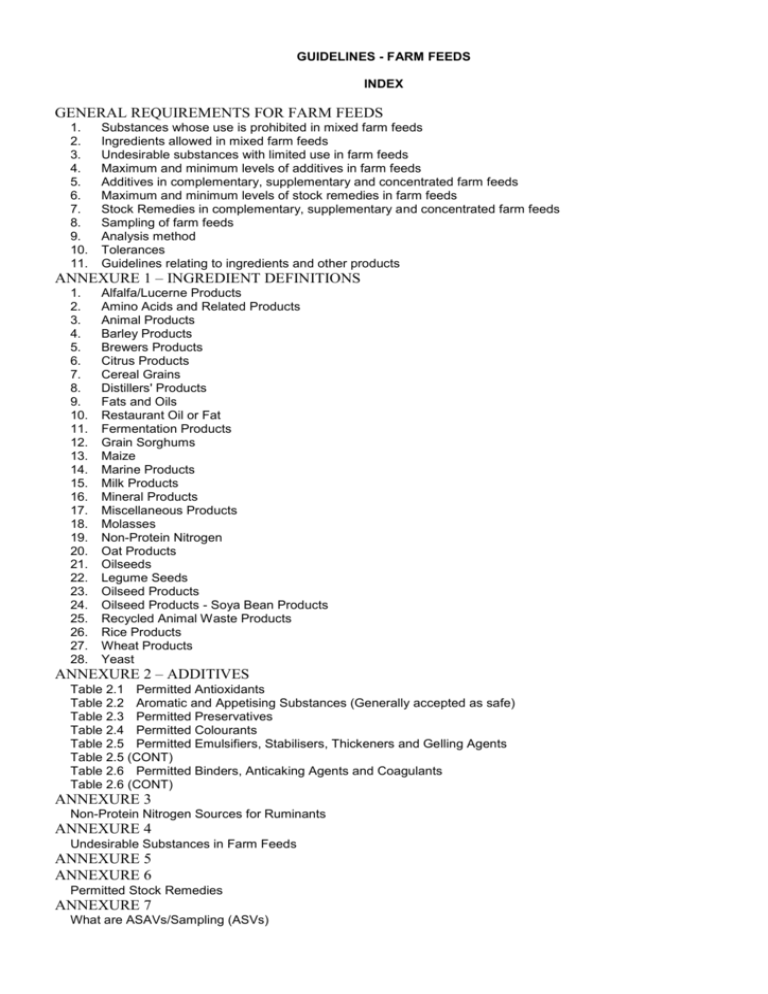

GUIDELINES - FARM FEEDS

advertisement