POLLUTION PREVENTION AND AUTOMOTIVE REPAIR SHOPS

advertisement

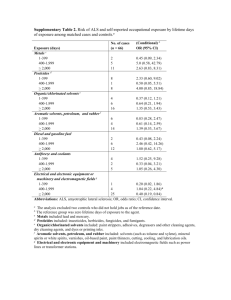

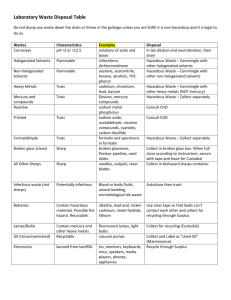

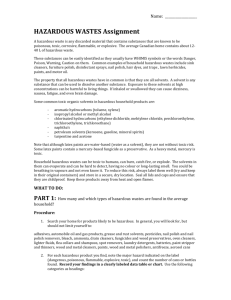

AUTOMOTIVE REPAIR SHOPS & POLLUTION PREVENTION Why should you be concerned? Automotive service and repair shops are the largest small quantity generators of hazardous waste in the U.S. It is to your advantage, both legally and financially, to manage shop wastes properly. Many of the wastes that are created in auto repair/maintenance shops can be toxic to fish, wildlife and human health if not managed. Shops sometimes wash their wastes into drains connected to wells or directly into storm drains. These wastes find their way into the soil, lakes, rivers, and the water that we drink. Old containers that leak can also allow chemicals to enter into soil and water. Remember that improper disposal of many of these wastes is a violation of the Safe Drinking Water Act and hazardous waste regulations. What do you have? What is the hazard? What can you do with it instead? Used tire/rubber products mosquitoes fire expensive to landfill recycle/retread Used oil filters water contamination at landfill recycle Used antifreeze water contamination filter and reuse Used batteries heavy metals in soil water contamination recycle Air conditioner refrigerants air pollution contain and recycle Shop rags expensive to landfill fire hazard industrial laundries Used oil and lubricants water contamination recycle Parts cleaners and solvents hazardous air pollution and smog effects liver and kidneys some may cause cancer use water based cleaners use non-chlorine cleaners HELPFUL HINTS By using fewer parts cleaner or using portable baths, you not only reduce waste but save money. If you filter the parts cleaners, you can reuse them. Properly dispose of all excess and old chemicals in your shop and only keep enough for short-term use. Reduce and recycle wastes and refrigerants Contain and recycle anti freeze. It will save you lots of money in the long run Always use drip pans to catch used oil. A recycler will usually pick it up for free Never mix used oil with antifreeze or other chemicals or fluids Do not wash vehicles unless you have the proper drainage system Use a mop or wet-vac to clean floors. Do not flush floors with water Use each service bay for a particular type of operation so it is easier to handle wastes Use waste collection stations that are labeled and convenient for all shop employees Make sure all chemicals are properly labeled and in good condition You should drain all used oil filters for 24 hours into a waste oil container Always recycle used batteries, store them safely where they cannot leak onto floors Keep records of the chemicals you use and store them properly Remember: Never wash dangerous solvents or chemicals into floor drains. Seal the floors with a sealant that allows you to mop up spills instead of rinsing them. If you do have a floor drain, make sure that there is an oil/sediment separator By using good management practices and good sense you can save money, time, and avoid possible fines. Fact: 2.1 tons of used crankcase oil ends up in our rivers and streams every year. A single quart of oil can pollute 250,000 gallons of drinking water. Fact: Between 1980 and 1986 98,000,000 batteries containing 1,000,000 tons of lead were buried or thrown away, they are now leaking into soil and waters. Fact: Coolant leaking from car A/C units or improperly handled in automotive shops contributes to 16% of ozone destruction . Automotive Body Shops & Pollution Prevention Why should you be concerned? Paints and solvents used in auto body shops are large sources of air pollution and hazardous wastes. New technologies and products are now available that not only reduce the amounts of pollution, but are also save money for auto body shops. Where does the pollution come from? Chemicals are released into the air during painting operations and hazardous wastes are created from solvents, thinners, metal based paints, and the dust created during sanding. The dust and sludge is often washed into storm water drains and find their way into our soils, rivers, streams and drinking water. Many of the wastes from auto-repair shops are also created in body shops, such as lubricating fluids, antifreeze, tires, batteries, brakes, refrigerants, filters, and shop rags. Many of these wastes are considered hazardous and improper management of these wastes can be a violation of