The Forrest Kerr hydroelectric project, located approximately 100 km

advertisement

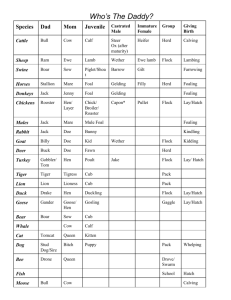

195 MW of new hydro power for British Columbia at Forrest Kerr The Forrest Kerr hydroelectric project, located approximately 100 km northwest of Stewart in northwestern British Columbia, has been safely commissioned and is producing power … Social impact assessment for floating LNG project in Australia UPCOMING CONFERENCES Renewables & Mining Summit Generate 2014 Ontario Waterpower Association 500 kV transmission development plan for Fort McMurray area in Alberta EPC[M] for Mining and Energy Projects CanWEA 2014 Energy efficiency for Inter-American Development Bank Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 Technical Meeting on Small Reactors Solar Canada 2014 www.hatch.ca 195 MW of new hydro power for British Columbia The Forrest Kerr hydroelectric project, located approximately 100 km northwest of Stewart in northwestern British Columbia, has been safely commissioned and is producing power. Owned and operated by AltaGas, the run-of-river facility will capture energy produced by the natural flow and elevation drop of the Iskut River to produce clean, renewable power for BC Hydro’s system via an interconnection at Bob Quinn Lake and the 287-kV Northwest Transmission Line. The new Forrest Kerr hydroelectric facility is owned and operated by AltaGas. The project includes a 3.3 km long power tunnel and nine Francis turbines that will deliver 980 GWh of clean power annually to BC Hydro’s transmission system. Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca Over the last several years, Hatch completed a number of feasibility and cost estimating studies to assist the developer in defining the optimal size and layout of the project. The final project feasibility study was completed by Hatch in 2009— this included resolution of several technical issues as well as comprehensive capital and operating cost estimates. This was done in accordance with the current terms of the BC Hydro Electricity Purchase Agreement and the stated terms of the British Columbia Environmental Assessment Certificate. In 2011, after the project had been ongoing for approximately eight months with another engineering firm, we were asked to assume responsibility for the final design and procurement of construction services. We quickly assembled a highly experienced design team—most members were in place within 30 days—and successfully managed the transition in conjunction with contractors already progressing with underground excavations. With significant modifications required to the headworks and underground powerhouse during this period, we conducted weekly design updates with the construction team and managed the changes with minimal lost time and rework in the field. Key elements Headworks facility: eight-bay forebay control structure/de-sander and power tunnel portal designed for a maximum flow of 262 m3/s; 7 m high overflow weir including two 10 m wide Obermeyer gates Gated sluiceway with a 6 m wide by 9 m high radial gate 7.5 m wide by 11 m high vertical power tunnel intake gate Riparian discharge conduit with a capacity of 10 m3/s 3.3 km long power tunnel 650 m long powerhouse construction access tunnel and 144 m long x 17 m wide x 22 m high powerhouse cavern Underground powerhouse with nine 23.49 MW horizontal axis Francis Generating Units 400 m long tailrace tunnel and 287 kV, five-node ring-bus surface switchyard including three 13.8 287-kV 85 MVA generator step-up transformers 44 km long, 287 kV transmission line 950 m long powerhouse main access tunnel 150 m long vertical shaft to accommodate the generator main lead cables AltaGas managed the various construction contracts, while we provided resident engineering support services. We delivered detailed construction drawings and specifications for the underground works contracts, general civil works, balance-of-plant electrical and mechanical works, and switchyard. We also provided drawings and specifications for a number of EPC contracts including the major mechanical equipment (gates, valves and powerhouse crane) and the 44 km transmission line. Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca One of the most interesting technical challenges involved addressing the strict flow ramping requirements of the facility which were imposed to limit the water level fluctuations in fishbearing areas of the river downstream of the powerplant. Together with AltaGas and Andritz Hydro, we developed an innovative configuration that allowed flow bypass through the nine generating units while running at over-speed. This avoided the need to construct a costly additional underground flow bypass and energy dissipation system. Another challenge involved managing the high levels of bedload and suspended sediment carried in the river. Innovative sediment collection and flushing capabilities were built into the project to reduce sediment ingress to the power tunnel in order to limit turbine runner wear. Before moving ahead, the design and performance of these facilities were confirmed through extensive numerical studies and physical hydraulic modeling. The plant is now in commercial operation with six generating units commissioned and delivering energy to the BC Hydro transmission system. The remaining three units are on schedule for completion and full commissioning this month—and the entire project is expected to come in on time and on budget. For further information, please contact: Shawn R. Smith, PEng Associate, Renewable Power Vancouver, British Columbia, Canada +1 604 630 7345 Tonawanda, New York, USA Shawn.Smith@hatch.ca Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca 500 kV transmission development plan for Fort McMurray area in Alberta Alberta’s Integrated Electric System (AIES) has limited interarea power transfer capability to supply the continually growing demand in the Fort McMurray (FMM) area. This is primarily due to the significant power demands of oil sands extraction and processing projects around FMM, which will continue over the planning horizon to 2022. Some of the load growth is offset by local generation, but the load and generation additions in FMM and other areas of the AIES are expected to increase power transfer levels between the two areas. Past planning studies identified the need for inter-regional transmission reinforcement and recommended a 500 kV development plan in the FMM area. It was designated as a Critical Transmission Infrastructure (CTI) project and included in the Electric Utilities Act, legislated to be completed through a The proposed solution involves a new 500 kV transmission line to transfer 1,500 to 1,800 MW over a distance of 500 km. competitive process. Alberta Electric System Operator (AESO) engaged Hatch to undertake comprehensive transmission system planning studies to validate