Portable Patient Training Device for Lung Cancer Treatment

advertisement

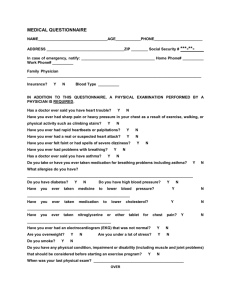

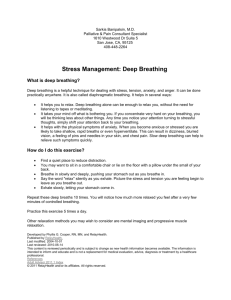

Portable Patient Training Device for Lung Cancer Treatment University of Wisconsin-Madison College of Engineering Biomedical Engineering 301 Final Report May 5th, 2004 Team Members Thomas Chia Brent Geiger Jason Ethington Kawai Chan Client Dr. Bhudatt Paliwal, PhD Department of Human Oncology Advisor Willis Tompkins, PhD Department of Biomedical Engineering Abstract The goals of this project are to design and construct a device to measure breathing patterns in lung cancer patients undergoing 4-D tomotherapy treatments. The hardware consists of a project box containing a string potentiometer, a 9V battery, and a SPDT switch attached to a chest strap. As the patient breathes, the circumference of the chest will change and in effect cause displacement of the string potentiometer and change the output voltage. The output voltage is sampled by an A/D converter and presented to the breathing trainer program written using LabView 7.0. The LabView program is separated into a client program that will acquire a guiding cycle for the patient and a patient program that will show his/her real-time breathing pattern compared to the guiding cycle. This project will be continued in BME 400. As part of this future work the team will scale the LabView program down to a personal digital assistant (PDA), make the hardware more economical, and improve the overall performance of the device. Problem Statement 4-D tomotherapy treatment outcomes for lung cancer depend on the stability and repeatability of a patient’s breathing pattern. A portable patient training system is desired to allow more breathing pattern practice for patients. The portable device should measure a patient’s breathing pattern, process the breathing pattern waveform signal and display the signal against an established reference waveform on a portable pocket PC. The display should provide feedback to the patient to allow him/her to practice a stable and repeatable breathing pattern. Background Tomotherapy Tomotherapy is a relatively new technique used to deliver radiation for the treatment of cancer. This technique uses high-energy radiation in order to damage and eventually kill target tissues, such as a tumors or cancerous tissue. One of the underlying principles of tomotherapy is to damage the target tissue more than the surrounding 2 healthy tissue. By concentrating the radiation on the target tissue and avoiding the healthy surrounding tissue the cancer can be treated with minimal damage to the body. Tomotherapy has several unique features that allow it to be effective. Before treatment a CT image of the target tissue is made. This allows the physicians to know exactly what the tissues or tumor looks like, and where they are before beginning treatment. This is a very important step in avoiding healthy tissue damage and limiting misplaced radiation. Tomotherapy also uses a helical radiation delivery pattern. This means that the radiation source rotates around the patient as it delivers the radiation. This allows the radiation to be delivered from many different angles and to effectively concentrate on the target tissue without damaging the surrounding healthy tissue (Figure 1). Figure 1: Helical delivery pattern used in tomotherapy. Tomotherapy utilizes technology called Intensity Modulation Radiotherapy (IMRT). IMRT is the changing of the intensity and shape of the radiation that is delivered to the target tissue. It does that by using a multileaf collimator, or MLC. A MLC uses leafs, or plates, that quickly move back and forth obstructing the radiation. This changes the intensity and shape of the radiation, allowing further control for the delivery of the radiation, making it more effective in killing the target tissue. 3 Design Motivation In the case of tomotherapy treatments for lung cancer, the tumor will move as the patient is breathing during the treatment. This adds another level of difficulty. Not only does the tomotherapy device have to track the tissue in three dimensional space it also has to track the tumor as the patient breaths, adding time as a fourth dimension. The tumor can be tracked as the patient breathes but it is important that the patient breathes in a steady repeatable pattern. By taking several CT images throughout the patient’s breathing cycle the exact location of the tumor can be known with respect to where the patient is in his or her breathing pattern. The physicians currently use several techniques to track the patient’s breathing patterns during the procedure. These consist of a sensor or reflector that is placed on the chest of the patient and either infrared light or laser beams. This enables the physician to know the position of the patient’s chest and the breathing pattern of the patient. By giving the patient a guiding cycle the patient can follow it and the position of the target tissue will be known. However, an