Production & Inventory Planning: Solved Spreadsheet Model

advertisement

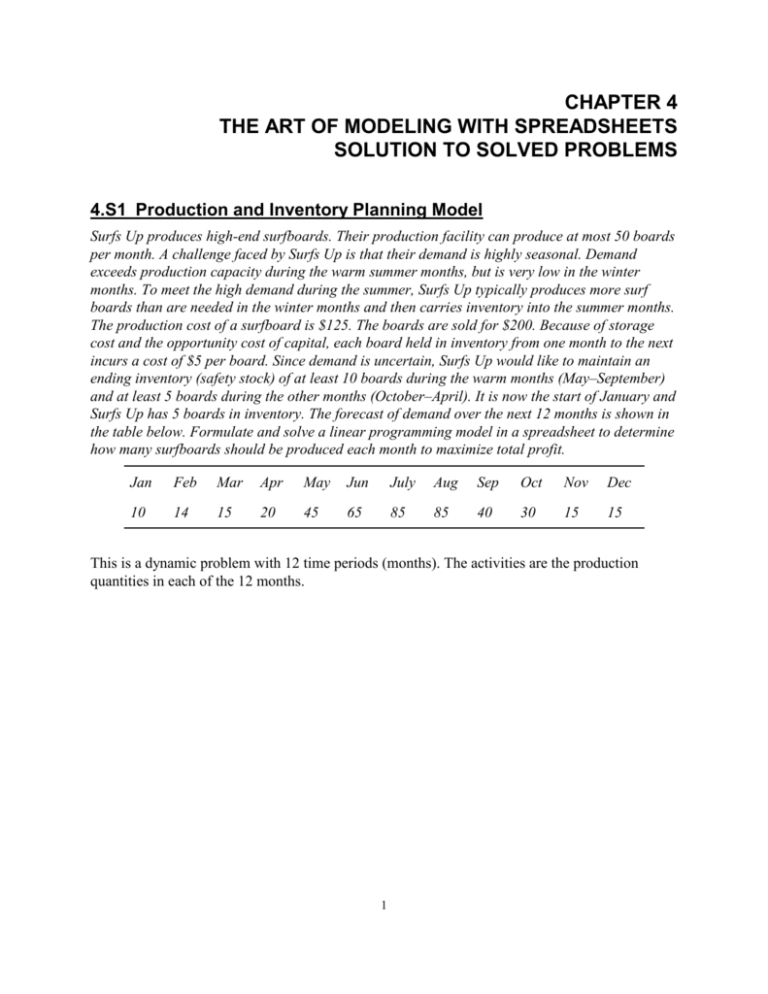

CHAPTER 4 THE ART OF MODELING WITH SPREADSHEETS SOLUTION TO SOLVED PROBLEMS 4.S1 Production and Inventory Planning Model Surfs Up produces high-end surfboards. Their production facility can produce at most 50 boards per month. A challenge faced by Surfs Up is that their demand is highly seasonal. Demand exceeds production capacity during the warm summer months, but is very low in the winter months. To meet the high demand during the summer, Surfs Up typically produces more surf boards than are needed in the winter months and then carries inventory into the summer months. The production cost of a surfboard is $125. The boards are sold for $200. Because of storage cost and the opportunity cost of capital, each board held in inventory from one month to the next incurs a cost of $5 per board. Since demand is uncertain, Surfs Up would like to maintain an ending inventory (safety stock) of at least 10 boards during the warm months (May–September) and at least 5 boards during the other months (October–April). It is now the start of January and Surfs Up has 5 boards in inventory. The forecast of demand over the next 12 months is shown in the table below. Formulate and solve a linear programming model in a spreadsheet to determine how many surfboards should be produced each month to maximize total profit. Jan Feb Mar Apr May Jun July Aug Sep Oct Nov Dec 10 14 15 20 45 65 85 85 40 30 15 15 This is a dynamic problem with 12 time periods (months). The activities are the production quantities in each of the 12 months. 1 To get started, we sketch a spreadsheet model. Each of the 12 months will be a separate column in the spreadsheet. For each month, the production quantity (a changing cell) must be no more than the maximum production quantity (50). Using on-hand inventory and current month production, there will be a quantity of surf boards available for sale that must be greater than or equal to the forecasted sales. The ending inventory at the end of each month must be at least the minimum safety stock level. Each month will generate revenue, incur production costs and inventory holding costs, and achieve a resulting profit. The goal will be to maximize the total profit over all 12 months. This leads to the following sketch of a spreadsheet model. Production Cost Selling Price Holding Cost Starting Inventory Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Production <= Maximum Available for Sale >= Forecasted Sales Ending Inventory >= Safety Stock Total Revenue Production Cost Holding Cost Profit 2 The amount available for sale will be the ending inventory from the previous month (or the starting inventory for January) plus whatever is produced in that month. The ending inventory will be the previous month’s ending inventory plus production minus sales. The revenue will equal the selling price times forecasted sales. The production cost will be the production quantity times the unit production cost. The holding cost will equal the ending inventory times the unit holding cost. The monthly profit will be revenue minus production cost minus holding cost. Finally, the total profit will be the sum of the monthly profits. Arbitrary production quantities of 25 each month leads to the following spreadsheet. 