PLCs and Relay Ladder Logic

advertisement

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

Chapter 2: Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL).

2.1

2.2

2.3

2.4

2.5

2.6

PLC Operation using scanning technique.

Understanding Relay Ladder Diagram (RLL).

Basic Instructions of RLL.

Motor control using PLC, two push buttons and motor starter.

Adding two indicators for the developed RLL.

PLC Programming.

2.1

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

Programmable Logic Controller (PLC)

And Relay Ladder Logic(RLL)

PLC stands for programmable logic controller. PLCs are electronic control devices that are

used in variety of industries, ranging from manufacturing plants to processing plants. A PLC

is a device that was invented to replace the necessary sequential relay circuits for machine

control and to replace analog controller. The PLC works by looking at its inputs (both logic

and continues types) and depending upon their state, turning on/off its outputs. Examples:

PLCs used in automotive assembly plants, automotive parts manufacturing plants, mineral

processing plants, semi-conductor manufacturing plants, steel mills ….etc. The user enters a

program, usually via software, that gives the desired results.

The PLC has three components;

1) Central Processing Unit CPU,

2) Inputs,

3) Outputs.

We could consider the PLC to be a box of hundreds of separate relays, counters, timers and

data storage locations. Do these counters, timers, etc. really exist? No, they "physically"

don't exist but rather they are simulated and can be considered software counters, timers, etc.

The internal relays are simulated through bit locations in registers, as shown in Fig. 2.1.

Analog

Input

Networking

module

Analog

Ouput

Modem

Fig. 2.1 Internal structure of a PLC.

The functions of these modules are given as follows:

INPUT RELAYS-(contacts): These are connected to the outside world. They

physically exist and receive signals from switches, sensors, etc. Typically they are not

relays but rather they are transistors. These inputs are called discrete or logic inputs.

INTERNAL UTILITY RELAYS-(contacts): These relays do not receive signals from

the outside world nor do they physically exist. They are simulated relays and are what

enables a PLC to eliminate external relays. There are also some special relays that are

dedicated to performing only one task. Some are always on while some are always off.

Some are on only once during power-on and are typically used for initializing data that

was stored.

2.2

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

COUNTERS: These again do not physically exist. They are simulated counters and

they can be programmed to count pulses. Typically these counters can count up, down or

both up and down. Since they are simulated they are limited in their counting speed.

Some manufacturers also include high-speed counters that are hardware based. We can

think of these as physically existing. Most of the time these counters can count up, down

or up/down.

TIMERS: These also do not physically exist. They come in many varieties and

increments. The most common type is an on-delay type. Others include off-delay and

both retentive and non-retentive types. Increments vary from 1ms through 1s.

OUTPUT RELAYS-(coils):These are connected to the outside world. They physically

exist and send on/off signals to solenoids, lights, etc. They can be transistors, relays, or

triacs depending upon the model chosen.

DATA STORAGE: Typically there are registers assigned to simply store the data.

They are usually used as temporary storage for math or data manipulation. They can also

typically be used to store data when power is removed from the PLC. Upon power-on

they will still have the same contents as before when power has been removed.

ANALOG MODELS: This covers analog inputs and outputs. The analog models

cover reading analog signals from sensor, provides analog signal such as thermocouples,

strain gauges, thermistor, pressure sensor….etc. The analog output signals can be used to

command external controller e.g. servomotors amplifier, solenoid amplifier …etc.

USER INTERFACE INPUT: Which contains extra push-bottoms that can be

configured by the user to set/reset logic output devices e.g. relays outputs, or can be used

as a storage of messages that can be displayed on liquid crystal display. Furthermore,

some of these interfaces has led which can be configured by the user.

NETWORKING MODULES: Larger PLCs could have serial port that can be used for

networking a multiple of PLCs that are to be programmed from one main computer or

sending/receiving data between PLC network. Furthermore, some of the PLCs are

equipped with remote control module (modem) to program the PLC from long distance

computer.

The CPU of the PLC contains a microprocessor, which means that a PLC is basically a

specialized computer that has been designed to control the operation of machines and

processes within the harsh environment of the plant.

The language used to program the PLC to perform the logic required to connect the filed

input to its outputs is called Relay Ladder Logic (RLL). The RLL language is programmed by

means of special software using personal computer (connected to the PLC using serial port)

or hand-held programmer which has led or liquid-crystal display and keyboard as illustrated

in Fig. 2.2.

Hand-held programmer or PC communication

Input

Module

(logic or

continuous)

+24V DC

User

interface

CPU & Memory

Output

module

(logic or

continuous

modules)

M

S

N

Serial port

Power Supply

2.3

Fig. 2.2 PLC structure, user communication and interfaces modules

interconnections.

