Gloves - Health and Safety Directorate

advertisement

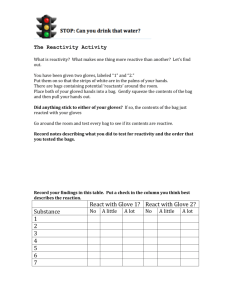

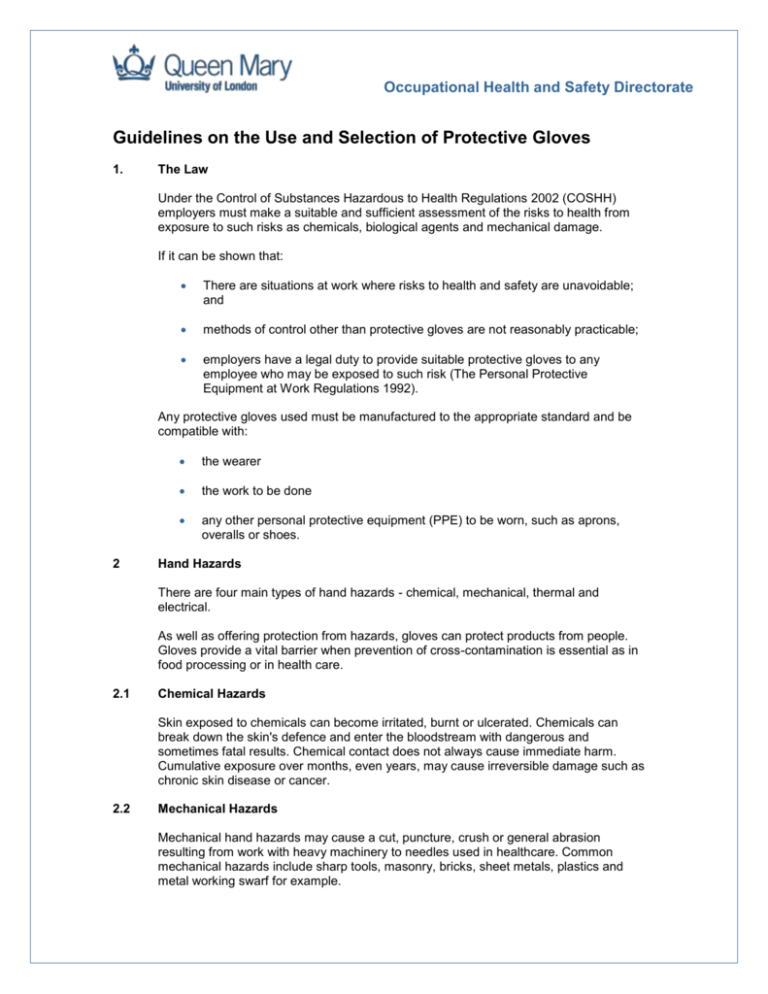

Occupational Health and Safety Directorate Guidelines on the Use and Selection of Protective Gloves 1. The Law Under the Control of Substances Hazardous to Health Regulations 2002 (COSHH) employers must make a suitable and sufficient assessment of the risks to health from exposure to such risks as chemicals, biological agents and mechanical damage. If it can be shown that: There are situations at work where risks to health and safety are unavoidable; and methods of control other than protective gloves are not reasonably practicable; employers have a legal duty to provide suitable protective gloves to any employee who may be exposed to such risk (The Personal Protective Equipment at Work Regulations 1992). Any protective gloves used must be manufactured to the appropriate standard and be compatible with: 2 the wearer the work to be done any other personal protective equipment (PPE) to be worn, such as aprons, overalls or shoes. Hand Hazards There are four main types of hand hazards - chemical, mechanical, thermal and electrical. As well as offering protection from hazards, gloves can protect products from people. Gloves provide a vital barrier when prevention of cross-contamination is essential as in food processing or in health care. 2.1 Chemical Hazards Skin exposed to chemicals can become irritated, burnt or ulcerated. Chemicals can break down the skin's defence and enter the bloodstream with dangerous and sometimes fatal results. Chemical contact does not always cause immediate harm. Cumulative exposure over months, even years, may cause irreversible damage such as chronic skin disease or cancer. 2.2 Mechanical Hazards Mechanical hand hazards may cause a cut, puncture, crush or general abrasion resulting from work with heavy machinery to needles used in healthcare. Common mechanical hazards include sharp tools, masonry, bricks, sheet metals, plastics and metal working swarf for example. 2.3 Thermal Hazards Many work activities expose hands to thermal hazards, for example; fierce heats generated by molten glass and steel, hot steam in boiler houses, boiling water in kitchens and high temperature kilns in potteries. Extreme cold is just as hazardous, especially for people whose hands are constantly dealing with frozen food, dipping in and out of freezers and cold stores, or handling cryogenic liquids. For people working outside for long periods of time, hot summers and over-exposure to the sun can lead to sunburn and skin cancer whereas exposure to cold winter winds and freezing temperatures dry out the natural oils that keep the skin supple, resulting in dry, cracked skin, open to infection. 2.4 Electrical Hazards Injuries can result from accidental contact with faulty wiring or contact with bare cables. Exposure to high voltage electricity is strictly controlled, however there is always the risk of contact with electricity used to power lighting, heat and equipment at work. Contact can come through maintaining machinery and in the building industry, contact is particularly hazardous during construction or demolition. 3. Selecting Suitable Gloves Care must be taken in the selection of suitable protective glove. When choosing gloves always seek expert help from the manufacturer/distributor of gloves or hazard. Selecting protective gloves must be part of an overall health and safety risk assessment for the job to be done. The risk assessment must clearly demonstrate that exposure to the health and safety risk is unavoidable and that other methods of control are not reasonably practicable. There are four main requirements that must be met for any protective glove selected to be suitable. The glove must: Be appropriate for the risk(s) and the conditions where it is used. Take into account the ergonomic requirements and state of health of the person wearing it. Fit the wearer correctly, if necessary, after adjustments. Either prevent or control the risk involved