devices associated with it.

This extended discovery protocol permits external devices to find out about

devices in a network and the services that they offer, which endpoints can report

when queried by the discovering device (which has previously obtained their

addresses). Matching services can also be used.

7

The use of cluster identifiers enforces the binding of complementary entities by

means of the binding tables, which are maintained by ZigBee coordinators, as the

table must be always available within a network and coordinators are most likely to

have a permanent power supply; backups may be needed by some applications,

whose

higher-level

layers

must

manage.

Binding

requires

an

established

communication link; after it exists, whether to add a new node to the network is

decided, according to the application and security policies.Communication can

happen right after the association. Direct addressing uses both radio address and

endpoint identifier, whereas indirect addressing requires every relevant field (address,

endpoint, cluster and attribute) and sends it to the network coordinator, which

maintains these associations and translates requests for communication. Indirect

addressing is particularly useful to keep some devices very simple and minimize their

need for storage. Besides these two methods, broadcast to all endpoints in a device

is available, and group addressing is used to communicate with groups of endpoints

belonging to a set of devices.

1.6 SECURITY SERVICES:

As one of its defining features, ZigBee provides facilities for carrying out secure

communications, protecting establishment and transport of cryptographic keys,

cyphering frames and controlling devices. It builds on the basic security framework

defined in IEEE 802.15.4. This part of the architecture relies on the correct

management of symmetric keys and the correct implementation of methods and

security policies.

1.6.1 Basic security model:

The basic mechanism to ensure confidentiality is the adequate protection of all

keying material. Trust must be assumed in the initial installation of the keys, as well

as in the processing of security information. In order for an implementation to globally

work, its general correctness (e.g., conformance to specified behaviors) is assumed.

Keys are the cornerstone of the security architecture; as such their protection

is of paramount importance, and keys are never supposed to be transported through

8

an insecure channel. There is a momentary exception to this rule, which occurs

during the initial phase of the addition to the network of a previously unconfigured

device. The ZigBee network model must take particular care of security

considerations, as ad hoc networks may be physically accessible to external devices

and the particular working environment cannot be foretold; likewise, different

applications running concurrently and using the same transceiver to communicate are

supposed to be mutually trustworthy: for cost reasons the model does not assume a

firewall exists between application-level entities.

Within the protocol stack, different network layers are not cryptographically separated,

so access policies are needed and correct design assumed. The open trust model

within a device allows for key sharing, which notably decreases potential cost.

Nevertheless, the layer which creates a frame is responsible for its security. If

malicious devices may exist, every network layer payload must be cyphered, so

unauthorized traffic can be immediately cut off. The exception, again, is the

transmission of the network key, which confers a unified security layer to the network,

to a new connecting device. Point-to-point encryption is also supported.

1.6.2 Security architecture:

ZigBee uses 128-bit keys to implement its security mechanisms. A key can be

associated either to a network, being usable by both ZigBee layers and the MAC

sublayer, or to a link, acquired through preinstallation, agreement or transport.

Establishment of link keys is based on a master key which controls link key

correspondence. Ultimately, at least the initial master key must be obtained through a

secure medium (transport or preinstallation), as the security of the whole network

depends on it. Link and master keys are only visible to the application layer. Different

services use different one-way variations of the link key in order to avoid leaks and

security risks.

Key distribution is one of the most important security functions of the network.

A secure network will designate one special device which other devices trust for the

distribution of security keys: the trust center. Ideally, devices will have the trust center

address and initial master key preloaded; if a momentary vulnerability is allowed, it

9

will be sent as described above. Typical applications without special security needs

will use a network key provided by the trust center (through the initially insecure

channel) to communicate.

Thus, the trust center maintains both the network key and provides point-to-point

security. Devices will only accept communications originating from a key provided by

the trust center, except for the initial master key. The security architecture is

distributed among the network layers as follows:

The MAC sublayer is capable of single-hop reliable communications. As a rule, the

security level it is to use is specified by the upper layers.

The network layer manages routing, processing received messages and being

capable of broadcasting requests. Outgoing frames will use the adequate link key

according to the routing, if it is available; otherwise, the network key will be used to

protect the payload from external devices.

The application layer offers key establishment and transport services to both ZDO

and applications. It is also responsible for the propagation across the network of

changes in devices within it, which may originate in the devices themselves (for

instance, a simple status change) or in the trust manager (which may inform the

network that a certain device is to be eliminated from it). It also routes requests from

devices to the trust center and network key renewals from the trust center to all

devices. Besides this, the ZDO maintains the security policies of the device.

1.7 PROTOCOLS:

The protocols build on recent algorithmic research (Ad-hoc On-demand

Distance Vector, neuRFon) to automatically construct a low-speed ad-hoc network of

nodes. In most large network instances, the network will be a cluster of clusters. It can

also form a mesh or a single cluster. The current profiles derived from the ZigBee

protocols support beacon and non-beacon enabled networks.

In non-beacon-enabled networks (those whose beacon order is 15), an

unslotted CSMA/CA channel access mechanism is used. In this type of network,

ZigBee Routers typically have their receivers continuously active, requiring a more

robust power supply. However, this allows for heterogeneous networks in which some

10

devices receive continuously, while others only transmit when an external stimulus is

detected. The typical example of a heterogeneous network is a wireless light switch:

the ZigBee node at the lamp may receive constantly, since it is connected to the

mains supply, while a battery-powered light switch would remain asleep until the

switch is thrown. The switch then wakes up, sends a command to the lamp, receives

an acknowledgment, and returns to sleep. In such a network the lamp node will be at

least a ZigBee Router, if not the ZigBee Coordinator; the switch node is typically a

ZigBee End Device.

In beacon-enabled networks, the special network nodes called ZigBee Routers

transmit periodic beacons to confirm their presence to other network nodes. Nodes

may sleep between beacons, thus lowering their duty cycle and extending their

battery life. Beacon intervals may range from 15.36 milliseconds to 15.36 ms * 214 =

251.65824 seconds at 250 kbit/s, from 24 milliseconds to 24 ms * 214 = 393.216

seconds at 40 kbit/s and from 48 milliseconds to 48 ms * 214 = 786.432 seconds at

20 kbit/s. However, low duty cycle operation with long beacon intervals requires

precise timing which can conflict with the need for low product cost.

In general, the ZigBee protocols minimize the time the radio is on so as to

reduce power use. In beaconing networks, nodes only need to be active while a

beacon is being transmitted. In non-beacon-enabled networks, power consumption is

decidedly asymmetrical: some devices are always active, while others spend most of

their time sleeping.