ideal breathing pattern is hard to achieve in many patients. Even normal breathing has deeper or shallower breaths and often changes in frequency. The situation a person is in will also change the pattern. This is obviously seen in breathing patterns when exercising compared to breathing patterns at rest. This can also come into effect when a person is nervous, for example before a radiotherapy session. Our client believes that through at-home practice, the patient will be able to breathe a repeatable pattern when it comes time for the tomotherapy procedure. Client Requirements 4 Our client would like a portable breathing trainer that would allow a patient to practice breathing in the comfort of his/her home. Currently, this is not feasible with the equipment used in the hospital for a number of reasons. First of all, the equipment used is extremely expensive. It is not possible to loan this equipment to the patient. Also, the current devices are large and bulky and would require special transport. The devices are also not very user friendly and it would take significant training for the patient to use it at home. In order to construct a portable breathing trainer, the client has specified a number of requirements for the device. The first requirement is that the device should be portable and be able to be used at the patient’s home. The display on the device should also show the patient’s breathing pattern in real-time on top of guiding cycles. The device should be easy to use and comfortable to the patient. Finally, the client informed us of what he envisioned as the three major components to the device: 1. Breathing measurement device 2. Signal processor 3. Personal Digital Assistant (PDA) + software Design Constraints There are several aspects that the design must encompass in order for it to be an effective training device for a repeatable breathing pattern. These aspects all revolve around one main issue; the patient needs to practice their breathing pattern outside of the hospital on their own. First of all proposed designs must give a guiding cycle that the patient can follow. This guiding cycle would be an example of a steady, repeated breathing pattern. It 5 should be specialized for each patient, since everyone’s breathing pattern is different. This guide will be constructed from a typical pattern of the patient’s breathing found through a number of calibration breaths. The device will then display the real-time breathing pattern of the patient. This is important so that the patient can accurately follow the guiding cycle and train for a repeatable pattern. Since the device is to be used at home it is important that the device is small, portable, and user friendly. The patients will need to use the device on their own so it must be simple and straightforward. If the device is too complicated the patient may become frustrated and not use the device at all, which in turn decreases the effectiveness of their treatment. Alternative Solutions The proposed design will consist of three discrete component stages (Figure 2). The first component of the overall design is the breathing pattern measurement hardware. This hardware must consistently measure the patient’s breathing pattern and output a signal that can be analyzed, processed, and graphically displayed. In the following section three proposed breathing measurement design alternatives will be outlined and evaluated. The second component of the design is the analog to digital signal (A/D) conversion and software used to analyze/graph the output signal from the breathing measurement hardware. Two programming languages, Microsoft Visual Basic® and National Instruments LabView 7.0®, will be considered for use in the final design. 6 Finally, the last component of the design will be the user interface and final display of the patient’s breathing waveform. Display of the breathing pattern waveform can be accomplished either on a laptop computer or a personal digital assistant (PDA). Breathing Pattern Measurement Hardware Signal and Data Processing User Interface and Breathing Waveform Display Figure 2: Three basic component stages of overall proposed design. Thermistor Design The first proposed design alternative to measure patient breathing patterns involves the use of a nasal thermistor or thermocouple sensor. This device detects the inherent changes in nasal airflow that result from normal breathing using a thermistor or thermocouple. Then the corresponding change in resistance would be processed using a low power microcontroller with an A/D converter for data acquisition and signal processing (Javanov et al., 2001). An advantage of this device is that it can generate a relatively accurate breathing pattern waveform (Graph 1). It is also capable of consistently measuring a patient’s breathing waveform for an extended period of time. 7 Graph 1: Breathing pattern waveform generated with a nasal thermistor breathing pattern measurement device. BAL corresponds to breath amplitude while BI corresponds to