What we Need to Know About the Anesthetic Machine

advertisement

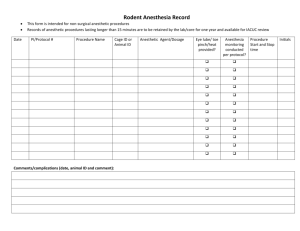

What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal What do we Need to Know about the Anesthesia Machine?? Pressure units: 1 atmosphere = 1 bar = 760 torr = 760 mmHg = 1020 cm H2O = 100 KPa = 14.7 psi (pounds per square inch) (1) Medical Gas Supplies A. GAS CYLINDERS Synthesis: Made of strong metal alloy to withstand very high pressures. There are cylinders made of aluminium (non-ferromagnetic) for MRI (MRI-compatible). Size: Available in sizes from A to H, A=10 inches height (25 cm), E= 31 inches (78 cm) used in anesthesia machines, pt transport and resuscitation. H=57 inches (145 cm) used in pipeline systems (shabakah) and ECT. Colour & form: Gas Shoulder Body Form Pressure (bar) 1- O2 White Black gas 137 2- N2O Blue Blue 50 liquid 3- CO2 Grey Grey 50 liquid 4- Entonox White & blue Blue Gas 137 quarters 5- Air Black & white Grey Gas 137 quarters Capacity: of cylinders containing gases is detected by the pressure gauge. Whereas capacity of cylinders containing liquefied gases (eg. N2O) is detected by weighing the cylinder. Therefore the tare weight (empty wt) and the gross weight (full cylinder wt) are stamped on the shoulder of the cylinder. How long will an O2 cylinder last?? Size E= 700 L (when full 137 bar), size H= 8000 L (when full 137 bar). So if FGF is opened at a rate of 10 L/min size E will last after (700÷10= 70 min), whereas size H will last after (8000÷10= 800 min). The cylinder capacity (volume in L) is stamped on the shoulder of the cylinder. E.g.: O2 cylinder size E reads 90 bar how long is it expected to last using a FGF of 8 L/min?? 137 bar = 700 L 90 bar = ?? By cross multiplication 90 bar = 460 L. If FGF is opened at a rate of 8 L/min it is expected to last after (460÷8= 57.5 min). Filling ratio: cylinders of liquefied gases (CO2 & N2O) are never filled to the point where they contain only liquid because any slight increase in temp will cause a dangerous rise in cylinder pressure because temperature will cause CO2 & N2O to expand, since liquid is not compressible as gases. The degree of filling of cylinders is expressed as the filling ratio. The filling ratio of CO2 and N2O cylinders is 65-75%. [Eg. Like putting a bottle of water in the freezer]. 1 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Cylinders are connected directly to the anesthetic machine or to a manifold by PISS: pin index safety system. Each gas cylinder has 2 holes in the cylinder valve that mate with 2 corresponding pins in the anesthetic machine to prevent attachment to the wrong cylinder. Pressure reducing/regulating valve: (monazem) to reduce the high pressure inside the cylinder (eg.137 bar) to low pressure entering the anesthetic machine (= 4 bar). Pressures exceeding 6 bar cause damage to the anesthetic machine (7 gera7a). Pressure gauge: (Bourdon gauge = 3addad) is present to measure the gas pressure inside the cylinder. The pressure in cylinders with gaseous contents (eg. O2) is directly proportional to the content of the cylinder, so the pressure gauge can indicate the volume of gas remaining inside the cylinder. On the other hand in cylinders containing liquid (eg. N2O) the pr gauge will indicate a steady pressure (50 bar) as long as any liquid still remains in the cylinder. When all the liquid is vaporized, the gauge pressure falls steadily until the cylinder becomes empty. In cylinders containing liquid the weight of the cylinder indicates the volume of liquid remaining inside it. Vaporization of liquefied gases requires latent heat of vaporization which is extracted from the metal cylinder. This causes water vapour to accumulate as frost on cylinders. Heat should be applied locally (eg. towels soaked in warm water). The level of the frost can also be used to indicate the amount of liquid remaining in the cylinder. General precautions regarding cylinders: Safety features & hazards Cylinders can withstand pr 65-70% above working pr. (E cylinders can withstand up to 340 bar). Cylinders are equipped with an emergency pr relief valve (rupture disc) to prevent explosion under conditions of unexpectedly high gas pr. (eg. unintentional overfilling or heating). The pr relief valve is designed to rupture at 220 bar so it protects against cylinder explosion. Heating cylinders is dangerous because it increases the pressure inside them. Most large cylinders are stored in the upright position, while smaller ones and entonox are stored horizontally. Should be stored indoors and protected from extremes of heat