SECTION 13

advertisement

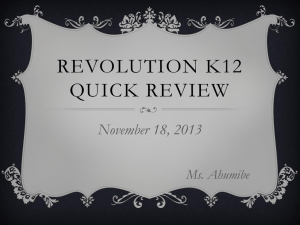

SECTION XIII - IRREVERSIBILITY Irreversibility – a very powerful tool in the design and optimization of complex thermodynamics systems. Consider the application of conservation of energy to a uniform-state, uniform-flow process such as the filling or emptying of a tank: W12 m i h i e Ki e Pi Q12 (from surroundings at T0) m e h e e K e e Pe m 2 (u 2 e K 2 e P2 ) m 2 (u 1 e K1 e P1 ) Consider now the application of conservation of energy to a reversible uniform-state, uniformflow process: Q0 Wrev Wc W12 rev m i h i e Ki e Pi Reversible heat engine to facilitate reversible heat transfer Q12 rev m 2 (u 2 e P2 e K 2 ) m e h e e Pe e K e m1 (u1 e P1 e K1 ) (net work done by the reversible heat engine) Wrev = W12 rev + WC Irreversibility: I = Wrev – W12 (i.e. actual) Conservation of energy: Q12 rev m i (h i e Ki e Pi ) W12 rev m e (h e e K e e Pe ) m 2 (u 2 e K e e Pe ) m1 (u 1 e Ki e Pi ) Reversible Heat Engine: WC = Q0 – Q12 rev (i) (ii) Section XIII - Irreversibility Second Law: Page 62 tQ Q0 12 dt 0 T0 T rev T0: temperature of surrounding (iii) tQ WC T0 12 dt Q12 rev 0 T rev Second Law for the process (i.e. uniform-state, uniform-flow): tQ m 2 s 2 m1s1 m e s e m i s i 12 dt 0 0 T rev reversible tQ m 2 s 2 m1s1 m e s e m i s i 12 dt 0 T rev (iv) WC T0 m 2 s 2 m1s1 m e s e m i s i Q12 rev (v) m u Wrev Q12 rev m i h i e Ki e Pi m e h i e Ki e Pi m 2 u 2 e K 2 e Pi 2 1 1 W12 rev [see (i)] e K1 e P1 T0 m 2 s 2 m1m1 m e s e mi s i Q12 rev WC [See (v)] Wrev m i h i e K i e Pi T0 s i m e h e e K e e Pe T0 s i m 2 u 2 e K 2 e Pi 2 T0 s 2 m1 u 1 e K1 e P1 T0 s1 (vi) For a nonflow process (i.e. a closed system): mi = me = 0; m1 = m2 = m (vi) becomes Wrev m u 1 u 2 e K1 e K 2 e P1 e P 2 T0 s1 s 2 w rev Wrev m u 1 (vii) u 2 e K1 e K 2 e P1 e P 2 T0 s1 s 2 (vii a) For a flow process (i.e. an open system: m i h i e K i e Pi T0 s i m e h e e K e e Pe T0 s e W rev d m 2 u 2 e K 2 e P2 T0 s 2 m1 u 1 e K1 e P1 T0 s1 dt (viii) Section XIII - Irreversibility Page 63 d 0 dt i m e m and If the flow process is steady, then m m h i h e e Ki e Ke e Pi e Pe T0 s i s e W rev w rev W rev (ix) h i h e e K i e K e e Pi e Pe T0 s i s e m I = Wrev – W12 Wrev m u m i h i e Ki e Pi T0 s i m e h e e K e e Pe T0 s e m 2 u 2 e K 2 e P2 T0 s 2 1 1 e K1 e P1 T0 s1 W12 m i h i e K i e Pi m e h e e K e e Pe m 2 u 2 e K 2 e P2 m1 u 1 e K1 e P1 I me T0 s e mi T0 s i m 2 T0 s 2 m1T0 s1 Q12 I T0 m 2 s 2 m1s1 T0 m 2 s 2 m i s i T0 Q12 T0 T0dstot e= 0 For a nonflow process: m1 = m2 = m, mi = m I T0 m(s 2 s1 Q12 i I T0 s 2 s1 q 12 m For a flow process: Q I T d m s m s m s m s T i i 0 T12 0 2 2 1 1 e e dt 0 For a stead-flow process: i m e m , m d 0 dt dSsys dSsurr In general, I T0 dt dt Q12 I T m 0 s e s i T0 T0 (x) Section XIII - Irreversibility Page 64 6.14 A small storage tank with a volume of 0.12 m3 initially contains 0.9 kg of argon at 40C. Heat is transferred to the argon from a reservoir