breath interval (Javanov et al.). The main disadvantage of this type of design is invasiveness. Many patients would feel uncomfortable having a thermistor placed inside their nostril for and extended period of time. Also, another major disadvantage of this type of device is that it only measures breathing from one nostril. This means that if the patient breathes through his/her mouth the pattern will not be detected by the thermistor device. Figure 3: Thermistor measuring airflow through nostril. Inductance Pnuemography The second proposed design alternative involves the use of a technique called impedance or inductance pnuemography. In each case instrumentation is used to measure either a change in inductance or electrical impedance corresponding to a patient’s breathing pattern. Impedance pneumography involves passing a very small high 8 frequency electrical current across ECG chest electrodes and measuring the change in impedance as the chest volume changes. The impedance change is caused by air (which is a poor electrical conductor), moving into the lungs and thereby changing the volume of the lungs (WelchAllyn, 2004). Inductance pneumography involves strapping a coil of wire around the patient’s torso (Figure 4). Since the inductance of the cable depends on cable length, as the patient breathes the measured change corresponds to magnitude of respiratory volume. An advantage of this technique is that it is accurate and minimally invasive. However, this design is prone to motion artifact. If the patient moves his/her chest in a fashion other than regular breathing it will cause breathing measurement errors. Furthermore, it requires proper electrode or wire placement on the patient’s chest based upon their individual breathing patterns. For example, some people breathe mainly through chest expansion, while others breathe mainly through stomach expansion. The electrode leads or wire strap must be positioned according to the patient’s breathing habits in order to obtain the clearest signal. Finally, this design would require the construction of more complicated circuitry to amplify, filter, and process the breathing pattern signal. 9 Figure 4: An example of an inductance pneumography device. Linear Position Transducer A third proposed design alternative involves using a technique called resistance pnuemography, which is similar to the technique described above. However, instead of measuring the inductance change of a cable, a miniature cable extension linear position transducer (Figure 5) is used to obtain a signal corresponding to the breathing pattern waveform. The position transducer is attached to an elastic strap tightened around the patient’s chest (Figure 6). 10 Figure 5: Image and schematic of the miniature linear displacement transducer. The diameter is approximately 20 cm. Figure 6: Example of a position transducer attached to a chest strap. As the patient breathes and the circumference of the chest expands the cable will extend a given distance based upon the magnitude to patient inhalation. The cable extension corresponds to a change in resistance of the potentiometer. Using a simple voltage divider the output is an analog signal ranging from zero to supply voltage with magnitude proportional to the amount of cable extension. The output signal can then be processed using an A/D converter and interfaced with a computer for data storage and breathing waveform display (Webster, 2004). The advantages of this design are that it is accurate, minimally invasive, and does not require any additional circuitry for amplification or filtering of the analog output signal. One disadvantage is the high cost of specialized position transducers. However, more research into position transducers should yield more economical potentiometers that 11 will meet the needs of this project. Also in order for best performance, the chest strap needs to be placed on the chest or on the stomach depending on each patient’s breathing habits. Design Matrix The design matrix contains four categories: accuracy, price, simplicity and invasiveness. Accuracy is an important factor because reliable measurements are vital to the establishing a repeatable breathing pattern. The inductor method is the most accurate among the three measuring device because it is the least affected by the different kinds of breathing types. By placing one sensing strap around the chest and the other across the stomach both breathing types can be measured. The potentiometer method achieves moderate accuracy, however, it cannot measure both chest and stomach breathing simultaneously. This problem can be solved by advising the patient to attach the device to the same area of the torso to get a reproducible signal. The thermistor method is the least accurate because it needs to be placed in the same location (i.e. same depth inside the nostril). This can prove difficult and invasive for the patient to accomplish. The price for the displacement transducer includes buying a linear potentiometer, elastic band, and