SWP for 32_ HCl decanting (2)

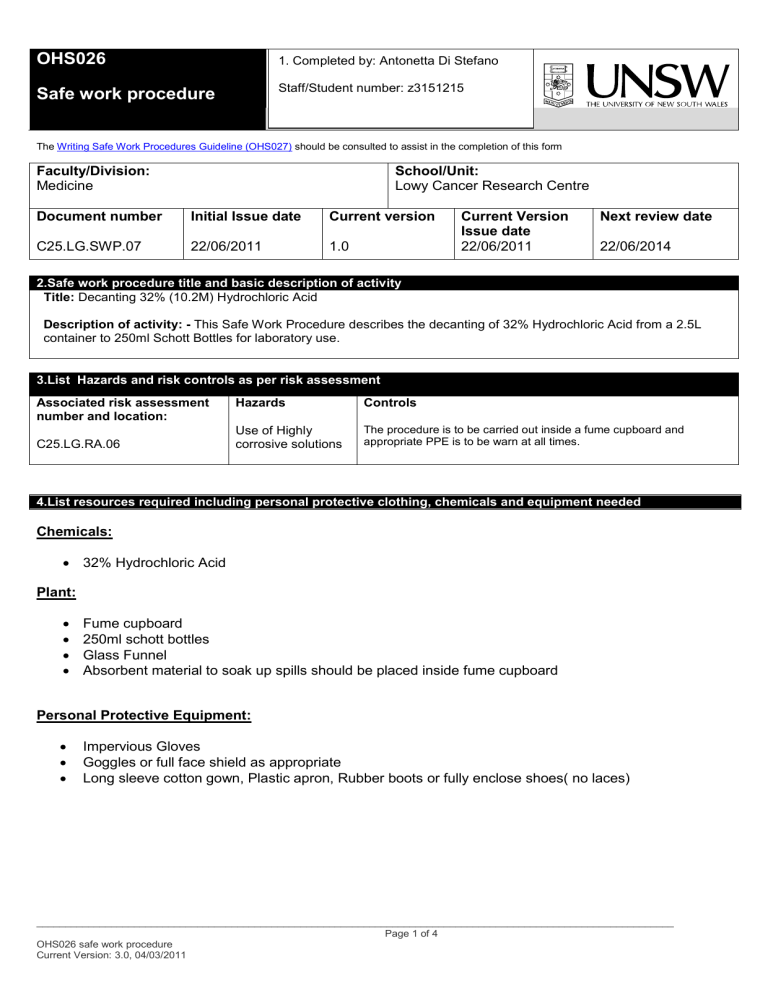

OHS026

Safe work procedure

1. Completed by: Antonetta Di Stefano

Staff/Student number: z3151215

The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form

Faculty/Division:

Medicine

Document number

C25.LG.SWP.07

Initial Issue date

22/06/2011

School/Unit:

Lowy Cancer Research Centre

Current version

1.0

Current Version

Issue date

22/06/2011

Next review date

22/06/2014

2.Safe work procedure title and basic description of activity

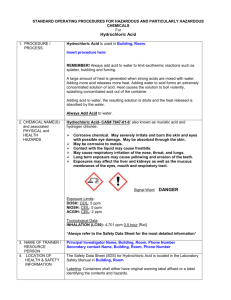

Title: Decanting 32% (10.2M) Hydrochloric Acid

Description of activity: - This Safe Work Procedure describes the decanting of 32% Hydrochloric Acid from a 2.5L container to 250ml Schott Bottles for laboratory use.

3.List Hazards and risk controls as per risk assessment

Associated risk assessment number and location:

C25.LG.RA.06

Hazards

Use of Highly corrosive solutions

Controls

The procedure is to be carried out inside a fume cupboard and appropriate PPE is to be warn at all times.