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

RAM and EPROM memory are used to store the program instructions in the PLC. The

computer or hand-held programmer can be used to load and save the RLL programs into the

PLC.

The physical input and output modules can be discrete or analog I/O modules and can be

selected and specified when purchasing the PLC, and depend on the number of the required

I/O lines.

The discrete I/O modules connects field inputs devices of the ON/OFF nature like limit

switches, push button switches, solenoids, solenoid valve or electro-mechanical relay ..etc.

Each discrete I/O module supply voltage source. Since these voltages can be of different

magnitude or types, I/O modules are available at various AC & DC voltages ratings as

shown in Table 2.1. Furthermore, the inputs and outputs are connected to LED’s to indicate

the operation of the I/O module

Table 2.1: common ratings for discrete I/O interface modules.

Interface input module

Interface output modules

24 V AC/DC

12-48 V AC

48 V AC/DC

120 V AC

230 V AC/DC

230 V DC

5 V (TTL)

5 V DC (TTL)

2.1 PLC Operation using scanning technique

A PLC works by continually scanning a program. We can think of this scan cycle as

consisting of 3 important steps, as shown in Fig. 2.3. There are typically more than three

steps but we can focus on the important parts and ignore the others. Typically the others are

checking the system and updating the current internal counter and timer values.

Fig. 2.3 Scanning technique in PLC.

2.4

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

Step 1: CHECK INPUT STATUS:

First the PLC takes a look at each input to determine if it is on or off. In other words, is the

sensor connected to the first input on? How about the second input? How about the third. It

records this data into its memory to be used during the next step.

Step 2: EXECUTE PROGRAM:

Next the PLC executes your program one instruction at a time. Maybe your program said

that if the first input was on then it should turn on the first output. Since it already knows

which inputs are on/off from the previous step it, will be able to decide whether the first

output should be turned on based on the state of the first input. It will store the execution

results for use later during the next step.

Step 3: UPDATE OUTPUT STATUS:

Finally the PLC updates the status of the outputs. It updates the outputs based on which

inputs were on during the first step and the results of executing your program during the

second step. Based on the example in step 2, it would now turn on the first output because

the first input was on and your program said to turn on the first output when this condition is

true.

After the third step the PLC goes back to step one and repeats the steps continuously. One

scan time is defined as the time it takes to execute the 3 steps listed above.

The total response time of the PLC is a fact that we have to consider when shopping for a

PLC. The PLC takes a certain amount of time to react to changes. In many applications

speed is not a concern, in others though. The PLC can only see an input turn on/off when it's

looking. In other words, it only looks at its inputs during the check input status part of the

scan.

Fig. 2.4 Variation of scanning time on detecting the high-speed inputs.

In Fig. 2.4 the input 1 is not seen until scan 2. This is because when input 1 turned on, scan 1

had already finished looking at the inputs. Input 2 is not seen until scan 3. This is also

because when the input turned on scan 2 had already finished looking at the inputs.

Input 3 is never seen. This is because when scan 3 was looking at the inputs, signal 3 was not

on yet. It turns off before scan 4 looks at the inputs. Therefore signal 3 is never seen by the

PLC. This illustrates the importance of scanning time of the PLC.

2.5

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

2.2 Understanding Relay Ladder Diagram (RLL)

To understand the programming of PLC relay ladder diagram, let us start with simple case of

relay control system. We can think of a relay as an electromagnetic switch. Apply a voltage

to the coil results in a magnetic field is generated. This magnetic field sucks the contacts of

the relay in, causing them to make a connection. These contacts can be considered to be a

switch. They allow current to flow between 2 points thereby closing the circuit.

Power circuit

Control circuit

Fig. 2.5 Simple control circuit of a bell

Let's consider the following example. Here we simply turn on a bell whenever a switch is

closed, as shown in Fig. 2.5. We have 3 real-world parts; A switch, a relay and a bell.

Whenever the switch closes we apply a current to the bell causing it to sound. The bottom

circuit indicates the DC control circuit. The top circuit indicates the AC control circuit. Here

we are using a DC relay to control an AC circuit. That’s the benefit of using relay. When the

switch is open no current can flow through the coil of the relay. As soon as the switch is

closed, however, current runs through the coil cause a magnetic field to build up. This

magnetic field causes the contacts of the relay to close. Now AC current flows through the

bell and we hear it. Fig. 2.6 shows a typical industrial relay.

Fig. 2.6 A typical industrial relay.

Next, we would like to replace the relay control system with PLC control system using relay

ladder logic. After seeing a few of these it will become obvious why its called a ladder

diagram. We have to create one of these because, unfortunately, a PLC doesn't understand a

2.6

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

schematic diagram. It only recognizes code. Fortunately most PLCs have software, which

convert ladder diagrams into code. This shields us from actually learning the PLC's code.

