Fabrication and Characterization of Metallic Cavity Nanolasers

advertisement

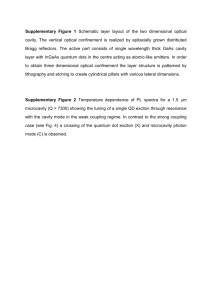

School of Electrical, Computer and Energy Engineering PhD Final Oral Defense Fabrication and Characterization of Metallic Cavity Nanolasers by Kang Ding April 18 2014 9:00 am Goldwater Center 409 Committee: Dr. Cun-Zheng Ning (chair) Dr. Hongbin Yu Dr. Joseph Palais Dr. Yong-Hang Zhang Abstract In this thesis, I present my research work in the fabrication and characterization of metallic cavity nanolasers. Nanolasers represents the research frontier in both the areas of photonics and nanotechnology for its interesting properties in low dimension physics and its appealing prospects in integrated photonics and other on-chip applications. By using low loss metals such as silver, which is highly reflective at near infrared, light can be confined in an ultra small cavity or waveguide with sub-wavelength dimensions. Based on this idea, I fabricated metallic cavity nanolasers with rectangular and circular geometries with InGaAs as the gain material and silver as the metallic shell serving as cavity. The lasing wavelength is around 1.55 μm, intended for optical communication applications. Continuous wave (CW) lasing at cryogenic temperature under current injection was achieved on devices with deep sub-wavelength physical cavity volume smaller than 0.2 λ3. With improved fabrication process and device design, CW lasing at room temperature was demonstrated as well on a sub-wavelength rectangular device with a physical cavity volume = 0.67 λ3. I also demonstrated experimentally that a small circular nanolasers supporting TE01 mode can generate anazimuthal polarized laser beam, providing a compact such source under electrical injection. Such sources could have many special applications. I also studied the digital modulation of metallic nanolasers, showingthat the laser noise is an important limiting factor that will affect the data rate of the nanolaser when used as the light source in optical interconnects. Due to its ultra-small size, fabrication of such nanolaser and its coupling to external waveguide are extremely challenging. For future development, improving device fabrication process for improved device performance and developing the techniques to realize nanolaser-Si waveguide integration will be the two critical aspects to finally enable practical applications of such metallic cavity nanolasers.