without increasing the overall risk. Proper selection must take into consideration: The wearer The workplace conditions The protective glove. If protective gloves are selected or worn incorrectly there is every possibility that this may increase the wearer's overall risk to health because: Contaminant may get inside the glove to reside permanently against the skin which could cause great exposure than if a glove had not been worn at all; or QM/H&S/0015 Version 01/01/2005 4. Wearing a glove for extended periods can lead to the development of excessive moisture (sweat) on the skin which in itself will act as a skin irritant; or, Wearing natural rubber (latex) gloves can cause an allergic reaction in susceptible individuals, causing the skin diseases contact urticaria and/or dermatitis to occur. Choosing the Right Glove for the Job Identify the hazard, e.g.: chemical, environment, mechanical. 1. Identify the glove required, e.g.: chemical, resistant, insulating, punctureresistant, etc. 2. Determine the importance of: 3. Resistance to chemical, thermal, mechanical and electrical hazards. Grip. Sensitivity. Comfort. 4. Identify the glove or gloves, which provide the most suitable mix of characteristics required. 5. Identify the type of protection required, i.e. prolonged or brief contact, infrequent but deliberate contact or splash protection. 6. Identify the correct 'useful time' for the glove to provide protection. 7. Check that the glove has an appropriate CE mark. (Appendix 1). Note: Gloves should be used as a control measure only as a last resort and where other methods of control are not reasonably practicable. This is because: Gloves only protect the wearer - they do not remove the hazard from the workplace environment. Some types of glove are inconvenient and interfere with the way people work. Wearing gloves interferes with the wearer's sense of touch. The extent of protection depends on good fit and attention to detail. If protective gloves are used incorrectly or badly maintained the wearer may receive no protection. For glove design to be effective, the glove needs to be used correctly in the workplace. QM/H&S/0015 Version 01/01/2005 5. GLOVE TYPES 5.1 Chemical Hazards Latex/Natural Rubber Nitrile Polyvinyl chloride (PVC) NeopreneTM VitonTM Others, e.g.: PVA, HypalonTM A General Guide to Protection from Chemicals Chemical group Glove material Latex Nitrile Neoprene PVC Butyl Viton Water Miscible Y Y Y Y N N Substances Weak Acids/ Alkalis Oils N Y N N N N Chlorinated N N N N N Y Hydrocarbons Aromatic Solvents N N N N N Y Aliphatic Solvents N Y N N N Y Strong Acids N Y N N Y N Strong Alkalis N N Y N N N Pcb's N N N N N Y Note: There is no single glove material (or combination of glove materials) able to provide unlimited resistance to any individual or combination of chemical agents Glove Manufacturers resistance charts MUST be referred to. 5.2 5.3 Thermal Hazards Leather Cotton KevlarTM Aluminised Mechanical Hazards Nitrile on a fabric liner Kevlar® PVC on a fabric liner Leather QM/H&S/0015 Version 01/01/2005 5.4 Electrical Hazards 6. Natural latex Checklist for Glove Wearers 1. Check correct gloves have been selected and issued. 2. Do not wear gloves beyond their limit. 3. Check the gloves for any defect. 4. Note when gloves are issued. 5. Store gloves safely. 6. Remove gloves carefully and dispose of them responsibly (diagram 2). 7. Do not share gloves. 8. Wash hands before gloves are worn. 9. Treat and cover cuts and abrasions before wearing gloves. 10. Do not ignore any sign of a skin rash or irritation. QM/H&S/0015 Version 01/01/2005 Guidelines on the Use and Selection of Protective Gloves QM/H&S/0015 Version 01/01/2005 Guidelines on the Use and Selection of Protective Gloves QM/H&S/0015 Version 01/01/2005 Document Control Initial Data Author: Mark Ariyanayagam Position: Health and Safety Manager (SEM) Checked by: Position: Approved by: Position: Status: Version Date of Issue: Version No. Date of alteration and re-issue QM/H&S/0015 Version 01/01/2005 Details of changes Changes made by