Studena Dam

advertisement

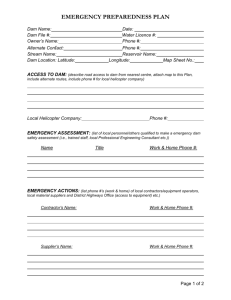

REPUBLIC OF BULGARIA MINISTRY OF REGIONAL DEVELOPMENT AND PUBLIC WORKS MUNICIPAL INFRASTRUCTURE DEVELOPMENT PROJECT ENVIRONMENT MANAGEMENT PLAN /EMP/ STUDENA DAM Sofia, December 2007 Studena Dam Environment Management Plan TABLE OF CONTENTS I INTRODUCTION p. 3 II. REVIEW OF THE INITIAL INFORMATION p. 4 III. ANALYSIS OF POSSIBLE ENVIRONMENTAL IMPACT IN THE EVENT OF REHABILITATION OF STUDENA DAM p. 7 MITIGATION MEASURES AGAINST THE ADVERSE ENVIRONMENTAL IMPACTS FROM REHABILITATION OF STUDENA DAM p. 9 V. MONITORING PLAN p. 10 VI. CONCLUSIONS AND RECOMMENDED STEPS FOR ASSURANCE OF EMP PERFORMANCE p. 11 VII. PUBLIC CONSULTATIONS AND DISCUSSIONS – DISCUSSION ON THE POSITIVE AND NEGATIVE IMPACTS, CONSULTATIONS HELD WITH ADMINISTRATIVE BODIES p. 12 IV. 2 of 27 Studena Dam Environment Management Plan І. INTRODUCTION 1.1. General The government of R. Bulgaria requested the World Bank’s assistance in financing of activities related to the Municipal Infrastructure Development Project which will help Bulgaria to comply to the European Union’s directives on potable and waste water and the environmental protection factors in the investment schemes that will be acceptable and eligible for financing from the European Union’s Structural Funds and are not covered by other EU grants. The Project, part of which is this Environment Management Plan /EMP/, encompasses the completion of water-supply dams (Neykovtsi, Plovdivtsi and Luda Yana) where construction was suspended in the last decade, and rehabilitation of the wall of an operating dam (Studena Dam), as well as rehabilitation of the water supply system of six companies providing water and sewerage services (Dobrich, Razgrad, Dobrich, Smolian, Stara Zagora and Targovishte). 1.2. Purpose of the Project The purpose of the Project is to ensure better water supply and responsible use of the water resources underlying the state policy for sustainable development of the water sector. That objective is completely in the spirit of the National Strategy of Bulgaria for Environmental Protection (2005 – 2014) that envisages „provision of good-quality water and sufficient water supply for all purposes”. The purpose of the Project will be achieved by means of improvement of the conditions of potable water supply in selected regions; ensuring the required quantity and quality of potable water; reduction of losses in the water supply network; improvement of the reliability and efficiency of water supply systems and facilities; provision for environmental requirements and regulations with respect to the systems; enhancement of the operators’ management and operating capability, etc. 1.3. Bank’s Requirements and Documents. The overall environmental category of the proposed Project is A in line with Bank policies with individual investments that belong to both category A (the proposed dam completion activities and category B (the rehabilitation of water networks). Based on the proposed Project Investments the following World Bank's safeguards policies and procedures are triggered: OP/BP 4.01 Environmental Assessment; OP/BP 4.12 Involuntary Resettlement; OP/BP 4.37 Safety of Dams; and OP/BP 7.50 Projects on International Waterways. Furthermore, adequate protection and maintenance of ecosystems downstream of the dams should be assessed during project preparation to determine the relevance of the OP/BP 4.04 Natural Habitats and OP/BP 4.36 Forestry safeguard policies. Also, given the possibility that proposed water companies might implement projects in cities with historic districts, the OPN 11.03 Cultural Property safeguard policy might be triggered. The following documents will be prepared by the Government of Bulgaria prior to project appraisal: (1) Environmental Framework of the Project (EF) for all proposed subprojects; (2) Environmental Due Diligence Report (EDR), including, in summary, assessment of the site conditions and assessment of the possible environmental impacts related to completion and operation of the proposed three dam sites; (3) Environment Management Plans (ЕМР) on investment in rehabilitation of the water distribution networks in which the contract provisions for construction works will be specified related to application of the technical standards and other requirements relevant to the construction phase. 4) project Land Acquisition Policy Framework that will outline the process to be followed in case there is land acquisition needed for the project; and (5) Social Due Diligence for the three dam sites that presents an overview of the past land acquisition process carried out by the Government. 1.4. Role of the EMP The present Environment Management Plan was developed by a Consultants Team by assignment of the Ministry of Regional Development and Public Works (MRDPW) and contains a Main Part, Explanatory Part, Contract Provisions /Annex1/ on environmental protection, Environmental Impact 3 of 27 Studena Dam Environment Management Plan Mitigation Program /Annex2/ including appropriate environmental protection measures that will help to mitigate the negative impacts arising from rehabilitation of the Studena Dam and the attendant costs, as well as an Environmental Monitoring Program /Annex 3/, pointing out to the parties in charge of the implementation of that program, their obligation to ensure adherence to all provisions related to environment and to the correct implementation of all environmental protection measures. The Monitoring Plan includes information on the inspections in the course of realization, internal and external monitoring and assessment, as well as a reporting system. The Plan presents cost estimates of the environment management measures and the time schedule of their performance. II. REVIEW OF THE INITIAL INFORMATION 2.1. Main Data on Studena Dam Rehabilitation of the dam wall of Studena qualified for financing with funds from the loan granted by the World Bank after assessment of the dam condition and its role in supplying the required quantity and quality of potable water for the town of Pernik. Studena Dam is in the valley of the river of Struma about 0,5 km upstream of the village Studena and 15 km upstream of Pernik, Sofia District. The dam was built mainly for the purpose of regulating the water of r. Struma and its tributaries, the rivers Mutnitsa and Kladnitsa for potable and service water supply, for irrigation in the region of Pernik, power generation and protection of arable lands downstream of the dam wall from floods. The dam regulates the water from its own water catchment area, and in addition the water from headrace tunnels “Vladayski” and “Palakariyski”. The Studena Water Power Works include: dam wall with spillway and stilling basin, bottom outlet with stilling basin, intake tower, penstock, power house, diversion and headrace tunnels. Dam wall The dam wall, built over the period 1950-1953 after the design of “Energohydroproject” is a massive Noetzli type saddle-dam. The dam fill consists of 26 concrete blocks. The low blocks at the two sides of the dam are solid. In the abutment of the upstream batter, there is a tooth with maximum depth in the river bed, reaching elevation 775. A grouting gallery runs in the lower part of the tooth. From there, a single-tier grout curtain is made. The curtain reaches 22 below the foot of the wall. The main parameters of the dam wall and the reservoir are: Dam wall type Maximum height Foundation width Crest length Crest width Buttress width Total concrete volume Concrete brand Total storage reservoir: - at spillway elevation - at roller gate elevation Unavailable capacity Water catchment area: - area incl. diversion systems - mean altitude