Optimization of ProIAPP purification

advertisement

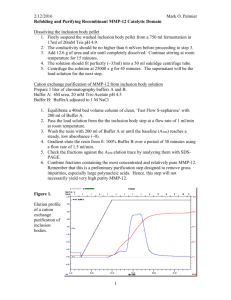

Chapter 3: Optimization of proIAPP purification 60 3.2 RESULTS 3.2.1 Previous methods for proIAPP purification The proIAPP had been overexpressed as a trx-proIAPP fusion protein (Figure 3.1) using the plasmid kindly provided by Aphrodite Kapurniotou (University of Tübingen, Germany) and purified as described in Krampert et al. (2000). Krampert et al. had purified trx-proIAPP by immobilised metal affinity chromatography utilising the his-tag in 6 M urea (Krampert et al., 2000). They then purified trx-proIAPP further by RP-HPLC, prior to cleavage of the trx-tag using enterokinase. The proIAPP was purified from the trx-tag by another RP-HPLC step. Krampert et al. obtained 25 mg of pure trx-proIAPP per litre of bacterial culture, resulting in 4.5 mg of proIAPP. The purification method that Krampert et al. used formed the basis of a variety of purification methods that we investigated to try to increase the yield of proIAPP. 3.2.2 Overexpression of trx-proIAPP in E. coli BL21 cells E. coli DH5 cells were used to prepare sufficient plasmid with which to transform E. coli strain BL21 as described in Section 2.2.3 and 2.2.4. DH5 cells were used first as DNA is easily extracted out of them. BL21 cells are deficient in lon and ompT proteases and are more suitable for protein production than are DH5cells. BL21 cells were then transformed with the plasmid as described in Section 2.2.3 and then were grown in LB supplemented with 100 µg/mL ampicillin, to maintain selection for E. coli containing the plasmid. In mid-log phase of bacterial growth, as judged by an absorbance at 600 nm of between 0.6 and 1.0, the bacteria were induced to produce the fusion protein by the addition of 1 mM IPTG (Section 2.2.5). The E. coli were then harvested by centrifugation and the cell pellets were stored at –20 oC until required. SDS-PAGE analyses showed that the 61 Chapter 3: Optimization of proIAPP purification overexpressed fusion protein migrated below the 31 kDa standard (Figure 3.2), which is consistent with its theoretical mass of 24. 5 kDa (Table 3.1). The overexpressed fusion protein accounted for approximately 25% of total bacterial protein. kDa 1 2 3 97.4 66.3 55.4 36.5 31 QuickTime™ and a TIFF (LZW) decompressor are needed to see this picture. 21.5 14.4 6 Figure 3.2 SDS-PAGE analysis of the overexpression of trxproIAPP. E. coli BL21 cells containing the plasmid were induced with 1 mM IPTG when the A600 reached ~0.8 and then allowed to grow until the A600 had plateaued as described in Section 2.2.5. The protein content of the uninduced and induced E. coli was analysed by Tris-glycine SDS-PAGE as described in Sections 2.2.6a and b. The samples were: 15 µL Mark 12 molecular standards (lane 1), uninduced bacterial lysate (lane 2), and total bacterial lysate after 3 h induction with IPTG (lane 3). Table 3.1 Theoretical characteristics based on the sequence of trx-proIAPP and proIAPP using the ProtParam tool (Swiss-Prot) Trx-proIAPP ProIAPP Theoretical molecular weight (g/mol) 24660.8 7516.5 Extinction coefficent (mLmg-1cm-1) 0.669 0.341 Theoretical pI 6.24 9.51 3.2.3 Attempts to solubilise trx-proIAPP Once successful overexpression had been achieved, we attempted to solubilise trxproIAPP by trying different lysis protocols before using the purification method used by Krampert et al. (2000). Krampert et al. purified trx-proIAPP by immobilised metal affinity chromatography utilising the his-tag under denaturing conditions and RP-HPLC. The trxproIAPP was refolded by lyophilization of the RP-HPLC solvent and redissolving trx- 62 Chapter 3: Optimization of proIAPP purification proIAPP in an aqueous buffer. Therefore, if trx-proIAPP could be purified under native conditions, this would remove the need to refold trx-proIAPP. Hence, the first step was to try to purify trx-proIAPP by immobilised metal affinity chromatography utilising the his-tag under native conditions. The cell pellet was thawed on ice, resuspended in 50 mM sodium phosphate, 300 mM NaCl, 10 mM imidazole, pH 8.0, incubated with lysozyme for 30 min and sonicated (Section 2.2.7a). The soluble and insoluble fractions of the lysate were separated by centrifugation. SDS-PAGE