DEHE-123871-v1-Ambient_Air_Sampling_VOC_s_(tr)

advertisement

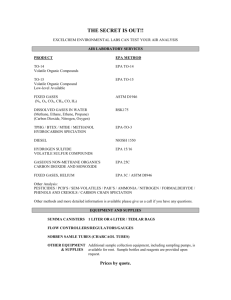

Ambient Air Sampling for Volatile Organic Compound Analysis Tribal Air Quality Program August 2010 Ambient Air Sampling for Volatile Organic Compound Analysis Tribal Air Quality Program Prepared by: Bertha Prince Jennifer Dobson Troy Ritter Edward Lohr Alaska Native Tribal Health Consortium Division of Environmental Health and Engineering 1901 Bragaw Street, Suite 200 Anchorage, Alaska 99508 August 2010 Table of Contents 1 QA Plan Identification and Approval ...........................................................................................5 2 Distribution ...................................................................................................................................6 3 Organization and Responsibilities ................................................................................................6 3.1 Roles and Responsibilities .............................................................................................................. 6 3.2 EPA Office of Air Quality Planning and Standards ........................................................................ 8 3.3 EPA Region 10 ................................................................................................................................ 8 4 Problem Definition and Background ............................................................................................9 4.1 Problem Statement and Background ............................................................................................... 9 5 Scope and Application ..................................................................................................................9 5.1 Nuiqsut Ambient Air VOC Site Sampling Plan .............................................................................. 9 5.2 Sampling Schedule ........................................................................................................................ 10 5.3 Data Collection and Quality Objectives ........................................................................................ 11 5.4. Training/Certification ................................................................................................................... 11 5.5 Documentation and Records ......................................................................................................... 11 5.6 Sampling Procedures ..................................................................................................................... 11 5.7 VOCs ............................................................................................................................................. 12 5.8 Laboratory ..................................................................................................................................... 13 5.9 Standard Operating Procedures (SOPs) ........................................................................................ 13 6 Summary of the Method .............................................................................................................13 6.1. Grab Sampling.............................................................................................................................. 13 6.2. Sampling Techniques ................................................................................................................... 13 6.3. Compendium Methods ................................................................................................................. 14 7 Definitions...................................................................................................................................14 8 Interferences ................................................................................................................................15 8.1. Particulates ................................................................................................................................... 15 8.2. Contaminants................................................................................................................................ 15 8.3. Moisture and Carbon Dioxide ...................................................................................................... 15 8.4. Potential for Overlap .................................................................................................................... 15 9 Equipment Description ...............................................................................................................15 9.1. Sample and Shipping Containers: ................................................................................................ 15 9.2. Flow Restrictors and Samplers ..................................................................................................... 16 9.3. Gas Chromatograph/Mass Spectrometer System ......................................................................... 16 10 Reagents and Standards ............................................................................................................16 10.1 Organic Solvents (Purge & Trap Grade) ..................................................................................... 16 10.2 Laboratory Reagent Water .......................................................................................................... 16 10.2.1 Type 1 Laboratory Reagent Water ........................................................................................... 17 10.3 Helium, Nitrogen and Air............................................................................................................ 17 10.4 Internal Standard and Tuning Standard ....................................................................................... 17 10.5 Calibration Standards .................................................................................................................. 17 11 Equipment Cleaning and Certification Procedures ...................................................................18 11.1 Canister Cleaning Procedure ....................................................................................................... 18 11.2 Canister Certification Procedure ................................................................................................. 19 12 Sample Collection, Handling and Storage ................................................................................20 12.1 Sample Collection: ...................................................................................................................... 20 12.2 Sample Handling, Storage and Hold Times: ............................................................................... 21 13 Sample Analysis Procedure and Instrument Operating Conditions ..........................................22 13.1. Entech Concentrator and Auto-sampler Settings (typical): ........................................................ 22 13.2 Gas Chromotograph/Mass Spectrometer Conditions (typical): .................................................. 22 13.3 GC/MS Instrument File Names ................................................................................................... 22 13.4 GC/MS Tuning ............................................................................................................................ 23 13.5 Initial and Routine Calibration: ................................................................................................... 