Organic matter digestion

advertisement

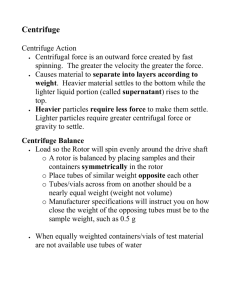

Standard Operating Procedures for Organic Matter Step “supernatant” = liquid remaining on top of sample after it has settled or been centrifuged Organic matter digestion Preheat water bath to 85 deg C Pour samples into 600-mL labeled beakers, and record which sample is in each beaker. Place beakers in 85ºC water bath, being careful that they won’t tip over. (Remove some water if the beakers float too much.) Add about 20mL of H2O2 (30% concentration) to each beaker to get started. This reaction can be violent and sporadic, so carefully monitor the beakers and disperse excessive bubbles with a spray of DI. Add more H2O2 as needed to keep the reaction active, perhaps adding some every 10 minutes or so. When the H2O2 has stopped reacting, probably by 30-60 minutes, keep heating beakers for additional 45 minutes to decompose remaining H2O2 . Keep adding DI as necessary so that samples do not dry out. If you are going to continue directly to the next step (carbonate removal), you may leave the samples in the labeled beakers. If you are going to leave them overnight, cover the beakers so they do not completely dry out (and thus cake all the sediment onto the beaker sides). If you are not going to continue directly to the carbonate removal, remove beakers from water bath and rinse sample into centrifuge tubes with DI. You may need to use a small spatula to remove caked-on sediment from sides of beaker. Standard Operating Procedures to Remove Carbonate If you are continuing directly from the previous step (organic matter removal), leave the samples in the labeled beakers and follow the “BEAKER DIRECTIONS” below. If you are not continuing directly from the previous step, you may try doing the carbonate removal in the centrifuge tubes. However, if the reaction is too violent you may need to use the beakers anyway. Follow the “CENTRIFUGE TUBE DIRECTIONS” below. 1. Prepare the NaOAc acid: Put about 500mL of DI into a 1000mL plastic volumetric flask. Weigh out 170g of dry sodium acetate (NaOAc) on balance using tared beakers or plastic weigh boats. Carefully pour the dry NaOAc into the flask, using a paper or plastic funnel if necessary. Cap the flask and swirl it vigorously until the acid is dissolved. Measure out about 60mL of acetic acid using a 100mL graduated cylinder. Uncap the flask and slowly add the acetic acid to the solution. Fill the flask to the 1000mL with DI. Cap and swirl to mix. * Extra acid solution may be stored for a few days in the graduated flask or another plastic container with a screwtop lid. In either case, be sure to clearly label the container with the type of acid, concentration and date you made it written on a piece of lab tape on the side of the container. BEAKER DIRECTIONS 2. Add about 150 mL of NaOAc acid solution to each beaker. Loosely cover beakers with watch glasses or plastic wrap, and let them sit on the counter overnight. 3. The next day, heat the water bath to 90 deg C. Carefully place the beakers into the water bath, making sure that the beakers do not float up and tip over. (If the beakers begin to float, remove some of the water bath water then try again.) 4. Bubbles mean a reaction is proceeding. Do not let the water bath or samples boil. 5. When there are no more bubbles, remove the samples from the water bath and let them settle or centrifuge them so you can decant the liquid. (If you centrifuge, you will likely need at least two centrifuge tubes per sample; pour the samples into tubes, rinsing tubes with DI to get all the sediment.) PUT THIS SUPERNATANT IN THE ACID WASTE CONTAINER IN THE HOOD. 6. Rinse once with DI water: After decanting in step 5. above, add a little DI water to each sample. Agitate the beakers or tubes by hand or on the electric tube shaker to make sure all particles get “rinsed” with the DI (and are not just stuck on the bottom of the centrifuge tube). (Pour samples into centrifuge tubes if they aren’t already in tubes.) Then, fill the tubes to 50mL with DI, cap well, and shake. Then, centrifuge and decant. THIS SUPERNATANT CAN GO DOWN DRAIN. CENTRIFUGE TUBE DIRECTIONS 2. Fill each centrifuge tube to the 40mL line with the NaOAc acid solution. Loosely place caps on tubes and let sit on the counter overnight. 3. The next day, heat the water bath to 90 deg C. Carefully place the centrifuge tube rack(s) into the water bath, making sure that the tubes do not float up and tip over. (If the tubes begin to float, remove some of the water bath water then try again.) 