ZigBee devices are required to conform to the IEEE 802.15.4-2003 Low-Rate

Wireless Personal Area Network (WPAN) standard. The standard specifies the lower

protocol layers—the physical layer (PHY), and the medium access control (MAC)

portion of the data link layer (DLL). This standard specifies operation in the

unlicensed 2.4 GHz, 915 MHz and 868 MHz ISM bands. In the 2.4 GHz band there

are 16 ZigBee channels, with each channel requiring 5 MHz of bandwidth. The center

frequency for each channel can be calculated as, FC = (2405 + 5*(k-11)) MHz, where

k = 11, 12, ..., 26.

The radios use direct-sequence spread spectrum coding, which is managed by

the digital stream into the modulator. BPSK is used in the 868 and 915 MHz bands,

and orthogonal QPSK that transmits two bits per symbol is used in the 2.4 GHz band.

11

The raw, over-the-air data rate is 250 kbit/s per channel in the 2.4 GHz band, 40 kbit/s

per channel in the 915 MHz band, and 20 kbit/s in the 868 MHz band. Transmission

range is between 10 and 75 meters (33 and 246 feet), although it is heavily

dependent on the particular environment. The maximum output power of the radios is

generally 0 dBm (1 mW).

The basic channel access mode specified by IEEE 802.15.4-2003 is "carrier

sense, multiple access/collision avoidance" (CSMA/CA). That is, the nodes talk in the

same way that people converse; they briefly check to see that no one is talking before

they start. There are three notable exceptions to the use of CSMA. Beacons are sent

on a fixed timing schedule, and do not use CSMA. Message acknowledgements also

do not use CSMA. Finally, devices in Beacon Oriented networks that have low latency

real-time requirements may also use Guaranteed Time Slots (GTS) which by

definition does not use CSMA.

1.8 NODE TYPES:

This page describes the types of node that are used in a ZigBee network.

Reference will be made to the toplogies introduced on the previous page (Star, Tree,

Mesh), but these topologies will be described in more detail later in this module.

The ZigBee standard has the capacity to address up to 65535 nodes in a single

network. However, there are only three general types of node:

Co-ordinator

End Device

Router

These roles described below exist at the network level – a ZigBee node may also be

performing tasks at the application level independent of the role it plays in the

network. For instance, a network of ZigBee devices measuring temperature may have

a temperature sensor application in each node, irrespective of whether they are End

Devices, Routers or the Co-ordinator.

These node types are described below.

12

1.8.1 ZigBee coordinator(ZC): The most capable device, the coordinator forms the

root of the network tree and might bridge to other networks. There is exactly one

ZigBee coordinator in each network since it is the device that started the network

originally. It is able to store information about the network, including acting as the

Trust Centre & repository for security keys.

All ZigBee networks must have one (and only one) Co-ordinator, irrespective of the

network topology.

In the Star topology, the Co-ordinator is the central node in the network.

In the Tree and Mesh topologies, the Co-ordinator is the top (root) node in the

network.

This is illustrated below, where the Co-ordinator is colour-coded in dark black.

At the network level, the Co-ordinator is mainly needed at system initialisation. The

tasks of the Co-ordinator at the network layer are:

Selects the frequency channel to be used by the network (usually the one with

the least detected activity)

Starts the network

Allows other devices to connect to it (that is, to join the network)

The Co-ordinator can also provide message routing (for example, in a Star network),

security management and other services.

13

In some circumstances, the network will be able to operate normally if the Coordinator fails or is switched off. This will not be the case if the Co-coordinator

provides a routing path through the network (for instance, in a Star topology, where it

is needed to relay messages). Similarly the Co-ordinator provides services at the

Application layer and if these services are being used (for example, Co-ordinator

binding), the Co-ordinator must be able to provide them at all times.

1.8.2 ZigBee Router (ZR): As well as running an application function a router can act

as an intermediate router, passing data from other devices.

Networks with Tree or Mesh topologies need at least one Router. The main tasks of a

Router are:

Relays messages from one node to another

Allows child nodes to connect to it

In a Star topology, these functions are handled by the Co-ordinator and, therefore, a

Star network does not need Routers.

In Tree and Mesh topologies, Routers are located as follows:

In a Tree topology, Routers are normally located in network positions that allow

messages to be passed up and down the tree.

In a Mesh topology, a Router can be located anywhere that a message

passing node is required.

However, in all topologies (Star, Tree and Mesh), Router devices can be located at

the extremities of the network, if they run applications that are needed in these

locations - in this case, the Router will not perform its message relay function, unless

in a Mesh network (see above).

The possible positions of Routers in the different network topologies are illustrated

below, where the Routers are color-coded in red:

14

1.8.3 ZigBee End Device (ZED): Contains just enough functionality to talk to the

parent node (either the coordinator or a router); it cannot relay data from other

devices. This relationship allows the node to be asleep a significant amount of the

time thereby giving long battery life. A ZED requires the least amount of memory, and

therefore can be less expensive to manufacture than a ZR or ZC.

End Devices are always located at the extremities of a network:

In the Star topology, they are perimeter nodes

In the Tree and Mesh topologies, they are leaf nodes

This is illustrated below, where the End Devices are color-coded in light blue.

The main tasks of an End Device at the network level are sending and receiving

messages. Note that End Devices cannot relay messages and cannot allow other

nodes to connect to the network through them.

An End Device can often be battery-powered and, when not transmitting or receiving,

can sleep in order to conserve power.

15

1.9 SOFTWARE AND HARDWARE:

The software is designed to be easy to develop on small, cheap

microprocessors. The radio design used by ZigBee has been carefully optimized for

low cost in large scale production. It has few analog stages and uses digital circuits

wherever possible.

Even though the radios themselves are cheap, the ZigBee Qualification Process

involves a full validation of the requirements of the physical layer. This amount of

concern about the Physical Layer has multiple benefits, since all radios derived from

that semiconductor mask set would enjoy the same RF characteristics. On the other

hand, an uncertified physical layer that malfunctions could cripple the battery lifespan

of other devices on a ZigBee network. Where other protocols can mask poor

sensitivity or other esoteric problems in a fade compensation response, ZigBee radios

have very tight engineering constraints: they are both power and bandwidth

constrained. Thus, radios are tested to the ISO 17025 standard with guidance given

by Clause 6 of the 802.15.4-2003 Standard. Most vendors plan to integrate the radio

and microcontroller onto a single chip.

1.10 USES:

ZigBee protocols are intended for use in embedded applications requiring low

data rates and low power consumption. ZigBee's current focus is to define a generalpurpose, inexpensive, self-organizing mesh network that can be used for industrial

control, embedded sensing, medical data collection, smoke and intruder warning,

building automation, home automation, etc. The resulting network will use very small

amounts of power so individual devices might run for a year or two using the originally

installed battery.

Typical application areas include:

• Home Entertainment and Control - Smart Lighting, Advanced Temperature Control,

Safety & Security and Movies & Music

• Home Awareness - Water Sensors, Power Sensors, Smart Appliances and Access

sensors

16

• Mobile Services – m-payment, m-monitoring and control, m-security and access

control, m- healthcare and tele-assist

• Commercial Building– Energy Monitoring, HVAC, Lighting, Access Control

• Industrial Plant– Process Control, Asset Management, Environmental management,

Energy Management

17

CHAPTER 2

CIRCUIT DESIGN

2.1 INTRODUCTION:

This chapter mainly deals with the circuit and the requirements of the project.

