Analysis of the Ecoshield Aqueous Cleaner Recycler

advertisement

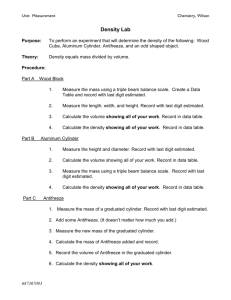

Waste Analysis Project - Antifreeze Quality Assurance Project Plan January 13, 2005 Waste Analysis Project - Antifreeze Quality Assurance Project Plan Iowa Waste Reduction Center January 13, 2005 Revision Number: 1.0 Contact Information: Refer questions to Jeff England, IWRC, 1-800-422-3109 Jeff.England@uni.edu APPROVALS Sue Schauls IWRC Project Manager __________________________ Signature __________________ Date Chilton McLaughlin EPA Project Manager __________________________ Signature __________________ Date Diane Harris EPA QA Manager __________________________ Signature __________________ Date Jeff England IWRC QA Manager __________________________ Signature __________________ Date A2 - Table of Contents A3 - Distribution List……………………………………………………………. A4 – Project/Task Organization…………………………………………………. A5 - Problem Definition/Background…………………………………………… A6 - Project/Task Description…………………………………………………… A7 - Quality Objectives and Criteria for Measurement Data……………………. A8 - Special Training/Certification……………………………………………… A9 - Documents and Records……………………………………………………. 1 2 2 3 4 6 6 B1 – Sampling Process Design…………………………………………………… B2 – Sampling Methods…………………………………………………….……. B3 – Sample Handling and Custody……………………………………………… B4 – Analytical Methods…………………………………………………………. B5 – Quality Control……………………………………………………………… B6 – Instrument/Equipment Testing, Inspection, and Maintenance……………… B7 – Instrument/Equipment Calibration and Frequency…………………………. B8 – Inspection/Acceptance of Supplies and Consumables……………………… B9 – Non-Direct Measurements………………………………………………….. B10 – Data Management…………………………………………………………. 6 6 7 7 7 7 8 8 8 8 C1 – Assessments and Response Action…………………………………………. 8 C2 – Reports to Management…………………………………………………….. 9 D1 – Data Review, Verification, and Validation………………………………… 9 D2 – Verification and Validation Methods………………………………………. 9 D3 – Reconciliation with User Requirements……………………………………. 9 Distribution List EPA Staff Chilton McLaughlin US EPA Project Manager Diane Harris Regional QA Manager EPA Region 7 EPA Region 7 IWRC Staff Sue Schauls Jeff England Project Manager Environmental Specialist 1 Iowa Waste Reduction Center Iowa Waste Reduction Center A4 - Project/Task Organization This project is undertaken by the Small Business Pollution Prevention Center (SBPPC) at the University of Northern Iowa. Funding was provided from the EPA. The SBPPC program manager will oversee the project. The IWRC QA Manager will prepare the QAPP, determine the data quality objectives, and perform the data analysis. TestAmerica, Inc. has been selected to provide sample containers, sample-handling guidelines, and perform the analytical testing. The EPA QA manager and EPA project manager will review the QAPP, and approve it when they are satisfied that it meets the requirements for this project. The IWRC website manager will place a report detailing the performance of the system, and a summary of these results, on the IWRC web site. A5 - Problem Definition/Background In the process of providing on-site visits for Iowa vehicle repair and maintenance businesses, the IWRC often recommends Toxicity Characteristic Leaching Procedure (TCLP) analysis for wastes such as antifreeze, sump sludge and used oil absorbent. Follow-up calls, however, reveal that small businesses rarely characterize these wastes through laboratory analyses. For financial reasons, many businesses simply do not perform hazardous/non-hazardous waste determinations on every waste recommended during an environmental assessment. This choice leaves the business open to potential enforcement action and bases disposal decisions on incomplete data that does not often lead to implementation of pollution prevention alternatives. The Waste Analyses Project endeavors to have the TCLP test performed on used antifreeze, used oil absorbent, and/or sump sludge to produce data that could be used as thorough knowledge to characterize waste. The data collected will be useful in developing meaningful measurements of the environmental impact of pollution prevention practices. The toxicity of the wastes will broken down into the component parts based on scientific analysis of the data. By first identifying the toxicity of the waste streams data can be used to focus the P2 recommendations and provide a better measure of the benefit of a change in behavior. The metrics developed in the Waste Analysis Project may be incorporated into the On-site Review data collection process when client confidentiality can be maintained. The objective of the Waste Analyses Project is to improve the implementation rate of P2 practices by making a hazardous/non-hazardous waste determination to categorize wastes 2 and determine the proper pollution prevention action and disposal method at volunteer facilities. By