whose temperature is 1300C until the entropy of the argon has increased by 0.46 kJ/kg K. Determine the amount of heat transferred, the final pressure of the argon, the reversible work, and the irreversiblity of the process. (Assume T0 = 25C, P0 = 100 k Pa) Q12 Argon m = 0.9 kg = 0.12 m3 T1 = 40C=313 K Tres = 1300C = 1573 K system boundary T1 = 313 K > Tcrit argon = 151 K P1 mRT1 0.9 0.2081 313 488.5 KPa Pcrit arg on 4.86 MPa 0.12 treat argon as ideal Assume tank rigid 1 = 2 = = 0.12 m3 Change in entropy s 2 s1 c v n T2 v R n 2 0.46 kJ / kg K T1 v1 (v1=v2) T2 T1e (s2 s1 ) c v 313 e 0.46 0.3122 1366 K T 1366 P1 mRT1 , P2 mRT 2 P2 P1 2 488.5 313 T1 P2 2.13 MPa Q12 W12 ( U 2 U1 mc v (T2 T1 ) (0.9)(0.3122)(1366 313) 295.9 kJ tan k assumed rigid Q 298(295.9) I 67.3 kJ I T0 ms 2 s1 T0 12 298(0.9)(0.46) Tres 1573 I Wrev Wactual Wrev 67.3 kJ Section XIII - Irreversibility Page 65 Steam at 1.4 MPa and 260°C enters an adiabatic nozzle with negligible velocity and exits at a pressure of 150KPa and a quality of 96 percent. Calculate the exit velocity, the adiabatic nozzle efficiency and the irreversibility per unit mass. (To = 25°C) inlet exit Flow is uniform at the inlet and exit ep h Nozzle walls are rigid Adiabatic nozzle Steam Pi = 1.4 MPa Ti = 260°C Vi 0 System boundary Assumptions Flow is steady i m e m m Conservation of Energy Pe = 150KPa Xe = 0.96 Ve = ? 2 v W m (h e e hi ) Q ie ie 2000 (adiabatic) V hi = he + e 2000 Walls assumed rigid d 0 2 Steam is superheated at the inlet since Ti + 260° > Tsat = 195.07°C corresponding to Pi = 1.4MPa hi = 2927.2 + 3040.4 2927.2 (260 250) 2949.8 KJ 300 250 Kg he = 467.11 + (0.96)(2226.5) = 2604.6 Exit Velocity: Ve = KJ Kg 2000(hi he ) 2000(2949.8 2604.6) Ve = 830.9 m/s Adiabatic nozzle efficiency N hi he ,a hi he ,s 2949.8 2604.6 0.816 (81.6%) 2949.8 2526.6 Section XIII - Irreversibility si = 6.7467 + se, s seg Page 66 (6.9534 6.7467)( 260 250) kJ 6.7880 se (300 250) KgK Pe0.150MPa , se,s se f Pe0.150MPa Saturated liquid-vapour mixture at xe,s = se , ,s se f S efg (6.7880 1.4336) 0.925 5.7897 he,s = 467.11 +0.925 (2226.5) = 2526.6 Irreversibility: e,s kJ Kg i = To (se –si) + q12 adiabatic se = 1.4336 + (0.96) (5.7897) = 6.9917 i = 298 (6.9917 – 6.7880) = 60.7 KJ KgK KJ Kg Steam at 4MPa and 450°C enters an adiabatic turbine at a rate of 12 Kg/s. Ten percent of the mass flow is extracted at a point where the temperature and pressure of the steam are 300°C and 1.2 MPa respectively, for use in an industrial process. The remainder of the steam is further expanded and exhausts from the turbine at 75 KPa with a quality of 98 percent. Determine the adiabatic efficiency of the turbine , the irreversibility rate and the reversible power. (Assume To = 25°C) Pi = 4MPa Ti = 450°C inlet Adiabatic Steam Turbine Intermediate exit Pint = 1.2 MPa Tint = 300°C System boundary Exit Pe = 75KPa Xe = 0.98 m i 12 Kg / s m int 0.1 m i 1.2 Kg / s Assumptions Flow is steady Fluid is at steady state