or cold. O2 cylinders (137 bar) should be at least half full (68 bar). N2O cylinders: below 36.5oC N2O cylinders contain both gas and liquid N2O at a pr of 50 bar. This pr remains steady as long as any liquid N2O remains in the cylinder. When all the liquid is vaporized the pressure falls steadily until the cylinder becomes empty and the pr gauge read zero. Entonox cylinders: trade name for premixed gaseous mixture 50% O2 and 50% N2O prepared by bubbling O2 gas through liquid N2O (Poynting effect). When the temp is above -7oC (pseudo-critical temp) entonox mixture remains in the gaseous state. Below -7oC the mixture separates into O2 and some N2O gas above and liquid N2O below due to liquefaction of N2O. This is a very dangerous situation because O2 is drawn out first and the gas mixture has a high % of O2, then the gas mixture becomes progressively hypoxic until pure N2O is drawn and inhaled by the patient. To prevent this hazard the following precautions should be taken: Safety measures for entonox cylinders: Cylinders should be warmed to > 10oC. The small cylinders should be inverted and shaken repeatedly before use to reconstitute the gaseous mixture. 2 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Large cylinders have a dip tube to draw out any liquid N2O first, thus preventing the delivered O2 concentrations falling below 20% at any time. Entonox cylinders have a special pr reducing valve which regulates the output pr to sub atmospheric levels for self-administration by the pt. (B) PIPELINE Gas stores: SYSTEM (shabakah) Gases are stored in large cylinders connected by a manifold. A manifold is a tube with several outlets which connect several cylinders of the same type of gas to give a continuous supply. Each manifold system consists of 2 groups of cylinders one on each side. Each group is called a cylinder bank. Each group is used at a time with the other as a reserve. When one bank is exhausted, the other reserve bank will work by a manual or automatic switch allowing time to replace cylinders in the first empty bank. Valves: a) Pressure reducing valve (pr regulator): reduces high pr issuing from the gas cylinder banks (137 bar for O2) to 10 bar, then a 2nd stage reducing valve to decrease pr from 10 bar to 4 bar (safe working pr in the pipelines). Pr > 4 bar → damage to anesthesia machine. [Aim: to protect the anesthesia machine]. b) Check valves: unidirectional valve which allows gases to pass from the cylinders to the pipelines and not in the reverse direction. It is placed between each cylinder and the manifold. It prevents loss of gas from the manifold if there is a leak in an individual cylinder. c) Pressure relief valve: a valve open to the atmosphere to vent excess gases if the pr in the central pipeline exceeds a preset value. This valve protects the anesthetic machines or ventilators from damage due to the high pressure. ► O2 failure safety devices: (O2 whistle alarm) alarm that gives audible and visual signals if the pressure increases or decreases from a preset value (~2.5 bar). (O2 whistle) Pipeline terminal outlets: Site: Pipelines terminate at terminal outlets situated on the walls or articulating arms. Types: O2 White 4 bar N2O Blue 4 bar Air Black and white 4 bar (anesthetic machine) 7 bar for instruments Vacuum Yellow 400-500 mm Hg Connections: non-interchangeable gas-specific connections to prevent incorrect attachment. This is achieved by diameter index safety system DISS. By the use of various sizes of collars so that a given collar only fits the appropriate outlet. Safety features for medical gas supplies: Cylinders Pipeline Colour coded Colour coded Pr regulator (137 bar → 4 bar) Pr regulator (137 bar → 4 bar) Pr relief valve Pr relief valve PISS DISS Alarms: O2 failure safety device (O2 whistle p.5) Filling ratio Confirm that O2 cylinders are full (137 bar) or at least half full (68 bar). Must NOT be used if less than half full. 3 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal (2) Flowmeter (Rotameter) 2 types: 1) Variable orifice. 2) Electronic/digital. Variable orifice flowmeters: Physical principle: It is a tapered glass tube narrow at the bottom, wide at the top, like an inverted cone, present vertically, with a metal alloy bobbin or a ball present inside the tube. When the flow increases it pushes/lifts the bobbin upwards against gravity. So the effect of gravity (weight of the bobbin) is balanced by the increase in flow. Readings are taken from the TOP of the bobbin, or from the CENTRE of the ball. Each flowmeter is GAS SPECIFIC. (Why??) Because it depends on the physical properties: viscosity & density of the specific gas. (At low flow rates flow is laminar and depends on the viscosity of the gas, whereas at high flow rates flow is turbulent and depends on the density of the gas). Safety features of the flowmeter: 1. The plastic cover of the flowmeter is made of anti-static material to avoid 2. 