analysis of the soluble and insoluble fractions showed that almost all the trx-proIAPP was in the insoluble phase (Figure 3.3A, lane 5). The soluble trx-proIAPP appeared to have degraded, being seen as an approximately 14 kDa band (Figure 3.3A, lanes 2-4, arrow) that was absent from the total cell lysate containing overexpressed trx-proIAPP (Figure 3.2, lane 3 and Figure 3.3B, lane 3). A kDa B 1 2 3 4 5 kDa 97.4 66.3 55.4 36.5 31 97.4 66.3 55.4 36.5 31 21.5 21.5 14.4 14.4 1 2 3 4 5 6 7 8 Figure 3.3 Effect of cell lysis by sonication or with Triton X-100 treatment on the recovery of trxproIAPP. E. coli BL21 cells were induced to overexpress protein as described in Section 2.2.5. The cell pellet was resuspended in native lysis buffer (50 mM sodium phosphate, 300 mM NaCl, 10 mM imidazole, pH 8.0), incubated with 1 mg/mL lysozyme in the absence of PMSF and briefly sonicated as described in Section 2.2.7a (A) or resuspended in native lysis buffer, incubated with 1 mg/mL lysozyme in the presence of 1 mM PMSF and mixed with 1% (v/v) Triton X-100, 5 µg/mL DNase, 5 µg/mL RNase, as described in Section 2.2.7b (B). The lysate was centrifuged to separate the soluble and insoluble fraction. The samples were analysed by Tris-glycine SDS-PAGE as described in Sections 2.2.6a and b. The samples in gel A: were 15 µL Mark 12 molecular standards (lane 1), 5 µL soluble fraction (lane 2-4), and 5 µL insoluble fraction (lane 5). The samples in gel B: were 15 µL Mark 12 molecular standards, uninduced E. coli (lane 2 and 4), induced E. coli (lane 3 and 5), 10 µL soluble fraction (lane 6), 5 µL soluble fraction (lane 7) and 5 µL insoluble fraction (lane 8). The arrows indicate a degradation product of trx-proIAPP. Chapter 3: Optimization of proIAPP purification 63 The use of sonication can lead to the rapid release of membrane proteins that can cause aggregation of his-tagged proteins (Sambrook and Russell, 2001). Therefore we modified the purification protocol by removing the sonication step and instead added 1% (v/v) Triton X100, a non-ionic detergent, to the resuspension buffer to aid cell lysis as described in Section 2.2.7b. 1 mM PMSF, a serine protease inhibitor, was also added into the lysis buffer to try to inhibit the degradation of trx-proIAPP. Analysis of these lysates by SDS-PAGE showed that the absence of sonication did not increase the proportion of trx-proIAPP that was in the soluble fraction (Figure 3.3B, lanes 6 and 7). The trx-proIAPP still appeared to be degraded, appearing as a 14 kDa product. This indicated that the protease(s) responsible were unlikely to be only serine proteases. We next tried lysis protocols that included detergents, sonication and EDTA. EDTA was included to inactivate metalloproteases that may have caused the degradation of trxproIAPP. The non-ionic detergent Triton X-100 and the anionic detergent sarcosyl were tested to see if these would improve trx-proIAPP solubility. As the absence of sonication did not increase the solubility of trx-proIAPP, sonication was again used to lyse cells. The cell pellet was resuspended in 50 mM Tris, 50 mM NaCl, 1 mM EDTA, 1.4 mM PMSF, mercaptoethanol, pH 8.0 and then either 1% (v/v) Triton X-100 or 1% (w/v) sarcosyl was added to the resuspended cells and the cells sonicated as described in Section 2.2.7c. This resulted in approximately a quarter of the trx-proIAPP being in the soluble fraction (Figure 3.4, lanes 1, 2, 4 and 5). The addition of EDTA was effective at preventing the trx-proIAPP from being degraded, suggesting that a metalloprotease had been responsible for this. Both Triton X-100 (Figure 3.4B, lanes 1 and 2) and sarcosyl appeared to be equally effective as detergents (Figure 3.4B, lanes 4 and 5). The combination of Triton X-100 and sonication Chapter 3: Optimization of proIAPP purification 64 (Figure 3.4, lane 1 and 2) was more effective than Triton X-100 alone (Figure 3.3B, lane 6 and 7), possibly because cell lysis was incomplete in the absence of sonication. 1 2 3 4 5 6 kDa 36.5 31 21.5 14.4 Figure 3.4 Effects of cell lysis by sonication in the presence of Triton X-100 and/or sarcosyl on the recovery of trx-proIAPP. BL21 cells were induced to overexpress protein as described in Section 2.2.5. The E.coli cell pellet was resuspended in 50 mM Tris, 50 mM NaCl, 1 mM EDTA, 1.4 mM PMSF, 1.4 mM -mercaptoethanol, pH 8.0. 