bulk transmission needs in the 10-year time frame and to prepare functional specifications for the required transmission facilities, including cost estimates. The proposed 500 kV transmission development plan needed to transfer over 1,500 MW of power for a distance of over 500 km between Edmonton and Fort McMurray areas. The key objectives of the study were to: Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca Validate the need and timing of the proposed 500 kV development based on 2012 long-term outlook (LTO) load and generation forecast and system topology Conduct related engineering studies to determine the design parameters of the transmission development to ensure the project is compliant with the Alberta reliability standards and meets all other engineering and performance standards Support the competitive procurement process in preparing the functional specifications for the project Prepare technical planning reports documenting the results of need assessment (phase 1), development and screening of transmission options (phase 2), and detailed technical and economic analysis of the preferred development option (phase 3). Accordingly, extensive transmission system studies and analyses were undertaken to establish power transfer capability of the existing transmission system between FMM and the rest of the AIES. This exercise provided insight into the potential gap between the existing capability and future power transfer needs. Once the need and timing of the bulk transmission reinforcement solution were identified, multiple transmission development alternatives were considered and analyzed for transferring 1,500 to 1,800 MW over a distance of 500 km. Alternatives included expansion of the existing 240 kV network, ±350 kV HVdc bipole lines, and 500 kV transmission options. These options were compared in view of technical, operational, land use and economic considerations in order to maintain system-wide performance targets for reliability, security and efficiency. Further detailed system studies and analyses were performed to evaluate long-term performance of the proposed 500 kV transmission solution under credible load and generation scenarios. The performance was assessed in terms of flows out of the FMM region, loading capability of 500 kV lines, shunt reactive compensation requirements, transformation capacity at 500 kV terminal substations, and future provisions for increasing power transfer capability. In addition, various important technical parameters were established for the development of functional specifications for these proposed facilities. Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca The project defined by these studies is currently the subject of a competitive procurement process administered by AESO. For further information, please contact: Fiaz Chaudhry, PhD, PEng Manager, Power System Planning Mississauga, Ontario, Canada +1 905 403 4122 mailto:FChaudhry@hatch.ca Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca Energy efficiency for IADB The Inter-American Development Bank has retained Hatch to provide energy efficiency consulting services to its customers in South America and the Caribbean. The program includes energy efficiency audits, small-scale renewable energy feasibility studies, and green engineering design services. Four task orders have been signed to date including: a study of behindthe-meter solar photovoltaic installations and a cogeneration plant at a university campus in Jamaica; energy efficiency initiatives at an agroindustrial complex in Peru; operational improvements, energy audits and assistance with LEED certification of large warehouses in Argentina; and assistance in outsourcing the development and O&M responsibility for a large-scale city street lighting system in Brazil, including conversion to LED technology. Solar PV is an energyefficient option For further information, please contact: Robert Griesbach, MBA, PEng Director, Energy Consulting Hatch Management Consulting Mississauga, Ontario, Canada + 1 905 403 4102 RGriesbach@hatch.ca Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca Social impact assessment for floating LNG project in Australia The Browse Joint Venture’s proposed commercialization of gas and condensate fields in the Browse Basin (425 km from Broome, Western Australia) could involve up to three FLNG vessels and numerous onshore sites. Hatch is undertaking a comprehensive SIA of onshore activities, a stakeholder engagement process, development of social design criteria for concurrent BOD and FEED phases, and a draft social impact management plan with practicable options and measureable KPIs. Having recently completed a similar assignment for Shell’s Prelude project, Hatch’s Environmental Services Group is the only Australian consultancy with proven experience in this unique area. For more information, contact Brigid Hosmer Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca Upcoming Conferences Renewables & Mining Summit & Exhibition October 15 – 16, 2014 Toronto, Canada Hatch is the principal sponsor for this summit which brings together leaders from the global mining industry and the renewable energy sector to discuss mining’s energy challenges. Rob Lydan, Hatch director for Solar and Wind, will speak on “Customizing Integrated Energy Solutions for Mines” and is a panelist at the “Hybrid Solutions for Mines” session. Read a recent interview with Lydan here. Visit Booth 9 to meet Hatch’s power and energy experts. Generate 2014 October 15 – 17, 2014 Vancouver, Canada Meet our water power experts at Booth 3. Ontario Waterpower Association October 19 – 21, 2014 Niagara-on-the-Lake, Canada Visit Hatch at Booth 11. Noel Boucher will participate in Session 3C: “An Integrated Approach to Waterpower Development—Biologists and Engineers Working Together". EPC[M] for Mining and Energy Projects October 20 – 21, 2014 Calgary, Canada Hatch is an exhibitor, sponsor, and presenter. Ashok Kumar, a senior project manager at Hatch, will lead the workshop “EPC 101: A Primer on EPC Frameworks”. Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca CanWEA 2014 October 27 – 29, 2014 Montréal, Canada Hatch is an exhibiter and presenter. Meet our wind power experts at Booth 1615. Michel Carreau, an energy director at Hatch, will present: “An overview of challenges for wind power on remote mining sites”. AECL/CNS 3rd International Technical Meeting on Small Reactors November 5 – 7, 2014 Ottawa, Canada Brian Gihm, a senior nuclear engineer, will present on: “Design Considerations for Micro Nuclear Reactors to Supply Power to Off-Grid Mines”. Solar Canada 2014 December 8 – 9, 2014 Toronto, Canada Visit us at Booth 1217 and meet our solar energy experts. Hatch Corporate Office Sheridan Science & Technology Park 2800 Speakman Drive Mississauga, ON L5K 2R7 Canada Tel: +1 905 855 7600 | Fax: +1 905 855 8270 www.hatch.ca