InkReceptivity

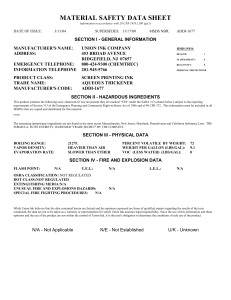

advertisement

INK RECEPTIVITY (K & N) Introduction The ink receptivity of paper may be described as its capacity to accept the transfer of inks from printing surfaces. The amount of ink necessary to attain a particular degree of color intensity in printing is related both to the paper and to the ink. One cannot speak of the absolute ink absorbency of a particular paper, but rather of the receptivity of that paper for particular kinds of ink. The quality of the ink and the surface characteristics of the paper are both important in determining the amount of ink used to give the desired result. In general, the smoother and denser the paper, the less ink required. In printing papers, the nature and distribution of the fillers influences the printability with a given ink, depending on the ease with which the filler is wetted by the vehicle of the ink. The effect of filler as an absorptive component of papers is also shown by the fact that the wire sides of most filled papers require less ink than the felt side, even though the felt side is normally smoother and less porous. In coated papers, the amount of coating, the types of adhesive and pigment, and the pigment/binder ratio all influence the ink receptivity. The interactions here are quite involved and one cannot determine ink requirements merely by referring to the chemical and physical characteristics of the paper and ink. In any case, the ink films transferred to paper are so thin 1 that the paper's surface absorbency or ink receptivity can play an important role in ink drying. Significance The determination of ink receptivity is quite empirical and measures only one of the properties defining the printing quality of paper. The arbitrarily chosen conditions for making the test and the subjective determination of the staining level make this test suitable primarily for direct comparisons. Ink receptivity is one of the properties of paper which defines its utility. It is closely associated with manufacturing as it is largely controlled by the kind, quality, and treatment of the fiber components, by the kind and amount of filler used, and by the uniformity and manner in which the sheet was formed on the paper machine. Control of ink receptivity is essential in the production of high quality printing papers, and a variety of tests have been devised to measure this property. Other factors being equal, the printing performace of paper may be reasonably predicted by the type of ink receptivity tests relying on surface-absorption, before the paper reaches the press. This is especially true if the test is run along with papers of known commercial printing properties. Test Specimens 2 The test specimen shall consist of a flat, uncreased sample of any convenient size. Method of Test Samples of the papers to be compared are placed on a flat surface in an overlapping arrangement so that each is exposed 1 or 2 inches. Work the K & N test ink a little with a spatula; then smear a thick film, about one inch wide, over the samples and immediately begin timing. After exactly two minutes, quickly remove the excess ink with the spatula, then wipe the remainder away with a clean soft cloth. The varnish which has penetrated the surface will be shown by a blue stain of varying depth. Deep discoloration indicates rapid varnish absorption, while light staining indicates good hold-out or good gloss-ink resistant properties. Such results may be reported as deep, medium, or light staining. When the K & N test is made under closely controlled conditions, it is possible to obtain reproducible results. Also, to obtain quantitative results, the reflectance of the absorbed color can be measured on a brightness meter or with a resflection densitometer (not required in this course). Report The intensity of the staining may be reported as deep, medium, or light or arbitrary 3 numerical equivalents. Notes 1. The excess ink scraped off the surface with the spatula may be returned to the container, but care should be taken as the ink quality may change due to differential absorption of its components into the stock during the test. 2. An examination of the stained area will be found helpful in solving such problems as ink lay, ink consumption, off-set, smear, and rate of set. The test gives an excellent indication of the uniformity of paper coatings. For best printing results, the color of the test area should be uniform. Mottled color or variations in depth indicate non-uniform absorbency which may result in mottled printing or non-uniform ink gloss. 3. The K & N test works best on coated papers and certain smooth-surfaced uncoated papers, but is of little value on papers with rough finishes. Reference TAPPI RC 19 4 5 6 7 Properties Related to Printing 7