3. 4. 5. 6. 7. 8. 9. sticking of the bobbin to the sides of the tube. Also a dust filter prevents sticking. Small slots are placed around the top of the bobbin causing it to rotate centrally in the gas flow and a dot is present on the body of the bobbin to indicate its free rotation. The dot is not used to indicate the level from which the readings are made. Accuracy of the flowmeter is within ±2-2.5% (eg. Adjusting 10 L/min flow may actually give 10.25 L/min or 9.75 L/min) In recent anesthetic machines with closed circuits where very low flow (< 1 L) is needed two flowmeters are present: one for low readings below 1 L (1000 ml), and the other for higher readings up to 12 L. Position of the flowmeter: when flowmeters are connected in series, one for O2 & the other for N2O, a break in the inner tubing may cause O2 to leak out from the leak resulting in delivery of a hypoxic gas mixture. To avoid this problem: 1) O2 is located DOWNSTREAM (after the N2O and air). This is the standard in north American anesthetic machines. 2) OR the O2 is located upstream but with a separate channel away from N2O (British system: UK). O2: N2O ratio. In modern anesthetic machines there is a link between the O2 flow controller and N2O controller to ensure administration of at least 25% O2. If N2O was turned on alone the O2 flowmeter is turned on obligatory to at least 25% of the total gas mixture. (This is achieved by: mechanical method: chain link, electronic or pneumatic method) known as: O2 N2O ratio controller or O2 N2O proportionating systems to maintain a minimum 1:3 ratio of O2 to N2O. The flow control valve: is a fine adjustment screw needle valve. Control knobs have the same colour code as gas cylinders (O2= white, N2O= blue). O2 knob is fluted, larger and protrudes further than the other knobs for safety purposes: touch-coded. They constitute an important landmark since they divide the anesthetic machine into 2 circuits: high pressure circuit upstream from the flow control valves 4 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal (pipleline system, cylinders and the tubes connecting them to the machine pr=4 bar) and low pressure circuit downstream from the flow control valves (flowmeter and vaporizers) = 1 bar. 10. Emergency O2 flush valve provides high flow: 35-55 L/min of O2 directly to the common gas outlet at a pressure of: 3-4 bar to provide O2 in case of emergency respiratory obstruction. It directly connects the high pr circuit with the common gas outlet bypassing the flowmeters and vaporisers. Accidental locking of the O2 flush valve in some machines may lead to barotrauma, & dilution of anesthetic gases resulting in the possibility of awareness. 11. O2 supply failure devices/alarm (whistle): these are pneumatic or electronic devices in the anesthesia machine that are activated by low O2 pressure. They give audible (whistle) and visual signs when the O2 pressure falls below a certain threshold value: 2.5 bar (7 gera7a). The O2 whistle alarm: the whistle-like sound that is heard when an anesthesia machine is turned off. It alerts the anesthetist that O2 supply has failed. (3) Vaporizers Physical principle of variable bypass vaporizers: A device that converts a liquid into a vapour. It splits the fresh gas flow into 2 streams. One stream bypasses the anesthetic gas (bypass channel/ bypass gas) ≈ 80%. And the other stream carrier gas ≈ 20% enters the vaporizing chamber to carry the anesthetic vapour. The gas comes out from this chamber fully saturated with anesthetic agent. The 2 streams then reunite and mix at the common outlet of the vaporizer before reaching the patient. The ratio of gas flow bypassing the vaporizer to the gas flow entering it is called the splitting ratio. It determines the anesthetic gas concentration. The amount of flow passing through the bypass channel (splitting ratio) and the output of the vaporizer are controlled by a concentration control dial calibrated in volume percent %. SVP (saturated vapour pressure): is the pressure exerted on the walls of the container when the vapour is fully saturated. Each vaporizer is agent specific: specific for only one agent for which it is designed and calibrated according to the physical properties (SVP) of its