xi_isdrs1 - ECE - University of Maryland

advertisement

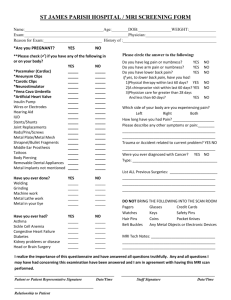

Simulation of On Chip Interconnects with Three-Dimensional FDTD Alternating-Direction-Implicit (ADI) Method X. Shao1 ,2, Neil Goldsman2, O. Ramahi2,3,4, P. N. Guzdar5 1 National Space Science Data Center, Goddard Space Flight Center, NASA, Greenbelt, MD 20171. Electrical and Computer Engineering Department, 3Mechanical Engineering Department, 4CALCE electronic Products and Systems Center, 5Institute of Plasma research, University of Maryland, College Park, MD 20742. 2 Introduction: Simulation of modern on chip interconnects or Metal-Insulator-Silicon Substrate (MIS) structure poses following challenges: 1. Need to resolve structure much smaller than the wavelength, e.g., the metal skin depth, SiO2 layer, both of which are in the micro meter range at the frequency of interest. 2. Being able to simulate broadband digital signal propagation. 3. Being able to simulate the induced substrate current loss. While conventional explicit Finite-Difference-Time-Domain (FDTD) method for solving Maxwell’s equation can meet the latter two challenges. It is limited by the first challenge since the simulation time step needs to satisfy the Courant’s condition ( t 1 / c 2 (1 / x 2 1 / y 2 1 / z 2 ) ). With the smallest grid size on the order of 0.1 um, in order to resolve the skin depth, the time step needs to be < 4×10-16 sec. But, we are only interested in the pico-second signal propagation. [1, 2] introduced Alternating-Direction-Implicit (ADI) method to solve the Maxwell’s Equation by breaking the Courant’s limit. The ADI method is well-suited for studying signal propagation along the MIS structure since the simulation step is not limited by the finest grid size. In this paper, we developed a three-dimensional multi-grid FDTD-ADI code to study the digital signal propagation along on chip interconnects. Simulation Method: We briefly summarize the ADI method. The Maxwell’s equation is discretized on Yee’s [3] grid and two equations are in the form of Equ. 1 and 2. At the first step, the first half of the left side in Equ. 1 and the first half of the left side in Equ. 2 are treated as implicit. We plug Equ. 2 ( Bzn,(i11 / 2, j 1 / 2,k ) ) back to Equ. 1 and obtain Equ. 3. Equ. 3 can be easily solved with a tri-diagonal matrix solver. This procedure is conducted for all three components of the electric field. In the next step, we treat the other half of the Equ. 1 and 2 as implicit and obtain equation similar to Equ. 3. These two steps are alternated thereafter. The detailed algorithm of ADI method can be found in [1, 2]. E E B B (1) 1 B 1 B E n 1 x , ( i 1 / 2 , j , k ) n 1 z , ( i 1 / 2 , j 1 / 2 , k ) n x , ( i 1 / 2 , j , k ) t B zn,( i11 / 2 , j 1 / 2 , k ) B zn,( i 1 / 2 , j 1 / 2 , k ) t n 1 z , ( i 1 / 2 , j 1 / 2 , k ) y n y , ( i 1 / 2 , j , k 1 / 2 ) E xn,( i11 / 2 , j , k ) E xn,( i11 / 2 , j 1, k ) y a E xn,(i11 / 2, j 1,k ) b E xn,(i11 / 2, j ,k ) c E xn,(i11 / 2, j 1,k ) d n y , ( i 1 / 2 , j , k 1 / 2 ) z n 1 x , ( i 1 / 2 , j , k ) E yn,( i 1, j 1 / 2 , k ) E yn,( i , j 1 / 2 , k ) (2) x (3) Simulation Results: To test the performance of our code in resolving the metal skin depth, we performed a 2D simulation of EM wave propagation under a metal strip. The configuration of the simulation is shown in Figure 1a. The metal strip conductivity= 3.9×107 S/m. The domain bottom is bounded with Perfect Electric Conductor (PEC) .The smallest grid size of 0.1 um is placed inside the metal. The metal is of thickness= 1.8 um. The grid along Z direction is of uniform size=150 um. The Courant condition requires ∆t<0.33×10-15sec. Our simulation time step ∆t =2×10-13 sec. The excitation frequency = 50 GHz. From