The Study of Elimination Reactions Using Gas Chromatography

advertisement

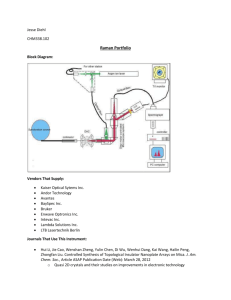

2-12-13 Chem 3125 Experiment #2 – The Study of Elimination Reactions Using Gas Chromatography. The Study of Elimination Reactions Using Gas Chromatography, Devin Latimer, J. Chem Ed, Vol 80, p. 1183, 2003 Introduction Elimination and substitution reactions (E1,E2, SN1, SN2) are among the most fundamental organic reactions. While each of these reaction types is relatively simple in mechanism, the 2 competing pathways complicate matters. In this experiment, you will investigate the effects of structural features of the alkyl halide and the base/nucleophile used on the outcome of the reaction. You will work in groups of 4-8 with each person completing a reaction between one of three alkyl halides and one of two bases, and the product distribution of each reaction will be analyzed by gas chromatography (GC). The GC data will be compiled by each student and then shared with the group. The effect of different bases/nucleophiles and primary versus secondary alkyl bromides gives a range of results that demonstrate the effects of substrate and nucleophiles on product distribution. Reactions Br H3C + + Na R O - + K H3C Br + CH3 H3C H3C + Na K R O - + Br + CH3 + Na K R O - + R = Me, Et, t-Butyl Required Chemicals Reagent 1-bromopentane 2-bromopentane 2-bromo-2-methylbutane Na Methoxide Na Ethoxide K t-Butoxide MTBE Saturated NH4Cl Molarity/MW 151.04 151.04 151.04 1.5 M 1.5 M 1.5 M Not relevant Amount 10 drops, ~ 0.5 mL 10 drops, ~ 0.5 mL 10 drops, ~ 0.5 mL 1.2 mL 1.2 mL 1.2 mL 10 mL 2*10 mL 2-12-13 Student Procedure You will be assigned a brominated alkane and a base for your particular elimination/substitution reaction. Note: the sodium methoxide, sodium ethoxide and potassium tert-butoxide salts will decompose on prolonged exposure to moisture in the air and so should be kept closed to the atmosphere as much as possible. In order to minimize contamination with water the condenser and RB flask should be dried in the oven for 20 minutes prior to setup. To minimize water contamination, setup your apparatus after drying before adding chemicals. In a 50 mL RB flask set up for reflux with heating mantel (hot water bath alternative) with a drying tube, add 1.2 mL of the 1.5 M sodium methoxide, sodium ethoxide or potassium tert-butoxide salt and stir with 10 drops of the brominated alkane (approximately 4.0 mmoles) heated at reflux for one hour. After the solution is cooled to room temperature, the product is transferred to separatory funnel and 10 mL of MTBE is added to wash the reaction flask. The organic layer is then washed with saturated aqueous ammonium chloride (2 x 10 mL) and water (1 x 10 mL). The organic layer is transferred to a dry 50 mL flask and dried with anhydrous magnesium sulfate. A 2-4 mL sample is put in a sample vial for GC analysis. Analysis of Results You will be given a spreadsheet with GC data of expected olefin products, 1-, 2- & 3pentene, MTBE, 1-bromopentane, 2-bromopentane, and expected substitution products. You will need to compare these to the GC data of your product mixture. A table of boiling points versus retention time should be created for the GC chromatograms. Since MTBE is present in such high levels, the scale is expanded to show products. Be sure to look for impurities in the GC traces of the starting alkyl bromides and not confuse them with your products. Gas chromatography gives relative wt. % of each component as measured in