SPCC & SWPPP - Maryland Center for Environmental Training

advertisement

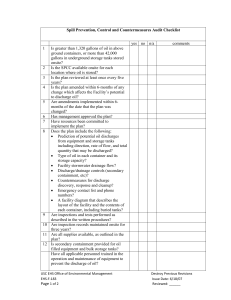

SPILL PREVENTION, CONTROL AND COUNTERMEASURES (SPCC) AND STORM WATER POLLUTION PREVENTION (SWPP) PLAN For 1 TABLE OF CONTENTS TAB REF. SECTION DESCRIPTION 1 PURPOSE 2 REGULATORY INFORMATION 3 MANAGEMENT APPROVAL / CERTIFICATIONS 4 SITE DESCRIPTION AND OPERATIONS INFORMATION 5 SPILLS AND EXPERIENCE 6 DESCRIPTION OF POTENTIAL POLLUTANTS 7 WORST CASE DISCHARGE ASSESSMENT 8 SPILL CONTROL EQUIPMENT 9 CONTAINMENT AND DIVERSIONARY STRUCTURES 10 BEST MANAGEMENT PRACTICES (BMP’s) 11 INSPECTIONS AND RECORDS 12 SECURITY 13 PERSONNEL, TRAINING, PREVENTATIVE MAINTENANCE AND SPILL PREVENTION PROCEDURES 14 SPILL COUNTERMEASURES 15 REPORTING REQUIREMENTS 16 Attachment 1: Site Topographic Map 17 Attachment 2: Facility Site Map 18 Attachment 3: Inspection Form 19 Attachment 4: Emergency Contact Numbers & Maryland SPCC Plan 20 Attachment 5: Copy of General Permit for Discharges from Mineral Mines,Quarries, Borrow Pits and Concrete and Asphalt Plants 21 Attachment 6: Quarterly Inspection Form 22 Attachment 7: Annual Report Form 23 Attachment 8: Sediment and Erosion Controls 2 1 PURPOSE The primary objective of this combined Spill Prevention, Control and Countermeasure (SPCC) Plan/ Storm Water Pollution Prevention (SWPP) Plan is to identify potential sources of pollution, which may reasonably be expected to affect the quality of storm water discharges from the facility. This plan has been developed to comply with the requirements of 40 CFR, parts 110 and 112, concerning the discharge of oils to waters of the United States and oil pollution prevention. The plan has been amended according to the final rule issued by the EPA on December 26,2006, and became effective February 26,2007. It describes procedures and practices, which will be used to minimize the level of pollutants in storm water discharges associated with industrial activity, and outlines the precautions taken to prevent the discharge of oil from storage tanks and plant equipment. This plan also provides information for responding to the discovery of any accidental discharge of oil. This facility has a current Oil Control Program Plan for Notification, Containment and Clean-Up of Oil Spills issued by Maryland Department of the Environment (MDE) which identifies the proper agencies, company personnel, on-site equipment, contractor and procedures to implement upon any oil spill event. Under Section 311 of the Clean Water Act or Best Management Practices (BMP) programs required by a State/NPDES permit, SPCC plans may be incorporated by reference and are done so in this combined plan. This plan must be retained on-site and include all subsequent notes and modifications related to the implementation and administration of the plan. Inspection and maintenance should be documented on the appropriate sheets included in this plan, and these records should be retained for a minimum of three (3) years. It is strongly recommended that other plans and permits referenced in this document be kept on-site and together with this document. Procedural information, such as sampling, monitoring and reporting for the NPDES requirements are not contained in this plan. The plant manager of this facility should thoroughly review the plan and become familiar with the requirements set forth in the plan. Carefully review the section regarding inspections and the requirements for documenting inspections and corrective actions. Also note the requirement for reviewing this plan with your employee and training certification. An owner/operator must schedule and conduct discharge prevention briefings for oil-handling personnel at least once a year to assure adequate understanding of the SPCC Plan for that facility. Such briefings must highlight and describe known discharges as described in section 112.1(b), or failures, malfunctioning components, and recently developed precautionary measures. 3 Keep in mind that this plan must be reviewed and/or updated: 1. 2. 3. 4. 5. Every five years; If modifications or additions are made to the containment areas; If a change occurs in the facility’s storage tank capacity; If site management, personnel, phone numbers, or ownership change; If a reportable spill occurs. In the event of a discharge or failure due to a brittle fracture or other catastrophe, an evaluation of the damaged containers must be performed. The owner/operator must amend the SPCC/SWPP Plan within six (6) months of the review to include more effective prevention and control technology if: 1. 2. Such technology will significantly reduce the likelihood of a discharge as described in Section 112.1(b) from the facility; and If such technology has been field-proven at the time of the review. The owner/operator must document completion of the review and evaluation, and sign a statement as to whether he will amend the plan. If amendments are made, you have six (6) months to implement any and all amendments. NON-TECHNICAL CERTIFICATION - 40 CFR 112.5(b) / SPCC I certify that I have reviewed the Texas facility SPCC/SWPP Plan, and being familiar with the provisions of 40 CFR Part 112, and will/will not amend the plan as a result of this review. Certification by a PE for non-technical amendments to the plan is not required. Review Dates Amend Plan Signature ____________________________ YES/NO ______________________________ ____________________________ YES/NO ______________________________ ____________________________ YES/NO ______________________________ 4 2 REGULATORY INFORMATION Spill Prevention, Control and Countermeasure (SPCC) Plans are prepared and implemented as required by the U.S. Environmental Protection Agency regulations contained in Title 40, Code of Federal Regulations, Part 112 (40 CFR 112). These regulations were amended and published December 26,2006 and effective February 26,2007. A non-transportation related facility is subject to SPCC regulations if the total aboveground storage capacity exceeds 1,320 gallons; or the underground storage capacity exceeds 42,000 gallons (completely buried tanks are not included in the calculation); and if, due to its location, the facility could reasonably be expected to discharge oil into or upon the navigable waters of the United States. Additional revisions to the current SPCC rules include the following: 1. All buried piping installed on or after August 16, 2002, must have protective wrapping, coating and cathodic protection (or other means of corrosion protection) for all soil conditions. 2. The SPCC Plan is not required to be filed with the EPA, but a copy must be available for on-site review by the regional administrator or MDE regulator during normal working hours. However, the SPCC Plan must be submitted to the EPA Region III administrator and the state agency along with a spill report (see below) within 60 days if either of the following occurs: 1. The facility discharges more than 1,000 U.S. gallons of oil into or upon the navigable waters of the United States or adjoining shorelines in a single event; 2. The facility discharges more than 42 U.S. gallons of oil in each of two spill events within any twelve month period. What is a reportable spill in Maryland? Reportable Quantities: o o o o o Quantities are unknown, and/or The release of petroleum product The release causes a sheen on nearby surface water, and/or The release is a hazardous substance The release threatens to reach or adversely affect a waterway. 