The PLC doesn't understand terms like switch, relay, bell, etc. It prefers input, output, coil,

contact, etc. It doesn't care what the actual input or output device actually is. It only cares

that its an input or an output.

First we replace the battery with a symbol. This symbol is common to all ladder diagrams.

We draw what are called bus bars. These simply look like two vertical bars. One on each

side of the diagram. Think of the left one as being + voltage and the right one as being

ground. Further think of the current (logic) flow as being from left to right. Next we give the

inputs a symbol. In this basic example we have one real world input. (i.e. the switch) We

Fig. 2.7 Contact relay symbol.

give the input that the switch will be connected to, the symbol shown below. Fig. 2.7 shows

the symbol for contact of switch or relay.

Next we give the outputs a symbol. In this example we use one output (i.e. the bell). We give

the output that the bell will be physically connected to the symbol shown below. Fig. 2.8

shows the symbol used as the output coil or relay.

Fig. 2.8 Output relay symbol.

The AC supply is an external supply so we don't put it in our ladder. The PLC only cares

about which output it turns on and not what's physically connected to it.

Second, we must tell the PLC where everything is located. In other words we have to give all

the devices an address. Where is the switch going to be physically connected to the PLC ?

How about the bell? We start with a blank road map in the PLCs town and give each item an

address. Could you find your friends if you didn't know their address? You know they live in

the same town but which house? The PLC town has a lot of houses (inputs and outputs) but

we have to figure out who lives where (what device is connected where). We'll get further

into the addressing scheme later. The PLC manufacturers each do it a different way! For now

let's say that our input will be called "0000". The output will be called "500", as shown in

Fig. 2.9.

Finally, we have to convert the schematic into a logical sequence of events. This is much

easier than it sounds. The program we're going to write tells the PLC what to do when

certain events take place. In our example we have to tell the PLC what to do when the

operator turns on the switch. Obviously we want the bell to sound but the PLC doesn't know

that.

2.7

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

Fig. 2.9 RLL for bell control circuit.

The Fig. 2.9 shows the final converted diagram (RLL) for bell control system. Notice that we

eliminated the real world relay from needing a symbol.

2.3 Basic Instructions of RLL

Main input instructions

Normally open contact :

Normally closed contact :

Main output instructions

Normally open relay

Normally closed relay

Fig. 2.10 Main instructions in RLL.

Example 1:

Draw ladder logic for the control circuit shown in Fig. 2.11:

Fig.2.11 Control and RLL for AND Boolean operation.

The Boolean logic equation for this control circuit: Coil = SW1 . SW2

Example 2:

2.8

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

Redraw the relay ladder logic of Example 1, using normally closed switch for SW2 ?

The amended RLL is shown in Fig. 2.12:

Fig. 2.12 Amended RLL using Normally closed switch for switch SW2.

The Boolean logic equation will be : Coil = SW1 . SW2

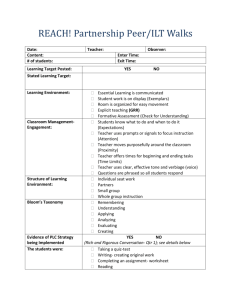

2.4 Motor control using PLC, two push buttons and motor starter

Here two push buttons

switches (Start/Stop) are used

to switch the motor on/off.

These switches are connected to

the two PLC inputs discrete

type), as shown in Fig. 2.13.

One of the output ports

(discrete outputs) of the PLC

used to switch motor starter

on/off, which will start/stop the

electric motor.

The control steps of the

electric motor using RLL is

shown in Fig. 2.14.

Motor

starter

Output

Motor

PLC

Input

Two bush bottom

switches

Fig. 2.13 Motor control using

PLC, motor starter and two

push bottoms.

1

2

3

4

2.9

Go to

step 1

Fig. 2.14 Developed RLL for motor control.

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

2.5 Adding two indicators for the developed RLL

Here two indicators to be added to the developed circuits. Red color to indicates that the

motor is off, and green color to indicates that the motor is running. The amended RLL is

shown in Fig. 2.15.

Motor starter

Output

Motor

Two indicators

PLC

Input

Input

Two push bottom switches

Fig. 2.15 Amended RLL for motor control after adding two indicators.

The modified RLL is given as follows:

Fig. 2.15 (a)RLL when Start push button undressed, (b)RLL when Start push button

pressed

2.10

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

2.6 PLC Programming

The programming technique through serial port via PC and using special software provided

by the manufacturer, as shown in Fig. 2.16 or using hand programmer.

Fig. 2.16 PLC Programming technique using PC computer through serial port.

