Phenol-Chloroform SOP - NIU Department of Biological Sciences

advertisement

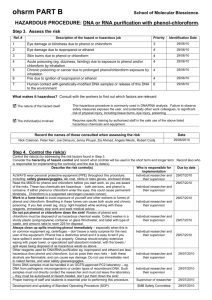

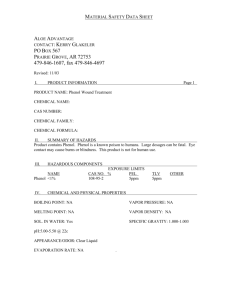

NIU Biological Sciences Standard Operating Procedure #1 CONTACT INFORMATION: Procedure Title Working with Phenol:Chloroform in Molecular Biology Procedure Author Barrie Bode Date of Creation/Revision September 23, 2012 Name of Responsible Person Barrie Bode Location of Procedure Montgomery 412 Approval Signature ORC#S11-0001 OR #S11-0002 #2 THIS STANDARD OPERATING PROCEDURE (SOP) IS FOR A: Specific laboratory procedure or experiment Generic laboratory procedure that covers several chemicals Generic use of specific chemical or class of chemicals with similar hazards #3 PROCESS OR EXPERIMENT DESCRIPTION Phenol and choloroform are widely-used chemicals for nucleic acid purification in molecular biology. Both are listed as hazardous by OSHA and must be handled very carefully. Phenol causes severe chemical burns upon exposure to skin; therefore, gloves, a lab coat and safety glasses must be worn when using this chemical. Frequency: □ one time □ daily weekly or monthly □ other:_____________ Duration per Expt: #4 1-2 hours SAFETY LITERATURE REVIEW & HAZARD SUMMARY For assistance with this form contact NIU Environmental Health and Safety, 815-753-0404. Page 1 NIU Biological Sciences Standard Operating Procedure Phenol causes severe chemical burns so appropriate PPE such as gloves, lab coat and safety glasses must be worn when working with it. Likewise, chloroform is listed as an irritant and carcinogen. #5 STORAGE REQUIREMENTS Phenol is stored at 4°C, usually as a saturated aqueous solution (Tris-buffered; pH 4.3 or 8.0), in a mixture with chloroform at a ratio of 25:24:1 (Phenol:chloroform:isoamyl alcohol), in a tightly-closed screw-cap amber bottle. The bottles are placed in a tray to avoid tipping or spilling. Chloroform is also stored at room temperature in a screw-cap bottle in the corrosives cabinet. #6 STEP-BY-STEP OPERATING PROCEDURE 1. Don personal protective equipment. appropriate street clothing (long pants, close-toed shoes) gloves; Nitrile □ safety goggles safety glasses □ face shield lab coat 2. Check the location and accessibility of the safety equipment that serves your lab: ITEM Fume Hood Eyewash station STATUS Location: MO 412 Location: MO 412 on south sink 1. The bottle of phenol should be opened under the fume hood to avoid breathing vapors. 2. Remove a pre-determined volume of the phenol:chloroform solution to a 50 ml screw-cap tube using a pipet, or by carefully pouring it. Replace the cap and place tube on ice. Use this as your working stock. 3. Typically, only 0.5 – 1.0 ml of phenol chloroform is used at a time in the purification of nucleic acids. Withdraw such volumes from the 50 ml tube using a micro pipette and disposable tips. After phenol solution has been dispensed, discard the pipette tip into a bag designate for phenol-chloroform solid waste. 4. Purification procedures take place in 0.6 or 1.5 ml snap-cap centrifuge tubes. Make sure that the cap is tightly secured closed prior to using the vortex mixer to For assistance with this form contact NIU Environmental Health and Safety, 815-753-0404. Page 2 NIU Biological Sciences Standard Operating Procedure blend the solutions. Check your gloves often to ensure that no residual phenol contaminates them. 5. All centrifugation steps are carried out in a closed micro-centrifuge in the cold box (4°C glass-door refrigerator) in MO 412. 6. Follow the nucleic acid purification protocol as written. You will end up with a lower organic phase in the tube after removal of the upper aqueous phase for nucleic acid recovery. 8-Hydroxyquinoline is added to the phenol:chloroform stock solution to tint it yellow and make it visually distinguishable from the clear upper aqueous phase. Leave this lower phase in the tube and snap the cap closed. Place to the side of your work area until the purification procedure is complete. 7. At the end of the purification procedure, take the waste tubes containing the phenol:chloroform waste to the fume hood, open them and pour out the liquid into the labeled “Phenol:Chloroform Liquid Waste” bottle. Snap the caps closed and place the empty tubes containing residual phenol into the bag designated for phenol-chloroform solid waste along with the pipet tips. 8. Make sure that the start date is on the phenol:chloroform liquid waste bottle, and record the approximate volume discarded during the session. Close the lid tightly on the screw-cap waste bottle and keep in the fume hood. 9. When full, both the solid and liquid phenol:chloroform waste are disposed of according to the NIU EH&S Hazardous Waste Program guidelines. Label the bottle and bag with the date and amount of Phenol:Chloroform. http://www.ehs.niu.edu/ehs/chemical/waste.shtml 10. Carefully remove your gloves and place them in the solid phenol:chloroform waste bag. Clean up the work area with Kimwipes if necessary, and dispose of them likewise. 11. Remove PPE and wash hands. #7 WASTE DISPOSAL We typically generate about 100 ml of Phenol:Chloroform waste every 6 months. Contact EH&S at 815-753-1610 to schedule a pickup or for questions and additional guidance. #8 TRAINING REQUIREMENTS General Training (check all that apply): □General Safety & Emergency Preparedness Chemical Safety for Laboratories □Radiation Safety Biosafety training □Other:________________________ For assistance with this form contact NIU Environmental Health and Safety, 815-753-0404. Page 3 NIU Biological Sciences Standard Operating Procedure Location Where Records Maintained: Montgomery 412 front desk Laboratory-specific training (check all that apply): Review of SDS for other chemicals involved in process/experiment Review of this SOP □Other:_________________________ Location Where Records Maintained: #9 Montgomery 412 front desk PRIOR APPROVALS Prior approvals are required by the following University Committees: IBC: Recombinant DNA, potential pathogens, human tissue/body fluids http://www.orc.niu.edu/orc/biosafety/niupolicy.shtml ORC# S11-0001 and S11-0002 For assistance with this form contact NIU Environmental Health and Safety, 815-753-0404. Page 4