theoretical calculation, we expect the EM wave propagates inside the metal in the form of exp( j (t k z z ( j ) y)) . Here, α = β= 1/δ for high conductivity metal; δ is the skin depth = 2 /( ) . Inside the metal, the wave is damped in the Y direction and grazes along the Z direction. The current Jz inside the metal have the pattern Jz cos(k z z y / ) exp( y / ) , is the phase angle. In our case, we expect the grazing wave angle θ satisfies Sin(θ)= kzδ = 3.77×10-4 with kz = 2π/(6 mm) and δ= 0.36 um at 50 GHz. The top two panels of Figure 1b show the comparison between the simulation and theoretical calculation for current Jz inside the metal. The agreement is excellent. The bottom panel of Figure 2b shows the Ey beneath the metal. With ADI method, we are able to reveal the wave pattern inside the metal. Figure 2a shows the MIS structure we simulated with the ADI code. Figure 2b shows the grid configuration. Along Z direction, we have 100 grids of uniform size = 25 um. Mur’s [4] 1st order absorption boundary condition is applied at free space. At Y=0, Perfect Electric Conductor condition is applied. We made use of the symmetry of the computational domain by applying Perfect Magnetic Conductor (PMC) condition at Z=0. The finest grid size= 0.1 um and we choose ∆t =1×10-13 sec. The XY cross section of the metal strip is 6um x 1.8 um and thickness of the SiO2 layer is 2 um. All simulations are performed on a single PC with P4 CPU. The simulation time is on the order of 3-4 hours. The conductivity of the metal strip= 5.8×107 S/m, typical for copper. The substrate doping is set to be n= 1017 /cm3, which corresponds to substrate conductivity= 2260 S/m. A digital signal (of rising time= 2ps, stable time= 20 ps and falling time= 2ps; magnitude= 1.0 V) is excited at one end and we observe the voltage signal at Z= 500, 750, 1000, 1250 um. Figure 3a shows the simulated voltage signal at these locations. We can see the signal is amplitude is lowered and signal is broadened. Frequency analysis shows that the higher frequency components of the signal suffer larger damping. Figure 3b shows XY-Cross section of Ey and Ex field at Z= 1000 um and t= 50 ps. The Ey field concentrates inside the SiO2 layer. Figures 3c shows the XY-Cross section of current Jz inside the metal , at Z = 1000 um and t = 37 ps.. We see the skin depth effect. Figure 3d shows the XZ cut-plane of substrate current Jz at 5 um below the SiO2 layer for t = 37 ps. The red and blue shaded area corresponds to the rising and falling of the signal. We also varied the substrate doping. We change the substrate doping to n= 1016 and 1018/cm3. Figure 3 shows the signal propagation observed at the different Z location along the MIS structure with different substrate doping. The substrate doping has an important on signal propagation. Discussion: We show that ADI method is efficient in simulating signal propagation along on-chip interconnects. The future challenges will be to simulate interconnects with biased voltage and added load. References: [1] T. Namiki, A new FDTD algorithm based on alternating-direction-implict method, IEEE Trans. Microwave Theory Tech., vol. 47, pp. 2003-2007, Oct., 1999. [2] F. Zheng, Z. Chen, and J. Zhang, A finite-difference time-domain method without the courant stability condition, IEEE Microwave Guided Wave Lett., Vol.9, pp. 441-443, Nov., 1999. [3] K. S. Yee, Numerical solution of initial boundary value problems involving Maxwell’s equation in isotropic media, IEEE Trans. Antennas Propagat., vol. AP-14, pp.302-307, May 1966. [4] G. Mur, Absorbing boundary conditions for the finite-difference approximation of the time-domain electromagnetic field equations, IEEE Trans. Electromagn. Compat., EMC-23, pp. 377-382, Nov., 1981.