In case of PC program, a special software program must be installed in the PC which is

provided by the manufacturer to write and edit user Relay Ladder Logic (RLL). This also

transfers the program between PLC and PC computer and vise versa. The program

developed to be friendlier with user during RLL development, as shown in Fig. 2.17.

Fig. 2.17 Example of RLL developed using TPDS software for Toshiba PLC.

Because the PLC uses Relay Ladder Logic diagrams, the convention from any existing relay

ladder to programmed relay ladder logic is simple. Each rung is a combination of input

conditions (symbols) connected from left to right, with the symbol that represents the output

at the far right. The symbols that represent the inputs are connected in series, parallel, or

some combination to obtain the desired logic. The following examples show how PLC can

be used to carry out different control logics, as shown in Fig. 2.18. Note, any combination

logic called Boolean equation.

Example 3:

Develop a relay-ladder logic that allows four switches in a room to control a single light?

The RLL is shown in Fig. 2.19.

SW1

Light

LIGHT=SW1+SW2+SW3+SW4

SW2

SW3

SW4

2.11

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

Boolean or Logic Function

SW1

SW1

SW2

LAMP

{ Relay Ladder Diagram}

LAMP =SW1 and SW2

LAMP= SW1 . SW2

SW2

Lamp

{ Relay Ladder Logic }

LAMP

SW1

{ Relay Ladder Diagram}

SW2

LAMP =SW1 OR SW2

LAMP= SW1 + SW2

SW1

Lamp

{ Relay Ladder Logic }

SW2

SW1

SW3

Lamp

SW1

SW3

Lamp

SW2

SW4

{ Relay Ladder Logic }

LAMP =(SW1 OR SW2) AND SW3

LAMP= (SW1 + SW2) . SW3

SW2

{ Relay Ladder Logic }

LAMP= (SW1.SW3) +(SW2.SW4)+SW5

SW5

SW1

SW3

Y20

SW2

SW4

Y20

Y20=(SW1+ SW2) . SW3

LAMP= SW4 . Y20

Or

LAMP=(SW1+ SW2) . SW3 . SW4

Lamp

Fig. 2.18 Development of RLL for different control logics.

2.12

Manufacturing Automation using PLCs

CHAPTER 2

SW1

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

SW3

Y20

SW2

SW4

Y20

SW1

SW3

SW2

SW4

SW4

SW1

Y20

SW3

Y20=(SW1+ SW2) . SW3

LAMP= SW4 . Y20

Or

LAMP=(SW1+ SW2) . SW3 . SW4

Lamp

Y20

Lamp

Y20

Y20

Y20=(SW1.SW3)+(SW1.SW4)

+(SW2.SW3)+(SW2.SW4)

LAMP= SW4 . Y20

Or

LAMP= ((SW1.SW3)+(SW1.SW4)

+(SW2.SW3)+(SW2.SW4)) . SW4

Y20=SW1. SW3+Y20.SW3

LAMP= SW4 . Y20

Note: 1st Boolean equation is memory or

filp-flop.

SW4

Y20

Lamp

Fig. 2.18 Development of RLL for different control logics

Example 4:

Modify the developed relay-ladder logic given in example 3 such that these switches are

enabled/disabled using external supervisor through switch (SW5) ?

SW1

SW5

LIGHT=(SW1+SW2+SW3+SW4) . SW5

Light

SW2

SW3

SW4

Fig. 2.20 Modified RLL by adding external switch SW5, refer example 4.

2.13

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

PROBLEMS

2.1) Develop the RLL diagrams for the following Boolean equations :

F1 = A . B + A . B

F2 = sw1 . sw2 . sw3 . sw4

F3 = ( sw1 . sw2 . sw3) + sw4

Y = (A.B.C + D ) . (E.F)

2.2) Drive the Boolean equations for the following relay ladder logics

(a)

SW1

SW3

SW4

Y20

Y20

SW4

Y20

Lamp

(b)

SW1

SW3

SW4

SW6

SW1

Y20

SW2

SW5

2.3) Develop a relay ladder logic that will switch on the motor on/off in automatic and

manual (called jog) modes?

(ans: SW1: START push bottom, SW3 STOP push bottom, SW2 JOG or Manual

operating mode, and Y20 memory that will run the relay that will switch the motor on)

SW1

SW3

Y20

Y20

SW2

Y20

Y20

motor

2.14

Manufacturing Automation using PLCs

CHAPTER 2

Programmable Logic Controller (PLC) and Relay Ladder Logic (RLL)

2.4) Give examples of where a PLC could be used?

2.5) Why would relays be used in place of PLC?

(ans: for some cases is simple and cost effective)

2.6) List the advantages of a PLC over relay control?

2.15