Chipcon cc2420 is a basic device needed for transmit and receive the data from the

remote device with the help of computer the display of the report is done. The

transmission and receive of signal is done in the standard form of IEE

802.15.4,2.4Ghz.The program for this device is done my using msp430,this

transmitting device is interfaced with the microcontroller as it is connect to analog to

digital converters which has the digital converted signals. Now when the data to be

fed to computer is available an input port is needed, through which interfacing is

done. In this system, for interfacing com port is used as it is an inexpensive platform

for implementing low-frequency data acquisition projects. By using the visual basic

the embedding is done.

2.2 BLOCK DIAGRAM OF SENSOR CIRCUIT:

HUMIDITY

SENSOR

TEMP

SENSOR

A/D

CONVERTER

MICROCONTROLLER

MAX 232

RAIN

SENSOR

(Fig 3a: Block diagram of sensor circuit)

18

RS

232

CIRCUIT DIAGRAM:

(Fig 3 : Circuit diagram of sensor circuit)

(Fig 4: Basic model of Zigbee )

19

2.2.1 Power Supply:

This circuit IC voltage regulator as the power source. IC voltage regulators are

versatile and inexpensive and are available with features such as a programmable

output, current-voltage boosting, internal short-circuit current limiting, thermal

shutdown and floating operation for high voltage application

Regulator IC units contain the circuitry for reference source, comparator

amplifier, control devices and overload protection all in a single unit. In this circuit,

three-terminal IC voltage regulator 7805 is employed. 7805 is a fixed positive voltage

regulator whose nominal voltage output is +5v. This IC are designed with adequate

heat sinking, can deliver output currents in excess of 1A.

2.2.2 Controller circuit:

The controller used in this module is 89C52 micro-controller this used

manipulated the data accessed from the ADC converters. This micro controller linked

to the conversion circuit which contains analog sensors. This is used to for the sensor

circuit and the program for this is written I Kiel software which is then integrated by

the module.

2.2.3 Sensors:

The sensors used for the weather parameters are Lm35 for the temperature

sensing,HIH3160 series is used and a short circuit is used for the rain fall sensing is

used. The data form this is transmitted through the ADC conversion circuit where the

analog data from the parameter transducers are changed to digital form by the circuit

used.

2.2.4 Transmission circuit:

The transmission of data is done in the zigbee module on the basis of IEEE

802.15.4/2.4 GHz standard. this is integrated in the chipcon CC22420.The

transmission of data data is done in encapsulation methods like it gathers the data

and send to the receivers end at a time like a single data packet so that it can send as

many possible data packets in a minute and also the data is not lost in the

transmission .

20

2.2.5 Conversion Circuit:

The output of sample and hold is fed ADC for conversion into digital format. In

this case ADC0804 is employed for conversion of the sampled input signal into 8-bit

digital output. The ADC0804 is compatible with microprocessors. It is a 20-pin IC that

works with 5V supply. It converts the analog input voltage to 8-bit digital output. The

data bus is tri-state buffered. With eight bit, the resolution is 5V/255=19.6mv.

The in built clock generator circuit produces a frequency of about 640 KHz with

R1=10 kilo ohms and c4=150 pf, which are the externally connected timing

components. The conversion time obtained is approximately 100 us.

21

CHAPTER 3

DESCRIPTION OF CIRCUIT COMPONENTS

3.1 CC2420 2.4GHz IEEE802.15.4/ZIGBEE-READY RF TRANSCEIVER

3.1.2 Product Description:

The CC2420 is a true single-chip 2.4 GHz IEEE 802.15.4 compliant RF

transceiver designed for low-power and low-voltage wireless applications. CC2420

includes a digital direct sequence spread spectrum baseband modem providing a

spreading gain of 9 dB and an effective data rate of 250 kbps.

The CC2420 is a low-cost, highly integrated solution for robust wireless

communication in the 2.4 GHz unlicensed ISM band. It complies with worldwide

regulations covered by ETSI EN 300 328 and EN 300 440 class 2 (Europe), FCC

CFR47 Part 15 (US) and ARIB STD-T66 (Japan).

The CC2420 provides extensive hardware support for packet handling, data buffering,

burst transmissions, data encryption, data authentication, clear channel assessment,

link quality indication and packet timing information. These features reduce the load

on the host controller and allow CC2420 to interface low-cost microcontrollers. The

configuration interface and transmit / receive FIFOs of CC2420 are accessed via an

SPI interface. In a typical application CC2420 will be used together with a

microcontroller and a few external passive components. CC2420 is based on

Chipcon’s SmartRF®-03 technology in 0.18 µm CMOS.

3.1.2 Features:

2400 – 2483.5 MHz RF Transceiver

• Direct Sequence Spread Spectrum (DSSS) transceiver

• 250 kbps data rate, 2 MChip/s chip rate

• O-QPSK with half sine pulse shaping modulation

• Very low current consumption (RX: 19.7 mA, TX: 17.4 mA)

• High sensitivity (-94 dBm)

• High adjacent channel rejection (39 dB)

22

• High alternate channel rejection (55 dB)

• On-chip VCO, LNA and PA

• Low supply voltage (2.1 – 3.6 V) with on-chip voltage regulator

• Programmable output power

• I/Q low-IF soft decision receiver

• I/Q direct up-conversion transmitter

• Separate transmit and receive FIFOs

• 128 byte transmit data FIFO

• 128 byte receive data FIFO

• Very few external components

• Only reference crystal and a minimised number of passives

• No external filters needed

• Easy configuration interface

• 4-wire SPI interface

• Serial clock up to 10 MHz

• 802.15.4 MAC hardware support:

• Automatic preamble generator

• Synchronisation word insertion/detection

• CRC-16 computation and checking over the MAC payload

• Clear Channel Assessment

• Energy detection / digital RSSI

• Link Quality Indication

• Full automatic MAC security (CTR, CBC-MAC, CCM)

• 802.15.4 MAC hardware security:

• Automated security operations within the receive and transmit FIFOs.

• CTR mode encryption / decryption

• CBC-MAC authentication

• CCM encryption / decryption and authentication

• Stand-alone AES encryption

• Development tools available

• Fully equipped development kit

• Demonstration board reference design with microcontroller code

23

• Easy-to-use software for generating the CC2420 configu-ration data

• Small size QLP-48 package, 7 x 7 mm

3.1.3 Operating Conditions:

Parameter

Min

Supply voltage for on-chip voltage regulator,

VREG_IN pin 43.

2.1

Supply voltage (VDDIO) for digital I/Os, DVDD3.3,

pin 25 .

