Generic Spill Prevention, Control and Countermeasure Plan

advertisement

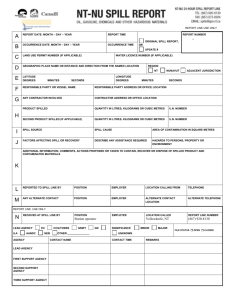

YOUR COMPANY, INC. SPILL PREVENTION, CONTROL, AND COUNTERMEASURE PLAN YOUR FACILITY Month Year YOUR COMPANY YOUR FACILITY SPCC PLAN CONTENTS CERTIFICATION SPCC PLAN SUMMARY FACILITY INFORMATION SPILL RESPONSE PROCEDURES EQUIPMENT/MATERIAL OPERATION AND MAINTENANCE INSPECTIONS SPILL REPORTS MAPS AND DRAWINGS fn: Your Company SPCC Plan.doc 2/13/2016 1 SPILL PREVENTION, CONTROL, AND COUNTERMEASURE (SPCC) PLAN Facility: YOUR FACILITY Street Address City, County, State Owner: Your Company Mailing Address City, State, Zip CERTIFICATION: The undersigned certify that the facility has been examined and, being familiar with the provisions of 40 CFR Part 112, attest that this SPCC Plan has been prepared in accordance with good engineering practices: ___________________________________ Name _____________________________ Date MANAGEMENT APPROVAL: This SPCC Plan has been reviewed and approved for implementation: ___________________________________ Name Your Company Manager Owner Other ______________________________ Name Your Company Manager Owner Other ___________________________________ Date ______________________________ Date A COPY OF THIS PLAN IS MAINTAINED ON SITE fn: Your Company SPCC Plan.doc 2/13/2016 2 SCOPE OF SPCC PLAN The Your Company, Your Facility Spill Prevention, Control, and Countermeasure (SPCC) Plan has been prepared to eliminate or minimize the potential environmental risk of oil/contaminate spills, resulting from substation operations. Applicable implementation components include the following: Prevention – Operational best management practices (BMPs) including operating procedures, maintenance, training, inspection, record keeping, housekeeping, and waste management. Control – Source control constructed to control the release of spills to the environment, such as secondary containment structures. Countermeasures – Emergency spill response procedures, including spill reporting, response, and cleanup procedures to be implemented by spill response personnel. This plan is intended to identify the spill risks present at the Your Facility and define the facilities and procedures used to prevent, control, and respond to spills. Information is provided in the following: Facility Information: Describes structures, equipment/material, and physical characteristics of the facility to control spills and prevent releases to the environment. Identifies oil/contaminate spill risks at the Your Facility, including the locations, types, and quantities of oil/contaminate on-site. Spill Response Procedures: Defines plans, procedures, and equipment/material to be used by personnel to implement spill detection, reporting, response, countermeasures, cleanup, and emergency notification contacts. Equipment/Materials Operation and Maintenance: Summarizes information related to operation and maintenance (routine and following system upset) of specific equipment/material used for spill response. Inspections: Defines a strategy for spill detection and facility maintenance, including checklists for documenting facility/equipment/materials inspections and spill kit inventory. Spill Reports: This section contains spill report forms to use in the event of a spill at the facility. Spill records for the Your Facility are kept at the Engineering Office. Maps and Drawings: Includes substation location information, regional topographic features, facility plan drawings, and aerial photography. fn: Your Company SPCC Plan.doc 2/13/2016 3 ADDITIONAL SPCC PLAN COMPONENTS SPCC Plan Revision: Any revisions to this SPCC Plan, in response to operational/facility modifications and/or in response to changes in regulatory requirements, are documented and certified by a professional engineer. Personnel Training: Briefings for Operations personnel are scheduled at least once per year for the purpose of keeping them informed of oil/contaminate control techniques and equipment/materials. Current SPCC Plan requirements and pollution control laws, rules, and regulations are also included in these briefings. Periodic information training sessions are held for field maintenance, operation, and construction employees who might be involved in containment and clean-up operations. The Operations Management Office maintains all training records. APPLICABLE REGULATION REFERENCES Requirements of the U.S. Environmental Protection Agency (EPA) regulations for Oil Pollution Prevention, as outlined in 40 CFR (Code of Federal Regulations) Part 112, amended July 17, 2002. SPCC Plan requirements result from aggregate aboveground oil storage capacity of the facility of 1,320 gallons or more and potentially affecting any natural resource under federal management authority. Part 112 amendments are provided as an attachment to this section. Requirements of the U.S. Environmental Protection Agency (EPA) PCB (polychlorinated biphenyl) Spill Cleanup Policy, under 40 CFR Chapter I, Part 761. State Environmental Regulator Policy No. ZZZ, Environmental Resources Protection, requires any activity having the potential to degrade the quality of the environmental resource to employ the use of best management practices (BMPs) and best practical methods (BPMs) to protect ground water quality. Local Health District requirements and certification for storage, use and handling of Critical Materials. fn: Your Company SPCC Plan.doc 2/13/2016 4 FACILITY INFORMATION Facility Name and Location: Facility Name: YOUR FACILITY Facility Location: From City intersection, go direction on Highway X to the junction with Highways X and Road Y., turn direction Z miles on Road Y, with Your Facility is located on the X side at approximate Z miles from the intersection. Physical Address: Street Address City, State Mailing Address: Your Company Mailing Address City, State, Zip County: Yours Location Descriptions: Section Z, Township XX North, Range YY West BM Latitude: Deg Min.dec” North Longitude: Deg Min.dec” West Date and Year of Initial Facility Use: Month, Day, Year Description of Facility Operations: Your Company purchased the Your Facility from: Facility type: Oil/contaminate -filled equipment/materials inventory: Summarized in Table 1 (Spill Response Procedures). Yard Drainage/Containment Systems: fn: Your Company SPCC Plan.doc 2/13/2016 5 A geomembrane lined containment pit protects: This containment pit system discharges to: The manhole outfall drains to: Containment piping consists of: Refer to the following sections for additional information: Spill Response Procedures Equipment/Materials O & M section Inspections Spill Reports Maps and Drawings Physical Dimensions of the Site: The facility’s total area: The facility’s total fenced area: Topography and Soil/contaminate Conditions of the Site: Surface Layer: Surface Soil: Subsurface Soil: Soil Permeability: Water Table Depth: Elevation of Site: Surface Topography: Natural Drainage Direction: Proximity to Surface Water and Hydrological Information: Annual Precipitation: Annual Evaporation: Is the Facility located in a 100-year flood plain? Proximity to surface waters: Located over the Aquifer: Drainage Direction and Downstream Features: Potential Magnitude of a Spill: The greatest total volume of: Security: fn: Your Company SPCC Plan.doc 2/13/2016 6 A security fence of surrounds: Gates are located, locked: All personnel enter: SPILL RESPONSE PROCEDURES SPCC PLAN OF ACTION FOR YOUR FACILITY Refer to attached: Spill Prevention, Control, and Countermeasure Site Plan Table 1: Oil/contaminate -Filled Equipment/Material Inventory and Spill Response Summary Summary Sheet – Spill Response Procedures PCB Accidents and Spill Procedures Notification List Oil/Contaminate Spill Log/Report Form Spill Response Materials Inventory 1. Contain the oil/contaminate spill within the facility. The containment system consists of: THIS FACILITY HAS X% SLOPE FROM Refer to Table 1 for Equipment/Materials Inventory and SPCC Site Plan. NOTIFY THE SPILL RESPONSE COORDINATOR. CONTAIN THE OIL/CONTAMINATE FLOW BY SURROUNDING THE SPILL with sorbent booms, matting, or a gravel berm lined with sorbent material. INTERCEPTOR TRENCHING can be utilized to limit the spread of released oil/contaminate. LINE THE TRENCHES with polyethylene and sorbent matting. DO NOT TEAR THE GEOMEMBRANE LINER WHEN WORKING ADJACENT TO ELECTRICAL EQUIPMENT/MATERIALS. 2. Keep the spill from reaching any body of water. fn: Your Company SPCC Plan.doc 2/13/2016 7 3. Oil/Contaminate Migrating Offsite. Oil/Contaminate Entering Surrounding Drainage Ditches Oil/Contaminate Entering Infiltration Pit PRIOR TO USED SORBENT RETRIEVAL, LAY POLYETHYLENE ON PIT EMBANKMENTS TO LIMIT CONTAMINATION TO THE GROUND. Pooling Areas In the event oil/contaminate reaches any pooling area, it may be possible to increase the holding capacity by building up soil/contaminate berms around the pooling area. Utilize sorbent booming techniques to contain and collect released oil/contaminate. IF MODERATE OR LARGE VOLUMES OF OIL/CONTAMINATE ARE PRESENT, NOTIFY THE SPILL RESPONSE COORDINATOR TO ENGAGE VACUUM TRUCKS OR PORTABLE SKIMMERS WITH CONTAINMENT BOOM, ON SITE WITH TRAINED RESPONSE PERSONNEL. 4. Spill Notification The person reporting the oil/contaminate spill shall then notify appropriate personnel (see NOTIFICATION LIST for names and phone numbers). 5. Spill Log/Report The first responder needs to document the sequence of events regarding the spill. Use the SPILL LOG/REPORT form. Spill Response Coordinator is responsible for the completion of any SPILL LOG/REPORT and subsequent regulatory notifications. 6. Spill Response Coordinator Should the spill prove to be operationally beyond the capability of company personnel, notify the Spill Response Coordinator (refer to the NOTIFICATION LIST). fn: Your Company SPCC Plan.doc 2/13/2016 8