Mean annual influx Area ponded up to elevation 840 Crest elevation Elevation at balustrade Elevation at highest operating water level (HOWL) concrete saddle dam 55 m 53 m 259 m 7,00 m 9 m 125 000 m3 В 9 and В 11 20,62.106 m3 22,22.106 m3 1,30.106 m3 144,30 km3 1255 m 58,22.106 m 1416 dca 845,00 846,00 843,00 4 of 27 Studena Dam Elevation at highest water level (HWL) Elevation lowest operating water level (LOWL) Elevation at lowest water level (LWL) Environment Management Plan 843,30 816,00 813,00 According to the applicable “Hydro-Engineering Facility Classification” the dam wall is of the 2nd class. It is situated in a region of 8th degree seismicity. Spillway The spillway is a front-side profile built upon four central blocks of the wall. It consists of three overflow bay with total overflow width 22,80 m. After revision of the high flood estimates, the overflow body was built over with bulkhead gates. It is designed to let through a retention flood amounting to 250 m3/s with probability of occurrence coefficient Qp 0,1% at overflow height 3,30 m. The spillway chute is situated on the downstream batter surface. The stilling basin is of a disspiating type. Bottom outlet A bottom outlet has been built for draining of the dam in emergencies – two Ø1000 mm steel pipes. Each pipe can drain the lake in 30 days. The water flows out into a rectangular stilling basin between the buttresses and, through a side weir, enters the spillway stilling basin. Intake tower The intake tower is a vertical cylinder situated on the right-hand slope. Water intake takes place through five levels at 5 m intervals. Penstock The penstock consists of a tunnel with diameter 1,60 m, with 0,30 cm thick reinforced-concrete lining. At 33,50 m from the tower, the tunnel extends into a 1100 mm steel pressure pipeline, with length 280 m. HPP Studena The hydro-power plant (HPP) includes two horizontal-shaft Francis turbines, for a total capacity of 2 m3/s, 780 кW. It can operate at fall heights varying from 25 to 51 m. Diversion Tunnel The water from the discharge channel of HPP Studena is directed through a diversion tunnel with total length 8 455 m. Seven siphons with total length 2 355 m have been built along the tunnel route to Pernik. Headrace Tunnels The following two gravity-flow conduits have been built for additional water feeding of the dam beside its own water catchment: the “Vladayski” tunnel with water catchment area 32 m2, collecting water from the north-east part of Vitosha mountain with main water intakes on the rivers Vladayska and Rudarska. The length of the tunnel is 13400 m, its throughput capacity - up to 2 m3/s, and 8 captations. In an year with average precipitations the tunnel feeds about 15.106m3 of water in Studena Dam. “Palakariyski” tunnel collects water from the river Palakaria and the upper parts of Vitosha, with water catchment area 8,87 km2. The tunnel length is 8,800 m and throughput reaching 0,9 m3/s. It can feed 3,63.106m3/year of water to Studena Dam. Ponding of the dam started in 1954. That was also the time of the first observations and measurements of processes taking place in the dam wall – infiltration and water rise since 1954, and strains since 1955. A rich experience was accumulated over an operation period exceeding 50 years from observations of the dam wall behavior. 2.2. Management and Operation of Studena Dam The facility is managed by Water and Sewerage Company W&S LLC of the town of Pernik. The maintenance and operation of Studena Water Power Works (WPW) consist of the following main activities: 5 of 27 Studena Dam Environment Management Plan Measurements and inspection of the dam and related facilities The technical condition of the wall is monitored by means of inspections and measurements using the installed Control and Instrumentation (C&I) System. Full and operative measurements of current phenomena – displacements, strain, filtration, movement of cracks and joints, temperature variations, water level changes, etc. – are carried out. Displacements are detected at measurement points on the dam crest, in the buttress foundations, in one reference point on the intake tower, as well as by plummets and measurement of cracks and joints. Full geodetic surveys are performed once in a month. The operative measurements include vertical displacements once a week, and horizontal displacement twice a week. Maintenance and repair Maintenance is carried out, in conformity with the organization schedule, of: the two bottom outlets, the spillway caissons, the intake tower adits, the penstock from the intake tower to Studena HPP consisting of tunnel and steel pressure pipeline with its shutting devices (follower-ring valve and throttle valve, and expansion joints for compensation of temperature deformations), of the Studena HPP in an operating water supply mode, Vladayski headrace tunnel and its water intakes, Palakariyski headrace tunnel and its water intakes. The Water and Sewerage Company W&S LLC - Pernik produces annual reports, and every three years independent experts make analysis and assessment of the dam condition. Their report is reviewed by a Technical Expert Board of the Ministry of Regional Development and Public Works (MRDPW). All these 50 years the dam operated without any variations in its operating mode. 2.3. Condition of Studena Dam Upon the experts’ visit to Studena Dam on 05.09.2007, the following was found: heavily corroded torcrete on the surface of the downstream batter; water penetrating into the wall through the expansion joints; the expansion joints are damaged and need repair; the upstream batter waterproofing is badly cracked and detached from the concrete surface in places; the wall crest is seriously damaged – the reinforced-concrete balustrades are damaged along about 70% of the crest length, sidewalks and dripstones are crumbled, the paving is badly distorted which threatens the stability of the geodetic benchmarks erected on the crest; the railings of the transition bridge to the intake tower are badly damaged, with large holes in the structure and cannot serve to protect the staff from falling in the water during dispatch of their duties; there are no data about the condition of the concrete or metal structures in the underwater parts of the tower; visible stains from chemical suffusion of the in the grouting gallery walls and deteriorated water tightness of the joints in the gallery; colmated (clogged) drain holes and piezometers in the gallery due to which it is impossible to obtain true information about seepage under the wall and the water rise along the wall-foundation contact surface. The rehabilitation program for Studena Dam includes: injecting of the contact zone in the grouting gallery, concrete injecting, checking the grout curtain, drain hole reconstruction, in-depth treatment of the concrete with cement and polymer compounds, torcreting of the downstream batter, upstream batter waterproofing, repair of the dam wall superstructure, penstock repair, repair of mud traps and ventouses along the headrace tunnel, dissipation basin repair, river bed regulation, installation of an I&C system. The Water and Sewerage Company W&S LLC – Pernik has not developed a schedule for rehabilitation and has not detailed the work types for repair works at each site. The access route to the dam is defined (the part of Strouma Highway currently used, and a sector of the national road network). Detailed elaborations will be produced after the financing arrangements are clarified. Financing, machines and transport vehicles have been provided for each of the contemplated activities, as well as software for the measuring and control instruments. The rehabilitation of Studena Dam will be performed only on the dam wall from stages used for its operation (at the dam crest, below the downstream batter and at the power house). The rehabilitation works will not affect the bordering areas. Cutting of ligneous vegetation or disturbance of habitats, 6 of 27 Studena Dam Environment Management Plan etc., are not necessary. The environment around the dam was developed thanks to phased recultivation since 1953. The dam (the lake tail) is situated outside the boundaries of Vitosha Natural Park included in Natura 2000. The Hunters & Anglers’ Association is performing fish stocking at 1000 m from the dam on the basis of granted permit. (Appendix: Dam situation, layout of drain boreholes 1:1000, C&I layout plan, intake and diversion facility cross section, photo) III. ANALYSIS OF POSSIBLE ENVIRONMENTAL IMPACTS IN THE EVENT OF REHABILITATION OF STUDENA DAM The financing project for rehabilitation of Studena Dam covers rehabilitation of the dam wall and the related facilities. 