23 13.5.1 Average Response Factor ......................................................................................................... 24 13.6 PQL Check Standard (PQLCS) ................................................................................................... 24 13.7 Internal Standard Retention Time and Internal Standard Response ............................................ 24 13.8 Analysis Sequence....................................................................................................................... 25 13.9 Pre-Analysis Checklist for the GC/MS Run Sequence: .............................................................. 26 13.10 Post-Analysis Checklist: ........................................................................................................... 26 13.11 Qualitative Analysis: ................................................................................................................. 27 13.12 Quantitative Analysis ................................................................................................................ 28 14 Quality Control .........................................................................................................................28 15 Data Processing, Review and Reporting ...................................................................................29 15.1 Data Processing ........................................................................................................................... 29 1 QA Plan Identification and Approval Title: Ambient Air Sampling into Stainless Steel Canisters for Volatile Organic Compound Analysis for the Alaska Native Tribal Health Consortium, Division of Environmental Health and Engineering department. The Ambient Air Sampling into Stainless Steel Canisters for Volatile Organic Compound Analysis Plan for the Alaska Native Tribal Health Consortium, Division of Environmental Health and Engineering is recommended for approval and commits the Program to follow the elements described within. ANTHC Troy Ritter, ANTHC ANV Air Project Manager Date Ed Lohr, ANTHC ANV Air Monitoring Project Coordinator Date EPA Region 10 Mary Manous, EPA Project Officer Date Christopher Hall, Quality Assurance Officer Date Ambient Air Sampling VOC’s Page 5 of 30 2/18/2016 2 Distribution A copy of the Ambient Air Sampling into Stainless Steel Canisters for Volatile Organic Compound Analysis is distributed to the following listed below: Name Troy Ritter Position Project Manager Organization ANTHC Ed Lohr Project Coordinator ANTHC Christopher Hall Quality Assurance Officer EPA Region 10 Mary Manous EPA Project Officer EPA Region 10 Contact Information 1901 Bragaw St. Anchorage, AK 99508 907-729-5683 tlritter@anthc.org 1901 Bragaw St. Anchorage, AK 99508 907-729-3527 elohr@anthc.org 1200 Sixth Avenue OEA-095 Seattle, WA 98101 206-553-0521 hall.christopher@epa.gov 1200 Sixth Avenue, Suite 900, AWT-107 Seattle, WA 98101 206-553-1059 manous.mary@epamail.epa.gov 3 Organization and Responsibilities 3.1 Roles and Responsibilities Federal, State, Tribal and local agencies all have important roles in developing and implementing satisfactory ANV air monitoring programs. As part of the planning effort, EPA is responsible for developing National Ambient Air Quality Standards (NAAQS), and identifying a minimum set of QC samples from which to judge data quality. The state and local organizations are responsible for taking this information and developing and implementing a quality system that will meet the data quality measurements. Then, it is the responsibility of both EPA and ANTHC and local organization to assess the quality of the data and take corrective action when appropriate. The responsibilities of each organization follow. Ambient Air Sampling VOC’s Page 6 of 30 2/18/2016 Title and responsibilities of key personnel are: ANV Air Quality Program Manager-Troy Ritter ● Management of the overall ANV Air Quality Program ANV Air Quality Program Assistants- Jennifer Dobson, Chris Fish ●Community Planning and Support ●Air Monitoring Procedures and Training Support ANV Air Quality Monitoring Program Assistant-Bertha Prince ●Air Monitoring Procedures and Training ●Quality Assurance Policies, Plans, and Procedures ●Performance and System Audits ●Reporting Technical Services Section Manager, TBD ●Calibration and Quality Control Standards ●Air Monitoring Equipment Procurement, Testing, and Calibration ●Parts and Supplies Inventory ANV Air Toxics Project Coordinator, TBD ●Network Evaluation and Design Coordination ●Station Installment and Operation Coordination ●Air Toxics Data Management ●Final Reports ANV Air Monitoring Station Operators, TBD Note: An operator in Nuiqsut will be hired by June 30, 2010. ●Station Installation, Operation, Sample Collection ●Sample Shipments to ANTHC ●Quality Control and Precision Checks ●First Level Data Validation ●Routine Maintenance and Repair Ambient Air Sampling VOC’s Page 7 of 30 2/18/2016 Figure 1 represents the organizational structure of the areas of the ANV Air Quality Monitoring Program that are responsible for the activities defined above. Figure 1 ANV Air Quality Monitoring Program Organizational Chart Troy Ritter, ANV Air Quality Program Manager EPA Staff Mary Manous Christopher Hall Jennifer Dobson, Chris Fish, Bertha Prince, ANV Air Quality Program Assistant ANV Air Quality Program Assistant ANV Air Quality Program Assistant 3.2 EPA Office of Air Quality Planning and Standards 3.3 EPA Region 10 The EPA Regional Offices will address environmental issues related to the States within their jurisdiction and to administer and oversee regulatory and congressionally mandated programs. The major quality assurance responsibilities of EPA’s Regional Offices are the coordination of quality assurance matters at the Regional levels with the State and local agencies. This is accomplished by the designation of EPA Regional Project Officers who are responsible for the technical aspects of the program including: Reviewing QAPP’s be Regional QA Officers who are delegated authority by the Regional Administrator to review and approve QAPP’s for the agency. Ambient Air Sampling VOC’s Page 8 of 30 2/18/2016 4 Problem Definition and Background 4.1 Problem Statement and Background The North Slope of Alaska is home to the largest oil field in North America, Prudhoe Bay, as well as several other smaller oil fields. ConocoPhillips began oil production at the Alpine oil field in November 2000. The Alaska Native village of Nuiqsut is located 56 miles away from Prudhoe Bay and 8 miles from the Alpine oil field where oil is extracted and undergoes initial refinement. Natural gas is generated as a waste product of oil drilled and ‘flared off’ as a means of disposal. Nuiqsut is an Inupiat Eskimo community of 425 people, many of whom follow a traditional subsistence lifestyle. Some community residents have expressed concerns about the proximity to nearby oil development, resulting in air pollution and potential health implications. There is one air monitor currently operating in Nuiqsut that measures only PM10. This air monitor is reportedly funded by ConocoPhillips. Data from the monitor is collected by ConocoPhillips and then provided to the community. Nuiqsut community members have expressed concerns about the legitimacy of this data. There has been no independent assessment of the impact of oil industry activities on the health of Nuiqsut residents. There is currently no available data on background levels of volatile organic compounds (VOC’s) in Nuiqsut’s ambient air. It is unknown if the nearby oilfield contributes to VOC levels in the community. This activity aims to determine ambient VOC levels in Nuiqsut and serve as a first-order assessment to determining if VOC’s produced at the oil field are influencing the community. It is unknown if other conditions will contribute to elevated VOC levels. Future projects may evaluate the effect of severe weather conditions such as southerly winds and inversion on extreme cold weather days, and process conditions such as flare purging. 