Anesthesia Unit

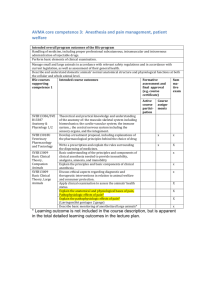

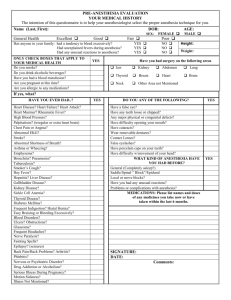

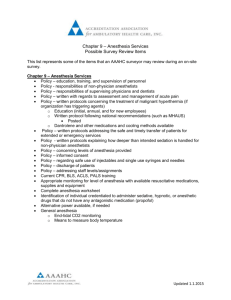

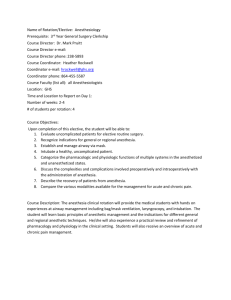

advertisement

BM 500 FINAL PROJECT Topic: Anesthesia Unit 1 1. About Anesthesia Unit: .................................................................................................... 3 1.1. What is Anesthesia? ...................................................................................................... 3 1.2. What is Anesthesia Unit ................................................................................................ 5 2. Anesthesia Unit Manufacturers: ..................................................................................... 7 Nambuk Mednics Co., Ltd Osdm Co., Ltd ........................................................................ 8 Details of Some Machines .................................................................................................... 8 2. Equipment Management Coefficient ................................................................................ 16 3. Technical Specifications: ................................................................................................... 16 Tender requirement ........................................................................................................... 16 WARRANTY .................................................................................................................. 18 Installation, commissioning, Testing Maintenance and after Sales service .................. 18 4.Standards: ............................................................................................................................ 21 Preventing Accidents: The Safety Features of Modern Machines ................................ 21 Low Accident Rate ............................................................................................................. 24 2 1. About Anesthesia Unit: 1.1. What is Anesthesia? Anesthesia means that the condition of having sensation blocked or temporarily taken away. This allows patients to undergo surgery and other procedures without the distress and pain they would otherwise experience. In other words, Anesthesia is a "reversible lack of awareness", whether this is a total lack of awareness (e.g. a general anaesthetic) or a lack of awareness of a part of the body such as a spinal anaesthetic or another nerve block would cause. Anesthesia is a pharmacologically induced reversible state of amnesia, analgesia, loss of consciousness, loss of skeletal muscle reflexes and decreased stress response. The three components of anesthesia are analgesia (pain relief), amnesia (loss of memory) and immobilization. The drugs used to achieve anesthesia usually have varying effects in each of these areas. Some drugs may be used individually to achieve all three. Others have only analgesic or sedative properties and may be used individually for these purposes or in combination with other drugs to achieve full anesthesia. Curariform skeletal muscle relaxants or neuromuscular blockers (e.g. succinylcholine, decamethonium, curare, gallamine, pancuronium) are not anesthetics and have no analgesic effects. They may only be used in conjunction with general anesthetics. Normally, artificial respiration must be provided. Physiologic monitoring methods must also be used to assess anesthetic depth, as normal reflex methods will not be reliable. History of Anesthesia: Ether synthesized in 1540 by Cordus Ether used as anesthetic in 1842 by Dr. Crawford W. Long Ether publicized as anesthetic in 1846 by Dr. William Morton Chloroform used as anesthetic in 1853 by Dr. John Snow Endotracheal tube discovered in 1878 Local anesthesia with cocaine in 1885 Thiopental first used in 1934 Curare first used in 1942 - opened the “Age of Anesthesia” Anesthesia can be; Inhalational anesthesia refers to the delivery of gases or vapors from the respiratory system to produce anesthesia. Pharmacokinetics uptake, distribution, and elimination from the body Inhalational Anesthetic Agents are Nitrous Oxide, Halothane, Enflurane, Isoflurane, Sevoflurane and Desflurane,. Intravenous Anesthetic Agents are Thiopental, Etomidate, Ketamine, Propofol, Benzodiazepines, Diazepam, Lorazepam and Midazolam. 3 Patients undergoing anesthesia usually undergo preoperative evaluation. It includes gathering history of previous anesthetics, and any other medical problems, physical examination, ordering required blood work and consultations prior to surgery. There are several forms of anesthesia. The following forms refer to states achieved by anesthetics working on the brain: General anesthesia: "Drug-induced loss of consciousness during which patients are not arousable, even by painful stimulation." Patients undergoing general anesthesia can often neither maintain their own airway nor breathe on their own. While usually administered with inhalational agents, general anesthesia can be achieved with intravenous agents, such as propofol. Deep sedation/analgesia: "Drug-induced depression of consciousness during which patients cannot be easily aroused but respond purposefully following repeated or painful stimulation." Patients may sometimes be unable to maintain their airway and breathe on their own. Moderate sedation/analgesia or conscious sedation: "Drug-induced depression of consciousness during which patients respond purposefully to verbal commands, either alone or accompanied