testing a representative sample of the waste from a multitude of facilities, other facilities may be able to use the results as thorough process knowledge. Using the EPA's Decision Error Feasibility Trials (DEFT) tool and published data from a test of metals in the wastes a sample population of approximately 50 facilities has been tentatively derived. In the event the study is unable to produce results that the EPA accepts as thorough process knowledge, the study may be able to reduce the number of TCLP parameters recommended for testing and thus reduce the cost to the businesses for future tests. If the facility can make a cost effective determination they will be more likely to invest in recycling, pollution prevention and proper disposal of the waste. Assisting businesses in becoming compliant will facilitate the first step toward P2 implementation. Hazardous/non-hazardous waste determinations will be made on common wastes from vehicle repair/maintenance and automotive salvage yard facilities in Iowa. Facilities that participate in the project will have a waste determination performed through TCLP analysis, allowing the facility to select the proper waste management practice and make informed pollution prevention choices. The data will be collected from Iowa automotive businesses in partnership with their trade associations. Partnerships will be facilitated with the Iowa Auto Dealers Association, the Iowa Tire Dealers Association, and/or the Iowa Automotive Recyclers Association. A6 - Project/Task Description The initial phase of the project will involve selecting the mechanism by which facilities will be selected. The QAPP will be written and submitted for approval. The sample collection procedure will be finalized and documented in a Standard Operating Procedure (SOP). Once facilities are identified, they will be contacted and asked to complete a simple survey to provide background on current management practices, and practices related to on site waste collection and housekeeping. Upon approval of this QAPP, a QAPP for the sump sludge and oil absorbent studies will be submitted. The data collection phase will consist of collecting samples from each business, and transporting them to the analytical laboratory. The current proposed schedule for the project anticipates completion by September of 2006. Task Develop Quality Assurance Project Plan (QAPP) Receive QAP approval from EPA Identify volunteer facilities Collect and analyze samples Perform data analyses Develop deliverables 3 Target Completion Date January 15, 2004 March 31, 2005 May 15, 2005 May 15 – December 20, 2005 January 1- June 30, 2006 July 31, 2006 A7 - Quality Objectives and Criteria for Measurement Data The main goals of this project are to examine the contamination of used antifreeze, and determine if antifreeze requires analytic testing prior to making a hazardous/nonhazardous waste determination. In the event that the data suggests that testing of site-specific samples of antifreeze should be continued, the secondary goal is to reduce the number of TCLP parameters that should be measured. Reducing the number of parameters will simplify record keeping, and may reduce testing costs. To determine the minimum number of samples required for the study, it is necessary to determine the baseline assumptions, and the decision rule. Baseline assumption (Ho): Waste antifreeze generated by automobile dealers in the state of Iowa is hazardous. Decision rule: If the true concentration of TCLP parameters is less than the RCRA levels, then the waste is non-hazardous. Action level: The action level in each case is the RCRA regulatory level, as specified in 40 CFR 261.24. Grey Region: The gray region is defined as 90% of the action level. The type-1 error (false acceptance) would be accepting the baseline assumption, when in fact it is incorrect. In this case, the baseline assumption is already the status quo, businesses that generate waste antifreeze must assume the antifreeze is hazardous prior to disposal. This error is also only likely if the true value of the parameter of interest is very close to Design/DQO Summary Screen the action level. For the Sampling Design of: Simple The type-2 error is rejecting the baseline Random Sampling assumption, when in fact it is true. In this case, we would be stating that antifreeze collected from Number of Samples: 49 automobile dealers is non-hazardous, when in fact it is hazardous due to toxicity. This error could result Data Quality Objectives in direct harm to the environment. This project is Action Level: 5.000 designed to reduce the possibility of a type-2 error. Gray Region: 4.500 - 5.000 Baseline Condition: mean >= 5.000 The acceptable type-1 error is 20%, while the Standard Deviation (SD): 1.38 acceptable type-2 error is 5%. Decision Error Limits In order to determine a sample size from the criteria conc. prob(error) type set above, an estimate of the standard deviation is required. Data was obtained from a study conducted 4.500 0.2000 FA by the Minnesota Pollution Control Agency for the 5.000 0.0500 FR House and Senate Environment and Natural Resource Committees, Feb 28, 1997. 