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 B Production Cost Selling Price Holding Cost Starting Inventory Production Maximum Available for Sale Forecasted Sales Ending Inventory Safety Stock C $125 $200 $5 5 D E F G H I J K L M N Jan 25 <= 50 Feb 25 <= 50 Mar 25 <= 50 Apr 25 <= 50 May 25 <= 50 Jun 25 <= 50 Jul 25 <= 50 Aug 25 <= 50 Sep 25 <= 50 Oct 25 <= 50 Nov 25 <= 50 Dec 25 <= 50 30 >= 10 45 >= 14 56 >= 15 66 >= 20 71 >= 45 51 >= 65 11 >= 85 -49 >= 85 -109 >= 40 -124 >= 30 -129 >= 15 -119 >= 15 20 >= 5 31 >= 5 41 >= 5 46 >= 5 26 >= 10 -14 >= 10 -74 >= 10 -134 >= 10 -149 >= 10 -154 >= 5 -144 >= 5 -134 >= 5 $2,800 $3,125 $155 -$480 $3,000 $3,125 $205 -$330 $4,000 $3,125 $230 $645 $9,000 $3,125 $130 $5,745 $8,000 $3,125 -$745 $5,620 $6,000 $3,125 -$770 $3,645 $3,000 $3,125 -$720 $595 $3,000 $3,125 -$670 $545 Revenue $2,000 Production Cost $3,125 Holding Cost $100 Profit -$1,225 B Production Cost 125 Selling Price 200 Holding Cost 5 Starting Inventory 5 C $13,000 $17,000 $17,000 $3,125 $3,125 $3,125 -$70 -$370 -$670 $9,945 $14,245 $14,545 D EFGHIJKLM N Feb Dec 50 Mar Apr May Jun Jul Aug Sep Oct Nov 25 25 25 25 25 25 25 25 25 25 <= <= <= <= <= <= <= <= <= 50 50 50 50 50 50 50 50 50 50 Available for Sale =StartingInventory+Production >= Forecasted Sales 10 =C17+Production >= 14 =D17+Production =E17+Production =F17+Production =G17+Production =H17+Production =I17+Production =J17+Production =K17+Production =L17+Production =M17+Production >= >= >= >= >= >= >= >= >= >= 15 20 45 65 85 85 40 30 15 15 Ending Inventory =AvailableForSale-ForecastedSales >= Safety Stock 5 =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales >= >= >= >= >= >= >= >= >= >= >= 5 5510 10 10 10 10 555 Jan Production 25 25 <= Maximum 50 Revenue =SellingPrice*ForecastedSales Production Cost =ProductionCost*Production Holding Cost =HoldingCost*EndingInventory Profit =C22-C23-C24 <= =SellingPrice*ForecastedSales =ProductionCost*Production =HoldingCost*EndingInventory =D22-D23-D24 3 O Total $87,800 $37,500 -$3,195 $53,495 O <= =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =E22-E23-E24 =F22-F23-F24 =G22-G23-G24 =H22-H23-H24 =I22-I23-I24 =J22-J23-J24 =K22-K23-K24 =L22-L23-L24 =M22-M23-M24 =N22-N23-N24 Total =SUM(C22:N22) =SUM(C23:N23) =SUM(C24:N24) =SUM(C25:N25) The Solver information and solved spreadsheet are shown below. 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 B C Production Cost $125 Selling Price $200 Holding Cost $5 Starting Inventory 5 Production Maximum Available for Sale Forecasted Sales Ending Inventory Safety Stock D E F G H I J K L M N Jan 10 <= 50 Feb 34 <= 50 Mar 50 <= 50 Apr 50 <= 50 May 50 <= 50 Jun 50 <= 50 Jul 50 <= 50 Aug 50 <= 50 Sep 40 <= 50 Oct 25 <= 50 Nov 15 <= 50 Dec 15 <= 50 15 >= 10 39 >= 14 75 >= 15 110 >= 20 140 >= 45 145 >= 65 130 >= 85 95 >= 85 50 >= 40 35 >= 30 20 >= 15 20 >= 15 5 >= 5 25 >= 5 60 >= 5 90 >= 5 95 >= 10 80 >= 10 45 >= 10 10 >= 10 10 >= 10 5 >= 5 5 >= 5 5 >= 5 Total Revenue $2,000 $2,800 $3,000 $4,000 $9,000 $13,000 $17,000 $17,000 $8,000 $6,000 $3,000 $3,000 $87,800 Production Cost $1,250 $4,250 $6,250 $6,250 $6,250 $6,250 $6,250 $6,250 $5,000 $3,125 $1,875 $1,875 $54,875 Holding Cost $25 $125 $300 $450 $475 $400 $225 $50 $50 $25 $25 $25 $2,175 Profit $725 -$1,575 -$3,550 -$2,700 $2,275 $6,350 $10,525 $10,700 $2,950 $2,850 $1,100 $1,100 $30,750 Range Nam e Avail able ForSal e Endi ngIn ve ntory Fore