Title_ “ Measure And Comparison Between River Sand And

advertisement

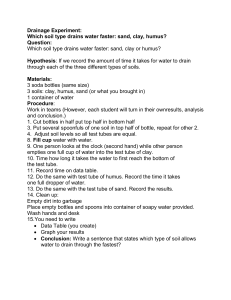

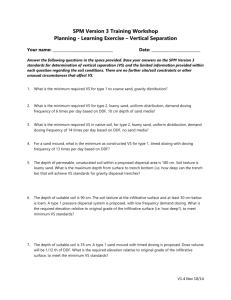

CHAPTER 3 MATERIALS AND TESTING 3.1 Introduction Upon completion of compaction at site, the In Situ Field Density Test is required to carry out with the appropriate apparatus, materials and unusual expertise. The methods of testing should be as stipulated in the specifications. Normally they will be methods specified in Malaysian Standards, or internationally recognized standard methods of testing specified by agencies such as the British Standards Institution, The American Association of State Highway and Transportation Officials (ASSSHTO), the American Society for Testing and Materials (ASTM), ETC. All test results should be recorded on standard forms especially prepared for the purpose. Work performed in relatively low levels of inspection, should be subjected to more intensive testing. Below are the stages involving the whole process of the research project as shown in Figure 3.1. 18 STAGE I : Preparation of the materials and apparatus: 1. Assemble all the necessary equipment and apparatus needed. 2. Preparation of standard sand and river sand. 3. Prepare form sheets. 4. Carry out soil classification tests and laboratory compaction test on The filled material. STAGE II : Calibration of the standard and river sand: 1. Oven dried and stored for 7 days the prepared sand. 2. Determine the mass of sand in the cone of the pouring cylinder. 3. Determine the bulk density of the sand. 4. Calculate the bulk density of the sand. STAGE III : Conduct the test at site: 1. Locate the site. 2. Carry out 2 series of test for standard sand and 3 series of test for river sand at various types of compacted sites and soils. 3. Collect data. STAGE 4 : Analyze the collected data: 1. Calculation for the field density. 2. Interpretation and comparison of the result. 3. Establish the correlation factor between standard sand and river Sand. Figure 3.1: Flow chart of the research procedures. 19 3.2 Apparatus and Equipment The apparatus to use for the laboratory testing and In-Situ Field Density test are: i. Small pouring cylinder, as shown in figure 3.1. ii. A bent spoon dibber and a scraper tool. iii. Cylinder, metal, calibration container, with an internal diameter of 100 + 2 mm and an internal depth of 150 + 3mm fitted with a lip 50mm wide and about 5mm thick surrounding the open end. iv. Balance, readable to 1 g. v. Glass plate of at least 10mm thick and about 500mm square. vi. Metal tray or container to take excavated soil about 300mm in diameter and about 40mm deep. vii. Apparatus for moisture content determination as specified in BS1377: Part2: 1990. viii. Material. The replacement sand shall be: a) Clean closely graded silica sand and b) River sand as prepared. ix. Apparatus for particle density test as specified in BS1377 Part 2 : Test 8.3 using Small Pyknometer Method (Density Bottles). x. Apparatus for the determination of liquid limit as specified in BS1377 Part 2 : Test 4.3 using Cone Penetrometer Method (definitive method). xi. Apparatus for determination of the plastic limit and plasticity index BS1377 Part 2 :Test 5.3 and Test 5.4. xii. Apparatus for determination of particle size distribution :AASHTO T87-70 & T88-70 or ASTM D421-58 7 D422-63. xiii. Apparatus for determination of laboratory compaction test BS1377 Part 4 : Test 3.5. 20 3.3 The Testing Procedures The test will be carried out accordance with BS1377: 1990 or AASHTO or ASTM. Descriptions of test methods have been broken down into smaller procedural stages. Only the relevant test methods will be discussed. 3.3.1 Determination Of Moisture Content (Oven-drying method) Water is present in most naturally occurring soils. The amount of water, expressed as a pro portion by mass of the dry solid particles, known as the moisture content, has a profound on soil behavior. Moisture content is required as a guide to classification of natural soil. It is also acted as a control criterion in re-compact soil and is measured on samples used for most field and laboratory tests. The oven-drying method is the definitive procedure used in standard laboratory practice. This method covers the determination of the moisture content of a specimen of soil as a percentage of its dry mass. The test method is accordance with BS 1377 : Part 2 : 1900 : Method 3.2 (Oven-drying method). 3.3.2 Determination Of Particle Density There are three methods can be used. The first is a gas jar method suitable for most soils including those containing gravel-sized particles. The second is the 21 small pyknometer method which is the definitive method for soils consisting of clay, silt and 22 sand-sized particles. The third method is a pyknometer method, suitable for soils containing particles up to medium gravel size. Small pyknometer method is suitable for soils consisting of particles finer than 2 mm. Larger may be ground down to smaller than this size before testing. At least two specimens shall be oven dried at 105 0C to 110 0C, and then stored in airtight containers until required. The test method is accordance with BS 1377 : Part 2 : 1900 : Method 8.3 (Small pyknometer method). 