specific agent. Misfiling the vaporizer by another agent will result in incorrect concentrations under-dosing or over-dosing. (The exception is halothane and isoflurane which may theoretically be used in the same vaporizer as they have the same SVP). A vaporizer should be placed between the flowmeter and the emergency O2 flush control so that there is NO risk that the high flow of O2 from the flush can be delivered through the vaporizer. O2 flush valve bypasses the vaporizer. [Draw over vaporizer: air or O2 is drawn over the vaporizer by the patients inspiratory effort creating sub-atmospheric pressure. These vaporizers should have low resistance to gas flow to allow easy inhalation by the patient. Used in portable anesthetic machines. They need no cylinder or gas supplies so they are ideal for use outside hospitals for emergency, in major disasters or remote areas. Eg: EMO (Epstein and Mackintosh of Oxford). As opposed to flow over vaporizers (plenum) which operate only by fresh gas flow]. 5 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Design of vaporizers: 1) Methods of increasing surface area of gas liquid interface in the vaporizing chamber: (1) Wicks: fabric wicks are present in the vaporizing chamber, one end immersed in the anesthetic liquid, while the other end projects up into the chamber. The liquid anesthetic moves up the wicks by capillary action. They provide a large surface area, and maintain surface area despite gradual emptying of the vaporizer. (2) Shelves: baffle system → ↑ surface area. 2) Problem of Cooling effect: temperature compensation: vaporization produces progressive cooling because it needs heat energy which is supplied by the anesthetic liquid. Cooling results in decreased vaporization, thus the output of the vaporizer decreases with cooling. Methods of compensating for the cooling effect: the vaporizer is made of a large mass of copper (about 5 kg). Why copper?? (1) Cu has high thermal conductivity: high speed of heat conduction through its substance so it can supply heat from the atmosphere to the vaporizer. (2) Cu has high specific heat: acts as a reservoir of heat. It needs a high quantity of heat energy to raise the temp of 1g Cu by 1oC (can lose a large quantity of heat before its temp falls by 1oC). So temperature compensation ensures a steady vaporizer output over a wide range of ambient temperatures. 3) Problem of Pumping effect: intermittent backpressure by positive pressure ventilation may cause retrograde flow of gas into the bypass channel. This may increase vaporizer output and the concentration of anesthetic levels reaching the patient. This is overcome by: one way unidirectional check valve at the outlet tube to minimize the pumping effect. NB. The output of the vaporizer depends on the temperature but NOT on the barometric pressure. Therefore the output of the vaporizer is the same at high and low altitudes and in pressurized chambers. Vaporizer mounting systems: a) Permanent mounting. b) Detachable mounting: selectatec on the back bar of the anesthetic machine. Advantages of selectatec vaporizers: Allows quick and easy removal or installation of any vaporizer by the user. Allows replacement of the vaporizer without interrupting the flow of gas. Interlock: allows the use of only one vaporizer at a time (avoids unintentional opening of both vaporizers at once) so prevents contamination of the downstream vaporizer by the upstream one. Avoids accidental simultaneous administration of 2 volatile agents. If malignant hyperthermia is a potential problem the vaporizers can be removed and the machine is decontaminated by continuous flushing with O2. This gives better results than if the vaporizer remains on the anesthetic machine in the off position. Disadvantage of selectatic system: substantial leakage may occur by improper fitting of the vaporizer on the back bar. Therefore leakage test must be done with the vaporizer turned on (see vaporizer leak check p.14). NB. Excessive titling of older vaporizers during transport may flood the bypass channel with the liquid anesthetic and lead to dangerously high anesthetic levels. This is avoided by the T switch on the concentration dial in more recent vaporizers. Safety features of vaporizers: 1) They are agent specific and do not allow misfilling: this is achieved by agentspecific connector for vaporizer filling. 6 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal 2) Do not allow over-filling because the filler port is located at the maximum safe level of the liquid anesthetic. Side-fill systems prevent over-filling rather than top-fill designs. 