3.1. Positive Impacts The positive impacts are related to a basic property of dam walls, their “longevity”. With the performance of repair operations, the design parameters of facilities are restored, and their safe operation under normal, extreme and accident conditions is secured for a long service life. The dam wall is upstream of the village Studena and Pernik, therefore the rehabilitation works guarantee also the population’s safety in emergencies, as well as uninterrupted potable water supply to Pernik which is extremely important for the health and quality of life of its residents. 3.2. Negative impacts The possible negative impacts due to rehabilitation of Studena Dam can be considered for the time of construction only. It will be performed outside the settlements in an anthropogenically affected territory (only at the dam itself and its facilities). Organization of repair operations At Studena Dam, there are ready service bays at the downstream batter toe, the dam crest and along the penstock, that will be used during the rehabilitation. The water supply to Pernik will not be disturbed with the exception of the upstream batter repair – placing of waterproofing, for which a special organization plan and technology have to be developed, as well as coordination with Danubian Area Basin Directorate in Pleven; 3.3. Negative impact on the environmental components and factors during construction 3.3.1. Atmospheric Air The repair operations (part of which will be on the dam bulk, others on the crest, stilling basin and downstream batter (torcreting)) will generate dust and rebounding particles of the torcreting material. There will be air pollution solely at the work site, so precautions and protection devices for the workers have to be adopted. There will be no impact on the population. The transport vehicles with building material and waste will not pass through Pernik or the village Studena, but will use the Strouma Highway and an access road to the dam. 3.3.2. Water All the effluents from the repair operations will be released into the stilling basin downstream of the spillway where the large-size impurities will settle, after which they will be discharged into the Strouma. The conditions that have been prevailing in the lower course during the 50-year long dam operation will be preserved the same. 3.3.3. Soils No soils will be disturbed during the rehabilitation works. All works will be done at the facilities, and to some of them there are existing roads. 3.3.4. Geological Conditions The purpose of the rehabilitation is to reduce infiltration under, around and through the wall whereby the dam wall stability will improve and water losses will be limited. 3.3.5. Waste 7 of 27 Studena Dam Environment Management Plan Insignificant quantities of waste will be generated during the repair operations keeping in mind that the efforts will be aimed at full utilization of the building materials. All wastes are defined in conformity with Regulation No. 3/01.04.2004. on waste classification. Studena Dam already has a system for collection, transportation and disposal of the domestic waste and construction debris at the Pernik Landfill, as well as delivery of waste oils for recycling to licensed firms. In the event of generation of hazardous waste with code “*” a firm possessing a license for their treatment is contracted. 3.3.6. Noise, Vibrations The machines used for performance of the rehabilitation works: drilling machines, injecting equipment, torcreting, concrete placing, produce noise levels 80 dBA – 92 dBA. The noise and vibrations will affect the construction workers and machine operators, i.e., within the work site boundaries. The vehicles can reach the main road without crossing any settlements. No areas with “special noise level conditions” will be affected. 3.3.7. Flora Since the rehabilitation works will be done at the facilities with available access to each of them, no ligneous or herbaceous vegetation will be disturbed. 3.3.8. Fauna No habitats will be destroyed during the rehabilitation works with the exception of upstream batter waterproofing. The only specific decision will be that about protection of the ichtiofauna during the repair of the upstream batter. It will result from the adopted organization plan and the waterproofing technology. Due to the permitted fish stocking of the lake, the plan of upstream batter repair will probably provide for performance of the construction work under water. 3.3.9. Landscape The dam wall of Studena is a component of an anthropogenically influenced landscape after more than 50 years of operation. It is perceived as a natural part of the environment. Its architecture, recultivation of disturbed lands, afforestation are proofs that dam walls can successfully fit into the natural landscape. The rehabilitation works will improve the visual impression of the wall. 3.3.10. Health Factor The rehabilitation of Studena Dam is localized within the work environment without affecting any adjacent territories or settlements. Therefore, the impacts will be felt only by the workers. During the construction works, a number of factors of the work environment and the labor process may have an adverse health effect, namely: Unfavorable microclimate. Work will go on for four seasons, inside the wall and, most of the time, on the wall, therefore, in an overheating or overcooling microclimate. The overheating microclimate bears a risk of occurrence of incidents such as a heat or sun shock. In the case of chronic exposure that leads to dehydration, depletion of salts and microelements and heat-induced exhaustion. The overcooling microclimate increases the frequency of colds, diseases of the skeletal-muscular and peripheral nervous systems.. Noise. The drivers of heavy-duty vehicles will be exposed to excessive noise levels of the order 80-90 to 100 dBA. The people working on the “rigs” or “carriages” during injection and drilling works will also be exposed to excessive noise. The excessive noise level has an adverse effect on the hearing system and may result in development of professional hard hearing. Noise has an adverse effect on the central nervous system, resulting in derangement of the sleep, development of neurosis-like conditions, and is a risk factor for development of arterial hypertension. Vibrations. The drivers of heavy-duty vehicles will be exposed to general and local vibrations. With the new, modern technology they may remain within the permissible limits. The people working on the “rigs” or “carriages” are also exposed to excessive local vibrations (for a comparatively short contact). The excessive levels of general vibrations may result in damage of the vestibulary system, the locomotory system, damages of the parenchimal organs and development of a vibration disease. The local vibrations harm the sensory and blood circulation system of the fingers. 