5 Scope and Application 5.1 Nuiqsut Ambient Air VOC Site Sampling Plan This document details the locations of sampling sites for organic compounds (VOC’s) in ambient air using stainless steel canisters. Samples will be taken at four locations around the perimeter of Nuiqsut using the combined EPA methods TO14A/TO-15 as described in this plan, with the possibility of adding two more locations. The rationale behind the locations of these samples is to identify the presence of contaminants as they may be transported into and through Nuiqsut as well as the possibility of dispersion and identifying other contaminant sources within the village. In the future, meteorological data from the airport station may be cross referenced with sample results. Ambient Air Sampling VOC’s Page 9 of 30 2/18/2016 Figure 5.1 Sampling Site Map NW sample location NE sample location SW sample location SE sample location 5.2 Sampling Schedule The ANV Air Quality Program is proposing conducting 4 rounds of sampling following this QAPP; one conducted June 30-31, 2010, one for September 7-8, 2010, and the remaining two sampling activities will be completed during the winter months. Due to the nature of travel in Rural Alaska, additional sampling schedules will be proposed and added as the project progresses and timelines can be confirmed. Table 5.2 Sample Schedule, September 2010 Sample Location Northwest Northeast Southwest Southeast Method EPA Method TO-14A/15 EPA Method TO-14A/15 EPA Method TO-14A/15 EPA Method TO-14A/15 Ambient Air Sampling VOC’s Start 9/7/2010 10:30am 9/7/2010 10:50am 9/7/2010 11:20am 9/7/2010 11:45am End 9/8/2010 10:30am 9/8/2010 10:50am 9/8/2010 11:20am 9/8/2010 11:45am Page 10 of 30 Rate 0.928 ml/min 0.928 ml/min 0.928 ml/min 0.928 ml/min Volume 1 liter 1 liter 1 liter 1 liter 2/18/2016 9/6/2010 Jennifer Dobson will travel to Nuiqsut and arrive in the afternoon of 9/6/2010. Accommodations will be setup. In the afternoon, all sampling equipment will be inspected for damage. Missing items or other needs will be gathered. 9/7/2010 Jennifer will prepare for sampling, and proceed to the Northwest sample location, the samples will be set up and sample runs will follow Table 5.2 Sample Schedule. 9/8/2010 Jennifer will collect the canister samplers following Table 5.2 Sample Schedule. The canisters will be packed and shipped following the laboratory instructions. 5.3 Data Collection and Quality Objectives This purpose of this project is to collect data on VOC’s in ambient air during mild weather conditions and typical process conditions at the oilfield and refinery. This data must be collected following the quality procedures set forth in this document. The quality of this data is important because it will be used to determine if further monitoring will be useful in defining the oilfield and refineries impacts on ambient VOC levels under other than typical weather and process conditions. The data to is to be collected and analyzed using the following methods: EPA Method TO-14A EPA Method TO-15 5.4. Training/Certification Personnel responsible for collecting the samples in this project will be familiar with the applicable EPA methods, laboratory established sample collection procedure and this document prior to mobilizing on the project. 5.5 Documentation and Records The most current QAPP will be provided by the ANV Air Quality Program Assistant to all sampling personnel prior to mobilization on the project. A field data sheet and a field log will be used to collect all relevant information during the project and maintained with all project records. All calibration and equipment maintenance records will be maintained by the equipment owner and referenced in the field data sheet. Copies of the laboratory chain of custody and results will be maintained in the project records. All relevant records collected will be appended to the final project report and maintained with the project records and retained according to EPA requirements. 5.6 Sampling Procedures This document details the procedures for sampling volatile organic compounds (VOC’s) in ambient air using stainless steel canisters. The whole air samplers are collected in stainless steel canisters using air sampling equipment. The samples are subsequently Ambient Air Sampling VOC’s Page 11 of 30 2/18/2016 analyzed by gas chromatography/mass spectrometry (GC/MS). The procedures describe the operational details required to collect sub-atmospheric pressure samples. 5.7 VOCs This standard operational procedure is applicable to VOC’s known to be stable when stored in stainless steel canisters. The compounds given in table 1 are listed in the EPA Methods TO-14A and TO-15, which describe the analysis of VOC’s in ambient air at sub parts-per billion (ppb) level. TABLE 1. List of Compounds and Associated Analysis Method: Acetone Acrolein TO-15 TO-15 Allyl chloride Benzene Benzyl chloride Bromodichloromethane Bromoform Bromomethane 1,3-Butadiene 2-Butanone (MEK) TO-15 TO-14A TO-15 TO-15 TO-15 TO-14A TO-15 TO-15 Carbon disulfide TO-15 Carbon tetrachloride Chloroethane Chlorobenzene Chloroethane Chloroform Chloromethane Cyclohexane Dibromochloromethane 1,2-Dibromoethane 1,2-Dichlorobenzene 1,3-Dichlorobenzene 1,4-Dichlorobenzene TO-14A TO-14A TO-14A TO-14A TO-14A TO-14A TO-15 TO-15 TO-14A TO-14A TO-14A TO-14A Dichlorodifluoromethane (Freon 12) TO-14A 1,1-Dichloroethane 1,2-Dichloroethane 1,1-Dichloroethene Cis-1,2-Dichloroethene Trans-1,2-Dichloroethene 1,2-Dichloropropane Cis-1,3-Dichloropropene Trans-1,3Dichloropropene TO-14A TO-14A TO-14A TO-14A TO-15 TO-14A TO-14A TO-14A Ambient Air Sampling VOC’s 1,4-Dioxane 1,2-Dichloro-2,2,3,3tetrafluoroethane (Freon 114) Ethyl acetate Ethyl benzene 4-Ethyl toluene Heptane Hexachloro-1,3 butadiene 2-Hexanone Methylene chloride 4-Methyl-2-pentanone (MIBK) Methyl-t-butyl ether (MTBE) 2-Propanol Propylene Styrene 1,1,2,2-Tetrachloroethane Tetrachloroethene Tetrahydrofuran Toluene 1,2,4-Trichlorobenzene 1,1,1-Trichloroethane 1,1,2-Trichloroethane Trichloroethene Trichlorofluoromethane (Freon 11) 1,1,2-Trichloro-1,2,2trifluoroethane (Freon 113) 1,2,4-Trimethylbenzene 1,3,5-Trimethylbenzene Vinyl acetate Vinyl bromide Vinyl chloride ortho-Xylene meta-Xylene para-Xylene Page 12 of 30 TO-15 TO-14A TO-15 TO-14A TO-15 TO-15 TO-14A TO-15 TO-14A TO-15 TO-15 TO-15 TO-15 TO-14A TO-14A TO-14A TO-15 TO-14A TO-14A TO-14A TO-14A TO-14A TO-14A TO-14A TO-14A TO-14A TO-15 TO-15 TO-14A TO-14A TO-14A TO-14A 2/18/2016 5.8 Laboratory ANTHC will be collaborating with Galson Laboratories in East Syracuse, New York for calibration, cleaning and analysis of the mini-canisters. Test ID’s and equivalent EPA methods covered by this SOP: ● A-TO14/15-EPA Method TO-14A and TO-15 analysis, Canister Air Analysis 5.9 Standard Operating Procedures (SOPs) Refer to the following Standard Operating Procedures (SOPs) for additional information: These supporting SOPs contain critical details not fully described within this method SOP. The analyst should be completely familiar with all of these SOPs. 5.9.1. Safety and Waste Management Practices in the Organic Analysis Groups 5.9.2. Glassware and Equipment Cleaning Procedures 5. 