crosstalk in passive matrix polymer led displays

advertisement

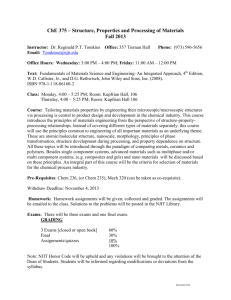

Semiconducting Polymers for Multidisciplinary Education David Braun1, Kevin Kingsbury2, Linda Vanasupa3 1 Electrical Engineering Department, 2Department of Chemistry and Biochemistry, 3 Materials Engineering Department, California Polytechnic State University, San Luis Obispo, CA 93407, U.S.A. ABSTRACT Cal Poly is in the process of revolutionizing how science and engineering students learn about semiconducting materials. Semiconducting polymers currently attract widespread attention as the subjects of numerous research and development projects. Semiconducting polymers are also excellent materials with which to teach structure-property relationships, polymer synthesis, polymer film preparation, optical and electronic properties, semiconductor device fabrication principles, and device testing. One key benefit of these materials is that they encourage student participation in educational activities that bridge several disciplines. Semiconducting polymers improve student learning by making normally obscure semiconductor concepts more tangible for students in several disciplines: chemistry students create electronics applications for the compounds they synthesize, materials engineering students learn about opto-electronics techniques, and electrical engineering students gain hands-on experience with core concepts in semiconductor devices. This presentation describes the interdisciplinary projects that students and faculty have participated in thus far, particularly during the phase of lab design and construction. INTRODUCTION Semiconducting polymers blend several attractive material properties that enable inexpensive and unique applications. Much interest in polymer and organic light-emitting diodes and photo-diodes derives from their potential to deliver the next generation of flat and flexible image sensors and multimedia displays [1-10]. Forming the subjects of numerous research and development projects, semiconducting polymers also make excellent materials with which to teach a wide range of undergraduate engineering topics extending from the macroscopic to microscopic. For example, systems engineering of displays and image sensors based on semiconducting polymers involves applications which teach students concepts such as structureproperty relationships, polymer synthesis, polymer film preparation, optical and electronic properties, semiconductor device fabrication principles, and device testing. Using a polymer light-emitting diode [LED] as an example illustrates several nice features of semiconducting polymers as a multidisciplinary instructional vehicle. A polymer LED consists essentially of a plastic film sandwiched between two electrodes. Figure 1 illustrates the device geometry. Applying a positive voltage to the anode relative to the cathode causes current to flow through the polymer film and light emission from the polymer film through the transparent bottom electrode and substrate. The devices are relatively easy and inexpensive to make, because of their simple geometry. A passive matrix display or image sensor results by patterning the anode into columns and the cathode into rows to form an array of pixels from the intersections between the cathode and anode electrodes. Applying a bias to one anode and the opposite bias to one cathode causes light emission or allows light detection at the pixel shared by the two electrodes. Metal Cathode Polymer Film ITO Anode Substrate Figure 1. Polymer LED Geometry. Applying a positive voltage to the anode relative to the cathode causes current to flow through the polymer film and light emission from the polymer film through the transparent bottom electrode and substrate. Devices made on plastic substrates can have flexible mechanical properties [3-5]. Figure 2 illustrates where each of the steps in the fabrication sequence takes place in the Polymer Electronics Lab. 1) Prepare substrate in dust free work area. 2) Transfer substrate into glove box. 3) Spin-coat polymer film. 4) Transfer coated substrate into glove box. 5) Deposit top metal electrode in vacuum evaporator. 6) Characterize polymer LEDs. The lab web site, http://www.ee.calpoly.edu/~dbraun/polyelec/, provides more information about semiconducting polymers, lab projects and course modules. 6 5 4 3 2 1 Figure 2. Polymer Electronics Laboratory. Samples proceed from the front right to the left rear of the fabrication and test facility. DISCUSSION Curriculum Development Educational activities make use of semiconducting polymers and semiconducting polymer devices in courses offered in several disciplines. Specifically, semiconducting polymers make possible new lab modules for the courses listed in table I. During the freshman year, engineering students at Cal Poly have their first practical exposure to the manufacturing branch of electrical engineering via IME 157, Electronic Manufacturing. The practical component of the course has students manufacture a project of their own choice. The students perform each activity necessary to translate the schematic diagrams of the circuits into an engineering prototype. They lay out the printed circuit board (PCB), perform the PCB lithography, choose from automated or manual