8 of 27 Studena Dam Environment Management Plan Air pollution. The drivers of heavy-duty vehicles will be exposed to exhaust gases. No adverse health effect is expected during work in the open. Traumatism. The construction workers engaged in excavation and erection works, the work of “climbers” on the waterproofing, are at the highest risk of labor traumatism. Physical strain. In spite of the machines available for most of the construction works, part of them still require physical strain, lifting and carrying of excessive loads. Another adverse factor in many of the works is that they have to be performed in an unfavorable position and with considerable static stress on the body and limb muscles. That results in microtraumas, diseases of the locomotory system and the nervous-muscular system. During the construction works, the factors of the working environment may have certain impact on the workers’ health. The effect will be temporary and, if measures for protection of workers’ health and safety are adopted, minimal. The repair operations will have no adverse health effect on the population. 3.3.11 Common Heritage There are no historical monuments in the vicinity of the dam. Building materials will be supplied from industrial zones (possibly from the village Studena or Pernik) outside the boundaries of any settlements connected to main roads and to the national road network. Along the course of the Strouma, there are no monuments of common heritage that can be affected during the prospective or future operation of the dam (the dam has been operated for 54 years). There are no declared monuments of cultural heritage in Studena or in Pernik. All construction work impacts are localized on the construction sites. They are temporary, short (only for the time of construction), direct, without a cumulative effect. After completion of the rehabilitation of Studena Dam its operation will not be a source of environmental impact different from the previous one. Its operation will continue according to the work schedule followed so far, while the rehabilitation will provide to the operator, the Water and Sewerage Company W&S LLC – Pernik, opportunities for improvement of the facility management, and hence – of the dam and reservoir operation. IV. MITIGATION MEASURES AGAINST THE ADVERSE ENVIRONMENTAL IMPACTS RESULTING FROM REHABILITATION OF STUDENA DAM The present EMP contains measures for mitigation of the negative environmental impact that will be implemented in the course of project performance: 4.1. Discharge all waste waters into the stilling basin downstream of the spillway for settling before releasing them in the Strouma; 4.2. Develop a special organization plan and technology for waterproofing of the upstream batter of Studena Dam; 4.3. Waste from the repair operations shall be treated in conformity with the Waste Management Act requirements; 4.4. Monitor the technical condition of the building machines and transport vehicles for oil leaks; In the event of pollution, perform pollutant sequestration; 4.5. Prevent or minimize “idle running” of the machines; 4.6. Use the existing water piping and sewerage system at the Studena dam wall; construction workers shall use the facilities of the dam – canteen, staff rooms, etc.; 4.7. In order to reduce the harm from unfavorable microclimate, the workers shall be provided with work clothes appropriate for the season; 9 of 27 Studena Dam Environment Management Plan 4.8. In order to contain the impact of physical factors in the work environment, the workers shall be provided with personal protection devices – dust masks, anti-vibration gloves, life belts, etc., depending on the specifics of work; 4.9. In compliance with applicable regulations (with a view to reducing the physical strain, overfatigue and development of skeletal-muscular diseases), introduce schedules of work and breaks during the working days. According to the Bulgarian legislation (Appendix: Regulation Acts) the use of aggregate materials, concrete mixes and asphalt products shall be permitted solely to enterprises possessing the respective licenses for their extraction and production. With respect to waste, the provisions of the Waste Management Act shall be met at all phases of construction. The impact mitigation measures related to investments in rehabilitation will be included in the Technical Specification to the Rehabilitation Contract. Contract support is a necessary condition assuring that the Contractor will adopt all required environmental protection measures on and off the site and to limit the damages and inconvenience to people that may arise from the construction works. Through implementation of the indicated measures, the Contractor shall make sure that the air emissions, surface run-off, treated waste water, etc., resulting from its activity do not exceed the levels indicated in the applicable law (Appendix: Regulation Acts). Preservation of the natural components is achieved through establishment of integration relations with the anthropogenic landscape components which, at the same time, will result in improvement of the visual aesthetic value of the environment. One important prerequisite for successful performance of the rehabilitation measures is coordinated action together with the local and municipal authorities and the competent bodies in charge of environmental protection and public health. With the approval of RIEW – Sofia, and whenever possible, 160 l/s is released from Studena Dam for flooding of the river bed downstream of the dam. V. MONITORING PLAN The contemplated model of monitoring the implementation of the environmental impact mitigation measures was adopted so as to cover all aspects and requirements in conformity with the law and good engineering practice. Monitoring and control during the construction phase: The adopted form of monitoring (Annex 3) includes a specific description of the monitoring measures and is designed to cover all aspects in the construction process (related to the adverse impact mitigation measures proposed in the adverse impact mitigation plan) with the parameters to be measured, methods to be applied, points of sampling, measurement intervals, concrete description of the organizational structures and reporting procedures. The data obtained from monitoring will be used to adopt adequate measures during the repair for the purpose of protecting the workers’ health and lives. As required, RIEW-Sofia, RIPCPH, Danubian Region BD – Pleven will be involved. Monitoring and control during the operation phase: The monitoring during operation shall be carried out in conformity with the Company’s approved Own Monitoring Plan. EMP Implementation organization and reporting: Monitoring and reporting will be applied in full by the Contractor’s management. The Contractor shall exercise everyday monitoring of the normal environmental practices by presentation of regular reports. 