peak area of desired peaks. You will need to fill out the table below and calculate moles of alkyl halide and products (Assume you have 100 grams to get relative moles). Convert the relative GC wt. % of each component to relative mole fraction by dividing by molecular weight of the component. Then total moles to determine mole fraction of each component. You then will need to calculate overall conversion of starting alkyl bromide and % yield of each product. For your conversion calculations, assume all the product came from alkyl halide to get total moles of products and reactants. Conversion is then, moles of product/total moles *100. Share this data with your group. Relative product yields are calculated only in percent of reacted bromoalkane for the olefin and ether products (moles olefin/total moles ether and olefin). 2-12-13 Component Relative wt. % Relative mmoles GC wt. % # Wt.%/MW Normalized mole %, conversion/unreacted 1-Pentene/2-methyl1-butene Trans 2-Pentene/2methyl-2-butene Cis 2-Pentene Alkyl-Pentyl Ethers 1 or 2-bromopentane Total moles Calculate % total conversion – Percent total conversion is simple summary of conversion to olefins and ethers. Calculate % conversion to olefin & ether – Yield of olefins (ethers) is simply the % conversion olefin/(% conversion olefin + % conversion ether)*100. Ratio % of 1-Pentene – Wt. % 1-Pentene/(total wt. % of all olefins, 1-pentene/trans 2pentene/cis 2-pentene) *100. Only calculated for products from 2-bromopentane! If desired the gc area % can be converted to weight % using relative response factors before completing the calculations. After sharing data with groups you will need to fill in table below. Rationalize the product distribution of each reaction based on your understanding of the relative reactivities of the bromides with each respective base. Regarding the table below 1. You should enter % conversions for each component. 2. Guidance above for % conversion to products, would be: total moles products(olefin & ether)/total moles*100). (e.g. if there were 90 mmoles products and 100 total moles of products and starting material, % conversion would be 90%). 3. The conversion % for olefin and ether should add up to 100, % olefin = mole olefin/(mole olefin + mole ether) * 100. Halide/Base % Alkyl Olefin % Ether % Ratio 1Combo bromide Pentene(butane)/total Reacted pentene(butane) * 100 1-Br/MeO 2-Br/MeO 2Br2Me/MeO 1-Br/EtO 2-Br/EtO 2Br2Me/EtO 1-Br/t-BuO 2-Br/t-BuO 2Br2Me/t-BuO The sum of olefin plus ether = 100% 2-12-13 Pre-lab Questions: 1. Draw and name all of the expected products from the reactions used in this experiment. Comment on the relative amounts of each expected. 2. Explain what is meant by ‘retention time’ in GC and compare this with ‘retention factor (or Rf)’ in TLC. Post lab questions/Report Lab report should include a discussion for each combination of alkyl halide and base why the products are produced and whether E2/Sn2 or E1/Sn1 was primary mechanism Mechanism for only your products is required in the lab report. Example 1-bromopentane/methoxide – Primary product is ether because of the primary carbon which favors substitution and small nucleophile. Primarily occurs by E2/Sn2. 