nylon strap. The estimated cost for this is approximately $225.00. The other two methods are more expensive because we would likely have to buy a complete instrumentation package in the case of the inductance pnuemography or deal with complicated electronics to build a thermistor measurement device. Simplicity is an important attribute for the measurement device. This is both for the sake of limited time to design and build the device as well to keep things simple for the patient. The potentiometer is the right choice because the basic working theory is a 12 voltage divider. By connecting the potentiometer with a power source and attaching it to a strap, the device is already outputting a meaningful signal. The other two required a rather complex theory and a more careful design process. Invasiveness is the other main concern in this design. The higher the score in this category, the less invasive the device is. The potentiometer and inductor methods are both ranked to the highest because they are placed around patients’ chest. As their components are lightweight, both of these devices will not obstruct normal breathing. On the other hand the thermistor design may require putting a thermistor inside the patient’s nostril which may cause annoyance to them. Each category is ranked on a one-to-five scale where a five means the best. A weight factor is applied to each category based on the relative importance. Since the simplicity and invasiveness is more important than the accuracy and price, the score in these categories are multiplied by two. The total score shows that the potentiometer method is ranked the best and this is the method to be developed in this semester (Chart 1). Chart 1: Design matrix for breathing measurement hardware. 13 Data Processing and Data Displaying Units After the breathing data is acquired from the measurement devices, it is important to interpret the data into a meaningful output. Therefore, we need a data processing unit that will convert the analog voltage signal into a digital signal that can be used to display the breathing pattern; this can be achieved through the use of an analog-to-digital (A/D) converter. By plugging in the voltage output to an A/D converter and connecting the converter to a PC, the analog signal can then benefit from digital signal processing. The search for an A/D converter has led to two possible options, the Measurement Computing PMD-1208LS and the National Instruments DAQ-6024E PCMCIA card. The PMD has a 10-bit analog output, while the 6024E has a 12-bit analog output. Either one should have more than enough resolution then we need for our application. The PMD has a USB output which will make it easy to interface with a PC and costs $109.00. The 6024E uses a PCMCIA output and will interface nicely with LabView software. Unfortunately, the cost for this card is $600.00. Since the PCMCIA output is necessary for the eventual incorporation of a PDA we will use the 6024E converter. After the D/A converter, the PC still needs instruction on how to organize the digital data to a meaningful way (i.e., by writing a program to tell the PC how to manage the input data). The two programming languages being considered are Visual Basic and LabView. Visual Basic is one of the most popular programming tools developed by Microsoft. The language is rather simple compared with other high-level languages. The main advantage is that it is relatively easy to learn can be used by various Windows applications (Predko, 2003). A disadvantage to this language is that it is slow (Tompkins, 2004). LabView is developed by National Instruments and is specially 14 designed for hardware-interface applications on the PC. This program also uses a graphical programming environment that allows those who are not familiar with normal programming create a program relatively easily. Instead of using normal code-structure, LabView programs are created by selecting appropriate functional blocks and connecting the blocks by “wires” (Predko, 2003). LabView programs can be developed into standalone applications. Which means the end-user does not need LabView installed or know how to use LabView. If we use a National Instruments DAQ card, LabView will recognize the card and configure itself properly. This will greatly reduce the difficulty of writing a hardware-interface application. Our team will begin the programming of the device on LabView. The output of the device is ultimately presented to the patient through some type of visual monitor. Instead of programming directly for a PDA, we will first create the program on a laptop PC. Once the LabView program is completed on the laptop, we can compile the program to fit onto a PDA running Windows CE. This compilation is accomplished through a program called LabView PDA module made by National Instruments. The PDA will then show the patient the real-time breathing cycle and the guiding cycle simultaneously on a small, portable device. Hardware The decision was made to proceed with the linear potentiometer as the method to quantify the breathing patterns of patients for this project. This design is the ideal choice because it balances the client’s requirements for simplicity, non-invasiveness, and accuracy when compared to the other design alternatives. 