10 of 27 Studena Dam Environment Management Plan These reports shall be addressed to the institutions indicated in the normative requirements and once in a month – to the Employer /Engineer/. The Contractor shall appoint its specialist in charge of the environmental aspects of the Project. The Engineer auditing the process will report on the performance of environmental impact mitigation measures included in the Technical Specification to the Contract; on the correct understanding and application of EMP by the Contractor; on assurance of the relevant steps; on keeping correct record of any discrepancies, on the conducting of briefing and training, emergency aid measures, and shall evaluate and correct the Contractor’s reports. The Engineer shall report on the EMP performance and progress to the Employer every month. The respective government institutions will be involved in auditing of all environmental protection and social measures and the progress on the Project by receiving regular reports in conformity with the normative requirements. The Project Management Unit (PMU) established at the MRDPW shall keep and store the documentation required by law and by contract. On the basis of the Engineer’s reports and site visits as required, EMP performance and progress reports will be presented to the World Bank every six months. Institutional Responsibilities in Implementation of the Environment Management Plan Impact mitigation and monitoring responsibilities Reporting relations and frequency MRDPW (Employer) RIEW – V. Tirnovo RIPCPH MOEW (IAE – depending on whether the dam is covered by the national monitoring during operation) Contractor to the Engineer (monthly); The Engineer to MRDPW, to RIEW /quarterly/; PMU at MRDPW to the Bank (every 6 months) Decision making on EMP /on start of action, expense authorization, completion/ Responsible institutions Activities and persons Monitoring of EMP Engineer Supervisor, performance. contact person appointed by Employer /MRDPW/; RIEW; MoEW; RIPCPH VІ. CONCLUSIONS AND RECOMMENDED STEPS FOR ASSURANCE OF EMP PERFORMANCE The Environment Management Plan is in conformity with the requirements for assuring normal operation of high-risk infrastructure elements such as dam walls. According to the developed Environmental Impact Mitigation Program (Annex 2) and Environmental Monitoring Program (Annex 3), the Contractor is not required to provide additional facilities (for performance of the proposed mitigation measures) requiring significant expenses. The recommended steps needed to ensure performance of the EMP are: A. Provide for funds for implementation of the adverse impact mitigation measures and EMP performance monitoring by including it in the Technical Specifications to the Construction Contract. B. Obtain the Contractor’s correct understanding of the steps and resources required for environment management, the required steps and measures being evaluated and offered. C. D. Discuss the EMP at preliminary clarification sessions. After signing of the Contract, the Employer shall officially familiarize the Contractor with the prevention and impact mitigation by means of the EMP included in the Contract and the implementation of monitoring. 11 of 27 Studena Dam Environment Management Plan The main problems, conclusions, recommendations and negative impact mitigation measures are defined in conformity with the objectives set in the Terms of Reference. In the longer term, with the proposed investment projects, EMP implementation and through application of good engineering practices for optimization of the set of activities in the process of producing and supply of drinking and washing water to the population, the objectives of responsible use of water resources set in the government’s policy for sustainable development of the water sector are achieved without any risk to the environment and with a beneficial effect on the life quality of the population, which leads to the conclusion that the Project is beneficial. VII. PUBLIC CONSULTATIONS AND DISCUSSIONS – DISCUSSION ON THE POSITIVE AND NEGATIVE IMPACTS, CONSULTATIONS HELD WITH ADMINISTRATIVE BODIES In connection with the Municipal Infrastructure Improvement Project and more particularly, with implementation of rehabilitation of Studena Dam funded from a World Bank loan, the Environment Management Plan was announced to the public at the W&S LLC – Pernik and at the Municipality of Pernik on 22.10.2007. Besides, consultations were held with administrative bodies as follows: Pernik Municipality. A meeting with the Mayor of the Municipality Dipl. Eng. A. Georgieva. The Town Council emphasized the extreme importance of contemplated rehabilitation works for the reliability of water supply in the town (Appendix: Position Paper); W&S LLC Pernik. Meeting with Dipl. Eng. Ivan Kovachev. W&S LLC is the proponent of the repair operations and bears the responsibility for the normal operation of Studena Dam, for which reason it supports them. No objections or recommendations were received within the 14-days time limits set for such steps. The EMP was promulgated on the web site of MRDPW and on Infoshop in Washington, the USA. Studena Dam is one of the dams with the longest operation time in Bulgaria – 54 years, and the above-discussed rehabilitation operations are indispensable. 12 of 27 Studena Dam Environment Management Plan LIST OF ABBREVIATIONS USED BD Basin Directorate W&S Water Supply and Sewerage TTM Temporary Traffic Management MDT Main diversion tunnel EU European Union HSLC Healthy and safe labor conditions EPA Environmental Protection Act IAE Implementation Agency for Environment IAE Implementation Agency for Environment C&I Controls and Instrumentation MIA Ministry of Internal Affairs MoEW Ministry of Environment and Water MRDPW Ministry of Regional Development and Public Works EIA Environmental Impact Assessment FAS Fire and accident safety SHP Safety and Health Plan RIEW Regional Inspectorate of Environment and Water RIPCPH Regional Inspectorate for Protection and Control of Public Health WPW Water Power Works 13 of 27 Studena Dam Environment Management Plan APPENDICES 1. Situation of Studena Dam 2. Layout of Drain Boreholes 1:1 000 3. C&I arrangement 4. Cross Section of the Intake facility and Pressure Diversion Tunnel 5. Photo 6. Annex 1 – Contract Provisions 7. Annex 2 – Environmental Impact Mitigation Plan 8. Annex 3 – Monitoring Plan 9. List of Regulation Acts applicable to the Project 14 of 27 Studena Dam Environment Management Plan 15 of 27 Studena Dam Environment Management Plan 16 of 27 Studena Dam Environment Management Plan 17 of 27 Studena Dam Environment Management Plan ANNEX 1 Contract Provisions This Annex describes the environmental mitigation requirements to be followed by the Contractor and measures to be carried out by the Contractor(s) related to environmental protection which will be included in the performance Contract. General The Contractor shall adopt all measures to protect the environment on the construction site as well as off the site, and to limit the damage and inconvenience to people and property due to pollution, noise, and other consequences of its acts. The Contractor’s activity shall be in conformity with the requirements of all Bulgarian laws and bylaws related to environmental protection. The technology of work performance proposed by the Contractor shall be in conformity with the Environment Management Plan. The Contractor shall submit an Environmental Impact Mitigation Program and a program of monitoring the performance of the respective measures based on the provisions in this Environment Management Plan /Annex2 and Annex 3 to it/, prepared at the Conceptual Design Phase and included in the Technical Specifications of the Contract. The Contractor shall make sure that the air emissions, surface run-off, treated waste water, etc., resulting from its activity do not exceed the levels indicated in the applicable law. The Contractor shall provide the means, information, consumables, certified teams, tools and manpower needed for efficient test runs (sampling) wherever required. The Contractor shall nominate one of his senior staff members to be responsible for follow-up of the implementation of the provisions of the environmental plan as well as for the guidance of the rest of the staff and reporting to the Engineer. The Engineer shall