Industrial Robots and Flexible Manufacturing Systems In

advertisement

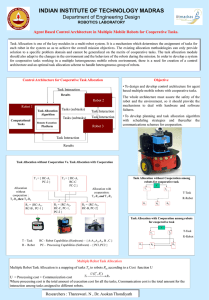

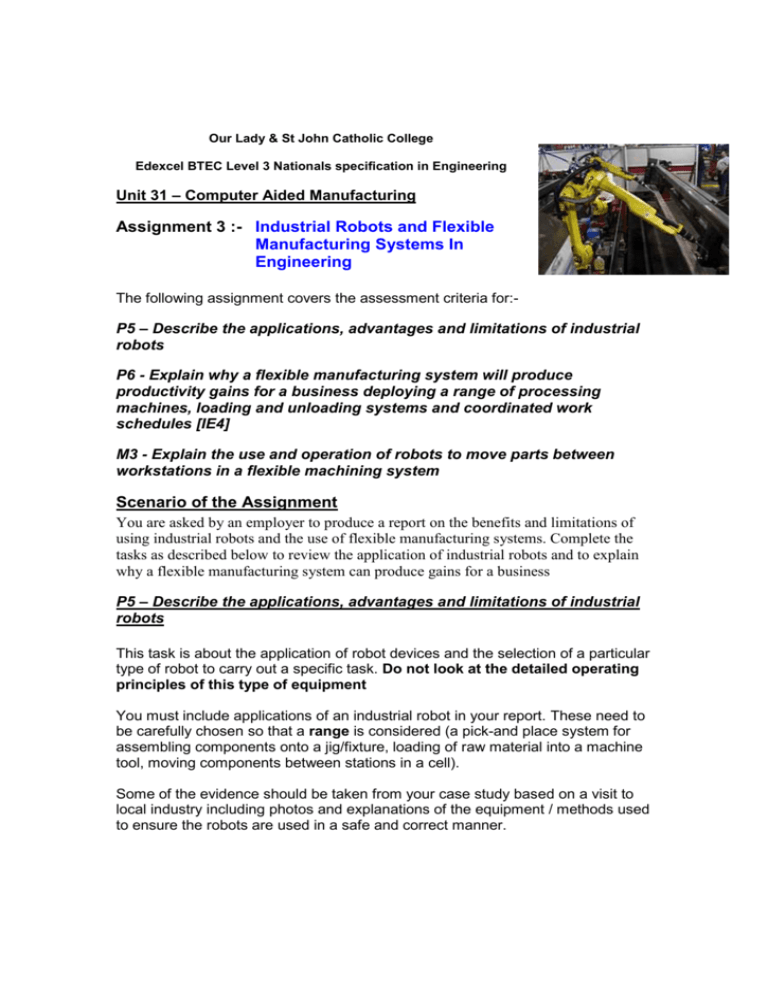

Our Lady & St John Catholic College Edexcel BTEC Level 3 Nationals specification in Engineering Unit 31 – Computer Aided Manufacturing Assignment 3 :- Industrial Robots and Flexible Manufacturing Systems In Engineering The following assignment covers the assessment criteria for:- P5 – Describe the applications, advantages and limitations of industrial robots P6 - Explain why a flexible manufacturing system will produce productivity gains for a business deploying a range of processing machines, loading and unloading systems and coordinated work schedules [IE4] M3 - Explain the use and operation of robots to move parts between workstations in a flexible machining system Scenario of the Assignment You are asked by an employer to produce a report on the benefits and limitations of using industrial robots and the use of flexible manufacturing systems. Complete the tasks as described below to review the application of industrial robots and to explain why a flexible manufacturing system can produce gains for a business P5 – Describe the applications, advantages and limitations of industrial robots This task is about the application of robot devices and the selection of a particular type of robot to carry out a specific task. Do not look at the detailed operating principles of this type of equipment You must include applications of an industrial robot in your report. These need to be carefully chosen so that a range is considered (a pick-and place system for assembling components onto a jig/fixture, loading of raw material into a machine tool, moving components between stations in a cell). Some of the evidence should be taken from your case study based on a visit to local industry including photos and explanations of the equipment / methods used to ensure the robots are used in a safe and correct manner. 1. Sectors of Manufacturing For each of the sectors of Manufacturing Industry identify some of the stages where an industrial robot may be used a) b) c) d) e) f) g) h) i) j) k) Automotive Aerospace Space Biotechnology Chemical Electrical and Electronics Food and Drink processing Metals/minerals/materials Marine, Nuclear Oil & Gas Pharmaceutical 2. Applications of industrial robots Show using annotated diagrams and photographs examples of the ways that industrial robots could be used for the following applications in any of the manufacturing sectors. a) b) c) d) e) f) g) h) Pick and place systems for assembling components onto a jig/fixture Joining parts together (riveting, welding, soldering) Product packaging Loading of raw material into a machine tool Moving components between stations in a manufacturing cell Robotic spraying of paint on an assembly line Material removal (Drilling of holes, machining) Inspection of parts / assemblies 3. Safe operation What are the Codes of practice that should be adhered to when