HW 7 Solutions

advertisement

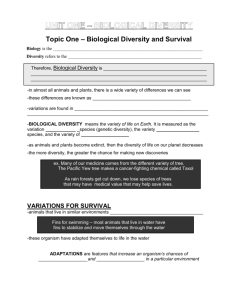

ASEN 3113 Thermodynamics and Heat Transfer Homework #7 Assigned: November 7, 2006 Due: November 14, 2006 (class time) (Total points noted in each section; must clearly show equations with values and units, drawings, assumptions, etc.) 1. (20 points, 15 points for equations, 5 points for correct answer) A 3-mm diameter and 10-m long electric wire is tightly wrapped with a 2-mm thick plastic cover whose thermal conductivity is k = 0.16 W/(m* ºC). Electrical measurements indicate that a current of 12 Amps passes through the wire and there is a voltage drop of 6.5 Volts along the wire. If the insulation is exposed to a medium at T∞ = 30 ºC, with a heat transfer coefficient of h = 20 W/(m2* ºC), determine (a) the temperature at the interface of the wire and the plastic cover in steady operation. Also determine (b) if doubling the thickness of the plastic cover will increase or decrease this interface temperature. Bonus (10 points) Plot a graph of interface temperature ºC vs. total radius (wire and plastic cover thickness) for the range of 2-mm to 20-mm in 1mm divisions on the plot. What temperature is the critical radius? Hint: Use Matlab or an Excel spreadsheet. Must show individual work for plot. Place your name in the title of the plot along with the homework assignment number and problem. Solution: At steady conditions, the rate of heat transfer from the wire is equal to the heat generated within the wire, Q W e VI 6.5V 12 A 78W The total thermal resistance is Rconv 1 h0 A0 20W R plastic 1 0.227 0.007m 10m m C W 2 ln r2 r1 ln 7 3 0.08428 C W 2kL 2 0.14W m C 10m RTotal Rconv R plastic 0.227 0.08428C RTotal C 0.312 C W W (a) Then the interface temperature becomes T T Q 1 2 T1 T Q RTotal 30 C 78W 0.312 C W 54.3 C Rtotal (b) The critical radius of plastic insulation is rcr k 0.16W m C 0.008m 8.0mm h 20W m 2 C Doubling the thickness of the plastic cover will increase the outer radius of the wire to 7mm, which is less than the critical radius of insulation. Therefore, doubling the thickness of the plastic cover will increase the rate of heat loss and decreases the interface temperature. Interface Temperature vs. radius of wire and insulation 54.5 54 radius of wire and insulation (m) 53.5 53 52.5 52 51.5 51 50.5 0.002 0.004 0.006 0.008 0.01 0.012 Temperature at interface (degrees C) 0.014 0.016 0.018 0.02 2. (20 points, 15 points for equations, 5 points for correct answer) Steam in a heating system flows through pure Copper tubes whose outer diameter is 5-cm and whose outside surfaces are maintained at a temperature of 180 ºC. Pure Copper fins [k = 389 W/(m* ºC)] of outer diameter 6-cm and constant thickness 1-mm are attached to the Copper tube. The space between the fins is 3-mm and thus there are 250 fins per m length of the tube. Heat is transferred to the surrounding air at T∞ = 25 ºC, with a heat transfer coefficient of h = 60 W/(m2* ºC). Determine (a) the increase in heat transfer from the tube per meter of its length as a result of adding fins. Assume that the temperature of the surfaces of the fins and tube is 180 ºC. Hint: See pg 456, Figure 8-145 for a diagram of the geometry, but the material and heat transfer variables have been changed from problem 8-145. Use Figure 8-60 to determine the efficiency of the fins (closest guess is ok for this chart, but show your equations and values that you use with this chart). Bonus: (40 points) You just started your first engineering job and your boss explains that the copper used for this fin design is too expensive. Use your engineering judgment and explain what you would do to make a more cost effective design. What kind of trade off would you have to make? Sizing? Material? Number of Fins? Size of the fins? Heat transfer performance vs. cost? There is no right or wrong answer on this bonus, but you must write up a convincing argument (1 paragraph, typed) and one plot to show that you can apply your engineering judgment. If you are uncertain about material costs, call a supply store and get the pricing for copper tubing, sheets of copper, or tubing and sheeting for other materials. Use your best available information to derive costs. This is the type of activity you would be expected to do in a real engineering job. Points awarded for clarity (10), neatness (10), persuasiveness (10), and engineering judgment (10). Convince your new boss that you know how to present your ideas so that you can get that “pay raise”. Solution: In case of no fins, heat transfer from the tube per meter of its length is Anofin D1 L 0.05m 1m 0.1571m 2 Q nofin hAnofin Tb T 60W 2 0.1571m 2 180 25 C 1461W m C The efficiency of these circular fins can be determined from Fig 8-60 to be L D2 D1 / 2 0.06 0.05 / 2 0.005m r2 t 2 0.03 0.001 / 2 1.22 r1 0.025 t h 0.001 0.005 L 2 kt 2 60 W m 2 C 0.0683 389 W m C 0.001m Eyeballing the Figure 8-60, nfin = 0.97 Heat transfer from a single fin is A fin 2 r22 r12 2r2 t 2 0.032 0.025 2 2 0.030.001 0.00192m 2 