9.3. Data Review/Authorization Procedures for the Volatile Organic and Methyl Mercury Laboratory 5.9.4. Quality Assurance/Quality Control Measurements in the Volatile Organics (VOC) Laboratory 5.9.5. Non-Conformance Reporting System 5.9.6. Laboratory Policy Regarding Manual Chromatographic Peak Integration 5.9.7. Standard Operating Procedure for Reporting Qualified Data 5.9.8. Standard Operating Procedure for Records Storage and Retention 6 Summary of the Method 6.1. Whole Air Sampling The passivated canister is designed to offer flexibility in collecting air samples. The primary mode for collecting samples will be: (1) Whole air sampling of ambient air. Specialized field equipment is described for both short-term and long-term monitoring scenarios. For this activity, 1 liter canisters equipped with 24 hour regulators will be used. 6.2. Sampling Techniques Whole air is collected into evacuated canisters using passive or pump-assisted air sampling techniques. Both of these techniques draw a sample of ambient air through a sampling train that removes particulates, regulates sampling flow rate, controls sample start and end times, and monitors start and end pressures. The instrumentation included Ambient Air Sampling VOC’s Page 13 of 30 2/18/2016 in the procedures may be used to collect and analyze both sub-atmospheric pressure and pressurized samples. The volatile compounds collected in the canisters are transported to the laboratory and are analyzed by gas chromatography / mass spectrometry, which provides both qualitative and quantitative information. During analysis in the laboratory, the sample canister is attached to an auto sampler where typically 10 to 1000 mL of the air sample is pumped out of the canister and collected on a cryogen-cooled glass bead trap. Internal standard and tuning compounds are also collected on the trap with the sample. The sample and internal standard compounds are then transferred to a second stage Tenax trap, effectively removing most of the water and CO2. The VOC compounds are then transferred to a third stage where they are cryogenically focused prior to injection onto the GC column. The detector used in the analysis is a mass spectrometer. 6.3. Compendium Methods The analysis method is based on TO-14A and TO-15 in the Compendium of Methods for the Determination of Toxic Organic Compounds in Ambient Air, Second Edition (EPA/625/R-96/010b). All of the procedures described here are designed to meet or exceed the criteria from both of these EPA quantitative methods. Please refer to these EPA guidance documents for additional details. 7 Definitions Cryogen: a refrigerant (typically liquid nitrogen) used to obtain sub-ambient temperatures in the VOC concentrator instrument prior to sample introduction on the analytical column. The cryogen used by our instruments is liquid nitrogen. Dynamic Calibration: calibration of the analytical system with gas standard concentrations at similar concentrations, in a form identical and through the same analytical path as in the real samples. Dynamic Dilution: means of preparing calibration mixtures or diluting a sample in which a concentrated gas stream is continually blended with zero air in a manifold and introduced at the inlet of the analytical system or a receiving canister. Pressure, Absolute: pressure measured with reference to absolute zero pressure expressed in psia. An absolute pressure value of zero is indicative of an evacuated system (vacuum). Pressure, Gauge: pressure measured with reference to the surrounding atmospheric pressure expressed in units of psi. A gauge pressure value of zero is equal to atmospheric pressure. Sub-atmospheric Sampling: collection of ambient air into an evacuated canister with a final canister pressure below atmospheric pressure. This is the normal practice when collecting air with passive sampling devices since the sample collection must be stopped prior to completely filling the canister. Ambient Air Sampling VOC’s Page 14 of 30 2/18/2016 8 Interferences 8.1. Particulates Particulates that cause blockage in the sample collection pathway are a potential problem during sample collection. The field equipment must be tested periodically to insure the integrity of the sampling equipment. The presence of these problems can often be observed by monitoring and recording the initial and final pressure when sampling. 8.2. Contaminants Contamination may occur in the sampling and concentrator systems if the equipment is improperly cleaned before each use. All sampling and analysis equipment coming into contact with the sample must be thoroughly cleaned and tested on a regular basis. 8.3. Moisture and Carbon Dioxide Moisture and carbon dioxide are two of the primary interferences encountered in whole air measurements due to the normally high concentration of these compounds in ambient air. Elevated levels of water or carbon dioxide may severely restrict the sample size that can be measured. Compendium Method TO-15 provides guidance for water management systems as it pertains to the analysis of polar organic compounds. 8.4. Potential for Overlap The potential for overlap of eluting compounds in the chromatography is significant when dealing with such an extensive compound list from two air analysis methods. The potential for encountering interferences is significantly reduced by using cryogenic focusing, a smaller ID capillary column and a mass spectrometer detector. Cryogen focusing and the small ID capillary column used in this method provides for an enhanced compound separation such that overlapping compounds are minimized. Also, the mass spectrometer can effectively resolve many of the remaining overlapped compounds based on the mass spectra of the compounds. 9 Equipment Description The operation, cleaning and scheduled maintenance procedures prescribed by the equipment manufactures are followed as provided in the manufacturer’s instructions. Documentation of cleaning, maintenance or system modification is recorded in a maintenance logbook that accompanies each instrument system. 9.1. Sample and Shipping Containers: Galson Lab canisters with fused silica lining in the can and valve. The laboratory maintains more than 20 canisters in its inventory. ●400-mL Entech canister with fused silica lining in the can and valve. The laboratory maintains 4 extra canisters, in addition to the 26 canisters in the field for the Bureau of Emergency Response. ●Aluminum shipping container that holds two 1-L canisters. The laboratory maintains 4 shipping canister in its inventory. Ambient Air Sampling VOC’s Page 15 of 30 2/18/2016 ●Entech CS1200P Flow Controller with sampling belt and holster. ●Entech Vacuum Check Gauge equipped with a quick connect adapter for the 400mL canisters ●Docosil Weather proof case used to transport 400-mL canisters and samplers ●Entech 3100A Canister Cleaner equipped with Entech SmartLab software 9.2. Flow Restrictors and Samplers The fill times indicated below are for the 400-mL mini-canisters. The larger canisters will require a longer fill time proportional to the volume. Most of the samplers are equipped with quick connections, but some have Swagelock connections. ●Quick Fill Grab Sampler ●1 Minute Fill Sampler ●15 Minute Fill Sampler ●8 Hour Fill Sampler ●24 hour Fill Sampler (only for 1 liter container) 9.3. Gas Chromatograph/Mass Spectrometer System ●Agilent 6890 or Finnigan Trace Gas Chromatograph. ●Agilent 5973 Inert or Finnigan Polaris Q Mass Spectrometer ●Entech 7100A Pre-concentrator ●Entech 7016CA 16-Position Auto-sampler ●Entech 4600A Dynatmic Diluter ●IBM-compatible Personal Computer. ●Agilent Enviroquant or Finnigan Xcalibur Computer Software. ●Entech SmartLab Network Software ●J&W Scientific DB-5MS, 60 m x 0.25 mm ID capillary column, 0.25 μm film thickness. ●Supelco High Capacity Gas Purifier 10 Reagents and Standards Working with volatile compounds presents a number of challenges not normally confronted in the handling of most other chemicals. Volatile compounds may escape from sample containers or, when present in the laboratory environment, can contaminate analytical equipment. Sources of the reagents and chemicals are given, but may change based on availability, quality and cost. The use of a different source is acceptable without modification of the procedures provided the products are equivalent. 