by light tactile stimulation." In this state, patients can breathe on their own and need no help maintaining an airway. Minimal sedation or anxiolysis: "Drug-induced state during which patients respond normally to verbal commands." Though concentration, memory, and coordination may be impaired, patients need no help breathing or maintaining an airway. The level of anesthesia achieved ranges on a continuum of depth of consciousness from minimal sedation to general anesthesia. The depth of consciousness of a patient may change from one minute to the next. The following refer to the states achieved by anesthetics working outside of the brain: Regional anesthesia: Loss of pain sensation, with varying degrees of muscle relaxation, in certain regions of the body. Administered with local anesthesia to peripheral nerve bundles, such as the brachial plexus in the neck. Examples include the interscalene block for shoulder surgery, axillary block for wrist surgery, and femoral nerve block for leg surgery. While traditionally administered as a single injection, newer techniques involve placement of indwelling catheters for continuous or intermittent administration of local anesthetics. o Spinal anesthesia: also known as subarachnoid block. Refers to a Regional block resulting from a small volume of local anesthetics being injected into the spinal canal. The spinal canal is covered by the dura mater, through which the spinal needle enters. The spinal canal contains cerebrospinal fluid and the spinal cord. The sub arachnoid block is usually injected between the 4th and 5th lumbar vertebrae, because the spinal cord usually stops at the 1st lumbar vertebra, while the canal continues to the sacral vertebrae. It results in a loss of pain 4 sensation and muscle strength, usually up to the level of the chest (nipple line or 4th thoracic dermatome). o Epidural anesthesia: Regional block resulting from an injection of a large volume of local anesthetic into the epidural space. The epidural space is a potential space that lies underneath the ligamenta flava, and outside the dura mater (outside layer of the spinal canal). This is basically an injection around the spinal canal. Local anesthesia is similar to regional anesthesia, but exerts its effect on a smaller area of the body. Anesthesia providers are: Anesthesiologists/Anaesthetists (medically-trained physicians), Nurse anesthetists, Anaesthesiologist Assistants, Anesthesia technicians and Operating Department Practitioners. 1.2. What is Anesthesia Unit The anaesthetic machine is used by anesthesiologists to support the administration of anaesthesia. The most common type of anaesthetic machine in use in the developed world is the continuous-flow anaesthetic machine, which is designed to provide an accurate and continuous supply of medical gases (such as oxygen and nitrous oxide), mixed with an accurate concentration of anaesthetic vapour (such as isoflurane), and deliver this to the patient at a safe pressure and flow. Modern machines incorporate a ventilator, suction unit, and patient-monitoring devices.The anaesthetic machine is usually mounted on anti-static wheels for convenient transportation. Simpler anaesthetic apparatus may be used in special circumstances, such as the TriService Apparatus, a simplified anaesthesia delivery system invented for the British armed forces, which is light and portable and may be used effectively even when no medical gases are available. This device has unidirectional valves which suck in ambient air which can be enriched with oxygen from a cylinder,with the help of a set of bellows. A large number of draw-over type of anaesthesia devices are still in use in India for administering an air-ether mixture to the patient, which can be enriched with oxygen. But the advent of the cautery has sounded the death knell to this contraption, due to the explosion hazard. 5 A modern machine typically includes the following components: connections to piped hospital oxygen, medical air, and nitrous oxide. Pipeline pressure from the hospital medical gas system (wall outlet) should be around 400 kPa (60 psi; 4 atmospheres). reserve gas cylinders of oxygen, air, and nitrous oxide attached via a specific yoke with a Bodok seal. Older machines may have cylinder yokes and flow meters for carbon dioxide and cyclopropane. Many newer machines only have oxygen reserve cylinders. The regulators for the cylinders are set at 300 kPa (45 psi; 3 atmospheres). If the cylinders are left on and the machine is plugged into the wall outlet, gas from the wall supply will be used preferentially, since it is at a higher pressure. In situations where pipeline gases are not available, machines may safely be used from cylinders alone, provided fresh cylinders are available. a high-flow oxygen flush which provides pure oxygen at 30 litres/minute pressure gauges, regulators and 'pop-off' valves, to protect the machine components and patient from high-pressure gases (referred to as 'barotrauma'). flow meters (rotameters) for oxygen, air, and nitrous oxide, which are used by the anaesthesiologist to provide accurate mixtures of medical gases to the patient. Flow meters are typically pneumatic, but increasingly electromagnetic digital flow meters are being used. one or more anaesthetic vaporisers to accurately add volatile anaesthetics to the fresh gas flow a ventilator 6 physiological monitors to monitor the patient's heart rate, ECG, non-invasive blood pressure and oxygen saturation (additional monitors are generally available to monitor end-tidal CO2, temperature, arterial blood pressure central venous pressure, etc.). In addition, the composition of the gases delivered to the patient (and breathed out) is monitored continuously. breathing circuits, most commonly a circle attachment, or a Bain's breathing system, which are breathing hoses connected to a anaesthesia face mask a heat and moisture exchanger (HME) with or without bacteria-viral filter (HMEF). scavenging system to remove expired anaesthetic gases from the operating room. Scavenged gases are usually vented to the atmosphere. suction apparatus There is generally a small work bench built into the machine where airway management equipment is kept within ready reach of the anaesthetist. 