15 The centerpiece of the breathing trainer device is the linear potentiometer (a.k.a. position transducer). The team acquired a SpaceAge Control linear potentiometer model 173-0241-R1N with a cable displacement of 3-inches (76mm). Full specifications on the linear potentiometer can be found in Appendix B. The position transducer was purchased directly from Space Age Control, Inc. under an academic discount of 50%. This brought the price of the transducer down to $197.50. The linear potentiometer has a built-in voltage divider circuit that allows the output voltage to range from 0V to the input voltage based on the amount of cable displacement. For this project the team chose to use a 9V battery as the power source/input voltage. Both the linear potentiometer and the 9V battery were installed into an ABS plastic project box measuring 4 inches x 1.5 inches x 2 inches. Finally, in order to keep the voltage divider circuit from continually draining power from the 9V battery, a single pole double throw (SPDT) switch (Alco, MTE-1060) was installed to allow the device to be turned on and off (Figure 7). Figure 7: Project box, 9V battery, potentiometer, and switch. 16 The project box and all its contents were attached to an adjustable chest strap. The nylon chest strap was purchased from REI (Item # 709047) for $2.50 and measures 1 inch in width x 60 inches in length. The strap can be connected together with a simple buckle. Two rivets were used to secure the lid of the project box to a position on the chest strap about 3-inches from the fixed buckle (Figure 8). This allowed the project box to fit securely against the chest when the chest strap was attached to the body. The cable extending from the potentiometer was fed out of a hole (approximately 0.7 mm in diameter) on the opposite side of the project box. A brass swivel was attached to the end of the cable outside of the box. This swivel could then be opened and hooked onto any location on the chest strap. The ideal location for where the swivel was attached on the chest strap was about 2.5 inches from project box (Figure 8). This allows the strap to limit the amount of cable that can be pulled out from the potentiometer. Figure 8: Chest strap with 2.5 inches of slack and elastic band connected to potentiometer wire. Also notice the steel riveting on top of the box that secures the strap in place. Connected from the bottom of the box to the strap is an elastic strap to provide adequate tension in the chest strap. During initial testing of the breathing trainer device it was discovered that the tension on the chest strap needed to be increased. This is due to the considerable 17 displacement created when trying to secure the chest strap on the body. If the tension was increased on the strap then the strap could be adjusted to fit snugly against the body without displacing the cable and leave all movement of the potentiometer cable to be introduced only while breathing. The tension was increased in the chest strap by sewing a one-inch wide band of elastic between the project box and where the potentiometer wire attached to the chest strap (Figure 8). Finally to allow for easier connectivity between the potentiometer and the A/D converter, a simple male/female electrical connector was attached just outside of the project box (Figure 9). Figure 9: Male/female electrical connectors used between the A/D converter and project box. A/D Signal Converter The analog to digital converter chosen for use in this project was a National Instruments DAQ-6024E for a PCMCIA slot (Figure 10). This is a 12-bit D/A card with 16 Analog Inputs and 200 kS/s sampling. This PCMCIA card can be inserted in most laptops and PDA’s with a PCMCIA slot for portable measurements. This DAQ card is chosen because of its small size and DAQmx-support feature. The DAQmx driver allows the card to be easily recognized by LabView and greatly simplifies the signal-processing steps. To connect the signal wires from the device to the D/A card, a terminal block NI – CB-68LP was used. 18 Figure 10: National Instruments PCMCIA DAQ-6024E A/D converter. The program complexity is greatly reduced by the use of the new kind of DAQ driver called DAQmx by National Instruments. This driver is capable of supporting real-time applications. As shown in Figure 11 the client program consists of only a “DAQmx assistant” VI (virtual instrument) that is responsible for the data acquisition. The data analysis part of signal processing is automated by the driver. The user can select the sampling rate and number of samples to get an optimum resolution of the signal. In this prototype the sampling rate is set as high as 1000Hz for a very smooth plot. However, in theory the sampling rate should only need to be twice the frequency of the patient’s breathing. Since an average person breathes with a frequency of about 0.2 – 1 Hz, a sampling rate of 3-4 Hz should be adequate. 