4.List resources required including personal protective clothing, chemicals and equipment needed

Chemicals:

32% Hydrochloric Acid

Plant:

Fume cupboard

250ml schott bottles

Glass Funnel

Absorbent material to soak up spills should be placed inside fume cupboard

Personal Protective Equipment:

Impervious Gloves

Goggles or full face shield as appropriate

Long sleeve cotton gown, Plastic apron, Rubber boots or fully enclose shoes( no laces)

_______________________________________________________________________________________________________________

Page 1 of 4

OHS026 safe work procedure

Current Version: 3.0, 04/03/2011

5.List step by step instructions or order for undertaking the task

1. Ensure you are wearing all appropriate PPE before removing Hydrochloric acid

2. Ensure Hydrochloric Acid container has no signs of leaking and remove from corrosives cupboard

3. Place hydrochloric acid in fume cupboard (ensure fume cupboard is not overly full with other vaporous material)

4. If needed, place a glass funnel into the opening of a 250ml schott bottle.

5. Pull down sash of fume cupboard ensuring arms can still move freely inside the cupboard

6. Open lid of Hydrochloric acid container

7. Carefully pour the acid into the 250ml container

8. Allow acid to evaporate from glass funnel before removing from hood

9. Close all lids and label 250ml bottles appropriately

10. Place all decanted and stock hydrochloric acid bottles in corrosives cupboard ensure stock bottles are bunded inside the corrosive cupboard

6.List emergency shutdown procedures

In the event of an emergency use emergency stop button of fume cupboard to shut down

7.List Emergency procedures for how to deal with fires, spills or exposure to hazardous substances

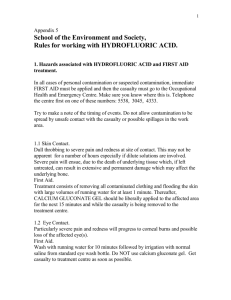

Skin Contact: Wash affected area with soap and water.

Eye Contact: Rinse eye with copious amounts of water, taking care not to contaminate unaffected eye. Seek medical attention

Ingestion: Do not induce vomiting, rinse mouth with water and seek medical attention

Inhalation: Remove from contaminate area. Apply artificial respiration if not breathing. Seek medical attention

Notes for physician: Treat symptomatically as for strong acids

Suitable extinguishing media: Extinguish fire with water fog, foam or dry chemical powder

Special Protective equipment for fire fighters: Fire fighters should wear full protective clothing and self breathing apparatus operated in positive pressure mode

8.List Clean up and waste disposal requirements

Dispose of unwanted containers and hydrochloric acid using UNSW chemical waste removal policy

In the event of a spill, Increase ventilation. If possible contain the spill using inert absorbent material and place into a secondary container

All materials used to mop up a spill are to be disposed of as chemical waste.

9.List legislation used in the development of this SWP

NSW OHS ACT 2000

NSW OHS Regulations 2001

MSDS for Hydrochloric Acid 32% (Ajax)

10a.List competency required – qualifications, certificates, licensing, training - e.g. course or instruction:

UNSW Laboratory Safety Awareness training or equivalent

UNSW Occupational Health & Safety Awareness training or equivalent

UNSW Hazardous Substances training or equivalent

_______________________________________________________________________________________________________________

Page 2 of 4

OHS026 safe work procedure

Current Version: 3.0, 04/03/2011

10b. List competency of Assessor

11.Supervisory approval, And review

Supervisor: Dr David Coomber Signature:

Responsibility for SWP review: Antonetta Di Stefano Date of review: 22/06/2014

12.SWP Sign off sheet

SWP name and version: Decanting 32% (10.2M) Hydrochloric Acid (Version 1.0)

In signing this section the assessor/ authorisor agrees that the following persons are competent in following this

SWP

Name Signature Date

Competent

Name of Assessor/Authoriser Assessor/Authoriser signature

_______________________________________________________________________________________________________________

Page 3 of 4

OHS026 safe work procedure

Current Version: 3.0, 04/03/2011

_______________________________________________________________________________________________________________

Page 4 of 4

OHS026 safe work procedure

Current Version: 3.0, 04/03/2011