2-bromopentane/methoxide 2-bromo-2-methylbutane/methoxide 1-bromopentane/t-butoxide 2-bromopentane/ t-butoxide 2-bromo-2-methylbutane/ t-butoxide 2-12-13 Instructors Notes The sodium bromide is readily observed precipitating out of solution as the reaction proceeds. Products from the ethanol reaction sometimes contains ethanol which can interfere with the olefin separation. A simple solution is to add ~0.2-0.4 mL of water to the GC vial and shaking removes most of the ethanol. If the student does the washing well, the amount of ethanol is low. You can avoid this entirely by simply using methoxide and not ethoxide. However, depending on your GC column you may obtain different interferences. The ethanol we utilized is denatured with a mixture of methanol and isopropanol. Therefore, you normally find the ether products from both methanol and the ethanol in the reaction products from reactants with Na ethoxide. We just had students lump total ethers from both methanol and ethanol together. The percent conversion does not enter into any of the explanations of the data and may be deleted from the summary table. In the analysis of the products from 2-bromopentane, toluene is often seen since the method concentrates it in the product. In our GC method it came right before 2bromopentane. In the current experimental procedure, the limiting reagent is actually the alkoxide 1.8 mmoles alkoxide versus ~4 mmoles of alkyl bromide. However, we obtained excellent conversions. We tried one or two experiments with higher levels of alkoxide, with similar results. Chemicals 1-bromopentane(CAS # 110-53-2), 2-bromopentane(107-81-3), 2-bromo2methylbutane(507-36-8), 21 wt. % sodium ethoxide (141-52-6) in ethanol (64-17-5), 30 wt.% Na Methoxide(CAS # 124-41-4) in methanol (67-56-1), t-butyl alcohol(75-65-0), potassium t-butoxide (865-47-4)and ammonium chloride (12125-02-9) were obtained from Sigma-Aldrich. Methyl tert-butyl ether (1634-04-4) was obtained from JT Baker. Methanol and denatured ethanol (~4.5 % by volume of methanol & isopropyl alcohol) were obtained from Pharmco through a local vendor. 1-pentene (109-67-1) and cis & trans 2-pentene (109-68-2) were prepared by distillation from a acid catalyzed dehydration of 2-pentanol (6032-29-7). This produced a typical distribution of the pentenes as well as an impurity of the di-2-pentyl ether. The 1.5 Molar solution were prepared by dilution of the concentrated reagent or dissolution of the pure alkoxide. The alcohols should be dried over molecular sieves to minimize effect of water. Preparation of the alkoxide from original metals can also be utilized. Sodium methoxide , sodium ethoxide and are strongly basic solutions and should be handled with care. Reagents,; 1-bromopentane, 2-bromopentane, Ethanol, methanol and t-butanol. Methyl t-butyl ether is highly flammable 2-12-13 Gas Chromatography method Gas chromatograph used was a Varian CP-3800 with flame ionization detector. Column was DB-624 (6 % cyanopropyl-phenyl, 94% dimethylpolysiloxane) from J&W Scientific, 30 meters long, 0.25 mm ID, film thickness of 1.4µm. Injection temperature was 200 C, with a split ratio of 10 to 1, Helium flow rate 1 mL/min constant flow, initial column temperature was 50 C for 4 minutes, ramp at 50 C/min to 150 C hold for 2 minutes, ramp at 40 C/min to 190 C and hold for 2 minutes. Total run time was 11 minutes. Detector was at 200 C. Attenuation was decreased from 12 to 9 from 4.95-5.50 minutes while the MTBE eluted. This increased the relative size of the product peaks relative to solvent. Responsive factors were not determined due to lack of pure materials, but pedagogically this will have a minimal impact on the comparison of the results. The 2-bromopentane contained small amounts of toluene identified by GC/MS. In the product chromatograms, the reaction of the 2-bromopentane