5 In the event of a spill of petroleum products: DO: o Enact ____Crisis Management Plan, if appropriate o Shut off supply, stop leak (if possible) o Shut off ignition sources o Contain spill and/or dike ahead of spill Call your supervisor and/or Environmental Department o Report the spill to MDE and NRC if no one else is available o Protect adjacent people, property, surface waters and equipment from contact with spill o Contact a spill contractor for clean-up if neccessary o Follow MSDS for clean-up guidance DON’T: o Do not smoke o Do not risk personal injury o Do not wash down spill with water o Do not try to hide spill Spill Reporting: A spill must be reported immediately to the Maryland Department of the Environment by telephone but no longer than 2 hours after the spill was detected and include: Company name and location Time of Discharge Location of discharge Type and quantity of spill Assistance required –if any. Your name address and phone number. Get the name of the person you are talking to for verification purposes. You must also report the spill to the National Response Center by telephone. It will usually suffice to report that the spill has been reported to the MDE. Copy the spill response number and name of the person you are reporting to for verification purposes. This verbal requires a written report to MDE within 10 days and must include: Date,time and place of spill Amount and type of oil spilled Complete description of circumstances contributing to the spill Complete description of containment,removal,clean-up and restoration operation including disposal sites and costs. Procedures,methods and precautions instituted to prevent a recurrence of an oil spill Other information required by the Department 6 A spill report sent to the Maryland Department of the Environment or EPA Region III administrator must contain the following information (see section 4 and attachments 1 & 2): 1. 2. 3. 4. 5. 6. 7. 8. Name of facility and individual submitting information; Name(s) of the owner/operator of the facility; Location of the facility; Date and year of initial facility operation; Maximum storage or handling capacity of the facility and normal daily thruput; Description of the facility, including maps, flow diagrams, topographic map; A complete copy of the SPCC Plan with any amendments; The cause(s) of such spill(s), including a failure analysis of system or subsystem in which failure occurred; 9. The corrective action and/or countermeasure taken, including an adequate description of equipment repairs and/or replacements; 10. Additional preventive measures taken or contemplated to minimize the possibility of recurrence; 11. Other information as regional EPA administrator may reasonably require that is pertinent to the plan or spill event. Note: This combined plan also includes appropriate information for storm water pollution prevention. 7 3 MANAGEMENT APPROVAL / CERTIFICATIONS - 40 CFR 112.7 / SPCC The SPCC/SWPP Plan for the ___facility is fully approved by the management of ____, and the necessary resources have been committed to implement the plan as described. NAME: TITLE: SIGNATURE DATE: CERTIFICATION OF NON-STORM WATER DISCHARGE FACILITY DRAINAGE - 40 CFR 112.7(e)(1) / SPCC/SWPP NON-STORM WATER DISCHARGES As part of the site-specific storm water permit requirements, a facility must certify that discharges from the site have been evaluated for the presence of non-storm water discharges that are not covered under your current Maryland Department of the Environment’s National Pollutant Discharge Elimination System (NPDES) Permit MD0000175 for discharges from Mineral Mines, Quarries, Borrow Pits and Concrete and Asphalt Plants. The following statement certifies that the ____has conducted this evaluation, and the facility does not have any non-storm water discharges from the site which are not covered by the site’s NPDES Permit (PERMIT # MD0000175) identifying three (3) active outfalls – 003, 008 and 011. I certify that I have evaluated the site for the presence of non-storm water discharges and certify that the site does not have any additional non-storm water discharges which are required to be covered by the current permit. NAME: TITLE: SIGNATURE DATE: 8 PE CERTIFICATION - 40 CFR 112.3(d) / SPCC I certify that I have reviewed ___SPCC/SWPP Plan, and being familiar with the provisions of 40 CFR Part 112, attest that this SPCC/SWPP Plan has been prepared in accordance with good engineering practices. Certification by a PE for non-technical amendments to the plan is not required. NAME: TITLE: SIGNATURE DATE: ROBERT ARCHIBALD 23235 STAMP_______________________________STATE____________________________ 9 CERTIFICATION OF THE APPLICABILITY OF THE SUBSTANTIAL HARM CRITERIA CHECKLIST - 40 CFR 112.20 (e) (f) (1) / SPCC FACILITY NAME ___ ADDRESS 1. Does the facility transfer oil over water to or from vessels and does the facility have a total oil storage capacity greater than or equal to 42,000 gallons above ground? YES______ NO___X___ 2. Does the facility have a total oil storage capacity (including mobile equipment holding more than 55 gallons of oil) greater than or equal to 1 million gallons and does the facility lack secondary containment that is sufficiently large enough to contain the capacity of the largest aboveground oil storage tank plus sufficient freeboard to allow for precipitation within any aboveground oil storage tank area? YES______ NO___X___ 3. Does the facility have a total discharge capacity greater than or equal to 1 million gallons and is the facility located at a distance (as calculated using the formula in Appendix C, 40 CFR 112 or a comparable formula*) such that a discharge from the facility could cause injury to fish and wildlife and sensitive environments? YES______ NO___X___ 4. Does the facility have a total oil storage capacity greater than or equal to 1 million gallons and is the facility located at a distance (as calculated using the appropriate formula (Appendix C, 40 CFR 112) or a comparable formula*) such that a discharge from the facility would shut down a public drinking water intake?** YES______ NO___X___ 5. Does the facility have a total oil storage capacity greater than or equal to 1 million gallons and has the facility experienced a reportable oil spill in an amount greater than or equal to 10,000 gallons within the last 5 years? YES______ NO__X____ CERTIFICATION I certify, under penalty of law, that I have personally examined and am familiar with the information submitted in this document, and that based on my inquiry of those individuals responsible for obtaining this information, I believe that the submitted information is true, accurate and complete. NAME: TITLE: SIGNATURE DATE: *If a comparable formula is used, documentation of the reliability and analytical soundness of the comparable formula must be attached to this form. **For the purposes of 40 CFR part 112, public drinking water intakes are analogous to public water systems as described at 40 CFR 143.2(c). Section112.20(e) of the facility response plan regulation requires that all facilities regulated by the Oil Pollution Prevention Regulation (40 CFR part 112) conduct an initial screening to determine whether they are required to develop a facility response plan. The criteria in this checklist can be found in 40 CFR 112.20(f)(1). Facilities should include this form with their SPCC Plan. 10 4 SITE DESCRIPTION AND OPERATIONS INFORMATION Facility Name: Mailing Address: Owner: Contact Name: Phone Number: Fax Number: Location: The facility is located in __ The site encompasses approximately 519acres of which 488.5 are within the mine permit limits. The site began mining operations around 1927 and has an average daily throughput of 1,500 tons per hour. The facility has a maximum petroleum storage capacity of approximately 48,000 gallons. The nearest body of water is __ The site is bounded on the north by __Rd., undeveloped woodlands and commercial/ industrial facilities. The site is bounded on the south by ___ Rd., U.S. Route ___ and residential housing. The site is bounded on the east by ___ Rd. the light rail system, commercial and residential development The entire perimeter of the facility has established well vegetated berms . The site is bounded on the west by US Route ---, woodlands and residential housing ½ mile away.. The nearest crossroads are US Route -- and ---- Road The approximate latitude is North 39 22’ 07”, approximate longitude is West 76 38’ 43” Attachments (1) Site Topographic Map and (2) Facility Site Map show the facility’s layout and location in relation to the surrounding community as well as elevations. Facility Description: This facility produces construction materials. The quarry is an aggregate mining operation. Within the mine permit area is a Ready Mix operation 11 as well. The facility extracts and processes a marble limestone. The primary end uses are road base, road construction, fill material and ready mix concrete. This site also hosts a maintenance shop, quality control laboratory blacktop plant and pulverized limestone operation (PLM). The blacktop and PLM operations are leased out. This facility includes numerous buildings and roadways. Please see the Site Map in Attachment (2) for details. The facilities entrance is secured with a chain link gate which is locked during non-working hours. There are no underground storage tanks at this facility. Drilling and blasting activities are supplied by outside contractors. One street sweeper on a rental basis and one water truck are in service throughout the facility. Numerous sediment traps and settling ponds are located throughout the facility. Cleaning and extraction of fines are conducted using Best Management Practices on an as needed basis. These controls are incorporated into the Surface Mining Permit Sediment and Erosion Controls and are approved by MDE and the SCD.,Permit Number 77-SP0055. The vast majority of surface water is directed back into the quarry pit or sediment ponds located throughout the plant and processing area ( See Attachment 8) Transformers are utilized and stored on site – They have all been certified as Non-PCB. 12 Petroleum products stored on-site include: A. Fixed Storage: Aboveground Storage Tanks (AST ) No Underground Storage Tanks (UST) are located at this facility. *NO UST’S ON-SITE (GALLONS) TOTAL PETROLEUM PRODUCT STORAGE (GALLONS) AST 20,000 20,000 12,000 12,000 AST/ UST ID # PRODUCT TANK SIZE Diesel AST Diesel LOCATION/ ID ON FACILITY SIT MAP TYPE OF CONTAINMENT (BERM, DIKE, ETC.) Intersection of 2nd &3rd streets ready mixplant Steel dike w? rainshields Concrete/block AST #2 fuel oil 6,000 6,000 Outside back of shop Concrete/block AST Used Oil 1,000 1,000 Diked AST Used Oil 1,000 1,000 Outside back of shop Truck barn AST #2 275 275 Basement scale house Indoors– no floor drain AST Motor Oils & anti freeze 4 each 275 275 Shop Indoors – drip pans AST Motor Oils 3 each 500 500 Grease shop Indoors AST Gasolineunleaded 1000 1000 Concrete double walled AST Dexron 500 500 Behind drivers room Grease Shop 13 Diked Indoor B. Portable Storage: AST/UST ID # PRODUCT *NO UST’S ON-SITE (GALLONS) TOTAL PETROLEUM PRODUCT STORAGE (GALLONS) LOCATION /ID ON FACILITY SITE MAP TYPE/SIZE OF CONTAINMENT (BERM, DIKE, ETC.) TANK SIZE Re-fueling Truck AST Portable AST High Sulphur Diesel 3,000 3,000 Internation al Tandem na Motor Oil 400 400 na AST Anti-Freeze 50 50 AST Used Oil 50 50 AST Grease 35 35 On fuel truck On fuel truck On fuel truck On fuel truck na na na There are varying amounts of 55 gallon drums diked in the maintenance shop. * There may be a 20% fluctuation in normal inventory due to production requirements. Note: Storage tanks with a capacity of less than 55 gallons do not need to be inventoried. C. Permanent Site Stationary Equipment Containing Oil Unit Type Primary Gyra-disc 54/74 Cone 13/84 Omnicone 1560 Spares Secondary Tertiary 3 each Transforme rs – 12 each Transforme rs 16 each Active Manufa cturer AC Type of Oil crusher Capacity Comments 300 gallons Symons crusher 450 gallons Nordber g Various crusher 125 gallons each Varies Includes Reservoir Includes Reservoir Includes reservoir Depleting stock Various Transfor mer nonPCB Transfor mer nonPCB 14 Varies See Attachment 9 Total On-Site Petroleum Storage is approximately 46,710 gallons. D. Non-Petroleum Related Storage from Ready Mix Plant Admixtures (SWPP) Type ID ADVA 170 WRDA- 35 DAVAVAIR DARACEM-50 DARATARD 17 Polar Set Lubricon NCA Daraccel ZEP High Foam Remover ZEP x 1000 Neutralizer DCI S Tank Size (gal.) 1,000 1,000 1,000 1,000 1,000 1,500 3,000 2 tanks 3,000 2 tanks 2,000 liters 2,000 liters 1,500 Tank Location Inside RM Storage Inside RM Storage Inside RM Plant Storage Inside RM Storage Inside RM Storage Outside RM Storage Outside RM Storage Outside RM storage In Trailer near wash off In Trailer near wash off Outside RM Storage There are no internal heating coils for fuel tanks present at this facility. There is one oil/water separator present at this facility. Polar Set, DCI and Lubricon are on the 313 water priority chemicals list. 15 5 SPILL EXPERIENCE - 40 CFR 112.7(a) / SPCC There have been no significant or reportable spill events within the past five years at this facility. POTENTIAL EQUIPMENT FAILURES - 40 CFR 112.7(b) / SPCC Plant Fixed Storage and Equipment Failures: This facility has a current Oil Control Program Plan for Notification, Containment and Clean-Up of Oil Spills issued by Maryland Department of the Environment which identifies the proper agencies, company personnel, on-site equipment, contractor and procedures to implement upon any oil spill event. Most transformers on site are owned by the company. They are inspected frequently for leakage. They are primarily located in areas where they will not impact the waters of the state. They have been certified as nonPCB . All potential fixed storage and/or equipment failures relative to the plant, equipment storage area and maintenance shop would be contained in the respective buildings and/ or geographic areas. The vast majority of the site drainage goes into the two mining pits. Potential Event AST Rupture Drum Rupture Pump Reservoir Rupture Spill Description Instantaneous Instantaneous Instantaneous Volume Released 20,000 gallons 55 gallons 10 gallons Spill Rate varies varies varies Portable Equipment Failures: Any accidental spill related to portable equipment would be extremely small. The estimated volume of the spill would be 1 to 75 gallons with the exception of the 3,000 gallon re-fueling truck. The vehicle has on board tools, absorbent and communication devices to quickly stop and contain any spill event. Mobile equipment is normally parked outside buildings or in designated parking areas during nonworking hours. Spills during these times would be confined to these areas and buildings. In the event of an uncontrolled or undetected spill associated with mobile equipment during normal working hours, there is a minimal risk a spill could enter Falls Run. This is unlikely due to the small volume released. The facility has numerous detention ponds along internal and external roads designed to control any discharge into public water lands. Potential Event Drum Rupture Mobile Equipment Failure Spill Description Instantaneous Instantaneous Volume Released 55 gallons Up to 3,000 gallons 16 Spill Rate varies varies 6 DESCRIPTION OF POTENTIAL POLLUTANTS (SWPP 2 (a)) Many of the activities conducted at the facility involve materials that are exposed, or potentially exposed, to storm water. These activities can generally be grouped into the following categories: Raw Materials Storage, Sand, Aggregate, Fly Ash, Cement Equipment and Machinery Storage Waste Material Storage Aboveground Oil Storage Tanks and Fueling Area Equipment Cleaning Concrete