2. Anesthesia Unit Manufacturers: In my research, I find nearly 30 manufacturers which provide anesthesia machines. Most of them located in China and others are in Korea . (http://www.ec21.com/companies/anesthesia_machine.html) Manufacturers in China: Shinova Systems Co., Ltd. Perlong Medical Equipment Co,Ltd Anjue Import & Export Co., Ltd. Beijing Read Eagle Technology Co.,Ltd. Perlong Medical Equipment Co., Ltd. Martvi Medical & Hospital Supply Medicalpoint Anjue Import & Export Co., Ltd Seeuco Electronics Technology Co.,Ltd. Martvi Medical & Hospital Supply Sunshine Medical Equipment Co., Ltd. Perlong Medical Equipment Co,Ltd. ZhendanTech Co., Ltd. Nanjing Tops and Trading Industrial Co., Ltd. Honkon Science and Technology Development Co.,ltd Martvi Medical & Hospital Supply . Perlong Medcial Equipment Co Ltd Nison Shanghai Beijing Aerospace ChangFeng Co., Ltd Perlong Medical Equipment Co., Ltd Medical Instruments Factory No.5 of Shanghai Medical Instruments Co.,Ltd 7 Perlong Medical Equipment Co.,Ltd. Beijing Aerospace Changfeng Co. Ltd Medical Devices Branch Manufacturers in Korea Nambuk Mednics Co., Ltd Osdm Co., Ltd Distributors Located in US Hi Grant International Tenko International Group Details of Some Machines Anjue Import & Export Co., Ltd. AJ-2102 Anesthesia Machine (Model Number : AJ-2102 ) Main Specification: * Working Mode: Closed system, half-closed system and half-open system * Application: adult ,child(options) * Gas supplies: O2: 0.3MPa~0.5MPa, N2O: 0.3MPa~0.5MPa * Oxygen flush: 35L/min~75L/min * Alarms Parameters: Upper and Lower Airway Pressure Alarm; Upper and Lower Tidal Volume Alarm; Lack of Oxygen Alarm; Apnea; Power Outage * High precise vaporizer: Enflurane or Isoflurane * Power: 220V±10%、50Hz±1% 8 Anesthesia Ventilator: * One Adult Bellows, (optional: Child's) * Gas Driven and Electrically Controlled * Digital LED Display; and Keys Conditioning Means * Monitoring Parameters: Tidal Volume, the Respiratory Rate; I/E Ratio; the Peak Airway Pressure; Airway Pressure Waveform * Working Mode: Manual Control or Automatic Control * Breathing Modes: IPPV , SIGH ,SIMV/F/2、(optional:PEEP(+0.5kPa~+2kPa)、SIPPV) * Tidal volume: 30~1500ml * Respiratory Rate: 4~60bpm * I/E Ratio: 3: 1~1:4 Adjustable * Upper Airway pressure: 2~6KPa * Lower Airway pressure: 0.6~2KPa Flow Meter: * O2/N2O Four-Tube Flow Meter (0-10L/Min) * Interlock of O2 and N2O; Keep Oxygen Concentration Over 25% Loop: * Integrated Design, Orderliness Respiratory Loop Vaporizer: * High Precise Vaporizer: Enflurane or Isoflurane * Scope of Concentration Regulation: 0.2~5%VOL * Automatic Compensation of Flow, Temperature and Pressure * Self-Lock * Volume: 140ml Perlong Medical Equipment Co., Ltd. Adopts a two stage regulator and a hight precision three-gas flowmeter with ORC system,ensures oxygen concentration not less than 25% · Automatic N2O cut off and an unique O2 deficiency alarm divice. · With Enflurane or lsoflurane vaporizer,or both. · Attachable cylinder bracket. · Pneumatic-driven and electic-controlled anesthesia ventilator(Optional) · With constant volume for adults and children(With Ventilator). · Real time airway measurement 9 · Exhaled tidal volume and Minute vlulme measurement(Optional). · Stainless steel ansesthesia writing surface Nanjing Sunshine Medical Equipment Co., Ltd. MHJ-III B1 is a univeral multi-functional anaesthesia machine incorporating anaesthesia, respiratory and monitorings. In design, it improves the reliability, safety and combination. Also consideration has been taken to the connection between anesthesia machine and all kinds of monitors, extending its functions. This machine is equipped with Model SC-M3A1 pneumatic-driven and pneumatic controlled anesthesia ventilator, suitable for closed, semi-closed and semi-opened inhalation anesthesia and non-inhalation anesthesia in all levels hospitals. Feathers: Flow meter with ORC system to ensure oxygen concentration not less than 25%. N2O cut-off device O2 deficiency alarm SC-M3A1 anesthesia ventilator,with easy operation and low air consumption Top plate intended for all kinds of monitors Main technical specifications: 1.Supply pressure:0.27~0.55MPa 2.Adjustment rang of flow: O2  0.1~10L/min N2O 0.1~10L/min 3.ORC system: Oxygen concentration no less than 25% (O2+N2O) 4.N2O cut-off device :Active when oxygen pressure less than 0.1MPa 5.O2 flush:50±10L/min (O2 pressure 0.45Mpa) 6.Adjustment concentartion of Enflurane Vaporizer:0~5Vol% 7.Adjustment range of APL: 0.5~7kpa 8.Control mode of SC-M3A1 anaesthesia ventilator 9.Pneumatic-controlled and pneumatic-driven,time-cycled,volume constant 10 Ventilation frequency:6~40bpm, adjustable 11. O2 deficiency alarm: audible alarm occurs when O2 pressure less than 0.2MPa 12. Minute volume:3~18L/min, adjustable 13. I:E ration:1:1.5 (fixed) 14. Air consumption:less than 0.8L/min( pneumatic-controlled part) 15. Dimensions:516×600×1370(L×W×H) 16. Weight:60kg 17. No need of power supply. Only compressed oxygen for pneumatic driving and pneumatic control. 