Aircraft Surveillance Checklist for Inspections

advertisement

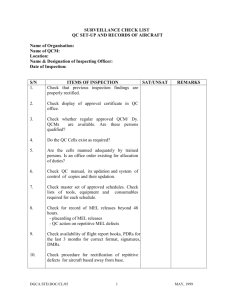

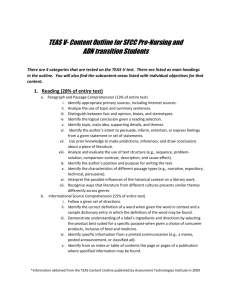

SURVEILLANCE CHECK LIST INSPECTION OF AIRCRAFT Name of Organisation: Name of QCM: Type of Aircraft: Regn.No.: Location: Name & Designation of Inspecting Officer: Date of Inspection: S/N ITEMS OF INSPECTION DOCUMENTS SAT/UNSAT 1. Check that there is a customised maintenance manual for each aircraft. 2. Check the availability of the followings: REMARKS i) ii) iii) iv) v) vi) vii) viii) ix) x) xi) xii) xiii) xiv) Operator's Permit, Customised inspection schedules, Flight Manual; MEL, Approved TBOs/ COSL, SRM, Wiring Diagram, Trouble shooting manual, IPC, C of A, C of R, Flight Release, Weight Schedule, Flight Manual and its updation with the manufacturer checklist xv) WT licence, xvi) Certificate of Flight Release xvii) Company Operations Manual xviii) Flight Crew Operating Manual and maps & Route Guide xix) Normal Checklist and Emergency Checklist 2. Check the availability of the following log books- i) ii) iii) Airframe log book Engine log books for each engine Prop. log books for each propeller DGCA STD.DOC/CL/04 1 MAY, 1999 iv) v) vi) Radio log book APU log book JLB or Flight Report Book 3. AIRCRAFT RECORDS Check for the following in the log books i) ii) iii) iv) v) vi) vii) viii) ix) x) xi) xii) Upkeep and general condition of log books; Certification duly signed and dated by AMEs/authorised personnel.; Carried forward hours are correct; Pages are numbered; Entries are correct and legible; Entries for replacement of components alongwith hours and major repairs carried out; Entry of duplicate inspections; Entry of major inspections; Check for released notes for components in the stores; Entry of mandatory modifications (check against master mandatory mod. list. 4. INSPECTION SCHEDULES i) ii) vii) viii) Check schedules for the last three months; Check whether schedules have been amended with regard to revisions in the MPD; All items have been signed by AMEs and Technicians completed schedules have been checked by QC cell; Numbering of off-job sheets and their cross reference in the main schedule; Preservation of schedule for two years; Task cards, if used, approved by QCM and DGCA and Defect rectification cards (DRC) are available with cross reference of main task cards/schedules; Suggestion: Each schedules to have list of special tools, equipment and consumables. Check availability of special inspection schedules; Check availability of bomb threat drill; ix) Life of Components on the aircraft; x) Check life components (list the components) iii) iv) v) vi) DGCA STD.DOC/CL/04 2 MAY, 1999 against approved TBOs. 5. Check the followings: i) ii) iii) iv) v) vi) vii) viii) ix) x) Check major item history cards; Check for repetitive defects; Check for MEL violations; Check for mandatory mod compliance; Check for EGT exceedances; Check for SOAP test results, if applicable; Check exceedances of system alert values and action taken by the operator; Check record of last CVR and FDR monitoring; Check whether drawings for major repairs carried out are available; xi) Check whether the following reports are available Delay reports Major defect reports Incident reports Ground incident/Bird hit damage reports Investigation reports on all incidents xii) Check availability of necessary tools, equipment, consumables and arrangements done with others 6. INSPECTION OF AIRCRAFT REGN NO. VTCheck for the following for the aircraft: i) ii) iii) iv) v) vi) vii) viii) Documents as listed in paras 1 and 2. Emergency equipment on board axe, smoke goggles, portable fire extinguishers oxygen bottles and PA system for serviceability megaphone,PBE, oxy-mike service. (if installed); Fire warning system in the cockpit; Torches for each cockpit and cabin crew; Fire locking of guarded switches (check Cu wire gauge); Dial marking of instruments; Check condition of wind shield, wiper operations, rain repellant if installed and operation of sliding window, inertial reel and harness and escape descent device; Operation of seats DGCA STD.DOC/CL/04 3 MAY, 1999 ix) Availability of signed compass correction card; 7. OperationaL/Functional check of the followings: i) ii) iii) iv) v) vi) vii) viii) ix) x) xi) xii) xiii) xiv) Comm check and Weather radar check; ELT operation; Stall warning system; Self test on auto pilot; Self test on Transponder; GPWS test modes; Cockpit door for locking from inside; Viewing port for downlocking of NLG; Operation of emergency window; Operation of escape slide (deploy random chute); CVR serviceability; Full movement of engine controls and take-off warning; Operation of engine controls and their indication; Operation of all lights; 8. Check the following items in the cabin: i) ii) iii) iv) v) vi) vii) viii) xi) xii) xiii) Escape slide pressure Placarding on the doors and emergency exits No-smoking placarding on toilet doors Serviceability of flush motors and lights Random check on reclining mechanism, reading lights First aid and Physician Kits and their contents Briefing Cards, stickers of "Fasten Seat Belt while seated" and "life jacket under seat" and its serviceability; Securing of galley carts; Seats at the emergency exits for deactivation of reclining mechanism; Auto-folding of cabin attendant jump seat; Viewing port for downlocking of MLG; Check seat tracks for corrosion; 9. Door strap availability. 10. Check exterior of the aircraft for: i) Missing fairings, dents or any damage; ii) Missing discharge wicks and bondings; ix) x) DGCA STD.DOC/CL/04 4 MAY, 1999 iii) Placarding of danger zones on engines; iv) Placarding of MTOW and Empty weight; v) Owner's plate; vi) Emergency exit and cut markings; vii) Fuel grade, quantity and grounding markings and locking arrangement of fuel cap; viii) Condition of brake-wear pin, creep mark; ix) Placarding of tyre pressure, graph for oleoextension; x) Tail skid and heavy landing marker; xi) Check wheel well light, nav and anti-coll. Lights; xii) Check functioning of jack point on NLG; xiii) Check for sign of leakage of toilet fluid, air pressure; xiv) Check flap position indication markings; xv) Pax and cargo doors for signs of cracks; xvi) Check fuselage for wrinkles (flaking of paint indicates corrosion); xvii) Check honeycomb structures for delamination (coin test); xviii Ground safety pins and covers for red flags; xix) Check drain holes for clogging; xx) Open panels and engine cowlings to check for corrosion; xxi) Cracks, chafings and condition of pipelines; xxii) Check rear pressure bulkhead (6 O'clock position) for any repairs or condition; DGCA STD.DOC/CL/04 5 MAY, 1999 DGCA STD.DOC/CL/04 6 MAY, 1999