3) Do not allow cross-filling or trans-filling. When 2 vaporizers are arranged in series the downstream vaporizer will be contaminated with the agent from the upstream vaporizer if both were unintentionally opened at the same time. This is prevented by the use of an interlock mechanism that prevents the concurrent use of more than one vaporizer at a time. 4) Do not allow leaks from the vaporizer into the circuit. When the vaporizer control knob is in the off position, both inlet and outlet ports to the vaporizing chamber should be occluded to avoid contamination of gas from the flowmeters with traces of anesthetic. 5) T = transport on the control knob prevents flooding of the bypass area if the vaporizer was titled during transport. 6) Vaporizer interlock ensures that: (1) Only one vaporizer is turned on at a time, (2) gas enters only the one which is on, (3) trace vapour output is minimized when the vaporizer is off, (4) vaporizers are locked into the gas circuit, thus ensuring they are seated correctly. 7) Care of vaporizers: a. Frequent calibration. (N.B. Dangerous halothane concentration = 10%) b. Frequent vaporizer evacuation is recommended for halothane every 1-2 weeks to prevent accumulation of thymol (a preservative) which is concentrated after halothane is vaporized and then administered to the patient in high concentrations causing: acute lung injury. It is washed by a bottle of halothane. 8) Hazards of vaporizers: a) Misfilling by incorrect agent. f) Underfilling: produces a fall in vaporizer output. b) Tipping ≥ 45oC. Causes filling of bypass chamber → ↑ vaporizer output & overdose. c) Simultaneous inhaled agent administration (eg: halothane and isoflurane together). d) Overfilling → liquid enters bypass chamber → pt overdose (up to x10 times). e) Leaks: are relatively common, often due to malposition of vaporizers on the selectatic back bar or loss of gaskets. Therefore leakage test must be done with the vaporizer turned on. (Vaporizer leak check p.14). Desflurane Vaporizer: Conventional vaporizers are unsuitable for desflurane because it has unique physical properties: 1. Low boiling point= 23oC (near room temp = 20oC). (Nearly boiling at room temp). 2. Low potency i.e. MAC= 6-9% therefore more vaporization is required which in turn causes more cooling effect that would overwhelm the ability of conventional vaporizers (5 kg Cu) to maintain a constant temperature. Therefore desflurane vaporizer is electrically heated to 39oC (double room temp = 20oC) and pressurized to 1500 mmHg (double atmospheric pressure = 760 mm Hg). Desflurane vaporizer is the only vaporizer affected by high altitudes. ► Calculation of the amount of anesthetic liquid consumption (ml/min): [FGF] (fresh gas flow L/min) x [concentration] x [constant] [The constant for halothane = 0.054 isoflurane = 0.050 sevoflurane = 0.055 per minute ~ 3 per hour.] Eg. Amount of iso used per min if the concentration is 1% and FGF is 8L/min: 8 x 1 x 0.05 = 0.4 ml/min (x 60 = 24 ml/hr). Roughly: 3 x [Fresh gas flow (FGF) (L/min)] x [concentration (volume %)] = mL liquid used per hour. 7 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal (4) Breathing Circuits/systems Components of a breathing circuit: A. B. C. D. E. Inspiratory limb Expiratory limb Pt limb (Y piece) Fresh gas inlet APL valve (adjustable pressure-limiting valve): to control pressure inside the circuit. 1. Fully open: during spontaneous ventilation. 2. Partially closed: during assisted manual ventilation. 3. Closed: during controlled mechanical ventilation. (In this case the ventilator exhaust valve allows gases to exit outside the circuit.) NB. If the valve is left unintentionally closed FGF continues to enter the circuit with a risk of barotrauma. The valve is designed to open at a peak pressure 60-70 cm H2O to avoid barotrauma to the patients lungs = pressure relief). (Pressure relief of APL valve of the Jackson-Rees pediatric circuit: 35 cm H2O). F. Reservoir Bag: is designed with a high compliance, and designed to ↑ in compliance when its volume increases. It is highly distensible and rarely reaches pressures above 60 cm H2O to avoid barotrauma. G. Additional components: O2 sensor, flow sensor, pressure sensor, capnogram, gas analyzer. Properties of breathing tubes: Made of: rubber (reusable, non-autoclavable, anti-static properties), silicon (reusable, autoclavable, expensive), or plastic (disposable single-use). Corrugated: to avoid closure during kinking. Coaxial systems (e.g. Bain): outer tube transparent to show inner tube (to visualize kinks or