be in charge of monitoring and verification of the overall construction compliance to the Environmental Impact Mitigation Plan and of the absence of any deviations from it or from the Contract. The Engineer shall have the right to interrupt the Contractor’s work if the conditions of the approved environmental plan are not met. Permits The Contractor shall be in charge of drawing up and approval of the documentation and site-specific information: technologies and methodologies utilized by the Contractor; specification of basic materials for potable water supply and of the natural resources to be used (quantity and quality): i.e. all raw material, including gravel, fill, and bituminous materials as well as fuel and energy; specification of final work output; list and characteristics of harmful substances generated by the Contractor in the construction process, if any; ; investigation and obtaining of directions for disposal of humus and/or spoil material and/or construction debris from the construction site; particular measures ensuing from the climate conditions in the region of rehabilitation works; specification of water supply sources and treatment of waste water; emissions from construction equipment and transport vehicles. The Contractor shall make arrangements for regular collection and removal of the solid waste from the construction site and construction camps to the agreed disposal site. Since the construction takes place at the site of an operating dam the solid waste can be included in the Waste Management Plan of the dam. In the event of generation of hazardous waste bearing the code “*” the Contractor shall contract a firm possessing a license for its treatment. Protection of Ligneous Vegetation The rehabilitation of Studena Dam does not affect any ligneous vegetation. It will be performed on the upstream and downstream batters of the dam, in the grouting gallery and the penstock. Access is 18 of 27 Studena Dam Environment Management Plan available to all facilities and the national road network will be used for transportation of materials and waste to the disposal site. Noise control The Contractor shall follow all the existing laws and regulations concerning the noise control and limiting. Due to the nature of rehabilitation, the noise is limited within the work environment. The Contractor shall adopt effective measures both in management and technology to minimize noise, such as: maintain the machines and plants used in good repair; idle running of vehicles and building machines shall not be allowed. The equipment shall be concentrated on the work sites only. Dust control The Contractor shall follow all the existing laws and regulations concerning the mitigation of dust impact on the environment in construction works and propose and follow measures for control of that parameter. The Contractor shall submit and coordinate a plan indicating the proposed routes for aggregate material or construction debris transport. The Contractor shall suppress the dust generated during operation of the equipment, cover the transport vehicles delivering aggregate material, sprinkle water at the sites and during earth works. Deviation and Traffic Measures: Temporary Traffic Management Plan The applicable Bulgarian regulation requires from persons performing construction or repair works to undertake steps to design and apply a Temporary Traffic Management Plan (TTM). In most cases, the Temporary Traffic Management Plan is prepared in advance as part of the Investment Project, and delivered to the Contractor together with the Water Supply Detailed Engineering Design of the rehabilitation. The Draft TTM Plan shall be reviewed by the Republic’s Road Infrastructure Fund (considering that a highway and a part of the national road network are used) as well as the control authorities of the Ministry of Internal Affairs minimum 15 days before the commencement of construction. Where the Plan is drawn up by the Contractor, besides the approval of the above-mentioned institutions, the Engineer’s approval shall be obtained within 28 days prior to the commencement of the construction. Where a Temporary Traffic Management Plan is prepared in advance as part of the Investment Project, all activities related to its implementation will be known in advance before the date of submission of the construction performance proposals and their detailed inclusion in the Bill of Quantities will be possible. In the event that the Contractor will be in charge of preparation and implementation of the TTM Plan, it can be included in the Bill of Quantities only as general items. Soil Erosion There will be no construction works that can cause soil erosion. Materials The Contractor shall meet the following general requirements towards the construction supplies used: they shall be of an origin indicated in advance, established and meeting the normative requirements shall be evaluated as complying with the substantial requirements to rehabilitation and meet the Technical Specifications in conformity with applicable legislation; and shall be accompanied with relevant documents (statements of compliance, certificates of compliance, test reports, etc.), evidencing their conformity with the normative regulations. Aggregate materials for backfilling (sand, gravel, rubble), beside the above-listed, shall be accompanied by a certificate evidencing that the borrow pits by which they are supplied possesses the needed license for their extraction. At the construction site, materials shall be kept in the designated locations to avoid possible pollution of soil, water courses, etc. 19 of 27 Studena Dam Environment Management Plan Protection of Water Resources and Soils The Contractor shall carry the full administrative and legal responsibility for any pollution of surface waters and soils according to the existing legislation, caused by its acts. For the purpose all construction effluents shall be discharged into the stilling basin below the spillway and then released into the river. The Contractor shall ensure that no oil products, fuel, lubricants, detergents, paint or other harmful substances are introduced into the soil, streams and irrigation or basins. Filling or service maintenance of any machinery or transport vehicles shall be restricted to the nearest filling station. In the event that filling has to be performed on the construction site, the appropriate devices shall be used. The discharge of oil and fuel onto open soils is prohibited. For prevention of accidental oil leaks, the technical condition of the machines shall be checked every month. Without overruling the above requirements, the Contractor shall submit to the Engineer an emergency action plan for hazardous spills and leakage, subject for approval before commencement of the works. The Contractor shall submit in writing to the Engineer the locations of the installations related to the provision of water, fuel, construction mixes, drainage, etc., and the distances to the nearest water supply, irrigation or draining facilities, particular green or protected areas. The above-said applies to both the construction site and the construction camp for the Contractor’s staff. The nearest existing toilets or chemical toilets shall be used in the construction sites or at the workers’ camps. The direct discharge of sewage from worker’s camps into any water basin is prohibited. Health, Safety and Accidents The Contractor shall undertake at any time all precautions required and relevant to securing the health and safety of all persons that have the right to be on the construction site and near it, and adhere to all applicable safety procedures, including fire and accident safety, safety of electrical