reduced this peak substantially; however the toluene was carried through and showed up as a sizable peak in many of the product chromatograms. Retention times key products and reactants Component 1-pentene 2-methyl-1-butene trans 2-pentene cis-2-pentene 2-methyl-2-butene Methyl 2-methylbutyl ether Methyl2-pentyl ether Methylpentyl ether Ethyl 2-pentyl ether Ethyl pentyl ether 2-bromo-2-methylbutane 2-bromopentane 1-bromopentane t-butylpentyl ether Retention times, minutes 3.73 3.86 4.00 4.14 4.21 6.25 6.29 6.70 6.82 7.34 7.05 7.45 7.92 8.34 Methanol 3.04 Ethanol RT 3.9 t-butanol 4.8 MTBE 5.0 Di-2-pentyl ether 8.94 Toluene 7.3 1-pentanol 7.44 Boiling points of products and similar products 2-12-13 Boiling Points, C 1-pentene trans 2-pentene cis-2-pentene methyl 2-pentyl ether Methylpentyl ether 2-ethoxy pentane Ethyl pentyl ether 2-bromopentane 1-bromopentane Di-t-butyl ether t-butyl, 2-pentyl ether 30 37 37 87 94 99 114 117 130 t-Butyl ethyl ether t-Butyl propyl ether t-Butyl butyl ether i-propyl pentyl ether 68 92 119 121 di-propyl ether Butyl propyl ether Di 2-butyl ether Dibutyl ether 85 112 116 137 Dipentyl ether 182 101 Identification of Ethers The six different ethers produced were identified by comparison of boiling points and confirmed by GC/MS analysis of the reaction mixtures; Methyl pentyl ether, ethyl pentyl ether, methyl 2-pentyl ether, methyl 2-methyl-2-butyl ether, ethyl 2-pentyl ether, and tbutyl pentyl ether. 2-12-13 Examples of Data from each variation are below. GC data corrected for Relative Response factor – GC wt. % * RRF for ether GC Data 1-pentene 2-Methyl-1butene trans 2-pentene cis-2-pentene 2-Methyl2butene Methyl 2methylbutyl ether Methyl2-pentyl ether RRF = 1.40 Methylpentyl ether RRF = 1.40 Ethyl 2-pentyl ether RRF = 1.31 Ethyl pentyl ether RRF = 1.31 2-bromo-2methylbutane 2-bromopentane 1-bromopentane t-butylpentyl ether RRF = 1.20 1-Br MeO 2-Br MeO 2BrMe MeO 1-Br EtO 2-Br EtO 1-Br tBuO 2-Br tBuO 2-BrMe tBuO GC wt.% 1.46 GC wt.% 2.44 GC wt.% GC wt.% 1.57 GC wt.% 12.7 GC wt.% 4.30 GC wt.% 31.63 GC wt.% 11.11 44.69 7.61 2.33 29.55 4.46 7.66 4.12 28.11 30.66 63.78 16.91 1.99 117.85 1.74 26.12 88.71 0.06 9.77 33.04 3.37 2.18 0.13 30.22 14.30 25.45 Legend – 1-Br =1-Bromopentane; 2-Br = 2-Bromopentane; 2-BrMe = 2-Bromo-2methylbutane; MeO = NaMeO/MeOH; EtO = NaEtO/EtOH; tBuO = Kt-BuO/BuOH; 2-12-13 Relative Moles Relative moles 1-pentene 2-Methyl-1butene trans 2-pentene cis-2-pentene 2-Methyl-2butene Methyl 2methylbutyl ether Methyl2-pentyl ether 2-Methyl-2butene Methyl 2methylbutyl ether Methylpentyl ether Ethyl 2-pentyl ether Ethyl pentyl ether 2bromomethylbuta ne 2-bromopentane 1-bromopentane t-butylpentyl ether Summary total moles Summary moles product 1-Br MeO Relative Moles 2.09 2-Br MeO Relative Moles 3.49 2BrMe MeO Relative Moles 1-Br EtO Relative Moles 2.24 2-Br EtO Relative Moles 18.14 1-Br tBuO Relative Moles 6.14 2-Br tBuO Relative Moles 45.19 15.87 2-BrMe tBuO Relative Moles 63.84 10.88 3.33 42.21 6.37 10.94 5.89 40.16 43.80 62.53 16.58 1.95 115.54 0.00 1.70 0.00 25.61 0.00 0.00 76.48 0.04 6.47 21.90 1.44 2.23 0.09 9.48 20.03 0.00 17.68 0.00 119.86 56.17 118.60 80.51 95.73 33.29 82.04 114.12 117.63 34.27 118.56 80.42 94.29 23.82 62.01 107.64 2-12-13 Percent conversion Percent conversion 1-pentene 2-Methyl-1-butene trans 2-pentene cis-2-pentene 2-Methyl-2butene Methyl 2-methylbutyl ether Methyl2-pentyl ether Methylpentyl ether Ethyl 2-pentyl ether Ethyl pentyl ether 2-bromomethylbutane 2-bromopentane 1-bromopentane t-butylpentyl