Admixtures- two Section 313 chemicals (See D above) Bulk Loading and Unloading Finished Products Storage Waste Product Process Waters The following sections provide a brief description of each activity and identify the significant materials associated with the activity that are treated, stored, disposed, exposed, or potentially exposed, to storm water. (SWPP 2 (a) (iii) Raw Materials Storage The primary raw materials used at the Ready Mix facility include cement, fly ash, sand and gravel. Flyash is stored in above ground water tight storage silos at the plant. Sand and gravel are dumped into open bunkers. The cement is stored in watertight silos at the plant. Equipment and Machinery Storage Some types of mobile equipment and process machinery are used and stored in areas exposed to precipitation. These items include such things as conveyor belts, steel, vehicles, and other miscellaneous equipment. These materials may at times contain minimal amounts of raw material residue, perhaps oils and greases. If exposed to precipitation, these materials could result in minimal amounts of storm water contamination that would be treated through the Sediment and Erosion Plans associated with the Surface Mining Permit Waste Material Storage Waste materials generated during the production processes are stored on-site. These waste materials; general trash, clean-up materials and steel are stored in separate roll-off dumpsters outside prior to disposal. The overburden from the mining process is utilized in the construction of perimeter berms surrounding the plant. 17 Aboveground Oil Storage Tanks and Fueling Areas The aboveground tanks are used to store petroleum products, admixtures, cleaning agents and fuels. Many of the tanks are located inside of buildings and sheds. The few outside AST’s are located in diked structures. The dike drains are maintained in a closed, locked position. These AST’s are exposed to precipitation, and could come in contact with storm water or any drainage system if a spill or leak occurred, outside the secondary containment. Potential storm water contamination could occur from spills or leaks related to activities associated with fueling equipment. Leaks could occur from the dispensing pumps. An oil/water separator is maintained at the two fueling stations. A switch to the pump motors is located outside within a few feet of the fueling area. Equipment Cleaning Oil, grease and other concrete waste materials may be washed off equipment during the cleaning process. Wash water from the ready mix operation is diverted to a sediment catch basin and allowed to evaporate or percolate into the ground. Concrete Admixtures Various chemical-based materials stored at the facility are used in the manufacturing process. These materials include admixtures that are used to enhance the quality of the concrete and releasing agents used to clean cement trucks. Most admixtures and releasing agents are water soluble. These materials are stored in a containment area as well as inside the ready mix storage building. Six (6) tanks are located outside the building and five (5) tanks are located inside the building. All are within concrete secondary containment. Bulk Loading and Unloading Materials received include bulk shipments of cement and flyash that are pneumatically transferred into storage silos. In addition, trucks are loaded for off-site shipment of the concrete product in the ready mix area. The raw materials, cement and flyash, may be spilled, leaked or lost during transport and may be carried away by storm water runoff. All materials will be diverted back to the settling ponds by way of sediment traps and diversion ditches. 18 Finished Products Storage Finished products stored at this facility consist primarily of aggregate products of various sizes. The finished products are generally stored in unpaved areas prior to being shipped off-site to the end user. These finished products would have limited impact on storm water. They are addressed in the Surface Mining Permit, Sediment and Erosion Control Plans. Waste Product The facility does produce an amount of concrete waste. Improper mixing or unused quantities would generate a concrete waste. Storm water contamination may occur if storm water contacts any waste prior to the concrete solidifying. All storm water which comes into contact with these items is diverted back to the inactive area of the quarry pit. Process Waters Cleaning wet concrete from mixers and/or equipment creates an amount of process wash water. These processes are typically preformed outdoors and controlled by a sediment trap and diversion ditches which directs the liquids back into the settling ponds.. 19 7 WORST CASE DISCHARGE ASSESSMENT Assessment of the worst case discharge includes measures to limit the outflow of oil, response strategy and operational plan. For the purposes of this section, the worst case discharge is the instantaneous release of the volume of the largest tank on the facility (125% of the volume of the largest tank for facilities with multiple tanks within a single containment dike) during adverse weather conditions. Facilities shall take into consideration that due to hydraulic pressure of the release, the secondary containment may not contain this volume in its entirety. The worst case discharge situation that could occur would constitute the instantaneous release of the contents of the largest volume tank, 20,000 gallons. This tank is located in a steel containment dike, in a low traffic area t the intersection of 2nd and 3rd streets. The tank is protected on all sides by the steel containment dike and bollards.. This spill would be absorbed or flow into the settling areas and would not enter the surrounding watercourse or storm sewer given timely remediation along the flowpath. A variety of earth moving equipment is readily available for creating adequate containment and/or diversionary structures. Worst Case Discharge Response Strategy In the event of a worst case discharge ____ would respond according to the following actions: 1. Stop the leak and contain the spill. Begin clean-up along the flow path of the spill. 2. Construct earthen dikes as necessary to impede/stop the flow to storm sewers and waterways. 3. Hire a contractor – if necessary. 4. Contact the appropriate Lafarge authorities and MDE. 5. Pump and clean-up spill from within the containment area or remaining contents of damaged tank. 6. If spill reaches a body of water, float containment boom to isolate and contain the advancement of the slick on the water’s surface utilizing sorbents on site. All personnel are aware that local fire departments have limited of sorbent materials available. 20 8 SPILL CONTROL EQUIPMENT 40 CFR 112.7(c) This facility contains spill control equipment stored within several buildings. The spill kits and related equipment include granular absorbent, empty drums, shovels, absorbent pads and booms for the purposes of meeting the requirements of 40 CFR 112.7(c). Inventory of facility containment equipment, including specification of quantity, type, location, time limits for gaining access to the equipment and identification of facility personnel trained in its use. Equipment Inventory List (See Oil Control Program Plan for Notification, Containment and Clean-Up of Oil Spills issued by (MDE) for more details) Type No. Absorbent pads, booms Spill Kits 1 Bagged sorbent or equivalent Earth material for dike construction Earth moving equipment Skid Shovels, brooms 1 9 loaders, backhoe, 5 haul trucks Location Time Limit for Access Maintenance Shop RM Plant 1 minute Maintenance Shop Outside Storage Area Various 1 minute Various 1 minute 21 1 minute 1 minute 1 minute Trained Personnel See training records See training records See training records See training records See training records See training records 9 CONTAINMENT AND DIVERSIONARY STRUCTURES 40 CFR 112.7(c)(1) / SPCC SWPP (2(v.)) This information pertains to all AST’s with capacities of 55 gallons or more, including on-site mobile equipment. This facility has mobile equipment with an individual tank capacity of 55 gallons or more. (See Section 4 (C.)) Drainage from secondary containment is restrained by lockable valves and inspected for visible sheens or other contaminants before discharged. Measurements of the frequency and volume of storm water will be kept at the facility for a minimum of 3 years. 