1.6

Supply voltage (VDD) on AVDD_VCO, DVDD1.8,

etc (pin no 1, 2, 3, 4, 10, 14, 15, 17, 18, 20, 26, 35,

37, 44 and 48)

1.6

Operating ambient temperature range

−40

Typ.

Max.

Units

3.6

3.6

1.8

2.0

85

3.1.4 Pin Assignment:

(Fig 5 : Pin assignment of cc2420)

24

Condition

V

V

The digital I/O voltage (DVDD3.3 pin)

must match the external interfacing

circuit (e.g. microcontroller).

V

The typical application uses regulated

1.8 V supply generated by the on-chip

voltage regulator.

°C

Pin Pin Name

Pin type

Pin Description

-

Ground

Exposed die attach pad. Must be connected to

(analog)

solid ground plane

Power

Connection of guard ring for VCO (to AVDD)

(analog)

shielding

Power

1.8 V Power supply for VCO

1

2

AGND

VCO_GUARD

AVDD_VCO

(analog)

3

AVDD_PRE

Power

1.8 V Power supply for Prescaler

(analog)

4

AVDD_RF1

Power

1.8 V Power supply for RF front-end

(analog)

5

GND

Ground

Grounded pin for RF shielding

(analog)

6

RF_P

RF I/O

Positive RF input/output signal to LNA/from PA

in receive/transmit mode

7

TXRX_SWITCH

Power

Common supply connection for integrated RF

(analog)

front-end. Must be connected to RF_P and

RF_N externally through a DC path

8

RF_N

RF I/O

Negative RF input/output signal to LNA/from

PA in receive/transmit mode

9

GND

Ground

Grounded pin for RF shielding

(analog)

10

AVDD_SW

Power

1.8 V Power supply for LNA / PA switch

(analog)

11

NC

-

Not Connect

12

NC

-

Not Connect

13

NC

-

Not Connect

14

AVDD_RF2

Power

1.8 V Power supply for receive and transmit

(analog)

mixers

Power

1.8 V Power supply for transmit / receive IF

(analog)

chain

-

Not Connect

15

16

AVDD_IF2

NC

25

17

18

19

AVDD_ADC

DVDD_ADC

DGND_GUARD

Power

1.8 V Power supply for analog parts of ADCs

(analog)

and DACs

Power

1.8 V Power supply for digital parts of receive

(digital)

ADCs

Ground

Ground connection for digital noise isolation

(digital)

20

DGUARD

Power

1.8 V Power supply connection for digital noise

(digital)

isolation

21

RESETn

Digital Input

Asynchronous, active low digital reset

22

DGND

Ground

Ground connection for digital core and pads

(digital)

23

DSUB_PADS

Ground

Substrate connection for digital pads

(digital)

24

DSUB_CORE

Ground

Substrate connection for digital modules

(digital)

25

DVDD3.3

Power

3.3 V Power supply for digital I/Os

(digital)

26

DVDD1.8

Power

1.8 V Power supply for digital core

(digital)

27

28

29

30

SFD

CCA

FIFOP

FIFO

Digital

SFD (Start of Frame Delimiter) / digital mux

output

output

Digital

CCA (Clear Channel Assessment) / digital mux

output

output

Digital

High when number of bytes in FIFO exceeds

output

threshold / serial RF clock output in test mode

Digital I/O

High when data in FIFO / serial RF data input /

output in test mode

31

CSn

Digital input

SPI Chip select, active low

32

SCLK

Digital input

SPI Clock input, up to 10 MHz

33

SI

Digital input

SPI Slave Input. Sampled on the positive edge

of SCLK

34

SO

Digital

SPI Slave Output. Updated on the negative

26

output

edge of SCLK. Tristate when CSn high.

(tristate)

35

DVDD_RAM

Power

1.8 V Power supply for digital RAM

(digital)

36

NC

-

37

AVDD_XOSC16 Power

Not Connect

1.8 V crystal oscillator power supply

(analog)

38

XOSC16_Q2

Analog I/O

16 MHz Crystal oscillator pin 2

39

XOSC16_Q1

Analog I/O

16 MHz Crystal oscillator pin 1 or external

clock input

40

NC

-

Not Connect

41

VREG_EN

Digital input

Voltage regulator enable, active high, held at

VREG_IN voltage level when active

42

VREG_OUT

Power

Voltage regulator 1.8 V power supply output

output

43

44

45

VREG_IN

AVDD_IF1

R_BIAS

Power

Voltage regulator 2.1 to 3.6 V power supply

(analog)

input

Power

1.8 V Power supply for transmit / receive IF

(analog)

chain

Analog

External precision resistor, 43 kΩ, ± 1 %

output

46

ATEST2

Analog I/O

Analog test I/O for prototype and production

testing

47

ATEST1

Analog I/O

Analog test I/O for prototype and production

testing

48

AVDD_CHP

Power

1.8 V Power supply for phase detector and

(analog)

charge pump

27

3.1.5 Circuit Description:

(Fig 5 :A simplified block diagram of CC2420)

CC2420 features a low-IF receiver. The received RF signal is amplified by the lownoise amplifier (LNA) and down-converted in quadrature (I and Q) to the intermediate

frequency (IF). At IF (2 MHz), the complex I/Q signal is filtered and amplified, and

then digitized by the ADCs. Automatic gain control, final channel filtering, despreading, symbol correlation and byte synchronisation are performed digitally.

When the SFD pin goes high, this indicates that a start of frame delimiter has been

detected. CC2420 buffers the received data in a 128 byte receive FIFO. The user

may read the FIFO through an SPI interface. CRC is verified in hardware. RSSI and

correlation values are appended to the frame. CCA is available on a pin in receive

mode. Serial (unbuffered) data modes are also available for test purposes.

The CC2420 transmitter is based on direct up-conversion. The data is buffered in a

128 byte transmit FIFO (separate from the receive FIFO). The preamble and start of

frame delimiter are generated by hardware. Each symbol (4 bits) is spread using the

28

IEEE 802.15.4 spreading sequence to 32 chips and output to the digital-to-analog

converters (DACs).

An analog lowpass filter passes the signal to the quadrature (I and Q) upconversion

mixers. The RF signal is amplified in the power amplifier (PA) and fed to the antenna.

The internal T/R switch circuitry makes the antenna interface and matching easy. The

RF connection is differential. A balun may be used for single-ended antennas. The

biasing of the PA and LNA is done by connecting TXRX_SWITCH to RF_P and RF_N

through an external DC path.

(Fig 6: cc2420 pin connections)

The frequency synthesizer includes a completely on-chip LC VCO and a 90 degrees

phase splitter for generating the I and Q LO signals to the down-conversion mixers in

receive mode and up-conversion mixers in transmit mode. The VCO operates in the

29

frequency range 4800 – 4966 MHz, and the frequency is divided by two when split in I

and Q.