1% (v/v) Triton X-100 (lanes 1-3) or 1% (w/v) sarcosyl (lanes 4-6) was added and the lysate sonicated as described in Section 2.2.7c. The samples were 10 µL Triton X-100 soluble fraction (lane 1), 20 µL Triton X-100 soluble fraction (lane 2), 5 µL Triton X-100 insoluble fraction (lane 3), 10 µL sarcosyl soluble fraction (lane 4), 20 µL sarcosyl fraction (lane 5), 5 µL sarcosyl insoluble fraction (lane 6). However, the presence of EDTA is incompatible with immobilised metal affinity chromatography as it removes the Ni2+ from the resin. Therefore, the lysates were dialysed against enterokinase cleavage buffer (20 mM Tris, 50 mM NaCl, 2 mM CaCl 2, pH 8.0) to remove the EDTA and prepare the lysate for enterokinase cleavage, at which point the most of trx-proIAPP precipitated (data not shown). In summary, the relatively low proportion of trxproIAPP in the soluble fraction after dialysis and the susceptibility of trx-proIAPP to protease degradation in the absence of EDTA suggested that optimising trx-proIAPP purification under denaturing conditions and refolding would be more successful than trying to further optimise native purification conditions. Chapter 3: Optimization of proIAPP purification 65 3.2.4 Purification of trx-proIAPP in 6 M urea using Ni-NTA chromatography The purification method used was from Krampert et al. (2000). In this protocol trxproIAPP was purified by immobilized metal affinity chromatography utilising the his-tag. The resin used for the chromatography was nickel immobilized on nitrilotriacetic acidagarose. Ni2+ ions bound to nitrilotriacetic acid, have two free ligand binding sites that are free to interact with the his-tag. Histidine residues have pKa values of approximately 6.0. The lysate is loaded on to the Ni-NTA column at pH 8.0, conditions where the his-tag fusion protein is able to bind. Endogenous bacterial proteins with histidine residues that interact with Ni-NTA are removed by washing at pH 6.3. The his-tag fusion protein was then eluted by decreasing the pH to 4.5. Under these conditions the histidine residues are unable to bind to the Ni-NTA. Therefore in a trial purification, trx-proIAPP was solubilized and purified under denaturing conditions, which do not affect the affinity of the his-tag for Ni-NTA. The cell pellet containing overexpressed trx-proIAPP were lysed by stirring in 6 M urea, 20 mM Tris, 100 mM sodium phosphate, pH 8.0 as described in Section 2.2.8a. The lysed cells were centrifuged to remove any remaining cell debris and the lysate was applied to a Ni-NTA column. SDS-PAGE analysis showed that a significant proportion of the trx-proIAPP was not solubilized by the urea (Figure 3.5, lane 2). Endogenous proteins with histidine residues were removed by washing with 6 M urea, 10 mM Tris, 100 mM sodium phosphate, pH 6.3 (Figure 3.5, lane 5). Trx-proIAPP was eluted with 6 M urea, 10 mM Tris, 100 mM phosphate, pH 4.5 (Figure 3.5, lane 6 and 7). The eluate contained trx-proIAPP, which was greater than 80% pure (Figure 3.5, lanes 6 and 7). Monomeric trx-proIAPP migrated below the 31 kDa standard, which is consistent with its theoretical weight of 24.7 kDa (Table 3.1), and the disulfide- 66 Chapter 3: Optimization of proIAPP purification bonded dimer migrated near the 55.4 kDa standard. This method typically yielded between 5070 mg trx-proIAPP from a litre of E. coli culture. kDa 1 2 3 4 5 6 7 8 9 10 97.4 66.3 55.4 36.5 31.0 21.5 14.4 Figure 3.5 Trx-proIAPP purified using Ni-NTA chromatography in 6 M urea, and C18 RPHPLC. The conditions under which Ni-NTA chromatography and C18 RP-HPLC were performed are described in Section 2.2.8a and 2.2.9a. The elution profile of C18 RP-HPLC is shown in Figure 3.6. Samples were taken at various stages throughout the purification and analysed by Tris-glycine SDSPAGE as described in Section 2.2.6a and b. Lane 1 contains 10 µL Mark 12 molecular size standards. Lanes 2-7 contain samples from various stages in the Ni-NTA purification: 5 µL insoluble fraction after solubilization with 6 M urea, pH 8.0 (2), 5 µL cleared lysate prior to loading (3), 5 µL flow through (4), 10 µL wash with 6 M urea, pH 6.3 (5), 10 µL eluate with 6 M urea, pH 4.5 (lanes 6 and 7). Lanes 8-10 contain three successive fractions of the peak from the RP-HPLC purification that eluted at 35, 36 and 37 min (Figure 3.6). 