3.3.3 Determination Of The Liquid Limit The liquid limit is the empirically moisture content at which a soil passes from the liquid state to the plastic state. It provides a means of classifying a soil, especially when the plastic limit is also known. Two main types of test are specified. The first is the cone penetrometer method, which is fundamentally more satisfactory than the alternative because it is essentially a static test depending on soil shear strength. It is also easier to perform and gives more reproducible results. The second is the much earlier Casagrande type of test. This test introduces dynamic effects and is more susceptible to discrepancies between operators. Cone penetrometer method covers the determination of the liquid limit of a sample of soil in its natural state, or of a sample of soil from which material retained on a 0.425mm test sieve has been removed. The test method is accordance with BS 1377 : Part 2 : 1900 : Method 4.3 (Cone penetrometer method). 23 3.3.4 Determination Of The Plastic Limit And Plasticity index The plastic limit is the empirically established moisture content at which a soil becomes too dry to be plastic. It is used together with the liquid limit for determine the plasticity index which when plotted against the liquid limit on the plasticity chart provides a means of classifying cohesive soils. It is convenient to carry out the test on a portion of the material prepared for one of the liquid limit test procedures. Method for plastic limit covers the determination of the plastic limit of a soil sample, i.e. the lowest moisture content at which the soil is plastic. The sample shall be of soil in its natural state, or of soil from which material retained on a 0.425mm test sieve has been removed. The test method is accordance with BS 1377 : Part 2 : 1900 : Method 5.3 (Method for plastic limit). 3.3.5 Determination Of Particle Size Distribution Two methods of sieving are specified. Wet sieving is the definitive method applicable to essentially cohesion-less soils. Dry sieving is suitable only for soils containing insignificant quantities of silt and clay. Two methods of determining the size distribution of fine particles down to the clay size by sedimentation are specified, namely the pipette method and the hydrometer method, in both of which the density of the soil suspension at various intervals is measured. 24 Combined sieving and sedimentation procedures enable a continuous particle size distribution curve of a soil to be plotted from the size of the coarsest particles down to the clay size. Some type of grain-size analysis is universally used in the engineering classification of soils. Part of the suitability criteria of soils for road, airfield, levee, dam and other embankment construction is the grain-size analysis. Information obtained from the grain-size analysis can be used to predict soil-water movement, although the permeability tests are more generally used. 3.3.5.1 Dry Sieving Method The grain-size analysis is an attempt to determine the relative proportions of the different grain sizes that make up a given soil mass. Obviously, to have significance the sample must be statistically representative of the soil mass. Actually it is not possible to determine the individual soil sizes. The test can only bracket the various ranges of sizes. This is accomplished by obtaining the quantity of material passing through a given sieve opening but retained on a sieve of smaller sized openings and then relating this retained quantity to the total sample. It is evident that the material retained on any sieve in this manner consists of particles of many sizes, all of which are smaller than the openings of the sieve through which the material passed but larger than the openings of the sieve on which the soil is retained. The sieving process does not provide information on the shape of the soil grains, that is, whether they are angular or rounded. It only yields information on grains that can pass, or with proper orientation do pass, through rectangular sieve opening of a certain size. 25 Information obtained from the grain-size analysis is presented in the form of a curve. Standard procedure uses the percent passing (also termed percent finer) as the ordinate plotted to a natural scale of the grain-size distribution curve. It should be evident that a grained-size distribution curve can only be approximate. This is for the several reasons considered here, including physical limitations on obtaining a statistically representative sample, the presence of soil lumps, the practical limitations of using sieve mesh openings for irregular-shaped soil particles, and the limit on the number of sieves used in a “stack” for the analysis. Sieve washing is not desirable or practical for soils (gravel and gravelly sands) when less than 10 to 15 percent passes the 2.00mm sieve. Sieve washing is usually not necessary when only 5 to 10 percent passes the 0.150mm sieve for the fine-grained soils. From the grain-size distribution curve, grain sizes such as D10, D60 and D85 can be obtained. The D refers to the grain size, or apparent diameter, of the soil particles and the subscript (10, 30, 60) denotes the percent which is smaller. An indication of the spread (or range) of grain sizes is given by the coefficient of the uniformity CU, Defined as Cu D 