4. Bubbles in the tubes means a reaction is proceeding. Do not let the water bath or samples boil. 5. When there are no more bubbles, remove the samples and let them settle or centrifuge until you can decant the liquid. PUT THIS SUPERNATANT IN THE ACID WASTE CONTAINER IN THE HOOD. Then, add more NaOAc solution to each tube. If a reaction occurs, repeat the heating procedure. 6. If a reaction does not occur with the second addition of NaOAc, and you confirm that with at least two batches of samples (so that you are sure there will never be further reactions), you can skip the second addition of NaOAc for future samples. 7. When all NaOAc reaction is done, settle or centrifuge and decant. PUT SUPERNATANT IN ACID WASTE CONTAINER IN HOOD. 8. Rinse once with DI water. After decanting in step 7. Above, add a little DI water to each tube. Agitate the tubes by hand or on the electric tube shaker to make sure all particles get “rinsed” with the DI (and are not just stuck on the bottom of the tube). Then, fill tubes to 50mL with DI, cap well, and shake. Then, centrifuge and decant. THIS SUPERNATANT CAN GO DOWN DRAIN. Standard Operating Procedures to Remove Iron Oxides Prepare reagent solutions: A. Sodium citrate solution Add about 400-mL of DI to a 500-mL graduated flask Weigh out 44.2 g of sodium citrate (Na3C6H5O7) on the balance Pour the sodium citrate into the flask, then fill flask to 500-mL with DI Cap and swirl until acid is dissolved. Pour into a labeled plastic screwtop container (like the dark brown rectangular bottles) B. Sodium bicarbonate buffer solution Add about 80-mL of DI to a 100-mL graduated flask Weigh out 8.4 g of sodium bicarbonate (NaHCO3) on balance Pour the sodium bicarbonate into the flask, then fill flask to 100-mL with DI Cap and swirl until grains are dissolved Pour into a labeled plastic screwtop container (or label the flask and leave it in there) C. Saturated NaCl solution Add about 200-mL of DI to a 250-mL graduated flask Weigh out 90 g of NaCl Pour NaCl into flask, then fill flask to 250-mL with DI Cap and swirl vigorously until grains are dissolved Pour into a labeled plastic screwtop container (or label the flask and leave it in there) 1. Heat water bath to 80 deg C (DO NOT EXCEED 80) 2. Add 20-mL of citrate solution and 2.5 mL of the sodium bicarbonate to each sample (in centrifuge tubes). 3. Carefully place samples (in centrifuge tubes) in centrifuge rack into water bath, being sure that tubes do not float and tip over. If they begin to float, remove some of the water bath water and try again. 4. When tubes have had time to reach 80 deg C, add 0.5 g of sodium dithionite powder to each sample. Stir constantly with a glass rod for 1 minute, then occasionally for 15 minutes. 5. Add 5-mL of NaCl solution and mix. 6. Remove from heat, cap and centrifuge. DECANT AND PUT SUPERNATANT IN A SEPARATE HAZARDOUS WASTE CONTAINER IN HOOD, NOT IN ACID WASTE. 7. Rinse with DI water THREE TIMES according to the general rinse, centrifuge, decant procedure below. THE FIRST SUPERNATANT SHOULD GO IN THE HAZ WASTE CONTAINER, the second and third supernatants can go down the drain. Centrifuge Rinse – 3 steps i. Centrifuge at 3500 rpm for 35 minutes (or however much more or less time is necessary to get clear liquid). Decant, rinse and mix (see explanation below). Put supernatant down sink. ii. Centrifuge at 3500 rpm for 35 minutes. Decant, rinse and mix. Put supernatant down sink. iii. Centrifuge at 3500 rpm for 35 minutes or let settle. Decant, rinse and mix (applies to all steps) If sediment is well-packed, you may carefully pour supernatant out of tube. If sediment is NOT well-packed, use a syringe or sipper mechanism hooked up to the vacuum pump (see diagram) to remove supernatant. First use the larger glass tube to draw down most of liquid in each beaker. Then use the smaller plastic sipper (from titration kit, modified) to remove the final milliliters from just above the sediment. Take care to preserve all the sediment in the centrifuge tubes. Mix well, and fill the tubes with DI water. Mixing may be accomplished by using the vortex touch mixer and/or by shaking by hand. The touch mixer is most effective if you add only a few milliliters of liquid, cap and mix, and then fill tube to the top. Sipper setup: Rubber stopper Plastic tubing Sipper Vacuum pump 1 L flask Small sipper has upturned end to avoid sediment disturbance