A crystal must be connected to XOSC16_Q1 and XOSC16_Q2 and provides the

reference frequency for the synthesizer. A digital lock signal is available from the PLL.

The digital baseband includes support for frame handling, address recognition, data

buffering and MAC security.

The 4-wire SPI serial interface is used for configuration and data buffering.

An on-chip voltage regulator delivers the regulated 1.8 V supply voltage. The voltage

regulator may be enabled / disabled through a separate pin.

A battery monitor may optionally be used to monitor the unregulated power supply

voltage. The battery monitor is configurable through the SPI interface.

3.1.6 IEEE 802.15.4 Modulation Format:

This section is meant as an introduction to the 2.4 GHz direct sequence spread

spectrum (DSSS) RF modulation format defined in IEEE 802.15.4.

The modulation and spreading functions are illustrated at block level in Figure .Each

byte is divided into two symbols, 4 bits each. The least significant symbol is

transmitted first. For multi-byte fields, the least significant byte is transmitted first,

except for security related fields where the most significant byte it transmitted first.

Each symbol is mapped to one out of 16 pseudo-random sequences, 32 chips each.

The symbol to chip mapping is shown in Table 3. The chip sequence is then

transmitted at 2 MChips/s, with the least significant chip (C0) transmitted first for each

symbol.

(Fig 7 : Modulation and spreading functions)

30

Symbol Chip sequence (C0, C1, C2, … , C31)

0

11011001110000110101001000101110

1

11101101100111000011010100100010

2

00101110110110011100001101010010

3

00100010111011011001110000110101

4

01010010001011101101100111000011

5

00110101001000101110110110011100

6

11000011010100100010111011011001

7

10011100001101010010001011101101

8

10001100100101100000011101111011

9

10111000110010010110000001110111

10

01111011100011001001011000000111

11

01110111101110001100100101100000

12

00000111011110111000110010010110

13

01100000011101111011100011001001

14

10010110000001110111101110001100

15

11001001011000000111011110111000

(Table 1: IEEE 802.15.4 symbol-to-chip mapping)

The modulation format is Offset – Quadrature Phase Shift Keying (O-QPSK) with halfsine chip shaping. This is equivalent to MSK modulation. Each chip is shaped as a

half-sine, transmitted alternately in the I and Q channels with one half chip period

offset. This is illustrated for the zero-symbol in Figure.

31

(Fig 8 : I / Q Phases when transmitting a zero-symbol chip sequence, TC = 0.5 µs)

3.1.7 Microcontroller Interface and Pin Description:

When used in a typical system, CC2420 will interface to a microcontroller. This

microcontroller must be able to:

• Program CC2420 into different modes, read and write buffered data, and read back

status information via the 4-wire SPI-bus configuration interface (SI,

SO, SCLK

and

CSn).

• Interface to the receive and transmit FIFOs using the FIFO and FIFOP status pins.

• Interface to the CCA pin for clear channel assessment.

• Interface to the SFD pin for timing information (particularly for beaconing networks).

3.1.8 Configuration interface:

A CC2420 to microcontroller interface example is shown in Figure 11. The

microcontroller uses 4 I/O pins for the SPI configuration interface (SI, SO, SCLK and CSn).

SO

should be connected to an input at the microcontroller.

SI, SCLK

and

CSn

must be

microcontroller outputs. Preferably the microcontroller should have a hardware SPI

interface.

The microcontroller pins connected to

interface devices.

SO

SI, SO

and

SCLK

can be shared with other SPI-

is a high impedance output as long as

CSn

is not activated (active

low).

CSn should

have an external pull-up resistor or be set to a high level when the voltage

regulator is turned off in order to prevent the input from floating.

set to a defined level to prevent the inputs from floating.

32

SI and SCLK should

be

(Fig: 9 : Microcontroller interface example)

3.1.9 Receive mode :

In receive mode, the

SFD

pin goes high after the start of frame delimiter

(SFD) field has been completely received. If address recognition is disabled or is

successful, the

SFD

pin goes low again only after the last byte of the MPDU has

been received. If the received frame fails address recognition, the SFD pin goes low

immediately. This is illustrated in Figure 12.

The

FIFO

pin is high when there is one or more data bytes in the RXFIFO. The first

byte to be stored in the RXFIFO is the length field of the received frame, i.e. the

FIFO

pin is set high when the length field is written to the RXFIFO. The

FIFO

pin then

remains high until the RXFIFO is empty.

If a previously received frame is completely or partially inside the RXFIFO, the

FIFO

pin will remain high until the RXFIFO is empty.

The

FIFOP

pin is high when the number of unread bytes in the RXFIFO exceeds the

threshold programmed into

the

FIFOP

IOCFG0.FIFOP_THR.

When address recognition is enabled

pin will not go high until the incoming frame passes address recognition,

even if the number of bytes in the RXFIFO exceeds the programmed threshold.

The

FIFOP

pin will also go high when the last byte of a new packet is received, even

if the threshold is not exceeded. If so the

FIFOP pin

will go back to low once one byte

has been read out of the RXFIFO.

When address recognition is enabled, data should not be read out of the RXFIFO

before the address is completely received, since the frame may be automatically

flushed by CC2420 if it fails address recognition. This may be handled by using the

FIFOP pin, since this pin does not go high until the frame passes address

recognition.

33

Figure shows an example of pin activity when reading a packet from the RXFIFO.

In this example, the packet size is 8 bytes,

MODEMCTRL0.AUTOCRC

IOCFG0.FIFOP_THR

= 3 and

is set. The length will be 8 bytes, RSSI will contain the average

RSSI level during receiving of the packet and FCS/corr contain information of FCS

check result and the correlation levels.

3.1.10 RXFIFO overflow

The RXFIFO can only contain a maximum of 128 bytes at a given time. This

may be divided between multiple frames, as long as the total number of bytes is

128 or less. If an overflow occurs in the RXFIFO, this is signalled to the

microcontroller by setting the

FIFO

pin low while the

FIFOP

pin is high. Data already in

the RXFIFO will not be affected by the overflow, i.e. frames already received may

be read out.

A SFLUSHRX command strobe is required after a RXFIFO overflow to

enable reception of new data.For security enabled frames, the MAC layer must

read the source address of the received frame before it can decide which key to

use to decrypt or authenticate. This data must therefore not be overwritten even if

it has been read out of the RXFIFO by the microcontroller. If the

SECCTRL0.RXFIFO_PROTECTION control bit is set, CC2420 also protects the

frame header of security enabled frames until decryption has been performed. If

no MAC security is used or if it is implemented outside C2420, this bit may be

cleared

to

achieve

optimal

use

of

the

(Fig: 10 : Pin activity examples during receive )

34

RXFIFO.

(Fig 11 :Example of pin activity when reading RXFIFO)

3.1.11 Transmit mode:

During transmit, the

The

SFD

FIFO

and

FIFOP

pins are still only related to the RXFIFO.

pin is however active during transmission of a data frame, as shown in

Figure .