Flow is uniform at inlet and exits ep & ek << h Section XIII - Irreversibility Page 67 Conservation of Mass m i m int m e m e m int 12 1.2 m e 10.8Kg / s Conservation of energy Q ie W ie m e he m int hint m i hi adiabatic turbine Ti = 450°C > Tsat = 250.4°C corresponding to Pi = 4Mpa Steam is superheated at the inlet hi = 3330.3 kJ kJ , si = 6.9363 Kg KgK Tint = 300°C > Tsat = 187.99°C corresponding to Pint = 1.2 MPa steam is superheated at the intermediate exit hint = 3045.8 kJ kJ , sint = 7.0317 Kg KgK he = 384.39 + 0.98 (2278.6) = 2617.4 kJ Kg se = 1.2130 + 0.98 (6.2434) = 7.3315 kJ KgK If process is turbine is reversible, it will be isentropic since it is also adiabatic si = sint = se = 6.9363 sint, sintg se,s < seg p 2 MPa p 75MPa kJ KgK 6.5233 6.5233 se,s > sef P75MPa 1.2130 kJ superheated also at KgK int,s kJ saturated liquid-vapour mixture at KgK kJ KgK e,s Section XIII - Irreversibility xe,s = Page 68 6.9363 1.2130 0.917 6.2434 he,s = 384.39 + (0.917)(2278.6) = 2473.9 hint,s = 2935.0 + hint,s = 2993.5 kJ kg (3045.8 2935.0)(6.9363 6.8294) (7.0317 6.8294) kJ kg Actual turbine power: i hi m e he m int hint Wie,a = m = 12(3330.5) –10.8 (2617.4)-1.2 (3045.8) Wie,a = 8040.7 kw Turbine power under isentropic flow conditions Wie,s = m i hi m e he, s m int hint,s = 12(3330.3) – 10.8(2473.9)-1.2 (2993.5) Wie,s = 9653.3 kw Adiabatic Efficiency T W ie,a 8040.7 0.833(83.3%) W ie,s 9653.3 Irreversibility Rate dSys I To (m e s e m int sint m i si ) To Qie dt steady adiabatic state turbine I 29810.8(7.3315) 1.2(7.0317) 12(6.9363) I 1306 KW Section XIII - Irreversibility Page 69 Reversible Power I W W W I W rev ie,a rev ie,a W rev 1306 8040.7 9364.7 KW Air at 275 KPa and 360k enters an internally reversible, isothermal turbine and exhausts at 105 KPa. Heat is transferred to the air in the turbine from a reservoir whose temperature is 550k, and To = 300k. Determine the work done per kilogram of air, assuming that changes in kinetic and potential energies are negligible. Compare the turbine efficiency and turbine effectiveness. Which of these performance characteristics is more meaningful? Q ie inlet Isothermal Turbine air Wie System boundary exit Ti Te 360 K Tcritair l 33K Pi 275 KPa Pcritair Pe 105KPa Given: Process is isothermal and internally reversible ek <<0, ep <<0 air can be treated as an ideal gas 3.76 MPa P Entropy change: se si se si R ln e Pi (Te = Ti) 105 kJ 0.2763 se-si = -0.287 ln 275 KgK Heat Transfer: 9ie = T (se-si) = 360 (0.2763) qie= 99.47 T= 550k Assumptions Flow through turbine is steady Flow is uniform at the inlet and exit System at steady state kJ kg Conservation of Energy qie-Wie = he-hi = Cpave (Te-Ti) Section XIII - Irreversibility Wie= qie = 99.47 Page 70 kJ kg For an isentropic process from inlet to exit se,s–si = s e, s si R ln Pe P se,s si R ln e Pi Pi se, s 6.8852 0.287 ln he,s = 270.12 + = 273.63 T Wie,a Wie, s 105 kJ 6.6089 275 KgK (280.14 270.12)(6.6089 6.5961) (6.6326 6.5961) kJ kg 