/thCESPHTB

advertisement

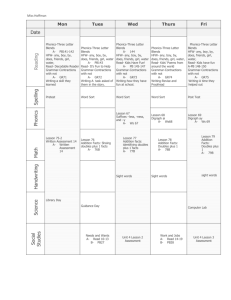

PROCEEDING FORM (1-3 pages with the given font types) Morphology and Rheological Properties of PP/SEBS/PS-HI Blends T. Holjevac Grgurić1, V. Rek2, Ž. Jelčić3, M. Mišak-Mlinac 1 Faculty of Chemical Engineering and Technology, University of Zagreb, Croatia 2 Pliva, Zagreb, Croatia 3 Dioki d.d., Research Laboratory, Zagreb, Croatia 1. Introduction The final properties of polymer blends are related to the quality of their morphology, which depends on processing conditions, composition of the blends, rheological properties of phases and compatibility of polymer components. The incompatibility between polymeric components is responsible for the very poor mechanical properties of most polymer blends [1,2]. Low adhesion between the phases results with poor stress transfer across the interface. The interfacial properties for such incompatible polymer blends can be improved with the addition of compatibilizers [3,4]. In this work, we report a study of the compatibilizing effect of styrene/ethylene-butylene/styrene block copolymer, SEBS, on mechanical and rheological properties as well as morphology of immiscible polypropylene/high impact polystyrene, PP/PS-HI, blends. 3. Results and Discussion Torque, TQ, versus content of PS-HI in PP/PS-HI blends obtained during preparation of the blends in extruder are reported in Figure 1. The results show higher value of torque, for the same PS-HI content, in compatibilized blends. Figure 1. presents lower values of TQ for blends compatibilized with 7 % of SEBS block copolymer. 2. Materials and Methods The investigations were done with high impact polystyrene, PS-HI 417, DIOKI, Croatia, polypropylene, PP, Moplen HP 500N, BASF, and their blends. Styrene/ethylene-butylene/styrene block copolymer, SEBS, Kraton 1650, Kraton Polymers, Germany, was used as compatibilizer. PP/PS-HI blends were prepared in two weight ratios, PP/PS-HI 90/10 and PP/PS-HI 50/50, and in presence of 5 % and 7 % SEBS blok copolymer. The blends were prepared by using a Haake Record 90 twin extruder, with the following zone temperatures 150/200/200/210 °C and the frequency of rotation 60 min-1. The specimens were obtained by injection molding at 230 °C. Torque, TQ, and output were recorded during the processing in extruder. Mechanical properties were done at Instron Model 1185, at room temperature and rate 50 mm/min. Impact strenght was determined according to ISO 180. Dynamic Mechanical Analysis, DMA 983, TA Instruments was used to obtain primary viscoelastic functions, under following conditions; fixed frequencies 1 Hz, temperature range from -100°C to 150°C, and heating rate 5 °C/min. Scanning electron microscope, SEM, JOEL J.S.M. – 5800 was used to investigate the morphology of the samples after the specimens were cut under liquid nitrogen atmosphere. Figures 2a) - 2c) show the mechanical properties of pure polypropylene, PP, high impact polystyrene, PS-HI, and their uncompatibilized and compatibilized blends. PP presents higher stress at break, as well as yield stress than PS-HI (Figure 2b). In relation to impact properties in Figure 2a) we can observe high value of impact strenght of PS-HI, what is result of its specific salamitype morphology. The effect of adding SEBS block copolymer as compatibilizer, results in variations of impact strenght, stress and elongation at break of binary PP/PS-HI blends (Figure 2a-2c). It can be seen that the uncompatibilized PP/PS-HI 90/10 blend presents higher stress at break as regards to compatibilized blend. SEBS block copolymer has a tendency to increase elongation at break, as well as impact strenght of the investigated blend. This is due to better compatibilization of the disperze phase PS-HI in the matrix of PP. Figure 1. Torque value of PP/PS-HI blends 2 impact strenght (kJ/m ) 10 0 % SEBS 5 % SEBS 7 % SEBS 8 6 4 2 0 100/0 90/10 50/50 blend composition (PP/PS-HI) 2a) Proceeding of the 8th Polymers for Advanced Technologies International Symposium Budapest, Hungary, 13-16 September 2005 0/100 PROCEEDING FORM (1-3 pages with the given font types) 0 % SEBS 5 % SEBS 7 % SEBS stress at break (MPa) 25 20 15 10 5 Higher content of compatibilizer in PP/PS-HI 90/10 blend, decrease Tg of soft, ethylene/butylene phase, EB, to lower values. Storage modul, E`, decrease with increasing of SEBS block copolymer. SEBS block copolymer effects at the same way on glass transition temperatures of hard phases in blend PP/PS-HI 50/50, but with increasing content of SEBS, T g of soft, EB phase increases, as well as Tg of soft, polybutadiene, PB, phase. 