4 From this data, several estimates of the standard deviation were made. The levels of cadmium and chromium in the samples were very consistent, and produced low standard deviations. However, the raw data for both lead and zinc included large outliers, data points that were more than five times the average, and in the case of lead, one data point was more than ten times the average. These data points produced standard deviations that were higher than the action level, making the design of a study based on them impossible. Rather than use the cadmium or chromium data and risk underestimating the standard deviation, the data on lead was used, after all data points more than 5 times the average were discarded. The result was an estimate of the standard deviation based on 26 data points. The EPA’s DEFT tool was used to determine the number of samples required to meet this projects goals. DEFT indicated that 49 samples would be needed. The project will proceed with gathering samples from 49 facilities, plus 5 duplicate samples, for a total of 54 samples. Samples for the sump sludge and oil absorbent studies will be collected at the same time, reducing the actual cost per study to less than the cost estimated by the DEFT tool. 5 A8 - Special Training/Certification No special training will be required for this project. A9 - Documents and Records The IWRC QA manager will distribute the most recent version of the QAPP to all interested parties upon approval. If changes are made, the QA manager will distribute updated versions as soon as approval for the new version has been obtained. A chain of custody log will be maintained that identifies each sample, the time, date and location at which it was collected, and who collected it. In addition, each time the sample changes ownership, this change will be recorded in the chain of custody log. Laboratory reports will be retained in the IWRC office for a minimum of three years from the completion of the final report. B. DATA GENERATION AND ACQUISITION B1 - Sampling Process Design The sampling process consists of selecting sites for sampling, and collecting the samples from each site. A number of sites have already indicated their willingness to participate in the study. From this set of businesses, a samples set will be selected based on the size (number of full time employees) of the maintenance operation. Ideally, and equal number of small, medium and large businesses will be available. The sample collection process is outlined in the analytical method employed, and will be performed in accordance with this method. B2 - Sampling Methods Participating businesses will be asked to produce a representative sample of antifreeze waste. This sample will consist of approximately 32 oz (1 qt) of waste antifreeze. Businesses are encouraged to collect antifreeze from a number of cars into a single container, from which the sample can be drawn. In addition to taking a single sample from each business, a number of duplicate samples will also be collected. These samples will be handled and analyzed just as the primary samples, and will be used for quality control purposes. 6 B3 - Sample Handling and Custody Chapter 4, Table 4-1 of EPA SW-846 specifies holding times for samples to be tested for volatile organic compounds. Aqueous samples with no residual chlorine may be held for 14 days. For this project, the intent is to deliver all samples to the laboratory within 48 hours of sample collection. This provides the laboratory with an acceptable window in which to perform the analysis. Samples will be cooled to 4° C, and pH adjusted as specified in SW-846. Samples may be collected by an employee of the business, staff from the IWRC, or an agent under contract by the IWRC. Each sample will be given a sample ID number, and sample custody will be recorded by the IWRC. B4 - Analytical Methods Title 40 CFR 261.24 specifies that method 1311 from EPA SW-846 must be used to determine toxicity. Section 1.2 of method 1311 allows a total analysis to be performed prior to the TCLP method to determine if analytes are present. The analytical laboratory will be instructed to characterize the samples in accordance with method 1311. The laboratory may substitute a total analysis for the TCLP analysis if results indicate that the analyte is not present, or is present at such low concentration that the appropriate regulatory levels could not possibly be exceeded. B5 - Quality Control Data quality will be measured through the use of duplicate samples. One out of every ten samples will be collected with a duplicate, taken from the same batch of waste at the same