99.47 99.47 1.144 (360.58 273.63) 86.95 T is not a good measure of performance for an isothermal turbine since the isentropic process is vastly different from the actual isothermal process W Effectiveness : ie,a (or sec ond law efficiency ) Wie,rev Irreversibility dS sys Q ie I To m ( se si ) dt Tres i= q I To ( se si ) ie m Tres 99.47 kJ i 300 (0.2763) 28.62 550 kg i = wrev - wactual wrev = i + wactual = (28.62 + 99.47) = 128.09 99.47 0.777 (77.7%) 128.09 kJ kg Section XIII - Irreversibility Page 71 is a better indicator of turbine performance under isothermal conditions than T since Wrev is the maximum work that should be produced for the given conditions. Refrigerant –12 enters a steady-flow adiabatic compressor as a saturated vapour at -10°C at a rate of 18 kg/min. At the exit of the compressor the temperature and pressure of the refrigerant are 30°C and 500KPa. Calculate the power input, the compressor efficiency, and the irreversibility rate if To = 25°C. 18 kg / min m 0.3 kg / s inlet Assumptions Flow properties are uniformly distributed at the inlet and exit. ep & eK << h Adiabatic Compressor R-12 Wie Given: Flow is steady exit System boundary h i h g / T 10 C 183.058 kJ kJ , s i 0.7014 kg KgK Te = 30°C > Tsat = 15.06°C corresponding to Pe = 500KPa R-12 is superheated at the exit he = 203.814, kJ kJ , se = 0.7230 KgK kg Conservation of Energy: Q ie W ie m (he hi ) adiabatic compressor W ie m (hi he ) 0.3(183.058 203.814) 6.23 kW Section XIII - Irreversibility Page 72 Compressor Efficiency C W ie,s W ie,a If process in compressor is reversible si =se,s = 0.7014 kJ/kg K since process is also adiabatic R – 12 is superheated at e,s s g P500KPa 0.6899 kJ / kg K s e,s s e,sg h e,s 196.935 C 203.814 196.9350.7014 0.6999 197.382 kJ / kg 0.7230 0.6999 197.382 183.058 0.69 (69%) 203.814 183.058 Irreversibility Rate I T (m se m s i ) 298(0.3)(0.7230 0.7014) 1.93 kW 0 P = 500 kPa T e e T = 303 K e,s T = 288.64 K T = 263 K ie si 6.7 sp s Two kilograms of steam expands isentropically in a closed, adiabatic system from 2 MPa and 350C to a final temperature of 90C. Sketch the T-s and P-v diagrams, and calculate the work and the irreversibility for this process. (Assume T0 = 25C, P0 = 100 kPa) T1 = 350C > Tsat = 212.42C corresponding to P1 = 2 MPa steam is superheated at state (1) s1 = s2 = 6.9563 kJ/kg K s 2g T 90 C 7.4791 kJ / kg K , s 2f T 90 C 1.1925 kJ / kg K s 2f s 2 s 2g state (2) is in the liquid-vapour saturation region Section XIII - Irreversibility x2 s 2 s f2 s fg 2 Page 73 6.9563 1.1925 0.917 6.2866 T T1 = 350C P T1 = 350C P = 2.0 MPa P1 = 2MPa Tsat = 212.42C S = Const T2 = 90C Psat = 0.07 MPa s system is expanding Pdv work is done system adiabatic Q12 = 0 Process is isentropic, since adiabatic internally reversible Actual work done = Reversible Work Irreversibility = 0 First Law: Q12 W12 U 2 U1 W12 U1 U 2 u1 2859.8 kJ / kg U1 2(2758.8) 5718.6 kJ U 2 2(2318.8) 4637.6 kJ W12 5719.6 4637.6 1082 kJ T2 = 90C v