disconnections). Diameter: wide 22 mm to create a low resistance pathway to expiration. Volume: should at least equal the patients tidal volume to act as a reservoir. (Very large volumes are avoided as they will increase FGF requirements). Compliance: very important during positive pressure ventilation. High compliance circuits make a greater difference between the volume of gas delivered to the circuit and the volume reaching the patient. The compliance of the standard adult breathing circuit is 5 ml/ cm H2O. The compliance of the rubber breathing circuit is 9 ml/ cm H2O. The compliance of the standard pediatric breathing circuit is 1.5-2.5 ml/ cm H2O. Silicon circuits have the least compliance (therefore used in ICU ventilators). Classification of breathing systems: (A) Open systems: Mapleson classification: A B C D E F (B) Closed/ circle system. Advantages of the closed circuit: (see Hazards of closed circuit p.27) 1- More economic (less consumption of expensive volatile agents and O2) eg. sevoflurane 2- Less pollution & contamination of operating room by exhaust gases. 3- Humidification and heating of inspired gases: reduces heat loss from the pt. Components of the closed circuit: (In addition to the above components) (A) CO2 absorbent (soda lime/ baralyme). (B) Inspiratory and expiratory unidirectional valves. (A) Unidirectional flow valve: Formed of a disc resting on a valve seat mounted in a transparent glass dome so that they can be observed to be functioning correctly. 8 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Forward flow displaces the disc upwards allowing gas to pass through the circuit. Reverse flow pushes the disc downwards preventing the return of gas. The expiratory valve placed on the expiratory limb is exposed to humidity of expired gas so it can be differentiated from the inspiratory valve by water vapour. Valve incompetence can cause rebreathing of CO2 resulting in hypercapnia. Stuck valve: If the valve sticks in open position rebreathing occurs, if it sticks in the closed position total occlusion occurs → barotrauma. (B) Canister (CO2 absorber): Placed on the expiratory limb. Transparent walls: to allow clear visualisation of the colour indicator dye. Uniform dispersion of exhaled gases to minimize channelling (→ incomplete CO2 absorption). The water formed by the reaction of soda lime with CO2 is useful in: (1) humidification of inspired gases, (2) dissipation of heat produced by the reaction (exothermic). The heat of the reaction can be detected by warmth of the canister. (Temp at the centre may exceed > 60oC. Absence of this warmth indicates failure of the soda lime). When CO2 is absorbed the colour of the dye will change. Ethyl violet is the most common indicator dye used. Its colour changes from white to violet when soda lime is exhausted. Exhausted granules may revert to their original colour if left, but must not be used because their absorbing capacity is not recovered. The CO2 absorber should be replaced when 50-70% of the granules have changed colour. Fresh gas flow FGF requirements for different circuits (to prevent rebreathing): Circuit Figure Spontaneous Mechanical (CMV) (a) Mapleson D 2-3 x MV 1 x MV (Bain) (inefficient) (MOST efficient) (10-12 L/min) (6-7 L/min) (b) Mapleson E (T-piece) ICU (Ayres T-piece) 2-3 x MV _ (c) Mapleson F 2-3 x MV (6-7 L/min) Pediatric MV~3L 1 x MV (Jackson Rees modification of Ayres T-piece) for ≤ 25 kg (d) Closed circuit (a) open circuit (full flow) (b) semi-closed (half flow) (c) low flow 1 x MV (6-7 L/min) < ½ MV (3-4 L/min) < 1 L/min MUST be monitored by capnography ► Mapleson E= Ayres T-piece. ► Mapleson F= modification of (Mapleson E = T-piece) by the addition of a small open-ended bag (0.5 L). ► The pediatric circuit Mapleson F has been further modified by the addition of an APL valve (with pressure relief = 35 cm H2O) and a closed-ended bag. ► Additional components of the breathing circuit: a) O2 sensor (analyzer): on inspiratory limb (measures FiO2). b) Flow sensor: on expiratory limb (measures Expired tidal volume VTE). c) Pressure sensor: on inspiratory limb (measures airway pressure cm H2O). 