60 D10 3.1 Where, Cu is the coefficient of the uniformity D60 is the grain size at 60 percent passing D10 is the grain size at 10 percent passing A larger value of CU indicates that the D60 and D10 sizes differ appreciably. It does not ensure that a condition of gap grading, as when sizes are missing or present in very small relative quantities, does not exist. The coefficient of concavity CC is a measure of the shape of the curve between the D60 and D10 grain sizes, defined as 26 Cc D 2 30 D10 D 60 3.2 Where, Cc is the coefficient of concavity D30 is the grain size at 30 percent passing D60 is the grain size at 60 percent passing D10 is the grain size at 10 percent passing Values of CC that greatly different from 1.0 indicates grain sizes missing between the D60 and D10 sizes. The test method is accordance with BS 1377 : Part 2 : 1900 : Method 9.3 (Dry sieving method) 3.3.5.2 Hydrometer Method The hydrometer analysis is a widely used method of obtaining an estimate of the distribution of soil particle sizes from the 0.075mm sieve to around 0.001 mm. The data is plotted on a semi-logarithmic plot of percent finer vs. grain diameters and be combined with the data from a mechanical analysis of the material retained on the .075 mm sieve. The principal value of the hydrometer analysis appears to be obtaining the percent clay (percent finer than 0.002 mm). Soil behavior for the cohesive soil fraction depends principally on the type and percent of clay mineral, geologic history, and water content rather than on the distribution of particle sizes. The hydrometer analysis utilizes the relationship among the velocity of fall of spheres in a fluid, the diameter of the sphere, the specific weights of the sphere and of 27 the fluid, and the viscosity of the of the fluid as expressed by the English physicist G. G. Stokes(ca 1850) in the equation termed Stokes’ law: 2s u D v 9 2 2 3.3 Where, V is the velocity of fall of the spheres, cm/s s is the specific weight of the sphere f is the specific weight of fluid is the absolute, or dynamic, viscosity of the fluid, dyne.s/cm2 (or g/cm.s) D is the diameter of sphere, cm g = 980.7 cm/s2 1 g =980.7 dynes For D and using the specific weight of water, ’w, then: D 18v s ' w 3.4 The range of soil particle diameters D for this equation to be valid is approximately: 0.0002 mm ≤ D ≤ 0.2 mm To obtain the velocity of fall of the particles, the hydrometer is used. This is a device originally developed to read the specific gravity of a solution, but by altering the scale it can be made to read other values. The test method is accordance with Engineering Properties Of Soil And Their Measurement Experiment No. 6 (Hydrometer method). 28 3.3.6 Determination Of Dry Density/ Moisture Content Relationship This test is for determining characteristics related to the compaction of soils, which can be used as a basis for specifying requirements for soils compacted in the field. Compaction of soil is the process by which the solid particles are packed more closely together, usually by mechanical means, thereby increasing the dry density of the soil. The dry density that can be achieved depends on the amount of water present in the soil. For a given degree of compaction of a given cohesive soil there is the optimum moisture content at which the dry density obtained reaches a maximum value. For cohesion-less soils an optimum moisture content might be difficult to define. Three types of compaction test can be used, each with procedural variations related to the nature of the soil. The first is the light manual compaction test in which a 2.5kg rammer is used. The second is the heavy manual compaction which is similar but gives a much greater degree of compaction by using a 4.5 kg rammer with a greater drop on thinner layers of soil. For both these tests a compaction mould of 1L internal volume is used for soil in which all particles passing a 20mm test sieve. If there is a limited amount of particles up to 37.5mm size, equivalent tests are carried out in the larger California Bearing Ratio (CBR) mould. The third type of test makes use of a vibrating hammer, and is intended mainly for granular soils passing a 37.5mm test sieve, with no more than 30 percent retained on a 20mm test sieve. The soil is compacted into a CBR mould. Compaction using 4.5kg rammer for soils with particles up to medium-gravel size will be discussed here. This test covers the determination of the dry density of soil passing a 20mm test sieve when it is compacted in a specified manner over a range of moisture contents. The range includes the optimum moisture content at which the maximum dry density for this degree of 29 compaction is obtained. The mass of the rammer is 4.5 kg, the height of fall to 450 mm, and the numbers of compacted layers are five. 1L compaction mould is used. The test method is accordance with BS 1377 : Part 4 : 1900 : Method 3.5 (Method using 4.5 kg rammer for soils with particles up to medium-gravel size). 