3.2.5 Further purification of trx-proIAPP by RP-HPLC The trx-proIAPP eluate, purified by Ni-NTA chromatography as described above, was further purified by RP-HPLC on an analytical C-18 column, using a method adapted from Krampert et al. (2000). Krampert et al. used a linear gradient of 10 to 90% buffer B in buffer A, with buffer A being 0.058% TFA in H2O and B being 90% acetonitrile, 0.05% TFA in H2O over 30 min. Our gradient was divided into three sections. Buffer B was increased from 10% to 60% in buffer A over 15 minutes during which time, no protein was detected eluting from Chapter 3: Optimization of proIAPP purification 67 the column. The rate of increase of buffer B to buffer A was slowed to an increase in buffer B from 60% to 70% in buffer A over 30 minutes. Trial experiments (results not shown) revealed that trx-proIAPP eluted at a sharp peak in 63% buffer B in buffer A. Therefore in the experiment the gradient had been slowed between 25-55 min as shown in Figure 3.6 to obtain the best possible separation. The third section of the gradient involved an increase in buffer B from 70% to 100% in buffer A over 10 min to allow for the column to be cleaned in 100% buffer B. The three fractions containing the large peak eluting between 35 and 37 min were lyophilised and their protein content assessed by SDS-PAGE. Despite eluting as a sharp peak from the RP-HPLC column, the protein composition of the fractions of the peak was not homogenous. Moreover, there was no significant increase in purity after the RP-HPLC (Figure 3.5, lanes 8-10) compared to the Ni-NTA eluate (Figure 3.5, lanes 6 and 7). Because of this the RP-HPLC step of trx-proIAPP was therefore dispensed with. As Krampert et al. had refolded trx-proIAPP by lyophilising the RP-HPLC solvent from the eluate and redissolving trx-proIAPP in enterokinase cleavage buffer, the removal of the RP-HPLC step necessitated a search for an alternative method for refolding trx-proIAPP. 68 Chapter 3: Optimization of proIAPP purification 0.25 100 0.20 80 70 0.15 60 50 0.10 40 30 0.05 Buffer B (%) Absorbance (280 nm) 90 20 10 0.00 0 0 10 20 30 40 50 60 70 80 90 Elution time (min) Figure 3.6 Elution profile of trx-proIAPP purified by RP-HPLC. Trx-proIAPP purified by Ni-NTA chromatography was loaded on to an analytical C-18 column and eluted with a gradient of buffer B (thin line) in buffer A, with buffer A: 0.058% TFA acid in water and B: 90% acetonitrile, 0.05% TFA in water as described in Section 2.2.9a. 3.2.6 Purification of trx-proIAPP in 6 M GuHCl using Ni-NTA chromatography and refolding by dilution Trx-proIAPP was purified from bacterial lysates by Ni-NTA chromatography in a similar manner to that described in Section 3.2.4 except that 6 M guanidium hydrochloride (GuHCl) was substituted for 6 M urea. Previous SDS-PAGE analysis of the soluble (Figure 3.5, lane 3) and insoluble fractions (Figure 3.5, lane 2) after lysis in 6 M urea showed that more than half of the trx-proIAPP remained in the insoluble fraction. In contrast, almost all the trx-proIAPP was solubilized in 6 M GuHCl (data not shown) indicating that GuHCl was more effective at solubilizing trx-proIAPP than urea. The purity of the trx-proIAPP in the eluate from the Ni-NTA column was the same regardless of whether it had been purified in 6 M urea, pH 4.5 (Figure 3.5, lanes 6 and 7) or in 6 M GuHCl, pH 4.5 (Figure 3.7, lane 6). The approximately 2-fold increase in solubilization of trx-proIAPP from one litre of cell culture 69 Chapter 3: Optimization of proIAPP purification using GuHCl compared to urea resulted in a corresponding increase in the purified trxproIAPP. Typically, using GuHCl solubilization 100-150 mg trx-proIAPP could be obtained from one litre of E. coli culture instead of 50-100 mg trx-proIAPP using urea solubilization. kDa 1 2 3 4 5 6 7 200.0 116.3 97.4 66.3 55.4 36.5 31 21.5 14.4 6 3.5 2.5 Figure 3.7 SDS-PAGE analysis of trx-proIAPP purification using Ni-NTA chromatography in 6 M GuHCl and refolding by dilution. The trx-proIAPP was solubilized in 6 M GuHCl, H 8.0 bound to the Ni-NTA column, washed in 6 M GuHCl, pH 6.3 and eluted in 6 M GuHCl, pH 