19 Figure 11: Client program, block diagram view with DAQmx-assistant. Software Since our prototype is designed for both client and patients use, it is more convenient to split the program into two: one for our client to detect and record the breathing cycle and the other one for the patient to run the recorded cycle and plot realtime breathing patterns on the screen. The program for the client can input the digital signal from the DAQ card and play the signal on the measuring tank as shown in Figure 12. Once the physician or medical assistant is convinced the breathing pattern of the patient shown in the measuring tank is normal, he/she can press the “write to file” button on the front panel and write the data to a file that can be used by the patient later on. This will become the guiding cycle for the patient. 20 Figure 12: Screen shot of client’s LabView program used to obtain guiding cycle. The patient program will play the guiding cycle saved from the client’s program and plot the real-time signal from the patient simultaneously. This enables the patient to see how well his/her breathing pattern matches the guiding cycle (Figure 13). Figure 13: Screen shot of patient’s LabView program used to track real-time breathing pattern against the guiding cycle. 21 Future work The design and prototype created this semester serves as an ideal “proof of concept,” however there is surely room for a considerable amount of refinement and future work to be done on the design. The work accomplished this semester effectively shows that a miniature position transducer can be used to measure a patient’s breathing pattern and that when used in association with LabView 7.0 it is possible to display the patient’s breathing cycle in real-time against an established guiding cycle. The next step in the design process would be to scale the display unit to a small and portable PDA device. A PDA device with a PCMCIA cradle has the capability to support this type of application. Portability of the breathing trainer device would allow the patient to practice with the device in the comfort of his/her home before beginning tomotherapy treatment. For the design to be implemented on a PDA device the chosen model of PDA would have to be fitted with a PCMCIA cradle to be compatible with the analog to digital DAQ card. An example of a PDA with a PCMCIA cradle and matching DAQ card are shown below in figure 14. Figure 14: An example of a PDA equipped with a PCMCIA cradle capable of interfacing with the A/D DAQ card. 22 In order for the LabView program to function on a pocket PC it needs to be compiled to work on the limited resources of a handheld device and execute as a standalone program. This can be done by installing a LabView PDA module. This module allows the current LabView program to be scaled down to fit onto a handheld unit. All designing and programming would need to be done on the master laptop, however when the software design is completed it will not be problematic to transfer the application to a PDA format. The LabView PDA module is sold separately from LabView 7.0 and is available for student use through the Computer Aided Engineering (CAE) department. There are several programming modifications that need to be done. In the future a better method to display the breathing pattern and the guiding cycle would be to place a waveform graph on the front panel so that the guiding cycle can be shown as a waveform plotted over time. Then the real-time signal can be superimposed on the guiding cycle so both the client and patient can have a better idea on how to anticipate the breathing cycle. Moreover, in the current patient program the guiding cycle file cannot be repeated when the end of the file is reached. The future program will need to solve this problem by reading the file repeatedly until the user presses stop. This can greatly reduce the size of the data file since the operator can just save two or three breathing cycles into file and repeat them indefinitely. Another design feature that will be refined is the connection cable between the position transducer output and the DAQ card input. Currently the cable is bulky, rigid, and requires the use of a large digital acquisition board shown below in figure 15 23 Figure 15: The current digital acquisition board Since this application only requires the use of two cables: one as the voltage output of the position transducer and one as reference ground, a custom cable design could easily be constructed fitting the proper specifications. The new cable could be constructed to any predetermined length and would eliminate the need for the massive DAQ connection cable or the digital acquisition board. Another future design issue that has been discussed is the use of video goggles to display the patent’s breathing waveform and corresponding guiding cycle. This would also serve as the first