time. The duplicate sample will be labeled with a sample ID number, and handled in the same manner as the original samples. Analysis of the duplicate will allow the precision of the data to be estimated. Any variation between duplicates beyond the known precision of the analytical method will be investigated, as such variations may indicate problems with the sample collection, handling, or analysis. B6 - Instrument/Equipment Testing, Inspection, and Maintenance Sample collectors will only be required to record the time, date, and location of the sample. No calibrated equipment will be required for the sample collection process. TestAmerica will maintain, test, and inspect equipment in accordance with their internal quality assurance guidelines. 7 B7 - Instrument/Equipment Calibration and Frequency TestAmerica will calibrate equipment in accordance with their internal quality control guidelines. B8 - Inspection/Acceptance of Supplies and Consumables Sample containers will be clean, with intact, easily legible labels. Sample containers may be prepared with a small quantity of acid in the container for preservation, in accordance with the requirements of SW-846. B9 - Non-direct Measurement No non-direct measurements will be required for this project. B10 - Data Management Data will be provided from the laboratory for each sample, the IWRC Quality Manager will maintain originals. Copies will be distributed to all interested parties upon request. Data will also be made available in electronic form as it is collected. Original paper copies of laboratory results, chain of custody documents, and field notes will be maintained by the IWRC for three years after the publication of the final report. C. ASSESSMENT AND OVERSIGHT ELEMENTS C1 - Assessment and Response Action Each sample will result in a laboratory report from TestAmerica. Upon receipt of each report, the IWRC Program Manger will examine the results for problems or unexpected results. Problems could include Samples with high levels of TCLP contaminants Duplicates that show inconsistencies Missing or incomplete data sets due to contamination or equipment failure The IWRC QA Manager and IWRC Program Manager will discuss any problems with data, and a response action will be determined. Possible response actions include Re-sampling a given site Using a duplicate instead of a primary sample (only in the case of contamination or equipment failure) Disqualifying data on the grounds that it is unreliable. If data is disqualified, a full explanation of the reason for disqualification will be made in the final report. 8 C2 - Reports to Management The IWRC QA manager will receive updates on the progress of this project monthly, and may request more frequent updates. A final comprehensive report will be prepared at the conclusion of the project. The final report will be distributed to the EPA project manager and the IWRC project manager. This report will also be made available to the public in electronic form at the IWRC web site and various publications. D. DATA VALIDATION AND USABILITY ELEMENTS D1 - Data Review, Verification, and Validation Data review will take place during the final phase of this project. D2 - Verification and Validation Methods Data verification will be accomplished through the use of duplicates, and comparison between similar sites, which should generate similar waste streams. D3 - Reconciliation with User Requirements The results of this study will provide a picture of the current status of waste antifreeze generated by automobile dealers in the state of Iowa. The results may be used to accomplish one of several goals. In the case that all results from the study, or alternatively, all results from a well-defined subset of the study, indicate that waste antifreeze is non-hazardous, these results may be used to argue that antifreeze should be accepted as non-hazardous based on thorough knowledge, and that businesses should not be required to submit waste to a laboratory for analysis prior to recycling. Alternatively, if a strong case cannot be made that the waste is always non-hazardous, the results may indicate that this is a subject that deserves an even more intense study, and may motivate more groups to look into the status of antifreeze as a hazardous waste. If the results clearly indicate that some waste antifreeze is indeed hazardous, than the status quo can be justified. Such results indicate that there is a need to determine the level of contamination in antifreeze prior to disposal. In this case, the study may still be used to reduce the number of parameters of concern from the current list of eight metals and ten VOC’s to just a few, or a single, parameter. Regardless of the results, this study will serve to clarify the status of waste antifreeze, and provide additional information for anyone concerned about the effects of waste antifreeze on the environment. 9