installations, safe operation of higher-risk plants, blasting and fire works etc. The applicable Bulgarian legislation (Regulation No. 2 / 22.03.2004 on meeting the minimum requirements for healthy and safe labor conditions during construction and erection works) requires preparation of a Health and Safety Plan (HSF) for construction involving risks defined in the Regulation at the investment project phase, providing for all necessary construction management and performance measures guaranteeing its safe performance. According to the applicable regulation a SHF shall contain: Organization Plan; Layout Plan; an Integrated project schedule of the sequence of Construction and Erection Works (CEW); Fire and accident prevention and fighting plans and plans for evacuation of the workers and persons present at the construction site; Safety and health measures and requirements applied to performance of CEW, inclusive of specific-risk sites; A list of plants, machines and facilities subject to control; A list of the persons in charge (with names, positions, employer) of supervision and review of individual builders’ plans concerning specific-risk sites, and of evacuation, drills and/or training; diagram of the temporary traffic management and safety in the transport and evacuation routes and pedestrian catwalks and crossings on the construction site and access roads; layout of the points on the construction site where two or more builders will work; layout of the specific-risk points on the construction site; layout of the points of erection of lifting equipment and scaffolding; layout of the points on of storage of building supplies and equipment, temporary site workshops and waste containers; layout of the locations of staff rooms; layout of the utilities; plan and operation schedule of the temporary artificial lighting on the construction site and at work sites; diagram and type of disaster, accident, fire or emergency alarm devices, with a site designed for first-aid provision. According to the same Regulation preparation of the SHF is assigned by the Employer as part of the investment Project, and the Contractor is in charge of its application and updating in the course of construction. Provision, update review, or absence of a HSF plan does not relieve the Contractor of any responsibilities to ensure the safety and health of its employees, subcontractors or any other persons on the site, or of its obligations by force of the applicable Regulation pertaining to: risk assessment during the construction; development and updating of safety & health instructions depending on the specific conditions on the construction site by CEW types and in the cases required by the applicable legislation; the provision of protective clothing and equipment in accordance with the regulatory 20 of 27 Studena Dam Environment Management Plan framework; provision of initial and regular instruction on healthy and safe labor conditions (HSLC) to the employees; defining, in written job descriptions, the senior staff’s (engineering managers, foremen, etc.) responsibilities as well as the responsibilities of persons in charge of risk elimination in the process of work, endowed with the powers and resources needed for that purpose; the provision of a qualified officer as HSLC Officer/Coordinator who has specific knowledge of safety regulations, and experience of safety precautions and who shall advise on all matters affecting the safety of workers, subcontractors and supervising officers; the provision of safety maintenance of the facilities and equipment (electrical and lifting equipment, building machines, transport vehicles, etc.) and their continuous monitoring with a view to elimination of defects that might affect the employees’ safety and health or the environment; adherence to Bulgarian legislation on fire protection and preparation of a fire prevention and fighting plan subject to the Engineer’s approval; the provision of latrines in conformity with the sanitary and hygiene requirements and fire and accident safety (FAS) requirements; the provision of instruction on handling of various materials, storage and disposal of used hazardous materials; the provision of collection, storage and transportation of waste and debris; the provision and maintenance of access to all points on the site in a safe condition free of injury risk; the provision of joint work of construction workers and free-lance employees, if any; the provision of collaboration with the industries in the region of or near the construction site; the provision of first-aid facilities for persons injured in an industrial accident, fire, disaster or incident; adoption of additional measures for the employees working in the open in adverse weather conditions; good order and cleanliness on the construction site; The safety officer/coordinator appointed by the Contractor shall have the power to receive instructions from the Engineer on matters relating to the health and safety of personnel on Site and the safe conduct of site operations. The Contractor shall send to the Engineer details on every accident as soon as possible after its occurrence. The Contractor shall keep a log book and produce reports on people’s safety, health and security as well as on damages inflicted on property as the Engineer may reasonably request. Cultural Heritage: Historical, Architectural and Archeological Not applicable. Social Issues The Contractor shall adhere to all labor laws applicable to the Contractors’ staff, including the laws pertaining to its employment, health, security, welfare, emigration or immigration and will provide for all its legitimate rights. The Contractor shall demand from its employees adherence to all applicable laws including those pertaining to labor safety. The Contractor shall not disturb, without any need for it or in an inappropriate manner, the community’s comfort. The Contractor shall adopt, at any moment, all precautions to prevent unlawful or unruly behavior and violations of the order by or among the Contractor’s staff as well as for preservation of peace and protection of persons and property near the Site against such behavior. Beside the mitigation measures against the adverse impacts on the environment due to performance of the Project listed in other subsections, the Contractor should take the following requirements into consideration: The operations conducted shall be adapted to the uninterrupted operating mode of the water supply system taking into consideration that Studena Dam is the only water source for Pernik; interruptions scheduled by way of exception of water supply shall be conducted after notification of the residents concerned; Alternative water supply shall be provided upon water supply interruptions lasting longer than the one instructed by the Operator of the W&S system. Supervision and Monitoring Without relieving the Contractor of its obligation for permanent compliance control, the Engineer will be in charge of the monitoring and verification of compliance of the overall construction work with the Environmental Impact Mitigation Plan and of making sure that there are no deviations from it or from the Contract. 21 of 27 Studena Dam Environment Management Plan Payment All costs associated with environmental protection will be considered as being covered by the overall payments specified in the Construction Contract. All costs entailed in sampling and testing for environmental purposes shall be deemed to be included in the prices and rates entered by the Contractor in the Bill of Quantities. 