Radiator Shop Site Inspection Form

advertisement

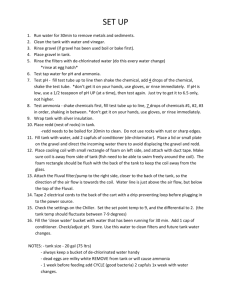

RADIATOR SHOPS SITE INSPECTION FORM Date: ________________________ Company Name: ___________________________________________________________ Facility Address: ____________________________________________________________ Street City Zip Telephone: _____________________ Persons at Inspection: _____________________________________________________ Name Title ______________________________________________________ Name Title Metro Inspector: _______________________________________ DRAINING and PHYSICAL CLEANING Description: Radiators are drained of all liquids before putting them in the boilout tank. Some shops also remove grease and dirt, usually with a hot detergent spray. Inspection Questions: What types of wastes come in with the radiators? ( ) Antifreeze ( ) Oils/greases ( ) Coolants (air conditioning fluids) ( ) Other _____________________________________ Which wastes are collected and segregated? Are the wastes recycled? How are the wastes disposed of or recycled? Antifreeze __________________________________________________________ Oils/greases ________________________________________________________ M:\T&F\IWP\Radiator Shops Site Inspection Form_03_05 page 1 Coolants ____________________________________________________________ Other _______________________________________________________________ Are the radiators cleaned to remove grit and dirt before being put in the boilout tank? _______ How? High pressure sprays? Hot cleaning solution? Detergent? Steel brushes? Oven? Other?_________ Where do the wastewaters go from this initial cleaning? BOILOUT (CAUSTIC STRIPPING) TANK Description: The radiator is immersed in a tank of caustic solution (pH greater than 12.5, typically 40% to 50% sodium hydroxide) which is heated to 140-200ºF. The radiator remains in this tank for 15 to 60 minutes. The objective of this cleaning is to soften or remove deposits, scale, corrosion, or other foreign materials from the radiator. Newer boilout tanks may also be equipped for ultra sonic cleaning. After cleaning, the radiator is removed from the tank and allowed to drain. Inspection Questions: Volume of boilout tank? _________ Temperature of boilout tank? ________ Do you use ultra-sonic cleaning? ______ What chemicals are added to boilout tank? Major chemical components per MSDS sheet. Is compressed air used to blow out any residual alkaline solution? ____ Is the oil-cooling section blown out? ______ Does the blow out take place over the boilout tank? ______ What source is used for make-up water? fresh water? rinse water? other? M:\T&F\IWP\Radiator Shops Site Inspection Form_03_05 page 2 How often is the boilout tank dumped? _______________________ Is it treated before it is dumped? ______ Type of treatment? Where is it dumped to? ______________________________________________________ Does sludge accumulate in boilout tank? How much sludge is removed? ____________ How frequently? ______________ Where is sludge disposed of? Are any waste manifests or bills of lading available? RINSE BOOTH Description: A rinse bath uses 5-10 gallons of water to rinse one radiator. This rinsing is usually done using a flow through system with fresh tap water. The primary objective of this step is to remove adhering caustic solution (which is highly viscous) and any loosened scale from inside and outside the radiator. * Water from the rinse booth is usually the greatest source of wastewater volume and discharged metals. Inspection Questions: Use a rinse booth or rinse bath? _____________ Does booth use high pressure and low water flows? Is the rinse water (check one): ______ Fresh water in a once-through system? ______ Wash water from a booth recirculation reservoir? ______ Treated wastewater? Volume of rinse water contained in booth or bath unit? ________ M:\T&F\IWP\Radiator Shops Site Inspection Form_03_05 page 3 How often is tank or bath dumped? __________________________________ Is it treated before it is dumped? ____________________________________ Type of treatment? Where is it dumped to? TEST TANK Description: Leak testing involves hooking a compressed air line to one end of the radiator, plugging the other end, and submerging the radiator in the test tank. Leaks are located by the stream of bubbles that appear in the water and are repaired by soldering. The soldering involves application of a flux or muriatic acid to prepare the surface, followed by spot heating and application of the solder. The soldering usually takes place while the radiator is supported on a rack over the test tank. Inspection Questions: Volume of test tank? _____ What chemicals are added to test tank? Major chemical components per MSDS sheet. Is soldering done over the test tank? ______ Is sludge removed from the tank? _______ Are tank contents filtered? _______ How often is tank dumped? ______ Is it treated before it is dumped? ______ Type of treatment? Where is it dumped to? M:\T&F\IWP\Radiator Shops Site Inspection Form_03_05 page 4 PAINTING Description: After leak repairs are completed the radiator is painted using a solvent-based black enamel paint. The painting is usually done in a spray booth. Inspection Questions: Are you using a water based or solvent based paint? Is there any discharge from the paint booth to the sanitary sewer system? What is done with waste paint and solvents? GENERAL Are radiators drained thoroughly before transferring them from one tank to another? How? Are the tanks located close together to minimize drippings on to the floor? Are there drain boards between tanks to divert drippings back into the source tank? Is there any kind of treatment system to treat wastewater before discharge or to allow for water reuse? Describe. Are solvents used for cleaning? What is done with spent solvents? What volume of solvents is disposed of? Identify what floor drains are present. Do they go to the sanitary sewer? What type of wastes do they receive? Does floor cleaning waste go down floor drains? Are any drains sealed or bermed? M:\T&F\IWP\Radiator Shops Site Inspection Form_03_05 page 5 Are any spill prevention measures implemented? Are there any written procedures? Where would the boilout tank contents go if the tank were to leak or fail? Where would stored chemicals or wastes go if their containers were to leak or be opened? SOLID WASTE ISSUES Is solder dross generated at the facility? Where is it stored? How is it disposed of? What type of waste sludges are generated? Are they dried or dewatered? Where are they stored? How are they disposed of? (Should be handled as a hazardous waste.) Are wastes manifests or bills of lading available for review? _____________ Manifest Date Type of Waste M:\T&F\IWP\Radiator Shops Site Inspection Form_03_05 page 6 Quantity OTHER ISSUES M:\T&F\IWP\Radiator Shops Site Inspection Form_03_05 page 7