3.3.7 In-situ Density Test Sand replacement method using small pouring cylinder is the test method that suitable for fine- and medium-grained soils. This method covers the determination in-situ of the density of natural or compacted soils for which a 115mm diameter sand-pouring cylinder is used in conjunction with replacement sand. The method is applicable to layers not exceeding 150mm in thickness. The whole research experiment can be divided into 4 stages. Stage (I): Preparation of the materials and apparatus: i. Assemble all the necessary apparatus both for laboratory calibration and for site use. ii. Prepare the standard sand and river sand as stated in BS1377 Part 9:1990 clause 2.1.3, that is, carry out the grading test or sieving analysis of the sand such that 100% passes a low m test sieve and 100% is retained on the 0.0063mm test sieve. Stage (II): Calibration of the standard sand and river sand at laboratory: 30 i. The prepare sand shall be oven dried and stored in a loosely covered container about 7 days to allowed its moisture content to reach equilibrium with atmosphere humidity. ii. Determination of the mass of sand in the cone of the pouring cylinder at the laboratory. Fill the sand pouring cylinder with clean sand so that the level of the sand in the cylinder is within about 10 mm from the top. Find out the initial weight of the cylinder plus sand (m1). And this weight should be maintained constant throughout the test for which the calibration is used. iii. Allow the sand of volume equal to that of the calibrating container to run out of the cylinder by opening the shutter, close the shutter and place the cylinder on the glass sand takes place in the cylinder close the shutter and remove the cylinder carefully. Weigh the sand collected on the glass plate. Its weight (m2) gives the weight of sand filling the cone portion of the sand pouring cylinder. Repeat this step at least three times and take the mean weight (m2). Put the sand back into the sand pouring cylinder to have same initial constant weight (m1). iv. Determination of the bulk density of the sand (ρa) that is determine the internal volume. V(in mL) of the calibrating container. v. Calculate the bulk density of the sand, ρa (in Mg/m3), from the equation, a ma V equa3.1 ma m1 m3 m 2 a ma V 3.5 3.6 Where, ma is the mass of sand required to fill the calibrating container (in g). m1 is the mass of cylinder and sand before pouring into calibrating container(in g). m2 is the mean mass of sand in cone (in g). 31 m3 is the mean mass of cylinder and sand after pouring into calibrating container (in g). V is the volume of the calibrating container (in mL). Stage (III): Conduct the in-situ field density at the chosen location. i. Chose the location at site to carry out the in-situ field density test. Approximately 60 square cm of area of soil to be tested should be trimmed down to a level surface, approximately of the size of the container. Keep the metal tray on the level surface and excavate a circular hole of volume equal to that of the calibrating container. Collect all the excavated soil in the tray and find out the weight of the excavated soil (Ww). Remove the tray, and place the sand pouring cylinder filled to constant weight so that the base of the cylinder covers the hole concentrically. Open the shutter and permit the sand to run into the hole. Close the shutter when no further movement of the sand is seen. Remove the cylinder and determine its weight (m3). ii. Carry out 2 series of test for standard sand and 3 series of test using prepared river sand at nearby location. iii. Collect data. iv. Determine moisture content at laboratory. Stage (IV): Analyze the collected data. i. Calculate the bulk and dry in situ field density test. ii. Interpretation of the result. iii. Establish the co-efficient factor between stand sand and river sand. 32 3.4 Data Analysis Method From the calibration at laboratory for the prepare sand, a is obtained. From the in-situ field density test the Mb, that is the mass of sand required to fill the excavated hole is obtained. To calculate the bulk density of the soil, ρ(in Mg/m3), from the equation: Mwa Mb 3.7 Where, Mw is the mass of soil excavated (in g). Mb is the mass of sand required to fill the hole (in g). Then, calculate, the dry density, d 100 b 100 w 3.8 Where, ρb is the bulk density w is the moisture content of the soil. Compare the ρd of the standard sand(silica) or river sand for the consistency and co-relationship, that is: K Where, dSilica dRiver 3.9 33 K is the correlation factor ρdriveris the dry density of river sand ρdsilica is the dry density for silica sand Photo 3.1: River Sand From Batang Sadong , Samarahan Division 34 Photo 3.2: Standard (silica) Sand Photo 3.3: River Sand and Silica Sand used For In Situ Field Density Test 35 Photo 3.4A: Laboratory Sand Calibration Photo 3.4B: Laboratory Sand Calibration 36 Photo 3.4C: Laboratory Sand Calibration Photo 3.5A: In situ Testing In Progress 37 Photo 3.5B: In Situ Testing In Progress Photo 3.6A: Field Density Test Set 2 38 Photo 3.6B: Field Density Test Set 5 Photo 3.6C: Field Density Test Set 6 39 Photo 3.6D: Field Density Test Set 8 Photo 3.6E: Field Density Test Set 9 40 Photo 3.6F: Field Density Test Set 10 Photo 3.6G: Field Density Test Set 11 41 Photo 3.7A: Moisture Content Test (Oven Dried Method) Photo 3.7B: Moisture Content Test 42 Photo 3.8: Particle Density Test Photo 3.9: Sieving Analysis 43 Photo 3.10A: Liquid Limit and Plastic Limit Test Photo 3.10B: Liquid Limit Test (Cone Penetration Test) 44 Photo 3.11: Laboratory Compaction Test