22 of 27 ANNEX 2. ENVIRONMENTAL IMPACT MITIGATION PLAN REHABILITATION OF STUDENA DAM Impact on: Impact Mitigation Measure Place and time of performance Implementation Funds Person in Charge Control functions performed by: 1 2 3 4 5 6 Monitor the technical condition of building machines and transport vehicles On the work sites; permanently No additional funds are required. The Contractor The Engineer Prevent or minimize “idle running” of the machines; On the work sites; permanently No funds are required. The Contractor The Engineer Atmospheric Air Use the existing water piping and sewerage system at the Studena dam wall; construction workers shall use the facilities of the dam – canteen, staff rooms, and chemical toiletes as required; Ensure discharge of all effluents to the spillway stilling basin for their precipitation before releasing them in r. Strouma Water Waste Landscape On work sites; permanently From every construction site, permanently If chemical toilets are required-acc.to The Contractor the contract with the maintaining firm Included in the contract cost Develop a special plan of management and technology of On the upstream Included in the placing of the waterproofing on the upstream matter of the batter; during rehabilitation cost dam and coordinate it with the Danubian Region BD project Pleven performance The requirements of the Waste Management Act shall be On every work site; Included in the met and the organizational structure created during the dam permanently rehabilitation costs operation shall be used Monitor the condition of the building machines and On work sites, Included in the costs transport vehicles for oil leaks; In the event of pollution, national road of machine fleet perform pollutant sequestration; network; maintenance; permanently Sequestration cost acc.to actual the work volume In order to reduce the harm from unfavorable microclimate, On every work site; Included in the the workers shall be provided with work clothes appropriate permanently rehabilitation costs for the season; The Engineer; The Contractor The Engineer, RIEW The Contractor MoEW, RIEW, Danubian Region BD – Pleven, the Engineer The Contractor RIEW, the Engineer The Contractor The Engineer; National Road Infrastructurr The Contractor The Engineer Studena Dam Health Factor Environment Management Plan In order to contain the impact of physical factors in the On every work site; work environment, the workers shall be provided with permanently personal protection devices – dust masks, anti-vibration gloves, life belts, etc., depending on the specifics of work; Included in the rehabilitation costs The Contractor The Engineer In compliance with applicable regulations (with a view to reducing the physical strain, over-fatigue and development of skeletal-muscular diseases), introduce schedules of work and breaks during the working days Included in the rehabilitation costs The Contractor The Engineer On every work site; permanently * Everywhere in this text Engineer means Consultant Engineer or any other expert who is appointed by the Employer and performs site supervision. 24 of 27 Studena Dam Environment Management Plan ANNEX 3. MONITORING PLAN How shall the parameter be monitored?/ type of monitoring equipment When shall the parameter be monitored? (at what intervals or continuously) Required Funds /Cost/ Organization in charge of Monitoring 6 7 Impact on: What parameter shall be monitored? Where shall the parameter be monitored? 1 2 3 4 5 Once per each repair operation and upon report Once per each repair operation and upon report At regular intervals during repair and upon report Noise and Vibrations Noise level; dB(A) On every work site Express check by an accredited laboratory (IAE at MoEW) Atmospheric Air Dust, gas emissions On every work site Express check by an accredited laboratory Below the stilling basin downstream of the spillway Accredited laboratory for analysis of water samples Water Pollution of the water in r. Strouma (turbidity) Protection of the ichtiofauna At laboratory’s price IAE at MoEW; (upon report); the Engineer At laboratory’s price The Contractor, IAE at MoEW; (upon report); the Engineer The Contractor, Accredited laboratory; the Engineer The Contractor; the Engineer At laboratory’s price Depending on the design of waterproofing on the upstream side Included in the Wastes Collection, temporary storage, transportation and disposal On every work site and to the disposal site Monitoring by the Contractor Permanently Health Factor Provision of conditions for protections of workers’ health and life On every work site Monitoring by the Contractor Permanently rehabilitation cost Included in the rehabilitation cost The Contractor, the Engineer The Contractor, the Engineer; RIWESofia, RIPCPH * Everywhere in this text Engineer means Consultant Engineer or any other expert who is appointed by the Employer and performs site supervision. 25 of 27 REGULATION ACTS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. Environmental Protection Act (State Gazette No.91/25.09.2002, amendments & supplements as of 2007). Waters Act (State Gazette No.67/01.09.1999, amendments & supplements as of 2007) Biological Diversity Act (State Gazette No. 77/09.08.2002, amendments & supplements as of 2007). Pisciculture and Aquaculture Act (State Gazette No. 41/24.04.2001 amendments & supplements as of 2006). Waste Management Act (State Gazette No. 86/2003 amendments & supplements as of 2007). Regulation on the terms and procedure for Performance of Environmental Impact Assessments (Council of Ministers Decree 59/07.03.2003, amendment & supplement of 01.2006). Forestry Act (State Gazette No. 125/1997, amendments & supplements as of 2006). Act on Protection against Noise in the Environment (SG No.74/2005, amend. and suppl. No.30/2006) Air Purity Act (SG No.45/1996 amend. and suppl. No.105/2006) Red Book of the Republic of Bulgaria, vol.2 – 1985 UN Convention on Preservation of the Biological Diversity (in effect in Bulgaria since 16.07.1996 – State Gazette No. 19/1999). Order No. РД-272/03.05.2001 on the Categorization of Surface Waters in Water Bodies or Parts of Them – MoEW. Regulation No. 3/01.04.2004 on Waste Classification (State Gazette No. 44/25.05.2004). Regulation No. 04/2/26.02.2004 on the Minimum Labor Health and Safety Requirements for Construction and Erection Works (State Gazette No. 37/04.05.2004). Council of Ministers’ Decision 122/02.03.2007 on Approval of a List of Protected Areas for Protection of the Wild Birds and the List of Protected Areas for Protection of the Natural Wildlife Habitats. Water Supply and Sewerage Service Regulation Act, 2005. Regulation No. 13/2004 on the Operation of Dams and Related Facilities MoEW, MH, MRDPW. Regulation No. 9/16.03.2001 of MH, MRDPW and MoEW on the Quality of Potable and Washing Water. MoEW Regulation No. 5/08.11.2000 on the Procedure and Method of Establishing the Networks and Activity of the National Water Monitoring System. MoEW Regulation No. 10/03.07.2001 on Granting of Permits for Waste Water Discharge in Water Bodies and Establishing of the Individual Emission Restrictions of Point Sources of Pollution. Regulation No. 6 on Environmental Noise Indicators – MH, MoEW (State Gazette No. 58/2006). Regulation No. 7/24.08.2005 on the Sanitation Requirements for the Health Protection of Community Environment MH, MoEW Regulation No. 14/1995 amendments & supplements as of 2007 on Permissible Limit Concentrations in the Air of Settlements Regulation No. 26/01.10.1996 (amendments & supplements as of 2007) on the Recultivation of Disturbed Lands, Amelioration of Low-Productive Lands and Utilization of the Humus Layer. Hazardous Substance Handbook – MoEW, 2003. Hydro-Engineering Facility Design Rates, Basic Principles, Civil Engineering and Architecture Newsletter – issue No. 11/1985 Studena Dam Environment Management Plan 27 of 27