step to creating a device that could be used in the actual tomotherapy environment. The video goggles would allow the patient to control their breathing while undergoing tomotherapy treatment and would most likely produce superior results during the treatment. However, if the device were eventually modified for use in the actual tomotherapy machine several factors would have to be considered. First, the material used for the position transducer enclosure, the position transducer itself, and all necessary wiring and supports would have to be analyzed and deemed safe for use in the high radiation environment of the tomotherapy machine. Then the exact attenuations of all materials used would have to be calculated and accounted for during the radiation treatment. Second, a modified or entirely new software platform would have to be 24 created to display the breathing cycles in the video goggles. Finally, the design would certainly have to be subjected to rigorous human subjects approval and testing before there is any possibility for use in the tomotherapy machine. Ethical Issues There are several ethical issues that should be addressed when working on our design. One issue is an economical one. It is important to make the best product we can while minimizing the cost. Our product should be as affordable as possible so that the people who need to use our design can afford it. Currently, we are using a potentiometer that is very expensive and more precise than the design requires. If the team could find a suitable alternative to our current transducer we could make a more affordable product and reach a larger number of patients. Another issue involves the use of universitylicensed software in our design. The software programming done in LabView 7.0 has been completed on a laptop from the UW-Biomedical Engineering Department. We have also obtained copies of the LabView 7.0 PDA module from UW Computer-Aided Engineering (CAE). The issue of concern is the line between academic usage and commercial usage by the client. More specifically, is it legal to use academic software for producing multiple copies of the breathing trainer software to the general public. If not, it may be necessary for our client to purchase an entirely new license in his name. Conclusion It is clear from earlier discussions that the device has great potential to function as a successful patient breathing training system. Based upon the significant progress made thus far it is the general consensus of the group that we would like to continue this as our BME 400 capstone design project in the fall semester of 2004. Ideally we would like to 25 refine and completely finish this design to the point were it can be proposed to a production company. We are also planning to disclose for a patent to gain rights to the intellectual property that we have created. Our client, Dr. Bhudatt Paliwal, has been extremely cooperative throughout the semester in terms of both funding and constructive input and we would like the opportunity to completely finalize the design and present him with the final product. 26 References 1. Javanov, Emil. “Thermistor-based Breathing Sensor for Circadian Rhythm Evaluation”. Pgs. 4-5. 2001. 2. Predko, Micheal. Programming Robot Controllers. Pgs. 338,341. New York: McGraw-Hill. 2003. 3. Space Age Control, Inc. “Position Transducer Solutions Guide”. Pg. 4-5. Palmdale, CA. 4. Tompkins, Willis. Professor of Biomedical Engineering. (Madison: February 6th, 2004) In-Person Interview. 5. Webster, John. Professor Emeritus of Biomedical Engineering. (Madison: Feburary 4th, 2004) In-Person Interview. 6. WelchAllyn. “Respiratory Impedance Pneumography”. Beaverton, OR. February 15th, 2004. www.monitoring.welchallyn.com/pdfs/clinicalsupport/RESP_basics.pdf 27 Appendix A Product Design Specification BME 301-Portable Patient Training Device for Lung Cancer Treatment Team Members: Thomas Chia – Leader Jason Ethington – BWIG Brent Geiger - BSAC Kawai Chan - Communicator Advisor: Willis Tompkins, Ph.D. Revision date – April 30th, 2004 Problem Statement: 4-D tomotherapy treatment outcomes for lung cancer depend on the stability and repeatability of a patient’s breathing pattern. A portable patient training system is desired to allow more practice for the patients. The portable device will measure a patients breathing pattern, then display the guiding cycles and provide feedback on the patient’s current breathing curve on the display of a Pocket PC. Client Requirements: Device should be portable and be able to be used at the patient’s home Display should show patient’s breathing pattern superimposed on the guiding cycles Device should be easy to use and comfortable for the patient The client envisions three major components to the device: 1. Breathing measurement device 2. Signal processor 3. Personal Digital Assistant (PDA) + software Design Requirements: Physical and Operational Characteristics a. Performance requirements Must be portable and intuitive to use by the patient. Able to be attached/operated solely by the patient. Simple to operate and as unobtrusive as possible. b. Safety Must not harm patient in any way. Device will not have any sharp areas, exposed wires, or abrasive material. All wires/electrical components should be consolidated into one location and should not come in contact with the patient. All currents and voltages used should not pose any risks to the patient. Minimal effort needed to transport and operate device. c. Accuracy and Reliability Must be able to accurately calibrate the patient’s natural breathing cycle. Afterwards, must accurately measure that patient’s breathing in real-time and display its position in reference to the guiding cycle. 