10 Nambuk Mednics. SAFER-100 Product Features Anesthesia Machine Specifications - Flowmeters O :0.1-10 L/min. overall-length 254mm X 1 N O:0.1-10 L/min. overall-length 254mm X 1 - Oxygen Flush Valve Auto-return system with min. flow rate of 35 L/min. - Safeguards N2O Shut-Off Mechanism In the event that oxygen flowate to 1.5L/min. or oxyzgen supply pressure faas to 1.1kgf/cm2, the delivery of nitrous oxide gas will be shut off. - Alarms -Oxygen Concentration In caseof falling below the sest lower oxygen concentration.(audible & visible) -Oxygen Pressure In case of oxygen pressure falls to 2kgf/cm2 or lower.(audible only) -Low Battery Indicator Lights up when the battery capacity lowered. - Airway Pressure Gauge Range:-20-+80cmH2O(-20-+80 X 100pa) - Canister Capacity:2,000ml(Double chamber) Adjustable height:30cm - Scavenging System It consists of extra gas evacuting valve, a corrugated tube and suction hose. - Vaporizer Mount 11 Two AIKA TCV Vaporizers can be mounted. - Premary Pressure gauge O2:Bourdon tube, range 0-250kgf/cm2 N2O:Bourdon tube, range 0-150kgf/cm2 - Gas Connections Yoke:O2 small pin-index type cylinder X 1 Pipping connector: O2 DISS Connecting port X 1 N2O DISS Connecting port X 1 - Power Requirement 6VDC(for oxyzen moniter, R6P X 4) - Size 870W X 555D X 1285H(mm) - Weight 50kg.approx., net Model No. Safer-100 Optional Accessories 1.AIKA Anasthetic Ventilator EVA 1200 2.AIKA Anasthetic Ventilator EVA 900N 3.AIKA Enfluramatic TCV-3 Vaporizer 4.AIKA Isoflumatic TCV-5 Vaporizer 5.AIKA Sevoflumatic TCV-7 Vaporizer 6.PAT Selector (bag/ventilator change-over valve) 7.Additional Drawer Hefei Lanrui Science and Technology Development Co., Ltd. Battery backup: More than 30 minutes Vaporizer: Single(position), GE DatexOhmeda TEC7 easy -filled Vaporizer. Power supply: 220-240VAC, 50/60Hz, 3A Technical Specification Alarm settings: Upper & lower limit for Tidal volume, O2 concentration, minute volume, airway Ventilator: Pneumatic driven, mocrocontroller. Volume control, pressure limited Tidal Volume: 45-1500ml I: E ratio: 2: 1-1: 6 Monitoring parameter: Tidal Volume, Breathing frequency, oxygen concentration, Minute volume, O2 Flush: 35~75 L/min Inspriratory pause: 5%T1-60% T1 increment of 5% T1 Breathing Frequency: 4-65 bpm Airway pressure: -20~100cm H2O Ventilator mode: VCV +PLV Tidal Volume Monitor with TV Compensation O2 Volume monitoring O2/N2O safe-guard interlink device: Provide a nominal minimum 25% concentration of O2 in. 12 Datex Ohmeda Excel 210 SE Accommodates 3 gases and 2 vaporizers Tek 5 vaporizers Powerful ventilation and monitoring capabilities Options 7800 Electronic Ventilator 7900 Smart Ventilator Specifications: Weight: 116 KG Height: 158.1 CM Width: 69.2 CM Top Shelf: Max Shelf load: 56 KG Size: 55.2 x 31.1 cm Table top: Height from floor: 87.6 Size: 55.2 x 31.1 Lower Cabinet: Fixed Shelf: 47.6 X 36.8 Sliding Shelf: 47.6 x 34.3 x 14 Drawer: 47.6 x 34.3 x 14 Drawer Cabinet: Contains two 26.7 cm x 38 cm x 10.2 cm drawers. Absorber Post: Arm length: 30.5 cm Ht Adjustment: 36.8 – 78.2 cm Casters: Number Size 127 cm Brake: Rear 13 Dräger Narkomed 2A Anesthesia Machine Narkomed 2A Introduces the Following Options: • Oxymed Oxygen Analyzer • Spiromed and Centralert (Central Alarm Unit) • Three Vaporizers : 19.1 or 19.3 Vaporizers (Isoflurane, Halothane, Enflurane) • Interlock System and Capability to Store up to Four Gases • CO2 Absorber, Oxygen Monitor, Volume Monitor • Standard Configuration includes AVE Electronic Ventilator with Ascending or Descending Bellows • Battery-Pack and 4 Electrical Outlets • Refurbishing Available - Includes Painting, New Casters, CRTs, Hoses, Batteries, and O2 Cells • O2 and N2O (Standard) • Air (Optional) • ORM (Standard), ORMC (Optional)(Hypoxic Guard) • Can be Configured with Ascending (A- or F-Style) or Descending Bellows • E-Cylinder and Central Gas Connections (Standard) • Drawer Pack Configurations May Vary 14 Battery Voltage / Capacity : 12 Volt / 7.0Ah Dimensions / Specifications Weight : Approximately 330 lb (147 kg) (Depending on Drawer Configurations) Height : Approximately 68 inches (173 cm) Width : Approximately 40 inches (102 cm) Depth : Approximately 25 inches (63.5 cm) Shelving : 200 square inches (1,290 cm2) (May Vary) Price: 16,000 USD Improved low flow/reduced life cycle costs Fresh gas flow compensation—automatically Smooth, faster acting fresh gas flow control Minimum O2 flow of 50 mL Dual air flow tube for low flow Two scheduled maintenance checks per year 15 2. Equipment Management Coefficient Equipment management number of anesthesia unit is determined by considering function, risk and required maintenance. Function of anesthesia unit is Life Support (10/10). Physical risk associated with clinical application is patient or operator injury (4/5). Maintenance requirements number is (4/5). Total of 10 + 4 + 4= 18 is the Equipment management coefficient number of anesthesia unit. Anesthesia Machine Consideration 3. Technical Specifications: The Anaesthesia Machine should have the following essential components. The quote for optional accessories should be submitted. Tender requirement 1) Anaesthesia machine complete with a) Anaesthesia gas delivery system. b) Circle absorber system. c) Precision vaporiser for halothane, isoflurane d) Anaesthesia ventilator. e) Monitoring system to monitor Anaesthetic gases, EtCO2, Pulse Oximeter and airway pressure & temperature. 