ether % 1-Pentene/2-Meethyl 1- butene Conversion % Conversion Olefin conversion Ether 1-Br MeO % conv 1.7 2-Br MeO % conv 6.2 2BrMe MeO % conv 1-Br EtO % conv 2-Br EtO % conv 1-Br tBuO % conv 2-Br tBuO % conv 0.0 13.4 1.9 19.0 18.5 55.1 2-BrMe tBuO % conv 53.8 19.4 5.9 44.1 6.7 13.3 7.2 33.9 36.9 52.7 29.5 2.0 96.4 2.0 94.3 39.0 1.5 1.9 100.0 98.1 1.8 98.2 26.8 0.1 19.7 61.0 51.6 48.4 28.3 100.0 47.3 52.7 100.0 99.9 2.8 97.2 24.4 28.5 53.1 27.2 98.5 70.8 29.2 100.0 71.5 25.8 74.2 72.9 75.6 100.0 0.0 59.3 94.3 100.0 0.0 2-12-13 Sample Gas Chromatograms of Reactants, products and by-products Figure #1 – GC of alcohols & MTBE µV pe ta n 1- 34,000 32,000 M et ha no 36,000 ol TB E alcohols1.DATA l 38,000 no l 30,000 Is o pr op a 28,000 26,000 24,000 la lc oh ol 22,000 20,000 ut y 18,000 l tB 16,000 M To l ue n e? et ha no 14,000 12,000 10,000 O W NK N U 4,000 ?? ?? ?? ? ?? N 8,000 6,000 2,000 0 -2,000 RT [min] 2.5 3 3.5 4 Name Methanol ethanol UNKNOWN Isopropanol t Butyl alcohol MTBE ?? ??? ???? UNKNOWN Toluene? 1-pentanol 4.5 5 5.5 6 6.5 7 7.5 Time [Min] Area [µV.Min] Area % [%] 3.07 559.8 0.425 3.97 28916.6 21.935 4.47 433.3 0.329 4.58 1552.2 1.177 4.83 2680 2.033 4.98 2017.2 1.53 5.69 88.4 0.067 6.09 63.9 0.048 6.58 20 0.015 7.19 24.2 0.018 7.3 98.4 0.075 7.52 95375 72.347 Figure #2 – GC of pentenes, 1-bromopentane, di-2-pentyl ether, 2-pentanol. 8 8.5 9 2-12-13 µV 3,800,000 1-br old pentenes1.DATA ta n e 3,600,000 en 3,400,000 te n e 3,000,000 1Br om op 3,200,000 en 2,800,000 -2 -p 2,600,000 s 2,400,000 ci 2,200,000 ne 2,000,000 200,000 r le th e 2pe ns D E i2 -p e en ty tra nt en M TB 400,000 pe 600,000 1 800,000 STH 10.00 1,000,000 SPW 0.20 1,200,000 2- 1,400,000 nt an pe n 1,600,000 ol te 1,800,000 0 RT [min] 0 0.5 1 1.5 2 2.5 Name 1 pentene trans 2- pentene cis - 2- pentene UNKNOWN MTBE 2-pentanol UNKNOWN UNKNOWN UNKNOWN 1-Bromopentane UNKNOWN Di 2-pentyl ether UNKNOWN Figure #3 – 2-bromopentane 3 3.5 4 4.5 5 5.5 6 6.5 7 Time [Min] Area [µV.Min] Area % [%] 3.75 4008.4 1.338 4.01 44745.8 14.936 4.15 27746.8 9.262 4.87 368.4 0.123 4.97 2435.4 0.813 6.80 40785.4 13.614 7.12 2211.3 0.738 7.46 277.3 0.093 7.68 551.4 0.184 8.01 166269.9 55.501 8.63 208.7 0.07 8.97 9164.2 3.059 9.04 805.5 0.269 7.5 8 8.5 9 9.5 10 10.5 2-12-13 µV 2 bromo pentane1.DATA op en ta ne 70,000 65,000 TB E 2Br om 60,000 M 55,000 50,000 45,000 40,000 35,000 30,000 25,000 To lu en e 20,000 15,000 10,000 5,000 0 -5,000 RT [min] 4.5 5 5.5 Name UNKNOWN MTBE UNKNOWN UNKNOWN UNKNOWN UNKNOWN Toluene 2-Bromopentane UNKNOWN 6 6.5 7 7.5 8 8.5 Time [Min] Area [µV.Min] Area % [%] 4.39 241 0.219 4.98 3356.7 3.051 5.7 133 0.121 6.05 23.6 0.021 6.64 33.6 0.031 6.76 79.1 0.072 7.32 173 0.157 7.49 105770 96.142 8.8 204.7 0.186 9 9.5 10 10.5 2-12-13 Figure #4 – Reaction product Methoxide with 2-bromo-2-methylbutane 600,000 µV methoxide 2-br-2Mebutane3.DATA eb ut yl et he r 550,000 2M et hy l-2 -M 500,000 450,000 2M e2Bu te ne 400,000 350,000 300,000 eB ut an e TB E 2Br -2 -M 50,000 M 100,000 2M e1Bu te ne 150,000 SPW 0.20 200,000 STH 10.00 250,000 0 -50,000 RT [min] 0 0.5 1 1.5 Name 2-Me-1-Butene 2-Me-2-Butene MTBE UNKNOWN 2-Methyl-2-Mebutyl ether 2-Br-2-MeButane Total 2 2.5 3 3.5 Time [Min] 3.86 4.21 4.97 6.16 6.25 7.05 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 Quantity Area Area % [% Area] Height [µV] [µV.Min] [%] 11.11 73266.4 4219.2 11.112 28.11 239661 10673 28.109 12.06 61763.8 4580.8 12.064 0.64 9470.7 243.1 0.64 45.56 0.06 669168.9 547.7 17299.5 24.1 45.561 0.063 100 1070998.5 37969.5 100 9.5 10 10.5