The SFD pin goes high when the SFD field has been completely transmitted. It goes

low again when the complete MPDU (as defined by the length field) has been

transmitted or if an underflow is detected. See the RF Data Buffering section on

page 37 for more information on TXFIFO underflow.

As can be seen from comparing Figure . and Figure , the SFD pin behaves

very similarly during reception and transmission of a data frame. If the

SFD pins

of

the transmitter and the receiver are compared during the transmission of a data

frame, a small delay of approximately 2 µs can be seen because of bandwidth

limitations in .both the transmitter and the receiver.

(Fig 12 : Pin activity example during transmit )

35

3.1.12 General control and status pins

In receive mode, the FIFOP pin can be used to interrupt the microcontroller

when a threshold has been exceeded or a complete frame has been received.

This pin should then be connected to a microcontroller interrupt pin.

In receive mode, the

FIFO

pin can be used to detect if there is data at all in the

receive FIFO.

The

SFD

pin can be used to extract the timing information of transmitted and

received data frames. The

SFD

pin will go high when a start of frame delimiter has

been completely detected / transmitted. The

SFD

pin should preferably be

connected to a timer capture pin on the microcontroller.

For debug purposes, the

signals as selected by the

SFD

and

IOCFG1

CCA

pins can be used to monitor several status

register. See Table 12 and Table 13 for available

signals.

The polarity of

FIFO, FIFOP, SFD

and

CCA

can be controlled by the

IOCFG0

register

(address 0x1C).

3.1.13 Demodulator, Symbol Synchroniser and Data Decision:

The block diagram for the CC2420 demodulator is shown in Figure .

Channel filtering and frequency offset compensation is performed digitally. The

signal level in the channel is estimated to generate the RSSI level (see the RSSI /

Energy Detection section on page 47 for more information). Data filtering is also

included for enhanced performance.

With the ±40 ppm frequency accuracy requirement from [1], a compliant receiver

must be able to compensate for up to 80 ppm or 200 kHz. The CC2420

demodulator tolerates up to 300 kHz offset without significant degradation of the

receiver performance.

Soft decision is used at the chip level, i.e. the demodulator does not make a

decision for each chip, only for each received symbol. De-spreading is performed

using over sampled symbol correlators. Symbol synchronisation is achieved by a

continuous start of frame delimiter (SFD) search.

When a SFD is detected, data is written to the RXFIFO and may be read out by

the microcontroller at a lower bit rate than the 250 kbps generated by the receiver.

The CC2420 demodulator also handles symbol rate errors in excess of 120 ppm

without performance degradation.

36

(Fig 13 : Demodulator Simplified Block Diagram)

3.2 MIXED SIGNAL CONTROLLER(MSP 430):

3.2.1 Features:

Low Supply-Voltage Range, 1.8 V . . . 3.6 V

Ultralow-Power Consumption:

Five Power-Saving Modes

Wake-Up From Standby Mode in less than 6 us

16-Bit RISC Architecture,125-ns Instruction Cycle Time

12-Bit A/D Converter With Internal Reference, Sample-and-Hold and

Autoscan Feature

16-Bit Timer_B With Seven Capture/Compare-With-Shadow Registers

16-Bit Timer_A With Three Capture/Compare Registers

On-Chip

Comparator

Serial

Onboard

Programming,No

External

Programming Voltage Needed Programmable Code Protection by

Security Fuse

Family Member Include :

MSP430F133: 8KB+256B Flash Memory,256B RAM

MSP430F135:16KB+256B Flash Memory,512B RAM

MSP430F147, MSP430F1471†:32KB+256B Flash Memory,1KB RAM

MSP430F148, MSP430F1481†:48KB+256B Flash Memory,2KB RAM

MSP430F149, MSP430F1491†:60KB+256B Flash Memory,2KB RAM

MSP Module:

37

(Fig 14 : basic core modele of mps430)

3.2.2 Description:

The Texas Instruments MSP430 family of ultralow-power microcontrollers

consist of several devices featuring different sets of peripherals targeted for

various applications. The architecture, combined with five low power modes is

optimized to achieve extended battery life in portable measurement applications.

The device featuresa powerful 16-bit RISC CPU, 16-bit registers, and constant

generators that attribute to maximum code efficiency.The digitally controlled

oscillator (DCO) allows wake-up from low-power modes to active mode in less

than 6us. The MSP430x13x and the MSP430x14x(1) series are microcontroller

configurations with two built-in 16-bit timers, a fast 12-bit A/D converter (not

implemented on the MSP430F14x1 devices), one or two universal serial

synchronous/asynchronous communication interfaces (USART), and 48 I/O pins.

Typical applications include sensor systems that capture analog signals, convert

38

them to digital values, and process and transmit the data to a host system. The

timers make the configurations ideal for industrial control applications such as

ripple counters, digital motor control, EE-meters, hand-held meters, etc. The

hardware multiplier enhances the performance and offers a broad code and

hardware-compatible family solution.

3.2.3 Pin Diagram:

(Fig 15 : functional block diagram of msp430)

3.2.4 Functional Block Diagram:

39

(Fig 16: block diagram of msp430)

3.2.5 Short-Form Description

CPU

The MSP430 CPU has a 16-bit RISC architecture that is highly transparent

to the application. All operations, other than program-flow instructions,are

performed as register operations in conjunction with seven addressing modes for

source operand and four addressing modes for destination operand. The CPU is

integrated with 16 registers that provide reduced instruction execution time. The

register-to-register operation execution time is one cycle of the CPU clock. Four of

the registers, R0 to R3, are dedicated as program counter, stack pointer, status

register, and constant generator respectively. The remaining registers are generalpurpose registers. Peripherals are connected to the CPU using data, address, and

control buses, and can be handled with all instructions.

Instruction Set:

The instruction set consists of 51 instructions with three formats and seven

address modes. Each instruction can operate on word and byte data. Table 1

shows examples of the three types of instruction formats; the address modes are

listed in Table .

40

(Table 2 :Instruction Set)

Operating Modes:

The MSP430 has one active mode and five software selectable low-power modes

of operation. An interrupt event can wake up the device from any of the five lowpower modes, service the request and restore back to the low-power mode on

return from the interrupt program.