2) Essential accessories to make the system complete Detailed specifications: 1. Anaesthesia gas delivery system. Should have provision for delivery of oxygen, nitrous oxide and medical air with pressure gauges. Should have independent attachments for connecting central gas supply and pin indexed cylinders. Should have provision for attaching 1 cylinder of(O 2 and N2O). Oxygen and Nitrous oxide should be linked either mechanically or pneumatically to ensure a minimum of 25% oxygen delivery at all times to avoid delivery of hypoxic mixture. Should have audio-visual oxygen Failure warning System with Nitrous oxide cut off. Should have back bar which is ISO pin type to attach vaporiser easily. Should be supplied with necessary attachments to use of the breathing circuits (Bains, Jackson-Rees and closed circuit etc.,) Should have top shelf to keep monitors and a tabletop to keep anaesthetic drugs, equipments etc. The machine should possess battery back up if any electrical components are present 16 Castor wheels should be durable and moisture resistance & Smooth. The Anaesthesia machine frame should be made of rust proof material/Stainless steel. 2. Standard Circle Absorber System Should have adjustable pressure limiting valve, breathing circuit pressure measuring device. Should have a bag/ventilator selecting valve integrated onto the absorber. Should be suitable to use low flow techniques involving total flow of 500 ml/min Facility to attach oxygen sensor. Should have dual absorbent chamber canister. Arranged vertically one above the other. 3. Precision Vaporisers (Temperature and flow compensated) for Halothane, Isoflurane. Should be easy to attach and dismount from the back bar. Vaporisers should have ISO pin type (Selectatec) mounting and vaporiser interlocking facility.. Should have a standard filling port with keyed filling device. Should be designed for transport with liquid in vaporiser chamber with protection against tipping and shaking Maintenance free vaporiser (desirable) 4. Ventilator Should be a bag in bottle anaesthesia ventilator with standing (ascending) bellows. Should be supplied with adult and paediatric bellows. Should be able to set tidal volume, respiratory rate and I:E ratio Ventilator should have audible alarms for ventilator failure, low oxygen supply pressure, inadequate volume delivery, disconnection alarm, and power supply failure. 5. Monitoring system Should provide facility to monitor a) Oxygen and Nitrous oxide and anaesthetic agent in the inspired mixture b) Inspired and end tidal carbon di-oxide through side stream c) Oxygen saturation of the blood with both adult & paediatric probes & sensors d) Monitoring of ECG, NIBP (inclusive of adult, paediatric & neonatal NIBP cuffs), IBP and CVP should be present e) Airway Pressure monitoring should be present f) Temperature Monitoring with 2 probes oesophageal and skin probe. g) Glare free monitors with large screen for easy visibility. h) Monitor should be accurate, prcise and standard monitoring modes in modular type. i) Trolley should be provided for the monitors. 6. Back-up power supply: 17 1 KV UPS systems suitable for Anaesthesia Machine for a minimum one hour 7. Power requirements: 220-240 V, 50/60 Hz Price quote for any other essential items with justifications, which are necessary for trouble free functioning of Anaesthesia Machine Quote for total CIF value at Chennai airport. The break up of cost of the equipment, agency commission, Airfreight and insurance charge should be given. Demonstration of the equipment before price bid evaluation is must. Otherwise it will not be taken into consideration. WARRANTY 1. The equipment and all accessories should be under WARRANTY for a period of THREE YEARS after successful commissioning. 2. If the WARRANTY period ends before the start of the Financial Year then the WARRANTY should be extended till the beginning of the next financial year. For example, if the warranty period ends in December then the warranty should be extended up to 31st March of the next financial year so that the Annual Maintenance Contract can commence from 1st April. 3. All essential spare parts, PC boards and service manuals should be available with the local service centre during WARRANTY Period and all steps should be taken for immediate servicing to prevent the down time. Annual Maintenance contract: 1. The Annual Maintenance contracts rates for a period of 5 years after warranty period should be quoted separately and this would be taken into consideration in comparing the price bids. 2. Annual Maintenance contract should include preventive maintenance and breakdown calls. A copy of service manual should be available with local service centre. Installation, commissioning, Testing Maintenance and after Sales service 1. The equipment and all accessories should be installed and tested and commissioned in the Department of Anaesthesiology, JIPMER, Pondicherry-6 free of cost. 2. All electric connections, plug points, wiring etc should be provided free of cost. 3. All spare parts and consumables should be available with the supplier or principals for the period of 10 years. Tender conditions: 1. The company should quote/send their technical and price bids in separate sealed envelops 2. Companies to indicate separately and clearly in their technical bids whether their products conforms/does not conform to each parameter in the specification and also to extent it deviates from the specifications as per enclosed proforma 3. Quotation should be valid for 1 year 4. Details of Agency commission should be given. This will be paid in Indian Currency 5. The user list from reputed Institutions should be provided. 