Paper

advertisement

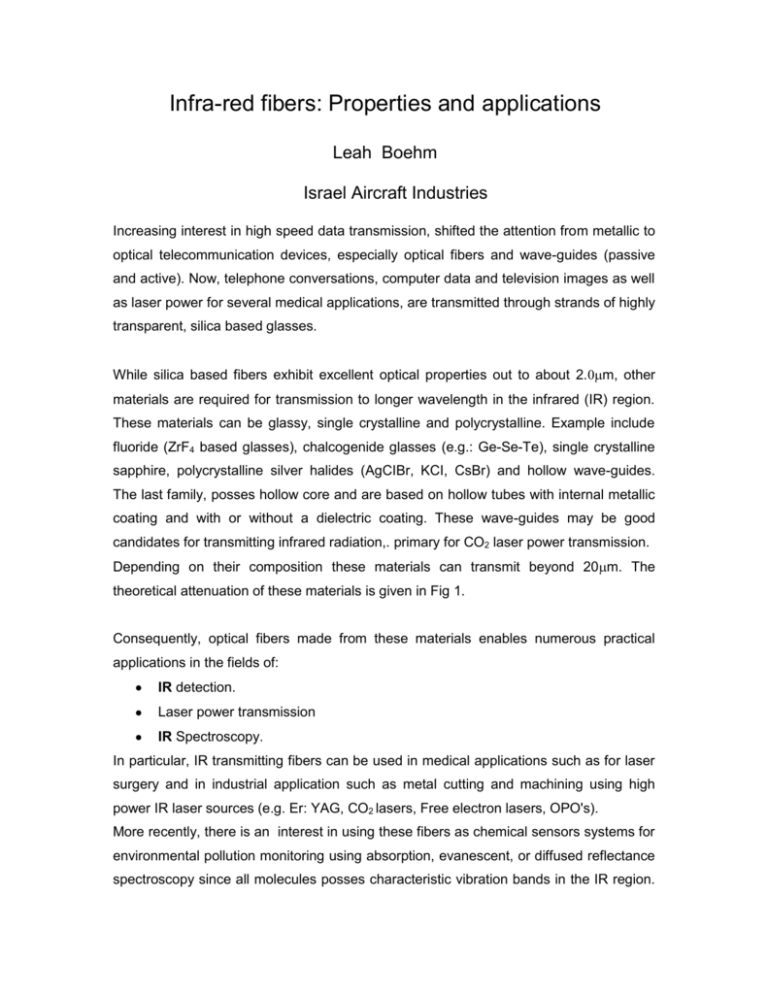

Infra-red fibers: Properties and applications Leah Boehm Israel Aircraft Industries Increasing interest in high speed data transmission, shifted the attention from metallic to optical telecommunication devices, especially optical fibers and wave-guides (passive and active). Now, telephone conversations, computer data and television images as well as laser power for several medical applications, are transmitted through strands of highly transparent, silica based glasses. While silica based fibers exhibit excellent optical properties out to about 2.m, other materials are required for transmission to longer wavelength in the infrared (IR) region. These materials can be glassy, single crystalline and polycrystalline. Example include fluoride (ZrF4 based glasses), chalcogenide glasses (e.g.: Ge-Se-Te), single crystalline sapphire, polycrystalline silver halides (AgCIBr, KCI, CsBr) and hollow wave-guides. The last family, posses hollow core and are based on hollow tubes with internal metallic coating and with or without a dielectric coating. These wave-guides may be good candidates for transmitting infrared radiation,. primary for CO2 laser power transmission. Depending on their composition these materials can transmit beyond 20m. The theoretical attenuation of these materials is given in Fig 1. Consequently, optical fibers made from these materials enables numerous practical applications in the fields of: IR detection. Laser power transmission IR Spectroscopy. In particular, IR transmitting fibers can be used in medical applications such as for laser surgery and in industrial application such as metal cutting and machining using high power IR laser sources (e.g. Er: YAG, CO2 lasers, Free electron lasers, OPO's). More recently, there is an interest in using these fibers as chemical sensors systems for environmental pollution monitoring using absorption, evanescent, or diffused reflectance spectroscopy since all molecules posses characteristic vibration bands in the IR region. Potential low attenuation Fused silica 1.E+02 Loss [db /km ] Loss (db /km ) 1.E+03 1.E+02 1.E+01 1.E+00 1.E-01 1.E+00 1.E-02 1.E-04 0 0.5 1 1.5 2 2.5 3 0 W avelength (micron) 2 4 6 b W avelength [micron] Silver halide crystal Chalcogenide glass 1.E+04 Loss [db /km ] 1.E+03 Loss [db /km ] CO2 Laser Catheter Fluoride glass 1.E+01 1.E-01 1.E-03 1.E+02 1.E+00 1.E-02 1.E-04 0 2 4 6 8 W avelength[m icron] 0 5 10 15 W avelength[micron] 7 39 \ Fig. 1: Theoretical attenuation of IR Fig. 2: Schematic setup of IR fiber bundle for Materials. endoscope use with CO2 laser. Optical fibers and wave-guides are basically just a mean to transmit radiation from one point to the other. The input can be any source at the optical spectrum and the target can be any interaction subject. In the field of biomedical optics we have two main ways of using of using this delivery device. Either deliver energy from a laser source to the human body to cause interactions (tissue removal, heating, cutting, etc.) or it can deliver signals from the human tissue (heat, fluorescence) and the target will be the appropriate detector. Laser delivery via fibers enables easy manipulation of the beam to the operating table. It becomes crucial when minimal invasive surgery is carried out. (Fig. 2) In this case fiber is inserted through the working channel of an endoscope and an operation can take place within body cavities, through existing openings of the body or through minor cuts made through the skin. The opposite way is receiving signals from the body to a detector. This enables the use of fiber as a vehicle to transmit signals for diagnostic purposes. These signals enable us to study tissue structure, tumor detection or tissue temperature. Such a system can be seen in Fig. 3, which shows possibility of sensing using a IR fiber bundle in human body. Things could have been very simple if one kind of material or fiber could serve all purposes but this is not the case. The optical spectrum is very wide. Useful wavelengths can vary from very short at the X-ray side, to the mid and far infrared on the other side. Signals can very from nano-jouls to joules and not every material can handle it. Remote IR Fiberoptic System Tunable IR Source core/clad IR fiber Detector IR cable Thick plastic jacket Lens