soldering techniques, insert the components, design and build a chassis, and test the prototype. Course theory also includes semiconductor device fabrication techniques. Adding the demonstration of semiconducting polymer device processing to this experience strengthens the impact of the course. MATE 345, Electronic, Optical and Magnetic Properties of Materials Laboratory, forms part of the foundation of Materials Engineering and serves to provide additional depth in materials issues for electrical engineering, computer engineering, and physics majors. Semiconducting polymers provide an excellent learning bed for this course as their operation is based on a combination of the principles that the course teaches. Since the energy gaps of some semiconducting polymers lie in the visible range, the three spectroscopy modules literally allow students to see photoluminescence and electroluminescence. Table I. Curriculum modules based on semiconducting polymers Course Number & Title Semiconducting Polymer Module(s) IME 157 Electronic Manufacturing Demonstration of Polymer LED Fabrication. MATE 345 Electronic Properties of Materials Laboratory Photoluminescence Spectroscopy Electroluminescence Spectroscopy Polymer Structure to Property Experiment EE 422 Polymer Electronics Laboratory Substrate Preparation Techniques Polymer Solution Preparation Polymer Film Coating Vacuum Evaporation Device Characterization CHEM 447 Polymers and Coatings Laboratory Semiconducting Polymer Synthesis Polymer LED Fabrication and Test In EE 422, Polymer Electronics Laboratory, students apply their knowledge of solid state device fabrication and characterization to build and analyze the performance of a solid state device based on a semiconducting polymer. Students interested in semiconductor electronics learn how to characterize semiconductor devices such as diodes and transistors. In theory, the students should also learn how these devices operate internally. Such comprehension is crucial for later course-work, but the concepts are relatively sophisticated. Consider an inorganic lightemitting diode. It is possible to observe under a microscope that tiny wires supply current to a semiconductor crystal and that light emerges from the crystal. Nevertheless, the process remains somewhat mysterious, primarily for two reasons. First, the fabrication of an inorganic lightemitting diode requires sophisticated and expensive fabrication techniques, which are not readily accessible to undergraduates. Secondly, the resulting device is microscopic in dimension, less than one millimeter square. Semiconducting polymers enable students to make and test devices large enough to be visible to the naked eye AND do so using simple and inexpensive fabrication techniques. CHEM 447 is a polymer synthesis laboratory taken during the second quarter of the polymer series (Chem 444-446), which builds the repertoire of techniques used to prepare and analyze a wide variety of organic polymers and coatings. A semiconducting polymer experiment such as the MEH-PPV synthesis [6] motivates the students to apply some of those techniques toward the synthesis and analysis of a semiconducting polymer that they then BUILD into a working electronic device such as a light-emitting diode. Students glean additional motivation from carrying an organic chemistry concept through to a working demonstration After fabrication, the student can operate the device by applying a voltage between the electrodes and observing light emission. The interesting thought processes begin with the realization that the device emits light when positive and negative charge carriers recombine in the conducting polymer. The students gain a graphic illustration of charge injection into a semiconductor, charge transport, and the process of light emission from a semiconductor. Characterizing the electrical characteristics and intensity of light emission for various devices can spark a variety of creative experiments and lead to refinements in the above model. Depending on students’ personal interests, the instructor can include aspects of polymer chemistry, engineering design, semiconductor physics, and/or materials science. For sufficiently motivated students who are unsatisfied with simplified energy band diagrams, the available research and patent literature on semiconducting polymers provides some answers and more questions. Student Projects As a result of some of those questions, and in the process of laboratory design and construction, students have embarked on a variety of projects. Table II lists several student projects made possible by semiconducting polymers. Students have participated in most aspects of lab design and construction, and they continue to advance lab development. One highlight of each student’s education at Cal Poly is a Senior Project involving design, independent research, and laboratory work. These projects are required of each student. Several of the projects in table II involve a student’s senior project. Most of the mechanical engineering projects are fruits of ME 428, a senior level course in Design. Table II. Student projects in the Polymer Electronics Laboratory Discipline Projects Chemistry Semiconducting Polymer Synthesis Polymer LED Fabrication and Test Computer Engineering