4.5. Trx-proIAPP was refolded in buffer at 4 oC and reconcentrated over a Ni-NTA column and eluted under native conditions with 300 mM imidazole as described in Section 2.2.8b. Samples were taken a various stages throughout the purification and analysed by Tris-tricine SDS-PAGE as described in Section 2.2.6a and c. The samples were 10 µL Mark 12 molecular size standards (lane 1), lysate (lane 2), flow through (lane 3), pH 6.3 wash (lane 4), pH 5.9 wash (lane 5), pH 4.5 elution (lane 6) and refolded trx-proIAPP eluted under native conditions (lane 7). Having achieved a substantial increase in yield, the next step was to refold trxproIAPP. A new method for refolding trx-proIAPP was required, as we had dispensed with the RP-HPLC protocol, which allowed refolding of trx-proIAPP by lyophilization of the trxproIAPP RP-HPLC eluate and dissolving it in aqueous buffer. Trx-proIAPP eluate was refolded by dilution into 20 volumes refolding buffer (50 mM phosphate, 10 mM imidazole, Chapter 3: Optimization of proIAPP purification 70 300 mM NaCl, 0.5 mM PMSF, pH 8.0) at 4 oC (Section 2.2.8b). The conditions were chosen because refolding is favoured by low concentrations of proteins and low temperature (Misawa and Kumagai, 1999). The putatively refolded trx-proIAPP was then reconcentrated by binding it to the Ni-NTA column. Trx-proIAPP was then eluted under native conditions, in phosphate buffer containing 300 mM imidazole. Imidazole acts as a competitor for binding to the NiNTA and disrupts binding the His-tagged Trx-proIAPP. Unfortunately some trx-proIAPP was observed to precipitate on the column, the eluate contained precipitated material and the trxproIAPP continued to precipitate during dialysis against enterokinase buffer. After this dialysis step approximately half of the trx-proIAPP remained in solution that was present on 6 M GuHCl eluate. The precipitated trx-proIAPP was cleaned from the column according to the manufacturer’s instructions (Section 2.2.8b). This column-cleaning procedure was time consuming and the spontaneous precipitation of trx-proIAPP was undesirable. Therefore an alternative refolding strategy was investigated, which entailed refolding trx-proIAPP while it was bound to the Ni-NTA column. 3.2.7 Purification of trx-proIAPP in 6 M GuHCl by Ni-NTA chromatography and refolding on the Ni-NTA column Refolding trx-proIAPP while it was immobilized to the Ni-NTA column was tested because this method has been previously shown to be successful with other recombinant proteins as it can restrict intermolecular interactions, which lead to aggregate formation. Thus, polyarginine tagged -glucosidase bound to heparin-Sepharose under denaturing conditions and refolded under conditions allowing the protein to remain bound to the matrix, has been shown to result in high yields of active protein (Stempfer et al., 1996). Similarly, histidine tagged surfactant B (Holzinger et al., 1996) and histidine tagged tissue inhibitor of Chapter 3: Optimization of proIAPP purification 71 metalloproteases (TIMP-3) (Negro et al., 1997) have been shown to be successfully refolded by binding the his-tag fusion protein to the Ni-NTA matrix under denaturing conditions, followed by refolding while bound to the matrix by the removal of denaturant and elution under native conditions. Trx-proIAPP was solubilized in 6 M GuHCl, pH 8.0 loaded on to the Ni-NTA column and washed with 6 M GuHCl, pH 6.3 as described in Section 3.2.6. Instead of eluting trxproIAPP, the Ni-NTA column was re-equilibrated with 6 M GuHCl, pH 8.0 and allowed to cool to 4 oC. Trx-proIAPP was refolded in an increasing linear gradient of buffer B: 20% (v/v) glycerol, 20 mM Tris, 500 mM NaCl, pH 8.0 in buffer A: 6 M GuHCl, 20 mM Tris, 100 mM phosphate, pH 8.0 (Section 2.2.8c). Trx-proIAPP was eluted under native conditions with 20% (v/v) glycerol, 20 mM Tris, 500 mM NaCl, 300 mM imidazole, pH 8.0. Typically, the eluate contained 100-150 mg trx-proIAPP, which was comparable to the amount obtained when eluting trx-proIAPP in 6 M GuHCl (Section 3.2.6). No precipitate was observed in the trxproIAPP glycerol eluate and even after several days no precipitate was observed. The glycerol and imidazole were removed by dialysis against enterokinase buffer and less than a quarter of trx-proIAPP precipitated. This procedure gave approximately 80-110 mg of folded trxproIAPP per litre of E. coli culture, indicating this method was more effective than refolding by dilution. 