1. A variety of earth moving equipment, including front-end loaders, quarry trucks,a grader, an excavator and materials are readily available at the site to be used for constructing adequate containment and/or diversionary structures in the event of a spill involving large quantities. 2. Secondary containment is provided for the 20,000 and 12,000 gallon fuel tanks located on site. The containment structure can hold 125% of the volume of the largest tank. This volume meets the requirement stated in 40 CFR 112.7(e)(2)(ii). 3. Secondary containment is provided for the four (4) tanks located in the maintenance shop. The containment structure can hold 125% of the volume of the largest tank. This volume meets the requirement stated in 40 CFR 112.7(e)(2)(ii). 4. The 55 gallon drums located within the maintenance shop are on a concrete floor within a containment area. This containment structure can hold 125% of the volume of the largest tank – This meets 40CFR112.7(e)(2)(ii) 5. The 6,000 #2 fuel oil tank located behind the maintenance shop has a containment structure that can hold 125% of the volume of the tank. This volume meets the requirement stated in 40 CFR 112.7(e)(2)(ii). 6. Secondary containment is provided for the eleven (11) admixture tanks located within the Ready mix storage area. The containment structure can hold 125% of the volume of the largest tank. This volume meets the requirement stated in 40 CFR 112.7(e)(2)(ii). 7. Secondary containment is provided for the two used oil storage tanks behind the maintenance shop and in the truck barn. . The containment structure can hold 125% of the volume of the largest tank. This volume meets the requirement stated in 40 CFR 112.7(e)(2)(ii). 22 8. The two (2) ZEP product tanks located within a stor trailer at the electric shop, are not exposed to storm water and are not petroleum based products. DEMONSTRATION OF PRACTICABILITY - 40 CFR 112.7(d) / SPCC/SWPP Facility management has determined that the use of the containment and diversionary structures and/or readily available equipment to prevent discharged oil from reaching navigable waters is practical and effective for this facility. 23 10 BEST MANAGEMENT PRACTICES (SWPP) The following Best Management Practices (BMP’s) are designed to minimize or eliminate the impact of potential pollutants in storm water runoff. BMP’s are physical, structural and managerial practices that can be implemented to reduce or eliminate storm water pollution. These are outlined in the Surface Mining Sediment and Erosion Control Plans. Raw Materials Storage The following practices will be followed to minimize potential impacts of raw materials storage (such as gravel, sand and aggregates) on storm water quality: Storage areas will be inspected on a regular basis to determine if storm water runoff patterns show evidence of sediment loss or erosion. If needed, sediment and erosion control measures will be considered such as diverting storm water flow around the storage piles or changing the storage pile locations. Also trapping any sediment before it enters the storm drain or roadways. Equipment and Machinery Storage To minimize incidental storm water contamination resulting from contact with miscellaneous equipment and machinery, the following guidelines will be followed: Any unusable piece of equipment or machinery will be scrapped and drained for salvageable parts. In-service equipment will be stored away from storm drains as far as possible. Equipment and machinery storage areas will be regularly inspected to determine if spills or releases of oil or chemical products have occurred. Excessively dirty or contaminated equipment or machinery will be stored indoors. Equipment or parts that are not regularly used will be covered where possible to protect the equipment from precipitation. Waste Materials Storage The following BMP’s will be used to minimize the potential for storm water contamination resulting from waste accumulation and storage: Dumpsters or roll-off boxes used for waste materials shall be covered if possible to reduce exposure of these materials to storm water. All dumpsters and roll-off containers shall be regularly inspected for possible holes or corrosion in the container walls that may allow accumulated precipitation to escape. 24 Regular clean-up will be conducted around trash dumpsters and roll-off containers, particularly if the units are in the vicinity of a nearby storm water catch basin. Chemicals which include oils, oil-based paints and solvents, in solid or liquid form, will be stored inside. Inside Aboveground Storage Tanks When possible aboveground storage tanks should be located inside structures, to avoid exposure to precipitation and avoid contact with storm water or any drainage system if a spill or leak occurs. Regular visual inspections will be conducted at all tank locations. Spills or leaks identified during these inspections will be properly addressed. Outside Aboveground Storage Tanks -Fueling Operations Where aboveground storage tanks are located outside for a fueling operation, the following control measures will be utilized to minimize or eliminate contamination from these tanks. Spills will be immediately cleaned up. Spill containment and clean-up materials will be located in the fueling area. Regular inspections of the necessary materials will be completed. Dry clean-up methods will be used for petroleum spills. Spills will not be flushed with water. “Topping off” fuel tanks will be forbidden.. Tank fueling systems should be equipped with secondary containment for spill protection during tank filling. Fuel oil tank areas will be inspected regularly for signs of contamination during the filling procedure. Fill lines are located inside the containment dikes. The primary fuel tanks are equipped with overfill protection and anti-siphon devices. The primary fueling is equipped with an oil/water separator. Tanks will be stuck prior to deliveries and the results recorded. Crushers, transformers and Section 313 Chemicals will be inspected more frequently. Equipment Cleaning The following BMP has been selected to reduce storm water contamination resulting from various equipment cleaning activities: When possible, equipment cleaning will be conducted inside the maintenance shop unless an oil/water separator or sorbents are used. Contamination will be cleaned up immediately. Bulk Loading and Unloading of materials 25 Small spills or leaks can occur during loading and unloading operations. Exposure of these materials to rainfall will be minimized by adhering to the following BMP’s: A company employee should periodically monitor the unloading of concrete and fly ash to prevent spillage. Hose connections will be inspected prior to and during unloading operations. All material spills shall be reported, immediately cleaned up and properly disposed. Chemical-based Materials Storage To minimize the potential for storm water contamination due to storage of chemical-based products, the following BMP’s will be utilized: All chemical-based products should be stored indoors where possible. If chemical-based products are stored