Computer Interfacing for Device Test Automation Driving Electronics for Dot Matrix LED Display Electrical Engineering Computer Interfacing for Device Test Automation Computer Interfacing for Spectrometer Current-to-voltage Converter Design and Test Fixture Design for Vacuum Evaporator Optimization of Polymer LED Fabrication Process Passive Matrix Polymer LED Display Circuit Analysis Polymer LED Lifetime Test System Materials Engineering Develop Spectroscopy Experiments Optimization of Polymer Film Coating Mechanical Engineering Fixture Design for Polymer Film Coating Holder for Substrate Preparation Shadow Mask to Pattern Metal Electrode Test Jig for Polymer LED Characterization Vacuum Chamber Parts Water Cooling System CONCLUSION As consumers make increasing demands in the areas of large-area electronics, lightweight displays, and portable computing, semiconducting polymers are promising candidates for applications that contain not only the display but also integrate the computing and input/output circuitry onto one or both sides of a single substrate, such as a piece of glass. Folding and/or mechanically flexible substrates will likely follow. Organic semiconductors now inhabit a growing subset of the opto-electronics field, and electroluminescent devices are finding applications as light sources such as backlights, indicators and matrix displays [4]. Semiconducting polymers are not only finding numerous new applications, but they also make excellent tools to teach students about semiconductors more efficiently, economically, and safely than present techniques based on standard non-organic materials. Semiconducting polymers are timely and directly relevant to the world’s technological development. The crossdisciplinary nature of the projects encourages breadth in technical skills and academic interests. The practical nature of semiconducting polymers makes them well suited to the environment at this primarily undergraduate institution, which has a strong reputation of enthusiastic student participation in engineering design projects. The semiconducting polymer curriculum may inspire students to study at the graduate level. Use of semiconducting polymers gives undergraduate students access to opto-electronic device design and characterization concepts and practice. As the importance of opto-electronic devices grows, so does the necessity of exposing undergraduate students to the relevant topics. Undergraduates have traditionally been denied this experience, because III-V inorganic materials require elaborate and expensive fabrication techniques. Semiconducting polymers remove these very practical barriers to including these topics in undergraduate programs. As a result of this project, students in several disciplines have gained the ability to make and test semiconducting polymer materials and devices. Actual experiments with semiconducting polymers are quite dramatic. Accordingly, the project has stimulated an additional improvement in student and faculty morale, both for those who participate directly and for those who make indirect acquaintance with the project. ACKNOWLEDGEMENTS This material is based upon work supported by the National Science Foundation under Grants No. 9702320 and 9820781. The project has also received support from the Cal Poly Plan Project, Covion Corporation, National Instruments Corporation and Ocean Optics, Inc. REFERENCES 1. 2. C. W. Tang and S. A. VanSlyke, Appl. Phys. Lett., 51, 913-915 (1987). J. H. Burroughes, D. D. C. Bradley, A. R. Brown, R. N. Marks, K. Mackay, R. H. Friend, P. L. Burns, and A. B. Holmes, Nature, 347, 539-541 (1990); R. H. Friend, R. W. Gymer, A. B. Holmes, J. H. Burroughes, R. N. Marks, C. Taliani, D. D. C. Bradley, D. A. Dos Santos, J. L. Brédas, M. Lögdlund & W. R. Salaneck et al, Nature, 397, 121-128 (1999). 3. D. Braun and A. J. Heeger, Appl. Phys. Lett., 58, 1982-1984 (1991); G. Gustafsson, Y. Cao, G. M. Treacy, F. Klavetter, N. Colaneri, and A. J. Heeger, Nature, 357, 477-479 (1992); Y. Yang, MRS Bulletin, 22, 31-38 (1997). 4. Links contained in http://www.ee.calpoly.edu/~dbraun/polyelec/moreinfo.html and http://www.chipcenter.com/eexpert/dbraun/main.html accessed April 10, 2000. 5. M.D. McGehee, E.K. Miller, D. Moses and A.J. Heeger, Twenty Years of Conducting Polymers: From Fundamental Science to Applications, Advances in Synthetic Metals: Twenty Years of Progress in Science and Technology, ed. P. Bernier, S. Lefrant and G. Bidan, (Elsevier, 1999) pp. 98-205. 6. F. Wudl and G. Srdanov, U.S. Patent 5,189,136 (Feb. 23, 1993) 7. G. Yu and Y. Cao, U.S. Provisional Patent Application: 60/055/840 (Aug. 15, 1997). 8. G. Yu, J. Wang, J. McElvain, and A. J. Heeger, Adv. Mater. 10 #17, p. 1431 (1998). 9. N.S. Sariciftci, L. Smilowitz, A.J. Heeger and F. Wudl, Science 258, p. 1474 (1992); N.S. Sariciftci and A.J. Heeger, U.S. Patent 5,333,183 (July 19, 1994); N.S. Sariciftci and A.J. Heeger, U.S. Patent 5,454,880 (Oct. 3, 1995). 10. G. Yu, K. Pakbaz, and A.J. Heeger, Appl. Phys. Letters 64, p. 3422 (1994); G. Yu, J. Gao, J.C. Hummelen, F. Wudl and A.J. Heeger, Science 270, p. 1789 (1995); G. Yu and A.J. Heeger, J. Appl. Phys. 78, p. 4510 (1995); J.J.M. Halls, C.A. Walsh, N.C. Greenham, E.A. Marseglia, R.H. Friend, S.C. Moratti and A.B. Holmes, Nature 376, p. 498 (1995).