Q fin finQ fin,max fin hA fin Tb T 0.97 60W m 2 C 0.00192m 2 180 25 C 17.32W Heat transfer from a single unfinned portion of the tube is Aunfin D1 s 0.025m0.003m 0.000236m 2 Q fin hAunfin Tb T 60W m 2 C 0.000236m 2 180 25 C 2.19W There are 250 fins and thus 250 inter-fin spacing per meter length of the tube. The total heat transfer from the finned tube is then determined from Q total, fin n Q fin Q unfin 25017.32 2.19 4878W Therefore the increase in heat transfer from the tube per meter of its length as a result of the addition of the fins is Q increase Q total, fin Q nofin 4878W 1461W 3417W 3. (20 points, 15 points for equations, 5 points for correct answer) The temperature of a gas stream is to be measured by a thermocouple whose junction can be approximated as a 1.2 mm diameter sphere. The properties of the junction are k = 30 W/(m*C), ρ = 8700 kg/m3 and Cp = 320 J/(kg*C), and the heat transfer coefficient between the junction and the gas is h = 70 W/(m2*C). Determine how long it will take for the thermocouple to read 99 percent of the initial temperature difference. Solution: The characteristic length of the junction and the Biot number are Lc V Asurface D 3 / 6 D 0.0012 0.0002m 6 6 D 2 hL 70W / m 2 C 0.0002m Bi c 0.00046 0.1 k 30W / m C Since Bi < 0.1, the lumped system analysis is applicable. Then the time period for the thermocouple to read 99% of the initial temperature difference is determined from T (t ) T 0.01 Ti T hA h 70W / m 2 C b 0.1257 s 1 3 C pV C p Lc 8700kg / m 320 J / kg C 0.0002m 1 T (t ) T e bt 0.01 e 0.1257s t t 36.7 s Ti T 4. (20 points, 15 points for equations, 5 points for correct answer) An ordinary egg can be approximated as a 5.5 cm diameter sphere whose properties are roughly those of water at room temperature [k = 0.6 W/(m*C) and α = 0.14 x 10-6 m2/s]. The egg is initially at a uniform temperature of 8 ºC and is dropped into boiling water at 97 ºC. Taking the convection heat transfer coefficient to be h = 1400 W/m2*C, determine how long it will take for the center of the egg to reach 70ºC. Solution: The Biot number for this process is hr 1400W / m 2 C 0.0275m Bi 0 64.2 k 0.6W / m C The constants λ1 and A1 corresponding to this Biot number are from Table 9-1. λ1 = 3.0863 A1 = 1.9969 Then the Fourier number becomes o,sph 2 2 To T 70 97 A1e 1 3.0897e 1.9969 0.582 0.2 Ti T 8 97 Therefore, the one term approximate solution (or the transient temperature charts) is applicable. Then the time required for the temperature of the center of the egg to reach 70 ºC is determined to be t r02 0.5820.0275m 2 0.14 10 6 m 2 / s 3144s 52.4 min 5. (20 points, 15 points for equations, 5 points for correct answer) Solar radiation is incident on the glass cover of a solar collector at a rate of 700W/m^2. The glass transmitters 88% of the incident radiation and has an emissivity of 0.90. The entire hot water needs of a family in summer can be met by two collectors 1.2 m high and 1 m wide. The two collectors are attached to each other on one side so that they appear like a single collector 1.2 x 2 m in size. The temperature of the glass cover is measured to be 35C on a day when the surrounding air temperature is 23C and the wind is blowing at 30 km/hr. The effective sky temperature for radiation exchange between the glass cover and the open sky is -40C. Water enters the tubes attached to the absorber plate at a rate of 1kg/min. Assuming the back surface of the absorber plate to be heavily insulated and the only heat loss occurs through the glass cover, determine: a) the total rate of heat loss from the collector, b) the collector efficiency, which is the ratio of the amount of heat transferred to the water to the solar energy incident on the collector and c) the temperature rise of the water as it flows through the collector. Soln: The properties of air at the film temperature of (35+23)/2 = 29C are k = 0.0261 W/m C υ = 1.57x10-5 m2/s Pr = 0.712 a) Assuming wind flows across 2m surface, the Reynolds number is determined from Re L V L (30 x1000 / 3600)m / s(2m) 1.062 x10 6 5 2 1.57 x10 m / s Which is greater then the critical Reynolds number (5x105). Using the Nusselt number relation for combined laminar and turbulent flow, the average heat transfer coefficient is determined to be: Nu h hL (0.037 Re 0.8 871) Pr 1 / 3 [0.037(1.062 x10 6 ) 0.8 871](0.712)1 / 3 1409.6 k k 0.0261W / mC Nu (1409.6) 18.4W / m 2 C L 2m Then the rate of heat loss from the collector by convection is Q conv hA(T Ts ) (18.4W / m 2 C )( 2 x1.2m 2 )(35 23)C 530W The rate of heat loss from the collector by radiation is: 4 Q rad A (Ts4 Tsurr ) (0.90)(2 x1.2m 2 )(5.67 x10 8 W / m 2 C )[(35 273K ) 4 (40 273K ) 4 )] 732W And Q total Q conv Q rad 530 732 1262W b) The net rate of heat transferred to the water is Q net Q in Q out AI Q out (0.88)( 2 x1.2m 2 )(700W / m 2 ) 1262W 216.4W collector Q net 216.4W 0.146 Qin 1478.4W c) The temperature rise of the water as it flows through the collector is Q 216.4W Q net m C p T m net 3.1C C p T (1 / 60kg / s )( 4180 J / kgC )