0 100/0 90/10 50/50 blend composition (PP/PS-HI) 0/100 Table 1. Glass transition temperatures Tg, storage modulus, E`, and intensities of loss tangent, tgδ, for PP/PS-HI blends b) 0 % SEBS 5 % SEBS 7 % SEBS 45 elongation at break (%) 40 35 30 25 20 15 10 5 0 100/0 90/10 50/50 blend composition (PP/PS-HI) 0/100 c) Tg PB °C E” Tg EB °C E” Tg PP °C E” Tg PS °C E” E` GPa 25 °C Is EB tg Is EB tg Is PP tg Is PS tg PP/PS-HI 90/10 / / 24,86 117,9 2,500 / / 0,057 0,129 PP/SEBS/PS-HI 90/5/10 / - 23,71 31,05 122,4 2,311 / 0,021 0,058 0,132 PP/SEBS/PS-HI 90/7/10 / - 26,07 31,67 119,4 2,288 / 0,023 0,058 0,133 PP/PS-HI 50/50 -80-90 / 20,20 113,3 1,967 / / 0,050 0,233 PP/SEBS/PS-HI 50/5/50 - 85-90 - 40,02 26,64 116,1 2,371 0,026 0,020 0,049 0,253 PP/SEBS/PS-HI 50/7/50 - 76,9 - 36,01 30,13 122,3 1,834 0,027 0,024 0,051 0,261 UZORAK Figure 2. Mechanical properties of PP, PS-HI and PP/PS-HI blends; a) impact strenght, b) stress at break, c) elongation at break By increasing SEBS content from 5 % to 7 % , impact strenght increase, while elongation at break decrease. The same behaviour of impact strenght is observed for blend PP/PS-HI 50/50, but the effect of SEBS block copolymer is lower than in PP/PS-HI 90/10 blend. Dynamic mechanical analysis of the investigated blends show multiphase, heterogeneous character of PP/PS-HI blends. DMA results for binary PP/PS-HI 90/10 blend presents two glass transitions, T g, of hard phases; Tg of polystyrene, PS, phase, at 117 °C and Tg of polypropylene, PP, phase, at 24 °C (Figure 3, Table 1). SEBS block copolymer added as compatibilizer, increase temperature of glass transitions of hard phases, Tg of PS phase as well as Tg of PP phase, as regards to binary blend. For PP/SEBS/PS-HI blends just one Tg of PS phase was obtained, due to good affinity of PS block of SEBS and polystyrene, PS, of PS-HI. SEM analysis of uncompatibilized PP/PS-HI blend show two-phase morphology with PS-HI particles disperzed in the PP matrix, as a result of high interfacial tension. On SEM micrographs we can observe a lot of holes formed from the stretching in the fracture. The addition of SEBS block copolymer to binary PP/PS-HI blend, which is located at the interface between PP and PS-HI, changes its phase morphology. The size of the disperzed PS-HI particles is reduced in both compositions, with 5 % and 7 % of added compatibilizer, but the effect is more pronounced with higher content of SEBS block copolymer. It can be seen a better adherence of the disperzed phase in the matrix, as well as reducing of holes in presence of SEBS block copolymer as compatibilizer in PP/PS-HI blends. 140 PP/PS-HI 90/10 PP/SEBS/PSHI 90/5/10 PP/SEBS/PSHI 90/7/10 120 100 E" / GPa 80 60 40 20 PP/PS-HI 50/50 PP/SEBS/PSHI 50/5/50 PP/SEBS/PS-HI 50/7/50 0 -150 -100 -50 0 50 100 150 200 T / °C Figure 3. The loss modulus, E",of PP/PS-HI blends 4 a) Proceeding of the 8th Polymers for Advanced Technologies International Symposium Budapest, Hungary, 13-16 September 2005 PROCEEDING FORM (1-3 pages with the given font types) References (max. 10) b) [1] Ismail H.H., Nasir M.: Polymer Testing 21: 163170 (2002) [2] Papadopoulou C.P., Kalfoglou N.K.: Polymer 41: 2543-2555 (2000) [3] Bassani A., Pessan L.A.: J. Appl. Polym. Sci. 88: 1081-1094 (2003) [4] Santana R.M.C., Manrich S.: J. Appl. Polym. Sci. 88: 2861-2867 (2003) ..... c) d) Figure 4. SEM microphotographs of PP/PS-HI blends a) PP/PS-HI 90/10, b) PP/SEBS/PS-HI 90/5/10, c) PP/SEBS/PS-HI 90/7/10, d) PP/SEBS/PS-HI 50/5/50 4. Conclusion The results show that SEBS block copolymer produce an improvement in toughness of PP/PS-HI blends. The effect of compatibilizer is the most pronounced in blend PP/PS-HI 90/10 with 7 % of SEBS. The results of SEM analysis show that SEBS block copolymer act as a compatibilizer in immiscible PP/PSHI blends. The stronger interactions of SEBS between the disperze phase, high impact polystyrene and the matrix, polypropylene results in reducing the average particle size of PS-HI, and increasing the interfacial adhesion between the both phases. Proceeding of the 8th Polymers for Advanced Technologies International Symposium Budapest, Hungary, 13-16 September 2005