10.1 Organic Solvents (Purge & Trap Grade) Methanol: CH3OH-Purge & Trap grade methanol is purchased in 500 mL amber bottles. 10.2 Laboratory Reagent Water Type 1 laboratory reagent water is prepared in the laboratory. The criterion for laboratory reagent water is that it must not contain any analytes of interest at a Ambient Air Sampling VOC’s Page 16 of 30 2/18/2016 concentration greater that 20% of the reporting limit. Other non-target compounds may be detected in the laboratory reagent water, but must not interfere with the analysis of the target compounds. Examples of non-target compounds commonly observed are methanol (used in glassware cleaning and standard preparation) and siloxanes (from surfactants, pump oils and column bleed). 10.2.1 Type 1 Laboratory Reagent Water Municipal water is purified with Solution 2000 Water Purification System that uses activated carbon cartridges and ion-exchange cartridges to remove impurities. 10.3 Helium, Nitrogen and Air Ultra high purity grade in gas cylinders from Air Products. Helium is used as the carrier gas in the GC/MS instrument system. 10.4 Internal Standard and Tuning Standard 100 ppbv Internal Standard and Tune Standard Mixture: the internal standard and tune standard mixture is purchased in a 3395 L (2A) cylinder from Spectra Gases at a concentration of 100ppbv. The internal standard compounds are bromochlorobenzene, chlorobenzene-d5, and 1,4-difluorobenzene. The mass spectrometer tune standard compound is 4-bromofluorobenzene. The 4 compounds in this mixture are prepared in nitrogen at a final cylinder pressure of 2000 psig. The standard mixture is certified by Spectra Gases for one year from preparation. 10.5 Calibration Standards ●100 ppbv TO-14A Calibration Standard Mixture: The TO-14A calibration standard is purchased in a 3395 L (2A) cylinder from Spectra Gases at a concentration of 100 ppbv. The TO-14A standard mixture contains 39 of the compounds listed in Table 1 and includes all of the Compendium Method TO-14A target compounds, except for benzyl chloride. The compound benzyl chloride is included in the TO-15 calibration mixture. The 39 compounds in this mixture are prepared in nitrogen at a final cylinder pressure of 2000 psig. The standard mixture is certified by Spectra Gases for one year from preparation. ●100 ppbv TO-15 Calibration Standard Mixture: The TO-15 calibration standard is purchased in a 3395 L (2A) cylinder from Spectra Gases at a concentration of 100 ppbv. The TO-15 standard mixture contains 25 of the compounds listed in Table 1 and includes only a subset of the Compendium Method TO-15 target compounds, except for benzyl chloride. The 39 compounds in this mixture are prepared in nitrogen at a final cylinder pressure of 2000 psig. The standard mixture is certified by Spectra Gases for 6 months from preparation. Ambient Air Sampling VOC’s Page 17 of 30 2/18/2016 11 Equipment Cleaning and Certification Procedures The equipment used for sample collection and analysis must be clean and certified before use. 11.1 Canister Cleaning Procedure The laboratory prepares the sample canisters by cleaning and testing the canisters in batches of 4 at a time using the Entech 3100A Canister Cleaner. The passivated canisters are expensive, so handle them with care. Please refer to the canister cleaner operating manual for more detailed operation and maintenance instructions. Use the following cleaning and testing procedure to prepare the canisters: 11.1.1 Inspect each canister for damage, corrosion and visible contamination. Make repairs as needed to insure the integrity of each canister. Inspect for loose or missing parts as well. Remove any external contamination with DI water or methanol solvents and soft cloth wipe. Do not use other solvents or abrasives unless specifically approved by your supervisor. 11.1.2 Turn on the power for the Entech 3100A cleaner and diaphragm pump. Enter the Entech SmartLab software to make sure the instrument is communicating and that the valves to the manifold are all closed. Turn on the molecular drag pump and allow it to come up to speed (check indicator on front instrument panel). At this point the instrument is ready to use. The manifold valves must be kept closed during the aforementioned startup procedures. 11.1.3 Program the Entech SmartLab software for the type of cleaning cycle (light, medium or heavy-duty). The type of cycle used depends on the previous use of the canisters. If the canisters are already relatively clean then use a light-duty cleaning cycle. Use the heavy-duty cleaning cycle for more contaminated canisters. 11.1.4 Remove the protective fitting plugs on the canisters and the manifold connections on the Entech 3100A canister cleaner. 11.1.5 Attach the canisters to the cleaner manifold. The current cleaning unit is designed to accept 4 canisters, but can be extended for up to 8 canisters. Each canister is attached to the manifold with a Swagelock fitting. Do not over-tighten or crossthread the fittings. 11.1.6 Open the valves on all of the canisters after all of the manifold ports have been connected to canisters or sealed with plugs. 11.1.7 Perform a leak check of the canisters and manifold through the SmartLab software. L ocate and correct any leaks. Pressurizing the manifold and canisters with Helium and using the leak detector is an excellent way to locate leaks. Do not over-tighten fittings. Leaking canisters must be repaired before being placed into service. Consult a supervisor on repairing canisters. Ambient Air Sampling VOC’s Page 18 of 30 2/18/2016 11.1.8 Initiate the cleaning cycle through the Entech SmartLab software. 11.1.9 Slip the canister heater bands onto each canister and connect the heater band electrical cord. Take care to remove all combustible materials from the area around the heater bands and avoid direct contact with the heater elements. Turn on the electrical heater bands. 11.1.10 Monitor the first cleaning cycle to make sure the Entech 3100A cleaner is working properly. The heater bands should heat up quickly and the molecular drag pump indicator must be on. Monitor to see if the instrument’s overheating light comes on at any time during operation. Shut the system down and consult the supervisor if any irregularities are noted. 11.1.11 The cleaner will perform vacuum/pressure cycles using moist (UPC) nitrogen for pressurization. 11.1.12 After the cleaning cycle is complete, turn off and remove the heater bands, close the manifold and close the valve to one of the canisters. The canister with the closed valve will be used to QC test the entire batch and must be marked with batch date. 11.1.13 Allow the manifold and open canisters to fill with zero-grade nitrogen or zero air using the controls in the SmartLab software. Close the manifold after the canisters have filled with nitrogen. 