the Safe Drinking Water Act, Clean Air Act, and hazardous waste regulations. What are the wastes? What are the hazards? What can you do instead? Paints heavy metals use non-metal high solids paint use HVLP paint guns Paint solvents and thinners hazardous air pollution highly flammable effects nervous system some may cause cancer recycle on-site with still use non-chlorinate cleaners use high flash point solvents What have other companies done? Material Pollution Prevention Option Benefits Paint switched to HVLP paint gun improved health and safety reduced air pollution cost savings in materials Paint waste switched to high solids coatings improved cost savings reduced air pollution cost savings in excess materials Lacquer thinner and solvents purchase on-site distillation unit reduced air pollution reduced hazardous waste cost savings in materials Solvent from paint gun cleaning recycled solvents trained employees cost savings in materials reduced air pollution reduced hazardous wastes HELPFUL HINTS Mix paint only when needed Always maintain equipment Schedule painting so color changes are reduced Never paint in booths that contain floor drains Always use reusable paint booth filters Recycle solvents by filtering and reusing to clean parts Use environmentally friendly cleaning solvents Do not create hazardous wastes by mixing different kinds of wastes Remember: Never wash dangerous chemicals down a floor drain. You should apply a floor sealant so that you can mop up spills instead if rinsing them away. If you have a floor drain, make sure that there is an oil/sediment separator. By using good management practices and good sense you can save money, time, and avoid possible fines. Parts Washing & Pollution Prevention Why should you be concerned? Repair shops create many different types of waste during their daily operations. These include used oil and fluids, dirty shop rags, used parts, asbestos from brake pads, and waste from solvents used for cleaning parts. All of which are expensive to dispose of and sometimes hazardous. The most dangerous waste commonly created in repair shops is from the solvents used to clean parts. Many of the chemicals that make up the solvents are extremely dangerous to humans, animals and the environment. If not handled properly these chemicals can find their way into the air we breathe, the water we drink, our soil, lakes and streams. Many of the solvents and cleaners you use may be regulated by hazardous waste regulations and federal and state laws enforced by the Environmental Protection Agency and South Carolina DHEC. What is so dangerous about solvents and cleaners? Many parts cleaners and solvents are dangerous to workers health. They have been known to damage the liver, kidneys and brain. Some solvents can cause cancer. When solvents evaporate, they cause hazardous air pollution and smog. What can you use instead of solvents and cleaners? There are a number of alternatives to traditional parts cleaning solvents. Many of these solutions cost less than the traditional methods. Most are less hazardous to the environment and less harmful to the employees. Try water based cleaners and non-chlorine based solvents. HELPFUL HINTS Pre-clean parts with a wire brush or rag Never use “throw away” cans of brake cleaner or choke cleaner types of solvents Use a multi-purpose solvent rather than several different types Always try to avoid chlorine based solvents Aqueous or alkaline cleaners are as effective as solvents Consider steam cleaning Use a solvent bath and recycle solvents then reuse the cleaner (inexpensive kits are available that can test recyclable solvent quality) Always clean parts in a designated area If just detergent and water baths will not work, try limeoline or naphtha cleaners instead of solvents Replace solvent only when needed instead of on a schedule Always keep solvent baths covered when not in use to keep them from evaporating Consider employing a service that will lease you the parts cleaning equipment and maintain it (they recycle 70 to 80% of the solvents and will sell it back to you at a reduced cost) Consider onsite filtering of solvents for reuse REMEMBER: Never wash dangerous chemicals down the drain. If you use a floor drain in your shop, make sure that you have an oil/sediment separator and that your floor is sealed so that you can mop up solvents instead of rinsing them with water. By using good management practices and good sense you can save money, time, and avoid possible fines.