18 Proforma for Technical Specifications of Anaesthesia Machine. (To be filled by the company and submitted along with Technical bid) Company name: Model Component Tender Specification 1. Anaesthesia Gas delivery system a) Should have provision for delivery of oxygen, nitrous oxide and medical air with pressure gauges. b) Should have independent attachments for connecting central gas supply and pin indexed cylinders. c) Should have provision for attaching 1 cylinder of N2O & O2. d) Oxygen and Nitrous oxide should be linked either mechanically or pneumatically to ensure a minimum of 25% oxygen delivery at all times to avoid delivery of hypoxic mixture. e) Should have audio-visual oxygen Failure warning System with Nitrous oxide cut off. e) Should have back bar which is ISO pin type to attach vaporiser easily. f) Should be supplied with necessary attachments to use of the breathing circuits (Bains, Jackson-Rees & Closed Circuit etc.) g) Should have top shelf to keep monitors and a tabletop to keep anaesthetic drugs, equipments etc. h) Castor (wheels should be durable and moisture resistant & smooth. i) The Anaesthesia machine frame should be made of Rust proof material/stainless steel. 2. Standard Circle Absorber a) Should have adjustable pressure limiting valve, breathing Model’s Specification (write Yes or No Additional feature ,if any 19 System 3. Precision Vaporisers (Temperature and flow compensation) for Halothane, Isoflurane circuit pressure measuring device. b) Should have a bag/ventilator selecting valve integrated onto the absorber. c) Should be suitable to use low flow techniques involving total flow of 500 ml/min d) Facility to attach oxygen sensor. f) Should have Dual Absorbent Chamber Canister arranged vertically one above the other. a) Should be easy to attach and dismount from the back bar. b) Vaporisers should have ISO pin type (Selectatec) mounting and vaporiser interlocking facility. c) Should have a standard filling port with keyed filing device d) Maintenance free vaporiser is desirable e) should be designed for transport with liquid in the vaporiser chamber with protection against tipping and shaking. 4.Ventilator a) Should be a bag in bottle anaesthesia ventilator with standing, ascending bellows. 2) Should be supplied with adult and paediatric bellows. 3) Should be able to set tidal volume, respiratory rate and I:E ratio. 4)Ventilator should have audible alarms for ventilator failure, low oxygen supply pressure, inadequate volume delivery, disconnection alarm, and power supply failure 5. Monitoring Systems Should provide facility to monitor Oxygen and Nitrous oxide and anaesthetic agent in the inspired mixture Inspired and end tidal carbon dioxide (side stream) Oxygen saturation of the blood with both adult & paediatric probes & sensors 20 Monitoring of ECG, NIBP, IBP and CVP should be present Airway pressure monitoring should be present. NIBP with Adult, Paediatric & Neonatal NIBP cuffs Temperature Monitoring with oesophaeal Probe and skin Probes. Glare free monitors with large screen for easy visibility Monitor should be accurate,Precise and standard monitoring mode in modular type Trolley should be provided for the monitor. 4.Standards: ISO standards related with anesthetic machines for use with humans is ISO 5358:1992 The European Standard for anaesthetic machines (EN740) requires them to have means to prevent the delivery of a gas mixture with an oxygen concentration below 20%. Some of the respondents to Saunders and Meek's survey probably regarded compliance with this standard as synonymous with the presence of an anti-hypoxia device on their anaesthetic machine.1-1 The European Standard refers to machines in the workshop. I have to attach these machines to patients via a patient circuit, and thus my interest is whether the machine in this configuration will prevent the inadvertent delivery of a hypoxic inspired gas mixture. In machines with a simple (ratio) oxygen/nitrous oxide linkage, a combination of 300 ml oxygen/min and 900 ml nitrous oxide/min into a circle absorber circuit is permissible and the machine will conform to EN740 but a hypoxic inspiratory mix will develop in adults and in children as young as 8. This machine will prevent the administration of an anoxic mix, and probably of a severely hypoxic mix, but not the administration of a hypoxic mix. Preventing Accidents: The Safety Features of Modern Machines Prior to the mid-late 1980s the prototypical intraoperative anesthesia catastrophe was an unrecognized accidental esophageal intubation during the induction of general anesthesia with muscle relaxation. In such a case, the first indication of trouble often was an expanding stomach and transient tachycardia and hypertension from the sympathetic response to hypoxemia and hypercarbia followed soon by the surgeon 21 making an incision and commenting with distress: “Hey! The blood looks really dark down here!” Ventricular ectopy leading quickly to fibrillation ensued, creating an immediate life-threatening crisis. The necessity was to get help, make the initial diagnosis by recognizing the cause of