outdoors, efforts will be made to ensure that they are stored in a covered, paved area and located as far as possible from storm drains. Regular inspections should be conducted on all chemical-based containers stored outdoors. Spill response equipment should be readily available in all product storage locations. Waste Product To minimize the potential for storm water contamination from the storage of waste concrete product, the following BMP will be utilized: Waste material that is generated from improper mixing or returned concrete will be placed in a designated area and allowed to cure prior to disposal. Runoff is directed to quarry pit. Good Housekeeping Good housekeeping practices act as a means for minimizing the potential release of contaminants into the storm drainage system. Good housekeeping BMP’s are for the most part “common sense” practices that not only reduce or eliminate storm water contamination but can also contribute to a safer and more pleasant working environment. Good housekeeping practices include the following tasks: Clearly label all containers. Ensure clean and orderly storage of raw materials and wastes (cover containers and/or raise off the floor or ground when necessary). Designate storage and handling areas in locations as far as possible from storm drains. Coordinate response to spills, whether with personnel or contractors, in order to minimize response time and prevent discharges to storm drains. Promptly remove generated wastes and empty containers, including 55 gallon drums, from the site. 26 11 INSPECTIONS AND RECORDS - 40 CFR 112.7(e)(8) / SPCC/SWPP 2 (vi) As part of the SPCC/SWPP Plan, an inspection of the facility will be conducted every quarter using the Quarterly Inspection Form located in the Attachments. One annual inspection will be conducted while storm water is draining from the facility, using the Annual Inspection Form located in the Attachments. Any of the SPCC/SWPP management team/ committee can conduct the inspections. The inspections will cover all areas used for storage, use, handling and management of significant materials, floor drains, storm drains, spill response, equipment inventory and housekeeping activities. Visual inspections are an effective way of ensuring that all elements of this combined SPCC and SWPP Plan are in place and working properly. Inspections should focus on those areas of the facility that can potentially contribute to petroleum discharge and other pollutants through storm water. Informal inspections of equipment and operating areas are made by the area supervisors or other qualified personnel on a regular basis. The results of the inspections are recorded and any actions implemented as soon as possible. The visual inspections will include the following: Equipment deterioration. Staining of ground or surface areas indicating a previous or ongoing release. Equipment malfunctions. Pipe and pump leaks. Corrosion or damage to storage containers. General area housekeeping. Tracking of sediments onto off-site roads and cross-ways. Conditions of storm drains and catch basins. Availability of adequate spill response equipment. Identify necessary follow-up repair or clean-up procedures. As part of this combined Plan, (112.8(c)(6)), aboveground containers are required to be tested for integrity on a regular schedule. ___ will combine visual inspections with another testing technique such as hydrostatic testing, radiographic testing, ultrasonic testing, acoustic emissions testing or other system of nondestructive shell testing. Secondary testing for certain “shop-built” containers may be considered impractical if all of the parameters apply: (1) internal corrosion poses minimal risk of failure, (2) the tanks are inspected 27 monthly and (3) all sides are visible. Comparison records will be kept, including tank supports and foundations in these inspections. Operation personnel will frequently inspect the outside of the container for signs of deterioration, leaks or accumulation of oil inside diked areas. Records of inspections and tests kept pursuant to usual and customary business practices are sufficient for purposes of the rule. An Annual Inspection Form is included in Attachment 3. 28 12 SECURITY - 40 CFR 112.7(e)(9) / SPCC SWPP (v) (c) Fencing or equivalent security measures are required around the fuel and oil handling areas of a facility. It is not required to fully fence the entire property. Equivalent measures, certified by a PE, may include locks on valves and fill piping of the tanks. Locks on fuel caps of mobile equipment would suffice as equivalent measures of security. Adequate lighting is also required in oil handling areas. 1. Dispensing pumps associated with diesel fuel and gasoline tanks are secured in an upright hung position to prevent leakage. 2. Dispensing pumps associated with storage tanks in fixed secondary containment area are closed and capped to prevent leakage when not in use. 3. Lighting around the maintenance garage, plant and storage areas is adequate for the discovery of spills or leaks at night and aides in the prevention of vandalism. 4. Power to the dispening pumps will be shut-off and locked-out during non business hours 5. Access roads are gated or chained during non-business hours. 29 13 PERSONNEL, TRAINING, PREVENTATIVE MAINTENANCE AND SPILL PREVENTION PROCEDURES 40 CFR 112.7(f) / SPCC/SWPP(g,h) 1. Designated facility personnel will be instructed by management in the operation and maintenance of oil pollution prevention equipment and pollution control laws and regulations as well as storm water pollution prevention. The following personnel are members of the SPCC/SWPP- Pollution Prevention Committee and are responsible for managing and implementing the SPCC/SWPP Plan, and complying with its reporting requirements. These personnel must be available at reasonable times of operation. In the event that at least one member of the management team is not available, an alternate will be assigned so that absences do not prevent adequate management of the plan. Employee Title Successful implementation of the combined SPCC/SWPP Plan is largely dependent on employee awareness of the cost of pollution and a commitment to a healthy environment. Employee training should focus on the following topics: Familiarization with goals, objectives and major components of the SPCC/SWPP Plan Operation and maintenance of equipment to prevent the discharge of oil and fuels Spill response procedures Applicable pollution control laws, rules and regulations General facility operations Material handling and management practices Good housekeeping and maintenance practices Informal and formal inspection and reporting procedures Storm water bypass events from diked/containment areas can be recorded with NPDES recording protocol to meet SPCC purposes This plan will be reviewed and updated on an annual basis or sooner if there is a significant physical change in the facility and/or a significant change in the operational procedures of the facility that could result in the discharge of significant materials to storm water or the sanitary sewer system. _____ will train designated employees in SPCC/SWPP procedures as part of its ongoing employee training programs. 30 2. The plant manager will be accountable for oil spill prevention and storm water management at this facility. 