installing and operating an industrial robot? You should make reference to :a) Health and Safety Executive HSG43 b) Provision and Use of Work Equipment Regulations For each of the 3 separate applications 4. Advantages What are the advantages of using industrial robots in manufacturing? Make reference to the following points:a) Consistency of performance, b) 24/7 continuous working, c) Reduced cycle times; d) Reduced amount of operator errors e) Improved quality of product 5. Limitations What are the limitations of using industrial robots in manufacturing? Make reference to the following points:a) b) c) d) e) f) High standard of maintenance required Precise programming needed (time, training, specialist knowledge) How computer systems failure will cause breakdown New products require complete reprogramming Certain processes still need a skilled operator Complex and expensive equipment to buy and install P6 - Explain why a flexible manufacturing system will produce productivity gains for a business deploying a range of processing machines, loading and unloading systems and coordinated work schedules 1. Explain how Flexible Manufacturing Systems can produce productivity gains for the following families of parts. a) By Assembly (to make a single assembly) b) By Type (similar products) c) By size and similar operations (allows product mix and volume changes) 2. Use your knowledge of an industrial visit and explain how it is important for that business to design their manufacturing system to be flexible. You may wish to Include photographs or diagrams of the business to help explain the flow of manufacture through the plant. M3 - Explain the use and operation of robots to move parts between workstations in a flexible machining system In your answer you should provide a range of annotated examples and explore into a) Material handling b) Automated Guided Vehicles (AGV) Websites http://www.prospects.ac.uk/engineering_manufacturing_sector_overview.htm Manufacturing Sectors http://en.wikipedia.org/wiki/Industrial_robot Industrial Robots http://en.wikipedia.org/wiki/Flexible_manufacturing_system FMS Systems http://www.osha.gov/dts/osta/otm/otm_iv/otm_iv_4.html INDUSTRIAL ROBOTS AND ROBOT SYSTEM SAFETY Textbooks Amiriouche F M – Principles of Computer Aided Design and Manufacturing (Prentice Hall, 2004) ISBN 0130646318 Colestock H – Industrial Robotics: Selection, Design and Maintenance (TAB Books Inc, 2004) ISBN 0071440526 Hill T - Manufacturing Strategy ISBN 0-333-57648-9 Manufacturing Flexibility: a literature review. By A. de Toni and S. Tonchia. International Journal of Production Research, 1998, vol. 36, no. 6, 1587-617. Computer Control of Manufacturing Systems. By Y. Korem. McGraw Hill, Inc. 1983, 287 pp, ISBN 0-07-035341-7 Manufacturing Systems – Theory and Practice. By G. Chryssolouris. New York, NY: Springer Verlag, 2005. 2nd edition. Design of Flexible Production Systems – Methodologies and Tools. By T. Tolio. Berlin: Springer, 2009. ISBN 978-3-540-85413-5