11.1.14 Open the valve on the QC canister (closed previously) so that nitrogen will flow from each of the open canisters attached to the manifold into the evacuated QC canister. Close the valve to the QC canister only after equilibrium is reached. 11.1.15 Evacuate the remaining open canisters to a vacuum of less than 5 mTorr through the SmartLab software. 11.1.16 Close the manifold and canister valves. Remove the QC canister for testing. 11.2 Canister Certification Procedure ●A single QC canister from each cleaning batch must be analyzed for volatile organics before the canisters may be used to collect air samples ●Attach the QC canister from a cleaning batch onto one of the connections on the Entech 7016CA 16-position auto-sampler ●Perform a leak check on the auto-sampler connections ●Perform an analysis of the QC canister as though it is a real sample Ambient Air Sampling VOC’s Page 19 of 30 2/18/2016 ●The canisters in the cleaning batch may be used for sample collection if the QC canister results are < 0.10 ppbv and are free of other interferences ●Reattach the QC canister to the cleaning manifold ●Repeat the cleaning process if the QC check indicates that the canisters are contaminated ●Once tested clean, the canisters are evacuated to < 5 mtorr. Close the manifold and canister valve, remove the canisters from the cleaner manifold and replace the dust caps on the open fittings ●Attach an identification tag that gives the date of cleaning and your initials ●The canisters are now ready for collection of air samples. 12 Sample Collection, Handling and Storage The sampling process begins with the preparation of the canisters used to collect the sample. The canisters are provided by the laboratory and are prepared based on the sample requests received. This section describes the steps involved in collecting and handling the air samples. 12.1 Sample Collection: Select the type of sampling to be performed. Samples are collected with either a passive critical orifice sampler or an active pump sampler with a mass flow controller. The canisters and sampling unit must be certified clean prior to collecting samples as described in Section 11. The flow rate setting of the sampler must be established prior to collecting samples. The internal flow control device in the sampling unit must be calibrated with a NIST certified flow meter prior to use. The sample collection time, canister volume and flow rate setting are interrelated by the equation: F= PxV T x 60 Where: F = flow rate, mL/min. P = final canister pressure, atmospheres V = canister volume, mL. T = sample period, hours. Remove the protective caps from the canister valve and selected sampler unit. Place the sampling apparatus in the area in which you wish to sample (i.e. breathing zone or contaminated area). Connect the canister to the sampling unit. The mini-canisters are equipped with quick-connections instead of the Swagelock fittings on the 6-liter Ambient Air Sampling VOC’s Page 20 of 30 2/18/2016 canisters. Do not over tighten the Swagelock connection since this can result in leaks and damage the fitting. Place the sampling orifice into the sampling zone. Be careful not to protect the orifice from precipitation or contact with standing liquids. The canister vacuum should be at least 26 inches Hg as measured by the canister test gauge. Do not use the canister if the internal vacuum is less. The mini-canisters begin collecting the sample immediately after they are connected since there is no manual valve. The mini-canister connection is maintained for a period of time equal to or less than the time stamped on the flow restrictor orifice and is then disconnected to end the sampling period. The 6-liter canisters are equipped with a manual on-off valve. Once the 6-liter canister is connected to the sampler, whole air is collected using the passive canister sampler by simply opening the canister valve. The canister valve is left open for a period of time equal to or less than the time determined by the flow rate of the restrictor orifice. More complex sampling devices can have timers and electronic valves to collect the air sample such as the AVOCs sampler manufactured by Graseby-Anderson. Please refer to the manufacture instruction manual for details of operation. After the air sample is collected, close the canister valve and cap the valve connections. The outside of the sample container must be tagged with a field identification. The minicanisters may be placed into a Ziplock bag and a chain-of-custody labels may be placed across the bag opening to give added protection to the integrity of the sample. Fill out all applicable chain-of custody forms that accompany the samples. A final canister pressure reading may be taken with the manual pressure gauge and recorded. Avoid attaching sticky labels directly onto the canisters since these labels are difficult to remove. Use labeled bags or tags instead. Place the canisters into the designated aluminum or plastic shipping boxes for added safety and convenience. 12.2 Sample Handling, Storage and Hold Times: The canisters are kept in the aluminum shipping boxes for added protection when they are not being sampled or analyzed. The chain-of-custody form for the cleaned canisters will have an expiration date listed for each of the canisters. The “use by” expiration date for the routine sampling containers is 1 month, although the containers are known to be stable for more than 6 months. Sample preservation includes storage of the canisters in a cool, dry location. The canister samples must be maintained in a secure and air-conditioned (25 °C) environment until submitted to the DEP laboratory for analysis. Ambient Air Sampling VOC’s Page 21 of 30 2/18/2016 The passivated sampling train and canisters are designed to hold an ambient air sample for up to 30 days with minimal degradation. The hold time for the compounds listed in this analysis is 30 days. The sample pressure must not exceed 40 psi. Increased pressure may cause the compounds in the canister to degrade more quickly 13 Sample Analysis Procedure and Instrument Operating Conditions Suggested Instrument Conditions: The instrument conditions are given below. Specific instrument conditions may vary. 13.1. Entech Concentrator and Auto-sampler Settings (typical): Line Temp = 100°C Bulk Head 1 = 30°C Bulk Head 2 = 30°C Module 1 Trap = -150°C Module 1 Preheat = 20°C Module 1 Desorb = 20°C Module 1 Bake = 130° C Module 1 Bake Time = 5 min Module 2 Trap = -10°C Module 2 Preheat = off Module 2 Desorb = 180°C Module 2 Bake = 190°C Module 2 Desorb Time = 3.5 min Module 3 Trap = -180°C Module 3 Inject = 2 min Module 3 Bake Time = 2 min Module 3 Event = 3 Module 3 Wait Time = 25 min Pressure Comp Factor = 25 Loop Flush = 30 seconds 13.2 Gas Chromotograph/Mass Spectrometer Conditions (typical): Initial Temperature = -20°C Initial Time = 0 min Ramp Rate = 7 C/min MS Source Temp =210°C Final Temperature = 200°C Final Time = 1 min Rate (A) = 5°C/min Note: The GC/MS software used by the ? Instrument is designed to collect MS data, setup calibration files, automatically perform calculations, report pass/fail for tuning, and report detect/non-detect for compound identification based on the method criteria. 