3. The objective of preventive maintenance is to eliminate pollution that results from spills or accidents due to improperly functioning equipment. Equipment that is well maintained is less likely to leak fluids, such as lubricants or fuel, onto areas where these pollutants could be mobilized through storm water runoff. Regularly scheduled inspections of areas and equipment used to store and handle materials are part of a preventive maintenance program and are conducted on an ongoing basis. General preventive maintenance responsibilities include the following: 4. Identifying equipment or areas of potential failures and/or spills. Periodic inspections of equipment for storage, transfer and use of potentially hazardous materials. Periodic inspections of containment systems. Periodic inspection of tanks for integrity. If underground piping exists, and it was installed after August 16, 2002, periodic inspections to verify wrapping, coating and cathodic protection is intact if work was performed on underground piping. Maintenance and inventory of spill response equipment and supplies. Regularly scheduled maintenance and repair of equipment used for storage, transfer and use of potentially hazardous materials. Verification that mechanical equipment is operated in accordance with manufacturers’ recommendations. Spill prevention briefings will be provided by management for designated oilhandling personnel at least once a year to ensure adequate understanding of the SPCC/SWPP Plan. These briefings will highlight any past spill events or failures and recently developed precautionary measures. Training will be held on oil spill prevention, containment and clean-up methods. Instructions and phone numbers regarding the reporting of a spill to the National Response Center and state agency are listed in the next section of this report and will be posted in the office or identified within _____ Emergency Response Action Plan. 31 Employee Initial Training Date 32 Briefing Date (Annually) 14 SPILL COUNTERMEASURES The following actions will be taken if an accidental discharge of a petroleum product is discovered. 1. Use all equipment and manpower at the plant’s disposal to minimize the amount of contaminant and to prevent it from entering any waterway or sewer inlet. 2. Close any valves, pipes, or sources contributing to the discharge if practically possible. 3. Shut off all pumps associated with the spill. 4. Immediately notify the plant manager. If the plant manager is not available, contact the plant supervisor and begin the verbal reporting procedures outlined below. (See the attached Emergency Contact Phone Numbers, Attachment 5) 5. Inspect the containment area for structural integrity. 5. Oncespill has been contained, use absorbent material to absorb the spilled petroleum product or contaminant. The oil or contaminant-soaked materials must be disposed of according to federal, state and local regulations. 7. Call a spill clean-up contractor – if necessary In the event of a spill of petroleum products: DO: o o o o o o Enact ____ Crisis Management Plan, if appropriate Shut off supply, stop leak (if possible) Shut off ignition sources Contain spill and/or dike ahead of spill Call your supervisor and/or _____Environmental Technical Services Protect adjacent people, property, surface waters and equipment from contact with spill o Follow MSDS for clean-up guidance DON’T: o o o o Do not smoke Do not risk personal injury Do not wash down spill with water Do not try to hide spill 33 SPILL REPORTING Verbal Reports Any spill, including those retained within the containment area, should be reported to your supervisor and/or _____Environmental Department personnel. If ____ Environmental Technical Services personnel cannot be reached and a reportable spill has occurred, the person reporting the spill should notify the following agencies: Maryland Department of the Environment (MDE) (410) 537-3000 or 1-800-633-6101 (866) 633-4686 National Response Center (800) 424-8802 U.S. EPA Region III Spill Phone (215) 897-9898 U.S. Coast Guard (410) 962-5105 34 35 Attachment 1 Site Topographic Map 36 APPROX. PROPERTY BOUNDARY SITE TOPOGRAPHIC MAP QUARRY AND READY MIX NOT TO SCALE 37 Attachment 2 Facility Site Map 38 FACILITY SITE MAP 39 Attachment 3 Annual Inspection Form 40 ANNUAL INSPECTION FORM One annual inspection will be conducted while storm water is draining from the facility. A member of, or all of the storm water management committee will conduct the inspection. The inspection will cover all areas used for storage, use, handling, management of significant material, floor drains, storm drains, spill response, equipment inventory and housekeeping activities. This section will assess the integrity of storm water diversions (ditches), collection and conveyance systems (catch basins and pipes), sediment control devices (silt fence) and containment structures (retention/detention ponds). Also, assess the conditions at the permitted discharge point(s). Are conditions satisfactory? (Circle one) Location(s): Comments: Y N Y N Y N Y N Location(s): Comments: Location(s): Comments: Location(s): Comments: The following section includes a visual inspection of the facility to evaluate to status of the following BMP’s, as identified in Section 10 (Best Management Practices). Raw Material Storage: Y N Y N Y N Y N Comments: Equipment and Machinery Storage: Comments: Waste Material Storage: Comments: Inside Aboveground Storage Tanks: Comments: 41 Page 1 of 2 ANNUAL INSPECTION FORM (CONT’D) BMP’s Are conditions satisfactory? (Circle one) Outside Aboveground Storage Tanks-Fueling Operations: Comments: Y N Y N Y N Y N Y N Y N Equipment Cleaning: Comments: Bulk Loading and Unloading of Materials: Comments: Chemical-based Material Storage: Comments: Waste Product: Comments: Good Housekeeping: Comments: Corrective Action(s) Taken: ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ ___________________________________________________________________________________________________ Date:________________Time:___________________Weather:________________________________ Inspected By: _______________________________________ 42 Page 2 of 2 Attachment 4 Emergency Contact Numbers Maryland State Plans (MDE) 43 MARYLAND DEPARTMENT OF THE ENVIRONMENT 1800 Washington Boulevard, Suite 620hBaltimore Maryland 21230-1719 (410) 537-3461 h 1-800-633-6101 (within Maryland) hhttp://www.mde.state.md.us Oil Control Program PLAN FOR NOTIFICATION, CONTAINMENT AND CLEAN-UP OF OIL SPILLS FULL COMPANY NAME: ____ DATE: March 16,2007 STREET ADDRESS: ____ I. A. The following agencies will be notified by our employees IMMEDIATELY, but not later than two (2) hours after detection of a spill at either our facility or a remote location, or from one of our vehicles. 1. LOCAL EMERGENCY AGENCIES - 911 2. MARYLAND DEPARTMENT OF THE ENVIRONMENT - all areas of the State 1-866-633-4686 24-hour basis 3. NATIONAL RESPONSE CENTER - (800) 424-8802 4. U.S. COAST GUARD - if east of I-95 or inside either Beltway (I-695 or I-495) (410) 576-2693 (Baltimore Marine Safety Office) 5. U.S. ENVIRONMENTAL PROTECTION AGENCY - if west of I-95 or outside either Beltway (I-695 or I-495) (215) 814-9016 B. The following individual(s) from this company will be notified in the event of a spill: Name 1. ____ 2. ____ 3. ____ Home Phone Work Phone C. Who is responsible for notifying the agencies in Section A, if a spill occurs? 1. Business Hours: _ 2. Non-Business Hours _ Form Number: MDE/ WAS/ PER.007 Page 1 of 3 Revised August 2006 Recycled Paper 44 Mobile Phone TTY Users 1-800-735-2258 PLAN FOR NOTIFICATION, CONTAINMENT AND CLEAN-UP OF OIL SPILLS (continued) II. A. The following personnel are assigned specific tasks to perform in the event of an oil spill: NAME & ASSIGNED TASK 1 Loader Operators . 2. ____ Set booms, enact equipment Coordinate Labor 3 The remainder will be enacted as needed and assigned various tasks 4. 