3.2.8 Optimization of enterokinase cleavage conditions. Having achieved a method for the satisfactory purification of trx-proIAPP, the next step was to carry out a trial of enterokinase cleavage conditions to work out the optimal conditions for cleaving trx-proIAPP. The trx-proAPP fusion protein contains an enterokinase cleavage site between the histidine tag and proIAPP (Figure 3.1). Enterokinase is a specific Chapter 3: Optimization of proIAPP purification 72 protease that cleaves after the lysine in asp-asp-asp-asp-lys sequences. Trx-proIAPP was tested at two concentrations: 2 mg/mL and 4 mg/mL, with digestion at various enterokinase concentrations between 0.05 – 10 ng/mL and the extent of the cleavage assessed by SDSPAGE at 8 h and 20 h. After an 8 h digest, the 17 kDa fusion tag and 7.5 kDa proIAPP were present indicating cleavage had occurred in all digests (Figure 3.8A, lanes 2-5 and 7-9). In the digests containing 10 ng/mL and 5 ng/mL enterokinase (Figure 3.8A, lanes 2, 3, 7 and 8), cleavage had gone to completion, as can be seen by the disappearance of the bands corresponding to trx-proIAPP at 24.5 kDa and disulfide bonded trx-proIAPP at 50 kDa. After 20 h, the digest containing 2 mg/mL trx-proIAPP and 0.5 ng/mL enterokinase had gone close to completion (Figure 3.8, lane 4) but the digests containing lower concentrations of enterokinase still had significant amounts of uncleaved trx-proIAPP (Figure 3.8, lanes 5 and 9). From these data 2 mg/mL trxproIAPP and 0.5 ng/mL enterokinase was judged to be the optimal conditions with the least amount of enterokinase for the maximum cleavage. In preparative scale digests, 1 mg/mL trx-proIAPP and 0.5 µg/mL enterokinase was used in later digests as little difference could be seen between using 1 mg/mL (Figure 3.11, lane 7) and 2 mg/mL trx-proIAPP (Figure 3.8B, lane 4). Trx-proIAPP was dialysed from GuHCl to enterokinase cleavage buffer at 1 mg/mL as this concentration minimised precipitation. PMSF, a serine protease inhibitor, which inactivates enterokinase, was added after 20 h to stop the digest. 73 Chapter 3: Optimization of proIAPP purification A kDa 1 2 3 4 5 6 7 8 9 10 116.3 97.4 66.3 55.4 36.5 31 21.5 14.4 6 3.5 B kDa 1 2 3 4 5 6 7 8 9 10 116.3 97.4 66.3 55.4 36.5 31 21.5 14.4 6 3.5 2.5 Figure 3.8 Optimization of enterokinase cleavage conditions for trx-proIAPP. Trx-proIAPP was cleaved at a concentration of 2 mg/mL (lanes 2-6) or 4 mg/mL (lanes 7-10) at various enterokinase concentrations: 10 ng/mL (lanes 2 and 7), 5 ng/mL (lanes 3 and 8), 0.5 ng/mL (lanes 4 and 9), 0.05 ng/mL (lanes 5) and no enterokinase (lane 6 and 10) as described in Section 2.2.10a. Enterokinase cleavage was stopped after 8 h (A) and 20 h (B). Lane 1 contains 10 µL Mark 12 molecular weight standards. The conditions of the Tris-tricine SDS-PAGE analysis of the samples are described in Section 2.2.6a and c. 74 Chapter 3: Optimization of proIAPP purification 3.2.9 Purification of proIAPP from trx-tag by RP-HPLC The final stage in the purification of proIAPP, was to separate the trx-tag from proIAPP. RP-HPLC using a semi-preparative C-18 column was tried first. The semipreparative column bound approximately 20 mg of cleaved trx-proIAPP. ProIAPP eluted from the column at 19 min, in 50% buffer B in buffer A (Figure 3.9), and was judged to be pure by SDS-PAGE (Figure 3.10, lane 2). The mass of proIAPP measured by mass spectroscopy was 7514.3 0.7 Da, which is in good agreement with its theoretical mass of 7516.5 Da (Table 3.1). The RP-HPLC profile showed minor peaks, which eluted at around 25 min (Figure 3.9); these contained disulfide-bonded dimers of trx-tag and some monomers of trx-tag (Figure 3.10, lanes 3-8). SDS-PAGE analysis also showed that most of the trx-tag eluted at 29 min (Figure 3.10), in 60% buffer B in buffer A. 0.40 100 90 80 0.30 70 0.25 60 0.20 50 40 0.15 Buffer B (%) Absorbance (280 nm) 0.35 30 0.10 20 0.05 10 0.00 0 0 10 20 30 40 50 60 70 Elution time (min) Figure 3.9 RP-HPLC elution profile of enterokinase digested trx-proIAPP. Enterokinase digests of trx-proIAPP