13.3 GC/MS Instrument File Names The GC/MS Instrument file names are generated using the 9-character naming convention YYMDDI## YY M DD I Year (2010 = 10, 2011 = 11) Month (1 = January, 2 = February, 3 = March, 4 = April, 5 = May, 6 = June, 7 = July, 8 = August, 9 = September, O = October, N = November, D = December) Day (1-31) Instrument number (1-4) Ambient Air Sampling VOC’s Page 22 of 30 2/18/2016 ## Sequential sample numbers from 01-99. 13.4 GC/MS Tuning The GC/MS system must be checked to ensure that acceptable performance criteria are achieved for the tuning compound bromofluorobenzene (BFB) at the beginning of each day and every 12 hours thereafter for as long as analysis are to be performed. This performance test must be passed and maintained before any samples or standards are analyzed. The internal standard and surrogate mixture added automatically by the sample concentrator contains BFB as one of the surrogates. Analysis of a humid zero air sample will serve as a GC/MS performance test. The tune analysis must meet the criteria listed in EPA Methods TO-14A and TO-15 for a 25-ng injection of BFB (bromofluorobenzene). Obtain the BFB mass spectrum average for the apex plus 1 scan before and after the apex. Confirm that all of the m/z criteria in Table 2 are achieved. If the criteria are not achieved, the operator must retune the mass spectrometer and repeat the test until all criteria are achieved. Table 2. BFB m/z Abundance Criteria Mass, m/z 50 75 95 96 173 174 175 176 177 Abundance Criteria 8-40% of mass 95 30-66% of mass 95 Base peak, 100% 5-9% of mass 95 <2% of mass 174 50-120% of mass 95 4-9% of mass 174 >93% but < 101% of mass 174 5-9% of mass 176 13.5 Initial and Routine Calibration: Each instrument is calibrated according to the procedures specified within EPA Method TO-14A and EPA Method TO-15. Clarification of the calibration requirements and practices of this laboratory are discussed below. Refer to the EPA method protocols for additional detail. Analytical standards for the initial calibration must be certified and NIST traceable. The standard solutions for the calibration and standard spiking solutions must be from independent sources. The term “independent source” means that the origin of the standard preparations is known to be different from one another. In practical terms this requires that the solutions be prepared by two different suppliers or at a minimum, have different lot numbers from the same supplier. Ambient Air Sampling VOC’s Page 23 of 30 2/18/2016 Initial calibration of the GC/MS is performed before sample analysis, with the assistance of the Entech 7100 calibration system. The Entech 7100 draws standard gas from cylinders purchased at a concentration of 100 ppbv. The standard gas flow into the Entech 7100 concentrator is regulated by a mass flow controller that is set through the system software. The calibration must include three concentration levels and a humid zero air sample as a minimum. The Relative Standard Deviation (RSD) for any one of the compounds must be <30% for sample analysis to proceed. For routine analysis, a single point calibration check (CCV) sample is evaluated daily to insure proper calibration. If the Relative Percent Difference (RPD) for the compounds in the single point check sample are <30%, then analysis of samples may continue. However, if the RPD for the single point check is >30%, then recalibration is required. 13.5.1 Average Response Factor An average response factor can be calculated for each target compound once the calibration curves satisfy the linearity requirement. The average response factor is calculated as follows: Average Response Factor = As x Cis / Ais x Cs Where: As = Cis = Ais = Cs = Peak area of analyte or surrogate Peak area of internal standard Concentration of analyte or surrogate Concentration of internal standard The retention time of the target analytes in each calibration standard must agree within within ± 6 seconds. Late-eluting compounds usually have much better agreement. A reference mass spectrum library must be generated for all the target compounds. The reference spectra can be extracted the calibration data, provided that the target compounds do not coelute. In the case of coelution, an individual compound standard analyzed using the same method conditions will be required to produce the reference mass spectrum. The reference spectra will be used for qualitative and quantitative analysis as described later in this section 13.6 PQL Check Standard (PQLCS) A sensitivity check sample is analyzed on a daily basis at the start of each analytical run. The PQL check standard contains analytes of interest at a concentration level of 1-2X the method PQL. The accuracy of the PQL check standard must be in the range of 70-130 % for analysis to continue. 13.7 Internal Standard Retention Time and Internal Standard Response The internal standard responses and retention times of each standard and sample analyzed are evaluated after data acquisition. If the retention time for any internal standard changes by more than 30 seconds from the QCCS in the most recent initial calibration, then the chromatographic system must be inspected for malfunctions and corrections Ambient Air Sampling VOC’s Page 24 of 30 2/18/2016 must be made, as required. If the extracted ion response for any internal standard varies by more than 50% from the last QCCS, the GC/MS system must be inspected for malfunctions and corrections must be made, as appropriate. Any standard or sample failing these internal standard checks must be re-analyzed. The system is re-calibrated, if necessary. 13.8 Analysis Sequence The Analysis Sequence should be similar to the following: ●Zero Air Check/BFB tune check (the zero air check and tune check can be analyzed together) ●Calibration Check Standard every 24 hours ●PQL calibration check standard every 24 hours ●Replicate laboratory fortified blanks (LFB1 and LFB2) ●Replicate matrix spikes ●Zero air check ●Samples (including duplicate sample) ●Zero air check ●Calibration Check Standard (Include CCV at the end of every analysis batch) Ambient Air Sampling VOC’s Page 25 of 30 2/18/2016 13.9 Pre-Analysis Checklist for the GC/MS Run Sequence: ●Check the GC temperature program ●Check the autosampler program ●Check the quantity of internal standard and liquid nitrogen ●Check the zero air cylinder pressure ●Check the Entech 7100 concentrator settings ●Check the job folders and field sheets for any special instructions ●Setup the acquisition sequence in the instrument log and in the computer acquisition program ●Check the acquisition parameters in the computer program ●Arrange the canisters on the auto-sampler ●Double check the order of the sample cylinders to insure that it is consistent with the computer acquisition and the instrument log ●Flush and pressure test the cylinder connections on the auto-sampler ●Open the valves on the sample cylinders. 13.10 Post-Analysis Checklist: The results of each analytical run must be examined promptly upon completion. The instruments are designed to create both an electronic file and hardcopy for each sample analyzed. The following items must be checked following each batch analysis: ●Check all tune blanks for compliance with tuning requirements ●Check to make sure the internal standards and spikes are in the retention time window and their mass spectra are correct. ●Check the surrogate and spike recoveries against acceptance limits. The acceptance criteria are tabulated in the Laboratory Information Management System (LIMS) statistics section and are updated quarterly. As a guide, the recovery limits for the surrogates are approximately 80 to 120%. The recovery limits for the spike compounds are approximately 70 to 130%. ●The zero air sample must be free of target compounds (less than 20% of the compound MDLs). Ambient Air Sampling VOC’s Page 26 of 30 2/18/2016 ●Duplicate sample results must be comparable. Reanalyze the sample if the duplicate varies by more than 20%. ●All detected target compounds must be within the calibration range. Reanalyze samples at a more appropriate dilution level if compounds are out of range. ●For complete reporting procedures, refer to SOP VO-010 for specific procedures. ●Hardcopies of all sample data must be put into the associated job folders. ●Hardcopies of the blanks, QC samples, calibration samples, LFBs, matrix spike must be put into the Daily QC folder. 