cas tedSa les Holdi ngCost Maximum Produ cti on Produ cti onCost Safe tyStock Sell ingPri ce StartingInvento ry TotalProfit 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 O B Production Cost 125 Selling Price 200 Holding Cost 5 Starting Inventory 5 C Cells C13:N13 C17:N17 C15:N15 C5 C11:N11 C9:N9 C3 C19:N19 C4 C6 O25 D EFGHIJKLM N Feb Dec 50 Mar Apr May Jun Jul Aug Sep Oct Nov 25 25 25 25 25 25 25 25 25 25 <= <= <= <= <= <= <= <= <= 50 50 50 50 50 50 50 50 50 50 Available for Sale =StartingInventory+Production >= Forecasted Sales 10 =C17+Production >= 14 =D17+Production =E17+Production =F17+Production =G17+Production =H17+Production =I17+Production =J17+Production =K17+Production =L17+Production =M17+Production >= >= >= >= >= >= >= >= >= >= 15 20 45 65 85 85 40 30 15 15 Ending Inventory =AvailableForSale-ForecastedSales >= Safety Stock 5 =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales =AvailableForSale-ForecastedSales >= >= >= >= >= >= >= >= >= >= >= 5 5510 10 10 10 10 555 Jan Production 25 25 <= Maximum 50 Revenue =SellingPrice*ForecastedSales Production Cost =ProductionCost*Production Holding Cost =HoldingCost*EndingInventory Profit =C22-C23-C24 <= =SellingPrice*ForecastedSales =ProductionCost*Production =HoldingCost*EndingInventory =D22-D23-D24 O <= =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =SellingPrice*ForecastedSales =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =ProductionCost*Production =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =HoldingCost*EndingInventory =E22-E23-E24 =F22-F23-F24 =G22-G23-G24 =H22-H23-H24 =I22-I23-I24 =J22-J23-J24 =K22-K23-K24 =L22-L23-L24 =M22-M23-M24 =N22-N23-N24 Total =SUM(C22:N22) =SUM(C23:N23) =SUM(C24:N24) =SUM(C25:N25) The values in Production (C9:N9) show how many surf boards Surfs Up should produce each month so as to achieve the maximum profit of $30,750. 4 4.S2 Aggregate Planning: Manpower Hiring/Firing/Training Cool Power produces air conditioning units for large commercial properties. Due to the low cost and efficiency of its products, the company has been growing from year to year. Also, due to seasonality in construction and weather conditions, production requirements vary from month to month. Cool Power currently has 10 fully trained employees working in manufacturing. Each trained employee can work 160 hours per month and is paid a monthly wage of $4000. New trainees can be hired at the beginning of any month. Due to their lack of initial skills and required training, a new trainee only provides 100 hours of useful labor in their first month, but are still paid a full monthly wage of $4000. Furthermore, because of required interviewing and training, there is a $2500 hiring cost for each employee hired. After one month, a trainee is considered fully trained. An employee can be fired at the beginning of any month, but must be paid two weeks of severance pay ($2000). Over the next 12 months, Cool Power forecasts the labor requirements shown in the table below. Since management anticipates higher requirements next year, Cool Power would like to end the year with at least 12 fully trained employees. How many trainees should be hired and/or workers fired in each month to meet the labor requirements at the minimum possible cost? Formulate and solve a linear programming spreadsheet model. Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec 1600 2000 2000 2000 2800 3200 3600 3200 1600 1200 800 800 This is a dynamic problem with 12 time periods (months). The activities are the number of workers to hire and fire in each of the 12 months. 5 To get started, we sketch a spreadsheet model. Each of the 12 months will be a separate column in the spreadsheet. For each month, there are changing cells for both the number of workers hired and fired. Based on the values of these changing cells, we can determine the number of trainees and trained employees. The number of labor hours generated by the employees must be at least the required labor hours each month. Finally, labor costs (for trainees and the trained workforce), hiring cost, and severance pay leads to a total monthly cost. The goal will be to minimize the total cost over all 12 months. This leads to the following sketch of a spreadsheet model. Labor Monthly Wage Hiring Cost Severance Pay Labor Hours/Trainee/Month Labor Hours/Trained Worker/Month Starting Trained Workforce Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Workers Hired Workers Fired Minimum to Start the Next Year Trainees Trained Employees >= Labor Hours Available >= Required Labor Hours Total Labor Cost (Trainees) Labor Cost (Trained Workforce) Hiring Cost Severance Pay Total Cost 6 When an employee is first hired, he or she is a trainee for one month before becoming a fullytrained employee. Therefore, the number of trainees (row 14) is equal to the number of workers hired in that month, while the number of trained employees (row 15) is the number of trained employees and trainees from the previous month minus any employee that is fired. The labor hours available in each month equals the sumproduct of the labor hours provided by each type of worker (trained or trainees) with the number of each type of employee. The labor costs in each month are the monthly wage multiplied by the number of employees. The hiring cost is the unit hiring cost multiplied by the number of workers hired. The severance pay is the unit severance cost multiplied by the number of workers fired. Then, the total monthly cost is the sum of the labor costs, hiring cost, and severance pay. Finally, the total cost will be the sum of the monthly costs. For arbitrary values of workers hired and fired each month, this leads to the following spreadsheet. 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 B C Labor Monthly Wage $4,000 Hiring Cost $2,500 Severance Pay $2,000 Labor Hours/Trainee/Month 100 Labor Hours/Trained Worker/Month 160 Starting Trained Workforce 10 D E F G H I J K L M N Workers Hired Workers Fired Jan 2 0 Feb 2 0 Mar 2 0 Apr 2 0 May 2 0 Jun 2 0 Jul 2 0 Aug 0 3 Sep 0 3 Oct 0 3 Nov 2 0 Dec 2 0 Trainees Trained Employees 2 10 2 12 2 14 2 16 2 18 2 20 2 22 0 21 0 18 0 15 2 15 2 17 1800 >= 1600 2120 >= 2000 2440 >= 2000 2760 >= 2000 3080 >= 2800 3400 >= 3200 3720 >= 3600 3360 >= 3200 2880 >= 1600 2400 >= 1200 2600 >= 800 2920 >= 800 $8,000 $40,000 $5,000 $0 $53,000 $8,000 $48,000 $5,000 $0 $61,000 $8,000 $56,000 $5,000 $0 $69,000 $8,000 $64,000 $5,000 $0 $77,000 $8,000 $72,000 $5,000 $0 $85,000 Labor Hours Available Required Labor Hours Labor Cost (Trainees) Labor Cost (Trained Workforce) Hiring Cost Severance Pay Total Cost $8,000 $8,000 $0 $0 $0 $8,000 $80,000 $88,000 $84,000 $72,000 $60,000 $60,000 $5,000 $5,000 $0 $0 $0 $5,000 $0 $0 $6,000 $6,000 $6,000 $0 $93,000 $101,000 $90,000 $78,000 $66,000 $73,000 B Labor Monthly Wage 4000 Hiring Cost 2500 Severance Pay 2000 Labor Hours/Trainee/Month 100 Labor Hours/Trained Worker/Month 160 Starting Trained Workforce 10 C Jan Workers Hired 2 Workers Fired 0 Trainees =WorkersHired Trained Employees =StartingTrainedWorkforce-WorkersFired $8,000 $68,000 $5,000 $0 $81,000 DEFGHIJKLMN O P >= Minimum to Start the Next Year 12 Total $72,000 $792,000 $45,000 $18,000 $927,000 O P Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec 102430.999999999999998 0002.00000000006961 0 000000310 000 Minimum to Start the =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired Next Year =C15+C14-WorkersFired =D15+D14-WorkersFired =E15+E14-WorkersFired =F15+F14-WorkersFired =G15+G14-WorkersFired =H15+H14-WorkersFired =I15+I14-WorkersFired =J15+J14-WorkersFired =K15+K14-WorkersFired =L15+L14-WorkersFired =M15+M14-WorkersFired >= 12 Labor Hours Available =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedWorker,C14:C15) =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedWor =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedWo =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedWo =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedW =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedW =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrained =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTraine =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrain =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrain =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTra =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTra >= >= >= >= >= >= >= >= >= >= >= >= Required Labor Hours 1600 2000 2000 2000 2800 3200 3600 3200 1600 1200 800 800 Labor Cost (Trainees) =LaborMonthlyWage*Trainees Labor Cost (Trained Workforce) =LaborMonthlyWage*TrainedEmployees Hiring Cost =HiringCost*WorkersHired Severance Pay =SeverancePay*WorkersFired Total Cost =SUM(C22:C25) 7 Total =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =SUM(C22:N22) =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =SUM(C23:N23) =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =SUM(C24:N24) =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SUM(C25:N25) =SUM(D22:D25) =SUM(E22:E25) =SUM(F22:F25) =SUM(G22:G25) =SUM(H22:H25) =SUM(I22:I25) =SUM(J22:J25) =SUM(K22:K25) =SUM(L22:L25) =SUM(M22:M25) =SUM(N22:N25) =SUM(C26:N26) The Solver information is shown below, followed by the solved spreadsheet. 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 B C Labor Monthly Wage $4,000 Hiring Cost $2,500 Severance Pay $2,000 Labor Hours/Trainee/Month 100 Labor Hours/Trained Worker/Month 160 Starting Trained Workforce 10 D E F G H I J K L M N Jan Workers Hired 2.1E-11 Workers Fired 0 Feb 4 0 Mar 0 0 Apr 0 0 May 6 0 Jun 2 0 Jul 1 0 Aug 0 3 Sep 0 10 Oct 0 0 Nov 2 0 Dec 0 0 Trainees 2.1E-11 Trained Employees 10 4 10 0 14 0 14 6 14 2 20 1 22 0 20 0 10 0 10 2 10 0 12 2000 >= 2000 2240 >= 2000 2240 >= 2000 2840 >= 2800 3400 >= 3200 3620 >= 3600 3200 >= 3200 1600 >= 1600 1600 >= 1200 1800 >= 800 1920 >= 800 Labor Hours Available Required Labor Hours 1600 >= 1600 Labor Cost (Trainees) $0 $16,000 $0 $0 $24,000 $8,000 $4,000 Labor Cost (Trained Workforce) $40,000 $40,000 $56,000 $56,000 $56,000 $80,000 $88,000 Hiring Cost $0 $10,000 $0 $0 $15,000 $5,000 $2,500 Severance