the problem, replace the endotracheal tube correctly in the trachea, successfully resuscitate the patient, verify that the incident had ended, institute care to minimize hypoxemic damage, and administratively manage the situation, including with investigation and teaching to reduce the probability of it happening again to another patient. Other examples also usually involving some type of failure of ventilation (such as from an unrecognized breathing circuit disconnection) or even a disruption of the oxygen supply are possible, but the point is clear regarding the need to organize the response to such a major event. By the end of the 1980s the nature of intraoperative anesthesia accidents changed with the creation and universal application of the strategies of intraoperative anesthesia safety monitoring. Specifically the change of behavior and mindset from intermittent to genuinely continuous patient and anesthesia delivery system monitoring coupled with the use of then-new electronic monitors as extensions of the anesthesia provider's senses allowed extremely sensitive real-time monitoring of patient oxygenation and ventilation. This resulted in much earlier warning of the potentially dangerous mishaps (that continue to occur still today) that previously would have evolved to patient injury. The information in the warning, in turn, directed and facilitated diagnosis and correction of the problems well before the onset of injury. As a result, the frequency and severity of intraoperative patient-injury accidents decreased dramatically. Thus, a significant component of the previously traditional training and experience of anesthesia practitioners was functionally eliminated. While overt unrecognized simple failures of ventilation are much less likely, they can still occur. Also, other, more modern, intraoperative accidents may be more complex and more subtle. Human error theory suggests analogies to other types of major accidents: airliner or train crashes and nuclear plant or electric power grid disasters. These usually involve 2 or more abnormalities or variances in conditions or procedures coincident in time that cause unusual interaction and results, making the operator (or anesthesia practitioner) face an unfamiliar situation. A listing of actual or potential situations is not possible in this setting, but they do happen—very rarely, but they do. Today, applying population statistics, a new practitioner could expect to be involved in a patient-injury accident once in an average career. This means, by definition, that the practitioner will have no direct experience in managing such a situation. The “Adverse Event Protocol” is specifically intended to fill that gap and arm every anesthesia practitioner with a detailed, carefully thought out plan to respond to a patient-injury intraoperative accident. Laminated copies of the printed protocol were attached to anesthesia machines in some operating rooms (ORs) in the 1990s. Today, a great many OR rooms and virtually all OR suites have immediate Internet access. The original “Adverse Event Protocol” is in the APSF website: www.apsf.org, “Clinical Safety Tools” under “Resource Center” at the top of any page on the site. When the urgent overhead page in an OR suite comes, “ANESTHESIA STAT! to OR X,” almost always several people respond, usually more than can physically get to the head of the involved patient at one time. One of the helpers later to arrive profitably could either be assigned or take their own initiative to 22 go immediately to an on-line computer and print or even simply read out loud the protocol from the APSF site. Based on experience gained from analysis of mishaps, the modern anaesthetic machine incorporates several safety devices, including: an oxygen failure alarm (also known as 'Oxygen Failure Warning Device' or OFWD). In older machines this was a pneumatic device called a Ritchie whistle. Newer machines have an electronic sensor. nitrous cut-off: the flow of medical nitrous-oxide is dependent on oxygen pressure. This is done at the regulator level. In essence, the nitrous-oxide regulator is a 'slave' of the oxygen regulator. hypoxic-mixture alarms (hypoxy guards or ratio controllers) to prevent gas mixtures which contain less than 21% oxygen being delivered to the patient. In modern machines it is impossible to deliver 100% nitrous oxide (or any hypoxic mixture) to the patient to breathe. Oxygen is automatically added to the fresh gas flow even if the anaesthetist should attempt to deliver 100% nitrous oxide. Ratio controllers usually operate on the penumatic principle or are chain linked. Both are located on the rotameter assembly, unless electronically controlled. ventilator alarms, which warn of disconnection or high airway pressures interlocks between the vaporisers preventing inadvertent administration of more than one volatile agent concurrently alarms on all the above physiological monitors the Pin Index Safety System prevents cylinders being accidentally connected to the wrong yoke the NIST (Non-Interchangeable Screw Thread) system for pipeline gases, which prevents piped gases from the wall being accidentally connected to the wrong inlet on the machine pipeline gas hoses have non-interchangeable Schrader valve connectors, which prevents hoses being accidentally plugged into the wrong wall socket The functions of the machine should be checked at the beginning of every operating list in a "cockpit-drill". Machines and associated equipment must