Sample EM field Thin protective coating unclad IR fiber 50 Fig. 3: Schematic setup of remote sensing in the IR using silver halides fibers. Fibers need to be bent to very small diameters (as is the case in endoscope) and each material is brittle to some extend. Pulses might be broaden while transmitted and this should be taken into consideration for time of flight measurements. Short pulses can have very high peak power. Materials do have damage thresholds. Transmission is not linear and can change with wavelength. Transmission can also change with bending. Input beam shape will not necessarily be kept the same after being transmitted in bent trajectories. Biocompatibility is also an important issue. For sure no hazardous material can be inserted into the human body no matter how efficient they are in delivering laser radiation. With all the above in mind, the fibers and wave-guides issue became a very big field of research. There is more than one solution and each solution is partially covering the requirements from the ultimate fiber. Different materials and ways of fabrication were investigated intensively in order to produce commercial lR fibers for different applications. Fluoride glasses based on ZrF4 material as the major component (these compositions contain also BaF2 and LaF3 which stabilize the glass), are predicted to have minimum optical loss of less than 0.01 dB/krn, which is more than an order of magnitude lower than the 0.12 dB/krn predicted and practically realized for silica fibers. This phenomenon is related to fact that these are low phonon frequency glasses and, hence, the multiphonon energy is shifted to longer wavelengths. In addition, fluoride glasses possess low non-linear refractive indices and these glasses are excellent hosts for rare earth elements. As a result, there are many applications for optical fibers, such as distance telecommunications, fiber lasers and amplifiers, as well as infrared laser power delivery. Fluoride fibers are prepared by the classical method of redrawing performs into fibers or drawing fibers from crucible. The majority of fluoride fibers are multimode or step index fibers. Attenuation of 0.45 dB/km at 2.3m was achieved with a 60m fiber. In Fig. 4 method of fluoride fibers fabrication is shown. AgClBr Crystals & Fibers Fabrication methods (b) Schematic representation of fiber fabrication using ( a ) rod- in- tube technique; ( b ) double crucible process ( DCP ) . 35 15 Fig. 4: Glass fiber fabrication. Fig. 5: Silver halides samples. Chalcogenide glasses such as As2S3 or more complicated compositions (Ge-Se-Te) are prepared in Quartz ampoules under vacuum at high temperatures. Fibers are drawn by the preform drawing for core fibers and by the double crucible method for core/clad fibers. No graded index fibers were reported in this case. Minimum loss of 23dB/km at 2.3m was achieved with fiber drawn from sulfide glass . At 10.6m the lowest attenuation measured with telluride glass fiber, was 1.5dB/km. Polycrystalline optical fibers have been fabricated from thallium halides, alkali halides and silver halides which were obtained by the extrusion of crystal perform through a die. Unclad fibers of composition AgClo.5 Bro.5 and core-clad fibers with AgClo.4Bro.6 core and AgClo.9Bro.I cladding are the main compositions fabricated and used. Different samples obtained from the above compositions are presented in Fig. 5. Optical loss of 59dB/km at 10m and less than 0.5 dB/km at 3m were reported with AgClBrI unclad fibers. Core/clad fibers are fabricated by the extrusion of a “rod in tube” preform. Hollow glass waveguides were constructed from a silica glass tube with diameter between O.5mm, and coated a layer of silver iodide AgI as dielectric coating. By this process, the glass tubing substrate is deposited with a thin flexible metallic layer, then, innermost part of this metallic coating is converted into a dielectric thin film. Other groups reported hollow plastic wave-guides with attenuation on 1.8dB/m at different IR wavelength for 1 mm hollow wave-guide. As already mentioned, the variety of applications of these IR materials and fibers, their future possibilities, will encourage more research and investment in the field. Both in the development of new materials, new processes of fabrications and also in finding more ways to utilize them.