The following six operating modes can be configured by software:

Active mode AM;

All clocks are active

Low-power mode 0 (LPM0);

CPU is disabled

ACLK and SMCLK remain active. MCLK is disabled

Low-power mode 1 (LPM1);

CPU is disabled

ACLK and SMCLK remain active. MCLK is disabled

DCO’s dc-generator is disabled if DCO not used in active mode

Low-power mode 2 (LPM2);

CPU is disabled

MCLK and SMCLK are disabled

DCO’s dc-generator remains enabled

ACLK remains active

Low-power mode 3 (LPM3);

CPU is disabled

MCLK and SMCLK are disabled

DCO’s dc-generator is disabled

ACLK remains active

41

Low-power mode 4 (LPM4);

CPU is disabled

ACLK is disabled

MCLK and SMCLK are disabled

DCO’s dc-generator is disabled

Crystal oscillator is stopped

Flash Memory:

The flash memory can be programmed via the JTAG port, the bootstrap

loader, or in-system by the CPU. The CPU can perform single-byte and singleword writes to the flash memory. Features of the flash memory include:

Flash memory has n segments of main memory and two segments of

information memory

(A and B) of 128 bytes each. Each segment in

main memory is 512 bytes in size.

Segments 0 to n may be erased in one step, or each segment may

be individually erased.

Segments A and B can be erased individually, or as a group with

segments 0−n.Segments A and B are also called information memory.

New devices may have some bytes programmed in the information

memory (needed for test during manufacturing). The user should

perform an erase of the information memory prior to the first use.

Peripherals:

Peripherals are connected to the CPU through data, address, and control

busses and can be handled using all instructions. For complete module

descriptions, see the MSP430x1xx Family User’s Guide, literature number

SLAU049.

Digital I/O:

There are six 8-bit I/O ports implemented—ports P1 through P6:

All individual I/O bits are independently programmable.

Any combination of input, output, and interrupt conditions is possible.

dge-selectable interrupt input capability for all the eight bits of ports P1 and

P2.

Read/write access to port-control registers is supported by all instructions.

42

Oscillator and System Clock:

The clock system in the MSP430x13x and MSP43x14x(1) family of devices is

supported by the basic clock module that includes support for a 32768-Hz watch

crystal oscillator, an internal digitally-controlled oscillator (DCO) and a high

frequency crystal oscillator. The basic clock module is designed to meet the

requirements of both low system cost and low-power consumption. The internal

DCO provides a fast turn-on clock source and stabilizes in less than 6 us. The

basic clock module provides the following clock signals:

Auxiliary clock (ACLK), sourced from a 32768-Hz watch crystal or a high

frequency crystal.

Main clock (MCLK), the system clock used by the CPU.

Sub-Main clock (SMCLK), the sub-system clock used by the peripheral

modules.

Watchdog Timer:

The primary function of the watchdog timer (WDT) module is to perform a

controlled system restart after a software problem occurs. If the selected time

interval expires, a system reset is generated. If the watchdog function is not

needed in an application, the module can be configured as an interval timer and

can generate interrupts at selected time intervals.

Recommended Operating conditions:

(Table 4 : operating conditions)

3.3 SENSORS:

43

To monitor parameters we sensors this type of sensors are discussed as

further in the review of each sensor

The type of sensors are as follows

3.3.1 LM 35:

LM 35 is a precision centigrade Temperature sensor. The LM35 is an integrated

circuit sensor that can be used to measure temperature with an electrical output

proportional to the temperature (in °C)

3.3.1.1General Description:

The LM35 series are precision integrated-circuit temperature sensors,

whose output voltage is linearly proportional to the Celsius (Centigrade)

temperature. The LM35 thus has an advantage over linear temperature sensors

calibrated in Kelvin, as the user is not required to subtract a large constant voltage

from its output to obtain convenient Centigrade scaling. The LM35 does not

require any external calibration or trimming to provide typical accuracies of ±1⁄4°C

at room temperature and ±3⁄4°C over a full −55 to +150°C temperature range. Low

cost is assured by trimming and calibration at the wafer level. The LM35’s low

output impedance, linear output, and precise inherent calibration make interfacing

to readout or control circuitry especially easy. It can be used with single power

supplies, or with plus and minus supplies. As it draws only 60 µA from its supply, it

has very low self-heating, less than 0.1°C in still air. The LM35 is rated to operate

over a −55° to +150°C temperature range, while the LM35C is rated for a −40° to

+110°C range (−10°with improved accuracy). The LM35 series is available

packaged in hermetic TO-46 transistor packages, while the LM35C, LM35CA, and

LM35D are also available in the plastic TO-92 transistor package. The LM35D is

also available in an 8-lead surface mount small outline package and a plastic TO220 package.

3.3.1.2Features:

Calibrated directly in ° Celsius (Centigrade)

Linear + 10.0 mV/°C scale factor

0.5°C accuracy guaranteeable (at +25°C)

Rated for full −55° to +150°C range

Suitable for remote applications

Low cost due to wafer-level trimming

44

Operates from 4 to 30 volts

Less than 60 µA current drain

Low self-heating, 0.08°C in still air

Nonlinearity only ±1⁄4°C typical

Low impedance output, 0.1 W for 1 mA load

3.3.1.3 Typical Applications:

(Fig 17 a : Basic Centigrade Temperature Sensor +2 c to +150 c)

(Fig 17: Full-Range Centigrade Temperature Sensor)

Choose R1 = −VS/50 µA

V OUT=+1,500 mV at +150°C

= +250 mV at +25°C

= −550 mV at −55°C

3.3.1.3

Maximum Ratings:

Supply Voltage +35V to −0.2V

Output Voltage +6V to −1.0V

Output Current 10 mA

Storage Temp.;

TO-46 Package, −60°C to +180°C

TO-92 Package, −60°C to +150°C

SO-8 Package, −65°C to +150°C

45

TO-220 Package, −65°C to +150°C

Lead Temp.:

TO-46 Package,

(Soldering, 10 seconds) 300°C

TO-92 and TO-220 Package,

(Soldering, 10 seconds) 260°C

SO Package (Note 12)

Vapor Phase (60 seconds) 215°C

Infrared (15 seconds) 220°C

ESD Susceptibility (Note 11) 2500V

Specified Operating Temperature Range: TMIN to T MAX

(Note 2)

LM35, LM35A −55°C to +150°C

LM35C, LM35CA −40°C to +110°C

LM35D 0°C to +100°C

Typical Performance Charecteristics:

Minimum Supply

Voltage vs Temperature

Thermal Resistance:

Junction to Air

46

Accuracy vs Temperature:

3.3.1.4

Application:

The LM35 can be applied easily in the same way as other integrated-circuit

temperature sensors. It can be glued or cemented to a surface and its temperature

will be within about 0.01§C of the surface temperature.This presumes that the

ambient air temperature is almost the same as the surface temperature; if the air

temperature were much higher or lower than the surface temperature,the actual

temperature of the LM35 die would be at an intermediate temperature between the

surface temperature and the air temperature. This is expecially true for the TO-92

plastic package, where the copper leads are the principal thermal path to carry

heat into the device, so its temperature might be closer to the air temperature than

to the surface temperature.To minimize this problem, be sure that the wiring to the

LM35, as it leaves the device, is held at the same temperature as the surface of

interest. The easiest way to do this is to cover up these wires with a bead of epoxy

which will insure that the leads and wires are all at the same temperature as the

47

surface, and that the LM35 die's temperature will not be affected by the air

temperature.