were lyophilised and redissolved in 10% acetic acid and loaded on to a semi-preparative C-18 column. Protein was eluted with a gradient of buffer B (thin line) in buffer A, with buffer A: 0.058% TFA acid in water and B: 90% acetonitrile, 0.05% TFA in water as described in Section 2.2.9b. 75 Chapter 3: Optimization of proIAPP purification kDa 1 2 3 4 5 6 7 8 66.3 55.4 36.5 31 21.5 14.4 6 3.5 2.5 Figure 3.10 SDS-PAGE analysis of fractions from the RP-HPLC of enterokinase digested trxproIAPP. The elution profile of RP-HPLC purification of enterokinase cleaved trx-proIAPP (Figure 3.9). Samples were: 10 µL Mark 12 molecular weight standards (lane 1), peak that eluted at 19 min (lane 2), fractions from minor peaks eluting around 25 min (lanes 3-5), fractions from peak eluting at 29 min (lanes 6-8). The data presented above show that RP-HPLC was successful at purifying proIAPP from enterokinase digests. The large binding capacity of semi-preparative column (approximately 20 mg) was advantageous however the maximum volume able to be loaded onto the column was 2.5 mL. As the enterokinase cleavage occurred at 1 mg/mL trx-proIAPP, the digests had to concentrated by up to 8-fold to be loaded on to the RP-HPLC column. This was done by ultrafiltration using Centricon centrifugal filter units with a nominal molecular weight cut-off of 10 kDa. Use of the low molecular weight cut-off filters necessary to retain the 7.5 kDa proIAPP meant the ultrafiltration was very slow. However, the greatest drawback of this method was that a substantial proportion of proIAPP precipitated on the membrane during centrifugation. To avoid this problem the digests were lyophilised and redissolved in a smaller volume of 10% acetic acid. However even in 10% acetic acid not all the proIAPP redissolved. Typically only 12-15 mg digested trx-proIAPP could be loaded on to the column Chapter 3: Optimization of proIAPP purification 76 at any one time, resulting in approximately 4 mg pure proIAPP per semi-preparative column run. In summary, separation of the trx-tag from proIAPP by RP-HPLC was successful in that it resulted in highly pure proIAPP. However the cleaved trx-proIAPP was not stable or very soluble at the high concentrations required to load it on to the RP-HPLC column. Therefore, an alternate method of purifying proIAPP from the enterokinase digests was sought. 3.2.10 Purification of proIAPP from trx-tag using Ni-NTA chromatography Separation of proIAPP from the trx-tag in enterokinase digests by Ni-NTA chromatography would avoid the need to concentrate cleaved trx-proIAPP and therefore the losses. SDS-PAGE analysis was used to assess the effectiveness of the separation. The enterokinase digest was adjusted to contain 500 mM NaCl before loading on to the Ni-NTA column. This was necessary because proIAPP in the absence of 500 mM NaCl binds nonspecifically to the Ni-NTA resin and was not present in the flow through fraction (data not shown). However, under these high ionic strength conditions the trx-tag remained bound to the Ni-NTA resin. In contrast proIAPP, was not retained but was present in the flow through fraction (Figure 3.11, lane 8). The trx-tag could be eluted by increasing the concentration of imidazole (Figure 3.11, lane 9). The proIAPP purified by this method is greater than 95% pure (Figure 3.11, lane 8) and was of comparable purity to that obtained by RP-HPLC (Figure 3.10, lane 2). 77 Chapter 3: Optimization of proIAPP purification kDa 1 2 3 4 5 6 7 8 9 10 200 116.3 97.4 66.3 55.4 36.5 31 21.5 14.4 6 3.5 2.5 Figure 3.11 SDS-PAGE analysis of purification of trx-proIAPP in 6 M GuHCl and separation of proIAPP from trx-tag using Ni-NTA chromatography. The trx-proIAPP was purified and refolded as described in Section 2.2.8c, cleaved with enterokinase as described in Section 2.2.10b. ProIAPP was separated from the trx-tag using Ni-NTA chromatography as described in Section 2.2.12. ProIAPP was reconcentrated on a Strata-X column as described in Section 2.2.13. Samples were taken at various stages throughout the purification procedure and analysed by Tris-tricine SDS-PAGE as described in Section 2.2.6a and c. Samples were: 10 µL Mark 12 molecular weight standards (lane 1), lysate (lane 2), flow through (lane 3), wash (lane 4), elution under native conditions with 300 mM imidazole (lane 5), enterokinase cleavage 0 h (lane 6), enterokinase cleavage 20 h (lane 7), proIAPP flow through from Ni-NTA (lane 8), elution of trx-tag and uncleaved trx-proIAPP of digest from Ni-NTA (lane 9) and Strata X elution (lane 10). 