be maintained and serviced regularly. Older machines may lack some of the safety features and refinements present on newer machines. However, they were designed to be operated without mains electricity, using compressed gas power for the ventilator and suction apparatus. Modern machines often have battery backup, but may fail when this becomes depleted. The modern anaesthetic machine still retains all the key working principles of the Boyle's machine (a British Oxygen Company trade name) in honour of the British 23 anaesthetist H.E.G. Boyle (1875-1941). In India, however, the trade name 'Boyle' is registered with Boyle HealthCare Pvt. Ltd., Indore MP. A two-person (Operating Theatre Practitioner and anaesthetist) pre-use check of the anaesthetic machine is recommended before every single case and has been shown to decrease the risk of 24-hour severe postoperative morbidity and mortality (Arbous et al. Anesthesiology 2005). Various regulatory and professional bodies have formulated checklists for different countries - see http://vam.anest.ufl.edu/guidelines.html. A free transparent reality simulation of the checklist recommended by the United States Food & Drug Administration is available from the Virtual Anesthesia Machine web site ( see below) after registration which is also free. Low Accident Rate There is no more supervised and monitored time during a patient’s stay in the hospital than in the operating room (OR). An OR is the most densely populated area of the hospital, in terms of staff and equipment. There are always one or two anesthesia personnel, a surgeon or two, a scrub nurse or two, a couple of circulating nurses, equipment operators, and several other assorted personnel in the room. The number of staff in an OR can often number eight or more. It is very difficult for anesthesia machine-related accidents to occur during surgery for several reasons, including the following: • There is a full-time, specially trained person dedicated to keeping the patient at just the right level of anesthesia—not too deep and not too light. • Vital-sign monitors, oxygen analyzers, anesthetic gas monitors, and pulse oximeters all are monitoring the patient’s parameters. The anesthesia machine, the ventilator, and all of the associated patient monitors feature alarms, which provide a level of safety and redundant security beyond that of the anesthesia staff. And in case the electronic equipment isn’t enough, there is always a stethoscope monitoring the heartbeat and breathing sounds directly. • The anesthesia machine itself has several built-in safety devices. Flow meters cannot deliver less than 21% oxygen. Nitrous oxide is shut off if the oxygen pressure fails. Vaporizers are linked so that no more than a single agent can be delivered at any time. An assortment of gauges and dials give the anesthesia personnel ready information about the state of the machine and the gases that it administers. • Each of these machines, monitors, and systems has its own preuse checkout procedure, which, if followed regularly and often, will virtually ensure that no equipment fails during a case. It would be logical that most incidents would occur at the start of a case, since the patient is being put to sleep, intubated, and hooked up to all of the equipment. But surprisingly, researchers1 found that most incidents occurred during the middle of a case, which also is the time when the anesthesia personnel have the least to do and can be less diligent in their attention to the patient. Indeed, only 2% of the failures (6 out of 359) documented in the study were due to machine failure of some sort. It seems an anesthesia machine is as safe as the person using it. 24 No Room for Error A certain type of repair person is needed for anesthesia service. The machines are straightforward, but the consequences of failure can be devastating—they are among only four or five items in the entire hospital that are truly “life support” (others include ventilators, heart–lung bypass pumps, and pacemakers). The person who works on anesthesia machines must, above all, be someone who always follows procedures. Diligently following all checkout procedures and postrepair tests is the final critical step every time you touch a machine. These checkouts are designed to determine whether a repair is done correctly or not. Life-support equipment is no place to cut corners or rush through a repair or preventive maintenance check. It doesn’t require a senior-level BMET to service anesthesia machines, though. I have taken recent graduates from a BMET school and sent them to a manufacturer’s school, and they have been very successful when working under the guidance of a seasoned BMET. It is the personality and attention to detail that determines their success. There is no room for error in anesthesia service. References: http://www.tradekey.com/ks-anesthesia-unit/ http://www.pjr.com/china/ISO_13485.htm http://www.pjr.com/china/ISO_13485.htm http://mohfw.nic.in/Anesthesia%20Machines.pdf http://209.85.129.132/search?q=cache:ovks5VBrjwJ:www.iso.org/iso/catalogue_detail.htm%3Fcsnumber%3D11385+Anaesthetic+mac hine+ISO+standards&cd=2&hl=tr&ct=clnk&gl=tr&client=firefox-a http://www.springerlink.com/content/64454u7172746685/fulltext.pdf http://www.somatechnology.com/MedicalProducts/Ohmeda%20Excel%20210%20SE .asp http://www.medikalborsa.com/index.php?blm=urunler&is=goster&urunno=991 http://en.wikipedia.org/wiki/Anaesthetic_machine http://www.tradekey.com/ks-anesthesia-machine/ 25