13.11 Qualitative Analysis: Qualitative identification of each compound is based on retention time and comparison of the sample mass spectrum with characteristic ions in the reference mass spectrum. The characteristic ions from the reference mass spectrum are defined to be the three ions of greatest intensity or any ions over 30% relative intensity. Compounds are identified as present when the following criteria are met: ●The characteristic ions of a compound maximize in the same scan or within one scan of each other. ●The retention time of the compound is within ± 6 seconds of the retention time of the standard component. ●The relative intensities of the characteristic ions agree within 30% of the relative intensities of these ions in the reference spectrum. The presence of coeluting compounds may alter the relative intensities and complicate the compound identification. Examination of extracted ion current profiles can aid in the selection of spectra and in qualitative identification of compounds. ●Structural isomers that produce similar mass spectra and are sufficiently resolved are identified as individual isomers. If the height of the valley between two close eluting isomers is more than 25% of the sum of the two peak heights, then the structural isomers must be identified as isomeric pairs. ●A library search must be performed for unknown chromatographic peaks when the total ion chromatogram of the sample contains unknown peaks larger than the internal standard peaks. A tentative identification can be assigned provided that relative intensities of major ions in the library reference spectrum are present in the sample spectrum and the relative intensities agree within ±20%. Ambient Air Sampling VOC’s Page 27 of 30 2/18/2016 13.12 Quantitative Analysis The quantitation of identified compounds is based on the integrated abundance of the extracted ion current profile of the primary characteristic ion(s). The internal standard used for quantitation is the one nearest to the retention time of the analyte. The average response factors from the initial calibration are used to calculate the concentration of each compound in the sample. See References 14.1 and 14.2 for the equations describing internal standard calibration. 14 Quality Control Quality control procedures for the air sampling operations include the following item. Please refer to the Chemistry Section Quality Manual for the laboratory to gain a broader prospective. ●A site sampling plan must be prepared and available. ●All data must be documented on site log books, field data sheets and chain-ofcustody forms. ●Equipment evaluation and calibration must occur and be documented according to procedures. ●The GC/MS system must be tuned to meet the BFB specifications. ●Blank or “zero air” samples must be analyzed at a frequency of no less than 5% of the samples. ●LFBs and matrix spikes must be analyzed at a frequency of no less than 5% of the samples. ●The laboratory must analyze a duplicate matrix spike sample for every 20 samples analyzed. ●The accuracy (% Recovery) and precision (%RPD) are calculated for every pair of spikes and a statistical analysis is performed quarterly on the last 20 points to calculate and update the quality control tables in the LIMS. The control limits are then set at R +/- 3s, where R is the average of %Recovery (for precision it is the average of %RPD) and s is the standard deviation. Appropriate corrective measures must be taken if the analyte recoveries or RPDs are outside of these limits and the affected samples must be reanalyzed. The spike recoveries and statistical analysis are uploaded into the LIMS and printed in the final report for the job. ●Evaluation of retention time windows to ensure that all compounds are detected within their respective time windows and meet the ± 6 second requirement Ambient Air Sampling VOC’s Page 28 of 30 2/18/2016 ●For more specific information regarding QA/QC measures see the TO-14A and TO-15 EPA Methods and SOP VO-001. 15 Data Processing, Review and Reporting 15.1 Data Processing The Quality Control Manager module in the LIMS is used for data processing. The data processing steps include such operations as converting raw instrument data, loading raw files into the QC-Manager, performing data calculation, and uploading into the LIMS. The software program is designed to take a significant amount of information from the data file including the raw data, sample name, sample type and dilution factor. Start QC Manager and Load File: Load the QC Manager program within the LIMS and choose the laboratory instrument on which the data was collected. Load the .RAW file to be reviewed by choosing the Open option from the Files menu, select the desired .RAW filename, and click OK. Review the TYPE and DILUTION FACTOR columns of the sample table to verify that the QC Manager program set them correctly, when necessary make appropriate selections: The TYPE column is used to define sample type. Use the following guidelines to set the TYPE if necessary: SAMP - Type used for ordinary samples. Assign this type to all samples that do not fit in another category. SRM - Assign this type to all Standard Reference Materials solutions. CCV - Assign this type to all Continuing Calibration samples. REPL - Assign this type to duplicate and replicate samples. SPK - Assign this type to spiked samples. MDL - Assign this type to all reagent blank samples. NONE - Assign this type to samples where calculations are not desired. The DILUTION FACTOR column should contain the dilution factors used by the instrument. Correct the DILUTION FACTOR when necessary. Select SPIKE CODES, SPIKE FACTORS, LIMS TESTS, MATRIX, BATCH ID; WEIGHT FACTORS and PREPARATION VOLUME: LIMS TEST ID and MATRIX: Edit the LIMS Test ID for the samples to match the test requested (W-VOC-MS or W-VOC-MS-A, for example), then enter the Matrix when prompted. Batch Assignments: A batch is a group of samples including precision and spike recovery samples and all of the associated samples analyzed together by the same method. Highlight the samples and click the header box on the BATCH column to assign a batch ID to that batch. Ambient Air Sampling VOC’s Page 29 of 30 2/18/2016 Spike Code: Assign the appropriate spike code for the spikes by highlighting all spikes that used a common spike stock solution and clicking on the Spike Code header box and choosing the correct code. Spike Factor: Assign spike factors to spiked samples to reflect the amount of spike added to the sample. For instance, a normal spike level as given in the spike tables would have a spike factor of ‘1’. Weight Factors: This is not used for water or air samples, but is entered using the % dry weights for soils and is entered on a wet weight basis for waste samples. Ambient Air Sampling VOC’s Page 30 of 30 2/18/2016