3.2.11 Removal of buffer salts and re-concentration of proIAPP using a Strata-X column Successful separation of the proIAPP and trx-tag by Ni-NTA chromatography under high ionic strength conditions as described above posed two difficulties: the proIAPP was very dilute and it was in the presence of 500 mM NaCl. To be useful in experiments proIAPP would have to be concentrated to make a stock or preferably lyophilized, as amyloid forming proteins tend to spontaneously form amyloid when stored in aqueous solution. Although solvents such as TFA and HIFIP are commonly utilised for maintaining amyloid forming proteins in a non-aggregated state, these solvents are cytotoxic and we wanted to carry out subsequent assays to measure the cytotoxicity of proIAPP. Chapter 3: Optimization of proIAPP purification 78 The removal of NaCl by dialysis was not practicable, as this would only cause proIAPP to become even more dilute. Since the RP-HPLC successfully removed the buffer salts from the enterokinase digest (Section 3.2.9), a modified form of this chromatographic method was adopted. ProIAPP was reconcentrated over a Strata-X column. Strata-X is a surface-modified styrene divinylbenzene polymer, which can be used for the extraction of proteins and is compatible with RP-HPLC reagents such as acetonitrile and TFA. The main advantage of Strata-X is that the volume of sample that could be loaded onto the column was not limited. Typically, approximately 100 mL of the proIAPP flow through was loaded onto a 6 mL Strata-X column, containing 200 mg Strata-X polymer. The amount of proIAPP loaded was limited only by the binding capacity of the Strata-X column, which was approximately 20 mg for a 200 mg Strata-X column. The proIAPP flow through fraction from the Ni-NTA purification of proIAPP and trxtag was adjusted from pH 8.0 to between 7.5 and 5.5, which was optimal for binding to the Strata-X polymer according to manufacturer’s instructions (Phenomenex, Australia). The pH was adjusted by adding 1/10th volume of 50 mM MES, pH 5.5 to the proIAPP flow through fraction. The proIAPP flow through was then loaded onto the Strata-X column, which had been conditioned with methanol according to manufacturer’s instructions and equilibrated with enterokinase buffer containing 500 mM NaCl, with the pH adjusted to between 7.5 and 5.5. ProIAPP bound to the Strata-X column and any contaminating buffer salts were removed by washing with 10% buffer B in buffer A, with buffer A: 0.058% TFA in water and buffer B: 90% acetonitrile, 0.05% TFA in water. SDS-PAGE analysis showed that proIAPP was eluted with 70% buffer B in buffer A (Figure 3.11, lane 10). The eluate containing proIAPP was lyophilised and stored at –20 oC until required. Typically 15-20 mg proIAPP would be obtained from one litre of E. coli culture. Chapter 3: Optimization of proIAPP purification 79 HOLZINGER, A., PHILLIPS, K. S. & WEAVER, T. E. (1996) Single-step purification/solubilization of recombinant proteins: application to surfactant protein B. Biotechniques, 20, 804-6, 808. KRAMPERT, M., BERNHAGEN, J., SCHMUCKER, J., HORN, A., SCHMAUDER, A., BRUNNER, H., VOELTER, W. & KAPURNIOTU, A. (2000) Amyloidogenicity of recombinant human pro-islet amyloid polypeptide (ProIAPP). Chem Biol, 7, 855-71. MISAWA, S. & KUMAGAI, I. (1999) Refolding of therapeutic proteins produced in Escherichia coli as inclusion bodies. Biopolymers, 51, 297-307. NEGRO, A., ONISTO, M., GRASSATO, L., CAENAZZO, C. & GARBISA, S. (1997) Recombinant human TIMP-3 from Escherichia coli: synthesis, refolding, physicochemical and functional insights. Protein Eng, 10, 593-9. SAMBROOK, J. & RUSSELL, D. W. (2001) Purification of Histidine-tagged proteins by immobilized Ni2+ Absorption Chromatography. Molecular cloning : a laboratory manual. 3rd ed., Cold Spring Harbor, N.Y. : Cold Spring Harbor Laboratory. STEMPFER, G., HOLL-NEUGEBAUER, B. & RUDOLPH, R. (1996) Improved refolding of an immobilized fusion protein. Nat Biotechnol, 14, 329-34.