The TO-46 metal package can also be soldered to a metal surface or pipe

without damage. Of course, in that case the Vb terminal of the circuit will be

grounded to that metal. Alternatively, the LM35 can be mounted inside a sealedend metal tube, and can then be dipped into a bath or screwed into a threaded

hole in a tank. As with any IC, the LM35 and accompanying wiring and circuits

must be kept insulated and dry, to avoid leakage and corrosion. This is especially

true if the circuit may operate at cold temperatures where condensation can occur.

Printed-circuit coatings and varnishes such as Humiseal and epoxy paints or dips

are often used to insure that moisture cannot corrode the LM35 or its

connections.These devices are sometimes soldered to a small lightweight heat fin,

to decrease the thermal time constant and speed up the response in slowlymoving air. On the other hand, a small thermal mass may be added to the sensor,

to give the steadiest reading despite small deviations in the air temperature.

3.3.2

Humidity Sensor(HIH-3610):

The HIH-3610 Series humidity sensor is designed specifically for high volume

OEM (Original Equipment Manufacturer) users. Direct input to a controller or other

device is made possible by this sensor’s linear voltage output. With a typical

current draw of only 200 A, the HIH-3610 Series is ideally suited for low drain,

battery operated systems. Tight sensor interchangeability reduces or eliminates

OEM production calibration costs. Individual sensor calibration data is available.

The HIH-3610 Series delivers instrumentation-quality RH (Relative Humidity)

sensing performance in a low cost, solder able SIP (Single In-line Package).

Available in two lead spacing configurations, the RH sensor is a laser trimmed

thermo set polymer capacitive sensing element with on-chip integrated signal

conditioning. The sensing element's multilayer construction provides excellent

resistance to application hazards such as wetting, dust, dirt, oils, and common

environmental chemicals.

3.3.3 FEATURES

Molded thermoset plastic housing with cover

48

Linear voltage output vs %RH

Laser trimmed interchangeability

Low power design

High accuracy

Fast response time

Stable, low drift performance

Chemically resistant

3.3.4 TYPICAL APPLICATIONS

Refrigeration

Drying

Metrology

Battery-powered systems

OEM assemblies

3.3.5 PERFORMANCE SPECIFICATIONS

Parameter

RH Accuracy

Condition

±2% RH, 0-100% RH non-condensing, 25 °C,

Vsupply = 5 Vdc

RH Interchangeability

±5% RH, 0-60% RH; ±8% @ 90% RH typical

RH Linearity

±0.5% RH typical

RH Hysteresis

±1.2% RH span maximum

RH Repeatability

±0.5% RH

RH Response Time

1/e 15 sec in slowly moving air at 25 °C

RH Stability

±1% RH typical at 50% RH in 5 years

Power Requirements

Voltage Supply

4 Vdc to 5.8 Vdc, sensor calibrated at 5 Vdc

Current Supply

200 A at 5 Vdc

Voltage Output

Vout = Vsupply (0.0062(Sensor RH) + 0.16),

typical @ 25 C

49

(Data printout option provides a similar, but

sensor specific,

equation at 25 C.)

0.8 Vdc to 3.9 Vdc output @ 25 C typical

Vsupply = 5 Vdc

Push/pull symmetric; 50 A typical, 20 A

minimum, 100 A maximum , Turn-on 0.1 sec

Temperature Compensation

True RH = (Sensor RH)/(1.093 -0.0012T), T in

°F

True RH = (Sensor RH)/(1.0546-0.00216T), T in

C

Effect @ 0% RH

Effect @ 100% RH

±0.007 %RH/°C (negligible)

-0.22% RH/°C (<1% RH effect typical in occupied space

systems above 15 °C (59 F))

Humidity Range

Operating

0 to 100% RH, non-condensing(1

Storage

0 to 90% RH, non-condensing

Temperature Range

Operating

-40 °C to 85 °C (-40 F to 185 F)

Storage

-51 °C to 125 °C (-60 F to 257 F)

Handling

Static sensitive diode protected to 15 kV

maximum

3.4 ANALOG TO DIGITAL CONVERTER-ADC0804:

3.4.1 CONNECTION DIAGRAM:

50

ADC0804

Dual-In-Line and Small Outline (SO) Packages

(Fig. 18: Connection diagram of ADC0804)

3.4.2 GENERAL DESCRIPTION:

ADC0804 is a CMOS 8-bit successive approximation A/D converter that

uses a differential potentiometric ladder similar to the 256R products. This

converter is designed to allow operation with the NSC800 and INS8080A

derivative control bus with TRI-STATE output latches directly driving the data bus.

This A/D appear like memory location or I/O ports to the microprocessor and no

interfacing logic is needed.

Differential analog voltage inputs allow increasing the common-mode

rejection and offsetting the analog zero input voltage value. In addition, the voltage

reference input can be adjusted to allow encoding any smaller analog voltage span

to the full 8 bits of resolution.

3.4.3 KEY SPECIFICATIONS:

Resolution

: 8 bits

Total error

: ±1⁄4 LSB, ±1⁄2 LSB and ±1 LSB

Conversion time

: 100 μs

3.4.4 FEATURES:

Compatible with 8080 μP derivatives—no interfacing logic needed - access

time - 135 ns.

Easy interface to all microprocessors, or operates “stand alone”.

Differential analog voltage inputs.

51

Logic inputs and outputs meet both MOS and TTL voltage level

specifications.

Works with 2.5V (LM336) voltage reference.

On-chip clock generator.

0V to 5V analog input voltage range with single 5V supply.

No zero adjust required.

0.3" standard width 20-pin DIP package.

20-pin molded chip carrier or small outline package.

Operates ratio metrically or with 5 VDC, 2.5 VDC, or analog span adjusted

voltage reference.

3.4.5 BLOCK DIAGRAM OF ADC0804:

(Fig. 19: Block Diagram of ADC0804)

3.4.6 PARAMETRIC TABLE:

52

Min. Supply Voltage

4.5 Volt

Max. Supply Voltage

6.3 Volt

Resolution

8 bit

Conversion Time

100 us

Interface Type

Parallel

3.5 Level Converter(max 232):

3.5.1 Pin Diagram:

(Fig 20: pin diagram of max 232)

The MAX232 is a dual driver/receiver that includes a capacitive voltage generator

to supply TIA/EIA-232-F voltage levels from a single 5-V supply. Each receiver

converts TIA/EIA-232-F inputs to 5-V TTL/CMOS levels.These receivers have a

typical threshold of 1.3 V, a typica

-V

inputs. Each driver converts TTL/CMOS input levels into TIA/EIA-232-F levels. The

driver, receiver, and voltage-generator functions are available as cells in the Texas

53

3.5.2 Internal Diagram :

Sure enough, the MAX232 is the chip for you. It runs on a single chip supply