5. B. The following listed equipment is immediately available at our facility or on our vehicles to contain and clean-up a spill 6 Stock Yard loaders 3 Pit Loaders: 5 777 100 Ton Quarry Trucks Cat Grader , Cat Excavator Tons of # 10 Screenings Sorbent C – booms , pillows , sheets Absorbents Speedi -Dri C. The following procedures will be used to contain and clean-up a spill: 1. Hire a contractor immediately __X__YES _____ NO I If necessary Name of Contractor (if known): A to Z 410 679-8877 Cell: 410-977-7419 Or Clean Harbors-800-622-3360 ( 24 hours) 2. Explain how you will handle a spill before a contractor arrives (outline specific procedures) Stop the leak – Contain the spill – Hire a contractor if necessary – Notify MDE and NRC – Clean the spill – Dispose of waste – Written report to MDE. Form Number: MDE/ WAS/ PER.007 Page 2 of 3 Revised August 2006 Recycled Paper 45 TTY Users 1-800-735-2258 PLAN FOR NOTIFICATION, CONTAINMENT AND CLEAN-UP OF OIL SPILLS (continued) III. A. The following communication resources are available to assist in containment and clean-up of a spill: 1. Office Telephone Number: ____ 2. Dock Telephone Number: - ____ 3. Dispatcher Telephone Number: ____ 4. Other Important Telephone Numbers at your facility (list): NAME OR GROUP TELEPHONE NUMBER ____ ____ ____ IV. Is your facility required to prepare any of the following federal documents? a. Spill Prevention Control and Countermeasures (SPCC) Plan: _X___ yes ____ no ____ unknown b. Facility Response Plan (FRP): ____ yes ____ no ____ unknown If your answer is "unknown", please contact the EPA Region III SPCC/FRP Hotline at 1-215-814-3452. If your answer is yes for the FRP plan, please provide a copy with this Plan as required by Code of Maryland Regulations (COMAR) 26.10.01.22A. For over-the-water transfer operations involving oil, contact the USCG at 1-202-493-6999 for OPA 90 Response Plan requirements. V. List of Oil Spill Contractors - The attached list of Oil Spill Contractors is for your convenience. It is not an endorsement of their capabilities or work quality. VI. This "Plan for Notification, Containment and Clean-up of Oil Spills" has been completed by the undersigned and accurately reflects the procedures that the referenced company will follow in a timely manner in the event of an oil spill or oil discharge. _____________________________________________________ __________________________________ Print Name Title _____________________________________________________ ___________________________________ Signature Date Form Number: MDE/ WAS/ PER.007 Page 3 of 3 Revised August 2006 Recycled Paper TTY Users 1-800-735-2258 46 Emergency Contact Numbers Facility Contacts Location Manager – ____ Safety Manager – Safety Manager – Location Administration – Local Emergency Assistance Contacts Local Fire Department Volunteer Fire Company Telephone: Local Rescue Squad Poison Center MSDS – 3E Company State Police MD Department of the Environment (MDE) Telephone: Telephone: Telephone: Telephone: Telephone: Telephone: Healthbridge Telephone: (410) 527-1634 911 (410) 706-7701 or 911 1-800-451-8346 911 (410) 537-3000 or 1-866-633-4686 1-800-633-4350 Regional Contacts Regional President Vice President Maryland Aggregates Operations Manager Page 1 of 2 47 Corporate Contacts General Counsel VP Environment & Government Director of Risk Management Assistant Risk Manager VP Communications (For crisis communications plans, media relations and spokesperson training) National Contacts National Response Center 1-800-424-8802 U.S. EPA Region III Spill Phone (215) 814-3229 Maryland Department of the Environment U.S. Coast Guard 24 hour Business hours note: same as NRC above 1-866-633-4686 (410)-537-3385 1-800-424-8802 Page 2 of 2 48 Attachment 5 Copy of General Permit for Discharges from Mineral Mines, Quarries, Borrow Pits and Concrete and Asphalt Plants 49 Attachment 6 Quarterly Inspection Form 50 SPCC/SWPP Quarterly Inspection Form As part of the SWPP Plan, an inspection of the facility will be conducted every quarter. One annual inspection will be conducted while storm water is draining from the facility. A member of, or all of the storm water management committee will conduct the inspection. The inspection will cover all areas used for storage, use, handling, management of significant material, floor drains, storm drains, spill response equipment inventory and housekeeping activities. Items to note during inspection (add items as needed): Condition of fuel areas- gas, diesel & fuel oil. Equipment malfunctions including spills or leaks. Use of tarps to cover equipment stored outside. Secondary containment drain valve is secure. Staining of ground areas indicating a previous or ongoing release. Oil sheen on any standing water. Color/clarity & odor of any standing water. Conditions of storm water drain covers/inlets. Description of Findings Corrective Action Material stored away from storm water drainage lines. Corrosion or damage to storage containers. General facility housekeeping. Waste concrete discarded properly. Adequate spill response equipment is available and readily accessible. Chemicals stored inside or protected from precipitation. Clean-up of debris and waste storage areas. Date: __________________ Time: __________________ Weather: _________________ Inspected By: ____________________________________________________________ Page 1 of 1 51 Attachment 7 Annual Report Form This form is to be used as a summary for all required inspections for the last calendar year. 52 ANNUAL REPORT FORM This form is to be used as a summary for all required inspections for the last calendar year. This form may be required by a state or federal agency if a reportable spill has occurred in the last calendar year. Facility Name: Physical Address Summary of Storm Water Plan: 1. The following is a list of spills or know contamination of storm water that occurred during the last calendar year: Date of Spill Material Spilled Quantity Spilled Clean-up Response 2. The following is a description of inspections at the site during the last calendar year. Date of Inspection Finding of Inspection Area Inspected Page 1 of 2 53 Corrective Action 3. The following is a list of Best Management Practices (BMP’s) that have been installed or conducted at the site during the last calendar year: (Please check boxes of all BMP’s that were undertaken or installed last year) Non-Structural BMP’s General SWPP employee training Employee spill training Parking lot/yard sweeping Clean-up of process waste General clean-up of equipment and yard Removal of discarded equipment Move significant materials inside Cover significant materials with tarps Change in material handling practices Installation of silt fencing Other non-structural measures Seeding and mulching of bare soil areas Purchase of spill containment and control material Structural BMP’s Construction of buildings or awnings to cover materials Installation of curbs or swales to divert storm water Installation of platforms to raise significant materials Installation of containment areas around storage tanks Construction of covering over outside AST’s Installation of oil/water separation systems Other structural measures installed The Storm Water Pollution Prevention Plan is to eliminate or minimize contact of significant materials with storm water. Where contact cannot be eliminated or reduced, then treatment of the storm water should be implemented. Describe measures (if any) which have been taken during the reporting year to: Reduce sources of potential pollutants Divert uncontaminated storm water runoff away from potential pollutants Treatment of contaminated storm water runoff before discharging from site. 5. Based on my inquiry of the person, or persons who manage the SWPP Plan, or those persons directly responsible for gathering the information, the information submitted is to the best of my knowledge and belief true accurate and complete. 4. Print name Signature Title of Individual Date 54 ATTACHMENT 8 SEDIMENT & EROSION CONTROL PLANS 55