Pay $0 $0 $0 $0 $0 $0 $0 Total Cost $40,000 $66,000 $56,000 $56,000 $95,000 $93,000 $94,500 $0 $0 $0 $80,000 $40,000 $40,000 $0 $0 $0 $6,000 $20,000 $0 $86,000 $60,000 $40,000 Range Na me Hirin gCost La borHours Availa ble La borHours PerTrai nedWorke r La borHours PerTrai nee La borMonthlyWag e Mini mumToStartNe xtYear Requ iredL aborHou rs Severa nce Pay Sta rting Train edWo rkfo rce To talCos t Tra ined Emplo ye es Tra inee s Wo rkers Fired Wo rkers Hi red 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 B Labor Monthly Wage 4000 Hiring Cost 2500 Severance Pay 2000 Labor Hours/Trainee/Month 100 Labor Hours/Trained Worker/Month 160 Starting Trained Workforce 10 C Jan Workers Hired 2 Workers Fired 0 Trainees =WorkersHired Trained Employees =StartingTrainedWorkforce-WorkersFired O P >= Minimum to Start the Next Year 12 Total $8,000 $0 $60,000 $40,000 $48,000 $664,000 $5,000 $0 $37,500 $0 $0 $26,000 $53,000 $48,000 $787,500 Cells C4 C17:N1 7 C7 C6 C3 P15 C19:N1 9 C5 C8 O26 C15:N1 5 C14:N1 4 C12:N1 2 C11:N1 1 DEFGHIJKLMN O P Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec 102430.999999999999998 0002.00000000006961 0 000000310 000 Minimum to Start the =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired =WorkersHired Next Year =C15+C14-WorkersFired =D15+D14-WorkersFired =E15+E14-WorkersFired =F15+F14-WorkersFired =G15+G14-WorkersFired =H15+H14-WorkersFired =I15+I14-WorkersFired =J15+J14-WorkersFired =K15+K14-WorkersFired =L15+L14-WorkersFired =M15+M14-WorkersFired >= 12 Labor Hours Available =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedWorker,C14:C15) =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedWor =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedWo =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedWo =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedW =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrainedW =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrained =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTraine =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrain =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTrain =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTra =SUMPRODUCT(LaborHoursPerTrainee:LaborHoursPerTra >= >= >= >= >= >= >= >= >= >= >= >= Required Labor Hours 1600 2000 2000 2000 2800 3200 3600 3200 1600 1200 800 800 Labor Cost (Trainees) =LaborMonthlyWage*Trainees Labor Cost (Trained Workforce) =LaborMonthlyWage*TrainedEmployees Hiring Cost =HiringCost*WorkersHired Severance Pay =SeverancePay*WorkersFired Total Cost =SUM(C22:C25) Total =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =LaborMonthlyWage*Trainees =SUM(C22:N22) =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =LaborMonthlyWage*TrainedEmployees =SUM(C23:N23) =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =HiringCost*WorkersHired =SUM(C24:N24) =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SeverancePay*WorkersFired =SUM(C25:N25) =SUM(D22:D25) =SUM(E22:E25) =SUM(F22:F25) =SUM(G22:G25) =SUM(H22:H25) =SUM(I22:I25) =SUM(J22:J25) =SUM(K22:K25) =SUM(L22:L25) =SUM(M22:M25) =SUM(N22:N25) =SUM(C26:N26) Thus, WorkersHired (C11:N11) shows the number of workers Cool Power should hire each month and WorkersFired (C12:N12) shows the number of workers Cool Power should fire each month so as to achieve the minimum TotalCost (O26) of $787,500. 8