Production - School Curriculum and Standards Authority

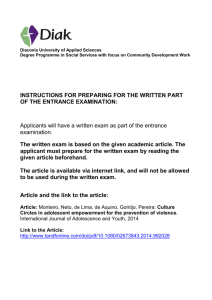

advertisement