Safety Test ()

advertisement

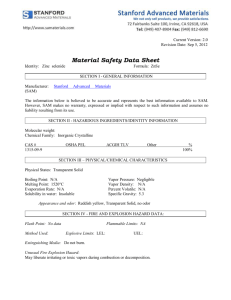

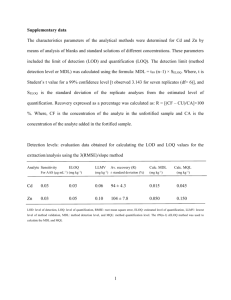

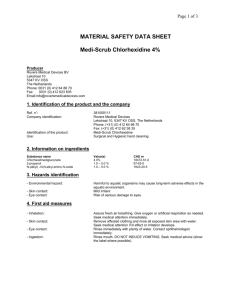

MDL Safety and Operation Procedure Exam Micro-Device Lab, Stevens Institute of Technology, June 2013 Please, read carefully the clean room usage safety and chemical safety files and do your best to answer the questions. 1. What are the MDL’s normal working hours? Explain the buddy system. Give the situation under which the buddy system is enforced if you are working within MDL 2. Describe the steps to become an MDL user. 3. Explain why it is important to submit a process proposal before you use tools in MDL. What is the consequence if you fail in submitting proposal before you use tools in MDL. What does PTC stand for? What is its function? 4. Give the procedure to follow if there is minor chemical spill, what about a major chemical spill? What is the purpose for mishap reporting and what is the consequence if you fail to report any accident or anomaly? 5. What does MSDS stand for? What information is included in MSDS? Why is it important to read it before interfacing with chemicals? 6. The Hazard communication Standard deals with_________ hazard. 7. ______________________________has a right to see the company’s written hazard communication standard. 8. The _________________________ section of the MSDS tells whether the substance is stable. 9. Fire and explosions are ______________________________hazard. 10. Describe the types of exposure to chemicals and the possible effects of chemical over-exposure. 11. Give the four major routes through which chemicals may enter the human body. 12. Give the three categories of control to minimize chemical exposure. 13. List the PPE available in the MDL and give a situation where you must wear at least one kind of PPE. 14. Please list the steps to wear the Personal Protective Equipment (PPE) before entering the MDL. 15. What are the special measures to be taken when using HF? 16. To work with chemicals, follow warnings and instructions, and know what to do in an __________________________________. 17. If a building evacuation alarm sounds, personnel should __________________. 18. A hazardous waste label must include a. The words “Hazardous Waste” b. The accumulation start date c. The identity of the generator d. The identity of the hazardous waste e. Emergency phone number f. Physical state 19. The most common route to harmful exposure levels to photoresist is: a. Skin absorption b. Inhalation c. Ingestion d. Absorption through eyeballs e. Injection from a photoresist syringe 20. Define Threshold Limit Value. 21. After handling hazardous materials, personnel should ________ prior to eating, drinking, smoking tobacco, chewing or using the restroom. 22. What is the main source of the cleanroom contamination? How could you help keep contamination at the minimum level? 23. In the event of a hazardous gas release in one’s work area, what action should you take? 24. In the event of physical contact with hazardous materials, the first course of action is to: a. Remove contaminated clothing and rinse all affected areas for a minimum of 15 minutes b. Remove contaminated clothing and walk to Occupational Health Services c. Remove contaminated clothing and rinse affected areas until the burning or irritating sensation has stopped d. Remove contaminated clothing and rinse clothing before deterioration or discoloration occurs. 25. Describe cleanroom etiquette and the courtesy rules for the booking calendar. 26. What’s the phone number you should call in case of fire or any exposure of hazardous chemicals? 27. Which kind of waste should be disposed in the blue plastic waste container, and which waste should be disposed in the red plastic waste container? True or False and explain why: 28. Chemical safety only stands for spill, fire, explosive and environment damages. 29. All acids should be stored together, and all bases should be stored together. 30. All acid waste should be collected in one bottle, while all base waste should be collected in another bottle. The solvent waste should be collected separately. 31. Some kinds of liquids can be drained in the MDL. 32. A face shield provides adequate protection against liquid chemical splashes. 33. Fill out the below table for toxic gases Component OSHA PEL ACGIH TLVIDLH Acute dose TWA (2009) Chlorine (Cl2) Boron Trichloride (BCl3) Sulfur Hexafluoride (SF6)