28 d. Life in Service Must be in service for as long as patient is able to utilize the device. PDA batteries should be replaced when necessary. Proper operation should be checked for each week. Major calibration checked for every patient. e. Shelf Life The shelf life will be five years stored at room temperature in a dry location. f. Operating Environment This device will be used in a home environment. It will be subjected to constant use by multiple patients. The device may be subjected to fluids and/or dust caused by everyday use. g. Ergonomics Device should be comfortable and not affect the patient’s natural breathing pattern. PDA display should be easily readable. Device should not require significant strength to assemble. h. Size The device must fit for a range of bodily sizes. Needs to be easily portable for the patient and contained in a box for easy transport. i. Weight The entire device should not weigh more then 2 kg. j. Materials There are no restrictions on materials. k. Aesthetics, Appearance, and Finish Device should not appear dangerous or fragile to the patient. Production Characteristics a. Quantity One prototype. b. Target Production Cost $600 Miscellaneous a. Standards and Specifications Human subjects testing approval may be required. b. Competition No devices are known that accomplish this goal. 29 Appendix B Data Sheet - Series 173, 174, 175 and 176 Analog-Output Subminiature Position Transducer Subminiature Size, Easy Mounting Key Features 1. 6.5-Inch (165-mm) Maximum Travel (Series 176) 2. Analog Signal Using Precision Conductive Plastic Potentiometer 3. AccuTrakTM Grooved Drum for Enhanced Repeatability 4. Bearing-Mounted Rotating Components 5. Optional Flexible Mounting Bases 6. DirectConnectTM Sensor-To-Drum Technology = Zero Backlash, No Torsion Springs or Clutches Potentiometer Specifications Potentiometer Type 1-turn, precision, conductive plastic Resistance: Value, Tolerance 5K ohms, ±10% Travel: Electrical, Mechanical 340°, 340° min Mechanical Life 100 million shaft revolutions min Output Signal analog signal from 0 to supply voltage (voltage divider circuit) Power Rating 1.0 W at 158° F (70° C) Supply Current 12 mA max Supply Voltage 35 VDC max (using voltage divider circuit) Independent Linearity Error ±0.5% max per VRCI-P-100A Output Smoothness 0.1% max Insulation Resistance 1000 Mohms at 500 VDC min Dielectric Strength 1000 VDC min Resolution infinite signal Operating Temperature -85° to +257° F (-65° to +125° C) Shock, Vibration 100 g for 6 ms, 10 to 2000 Hz at 15 g per Mil-R-39023 Temperature Coefficient ±400 ppm/°C max 30 Other Specifications Case Materials precision-machined anodized 2024 aluminum Displacement Cable 0.018-inch (0.46-mm) dia., 7-by-7 stranded stainless steel, 40-lb (177-N) min breaking strength Displacement Cable Hardware 1 each of 300196 loop sleeve, 300292 copper sleeve, 300688 ball-end plug, 300495 pull ring, 160026 brass swivel, and 301003 nickel swivel; all items provided uncrimped Series Nominal Mass Displ. Cable Tension (Nom., Min) Displ. Cable Tension (Nom., Max) Displ. Cable Accel. (Nom., Max) 173 (Opt. 1) 1 oz (28 g) 0.5 oz (0.1 N) 4 oz (1.1 N) 8g 173 (Opt. 2) 1 oz (28 g) 2 oz (0.6 N) 10 oz (2.8 N) 17 g 174 2 oz (57 g) 3 oz (0.8 N) 12 oz (3.3 N) 9g 175 3 oz (85 g) 2 oz (0.6 N) 10 oz (2.8 N) 8g 176 4 oz (113 g) 2.5 oz (0.7 N) 8 oz (2.2 N) 6g NEMA 3S / IP 54, DO-160D (ED-14D) Env. Cat. E1E1ABSHXFDXSAXXXXXXXXXX Environmental Protection Model Numbers and Ordering Codes 173-0241-abc position transducer (3.00-inch (76-mm) range) 174-0321-abc position transducer (4.00-inch (102-mm) range) 175-0401-abc position transducer (5.00-inch (127-mm) range) 176-0521-abc position transducer (6.50-inch (165-mm) range) Example: 173-0241-L2N (left-hand displacement cable pull, cable tension: -020, no base) Variable a b c Value Description L left-hand displacement cable pull R right-hand displacement cable pull 1 cable tension: -010 (173 only) 2 cable tension: -020 (173 only) 3 cable tension: -030 (174, 175, and 176 only) N no base C base: L (173 only); pn 173015 D base: L (174/175 only); pn 174015 E base: L (176 only); pn 176015 31 Drawing Electrical Connection for Increasing Output with Displacement Cable Extraction Left-Hand Pull black white red Right-Hand Pull red white black Signal input, V+ output, signal, S+ ground, common, V-, S- 32