9 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal d) Capnogram: on patient limb (measures inspired and expired CO2). e) Gas analyzer: on patient limb (measures inspired and expired gas concentrations). ► General rule: the more the connections in a breathing circuit (eg. water traps, filters, capnography) → the higher the incidence of disconnections (esp. water traps → leakage). ► Apparatus dead space: The part where there is no gas exchange through which inspiration and expiration occur. Eg: face mask, ETT, patient limb of the breathing circuit (Y piece), bacterial filter, main stream capnography. ↑ dead space → ↑ rebreathing → ↑ PaCO2. Safety features of breathing circuits: 1) 2) 3) 4) 5) 6) 7) 8) Corrugated to prevent kinking. In coaxial circuits outer tube is transparent to enable visualization of inner tube. APL valve pressure relief = 60 cm H2O in adult and 35 cm H2O in Jackson Rees circuit. Highly distensible compliant reservoir bag, does not exceed pressure of 50 cm H2O. Bag/ventilator switch to avoid errors with APL valve (eg. forgetting the valve open). Soda lime canister transparent to enable visualisation of colour indicator dye. The dome of unidirectional valve is transparent to show the inner disc. Recent CO2 absorbent Amsorb: does not result in formation of compound A (with sevoflurane) and Carbon monoxide (with Desflurane, Isoflurane & Enflurane = DIE). 9) O2 sensor should be used. Its alarm limit is set to sound when FiO2 falls below 30%. Capnography: excellent monitor for (1)intubation, (2)breathing circuit, (3)ventilation, (4)pulmonary perfusion. It can detect: esophageal intubation, disconnection, leakage, obstruction, rebreathing, soda lime exhaustion, dysfunction of unidirectional valves, hypo & hyperventilation, curare cleft, pulmonary embolism, cardiac arrest. Types: a) Main stream: attached to the patient limb of the breathing circuit. Adds to apparatus dead space. b) Side stream: sampling tube/line takes a sample of the tidal volume to be analyzed within the monitor. (5) Ventilators A ventilator replaces the reservoir bag in the breathing circuit. Power source: b) Pneumatic-driven (flow-driven): by pneumatic O2 power from pipelines (e.g. penlon). Does not require a generator/batteries during electrical power failure. c) Electrically-driven: requires a generator/batteries in case of an electrical power cut. Method of cycling from inspiration to expiration: Termination of the inspiratory phase and beginning of the expiratory phase is triggered by one of the following: a) Volume-controlled ventilation: delivers gas until a preset tidal volume is reached, regardless of the opposing pressure. Usually there is a pressure limit setting that allows venting of excessive pressure to prevent barotrauma. . (Can compensate for obstruction but not for leakage). b) Pressure-controlled ventilation: delivers a volume until a preset pressure is reached. (Can compensate for leakage but not for obstruction). c) Time-cycled: Gas flows into the lungs until a preset inspiratory time is reached (fixed duration). The method of ventilation most commonly used in modern anesthesia machines in adults is: time-cycled, volume-controlled, pressure-limited. 10 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Ventilator design: Double circuit system More common in modern ventilators. There are 2 distinct pneumatic circuits within the ventilator that are separated by the bellows: The internal circuit: It is the tidal volume preset by the anesthesiologist delivered to the patient from the bellows. It contains anesthetic gas mixture. The bellows (concertina) takes the place of the anesthetic bag on the breathing circuit. Tidal volume is determined by adjusting the level of the bellows. The bellows is formed from rubber or latex-free material situated in a clear rigid plastic case/cylinder. There are 2 types of bellows classified according to the direction of movement of the bellows during the expiratory phase: a) Ascending: attached at its base and ascends during expiration. Used in modern ventilators. b) Descending (hanging): attached at the top and descends during expiration. Used in old ventilators. Ascending bellows is safer because will not fill during expiration and will draw attention if a leakage or a total disconnection is present. On the other hand descending/hanging bellows will continue its upward and downward movement in spite of a leakage or total disconnection in the breathing circuit due to the effect of gravity especially weighted bellows. Fails to draw attention to disconnection or leakage. The external circuit: driving gas It is the compressed gas (3.5 bar) which acts as the driving force that compresses the bellows. It is present between the outside wall of the bellows and the inside wall of the plastic container. Pressurization of gas in the external circuit compresses the pleated bellows forcing the gas inside the bellows into the breathing circuit and to the patient. The driving gas is either 100% O2 or a mixture of O2 and air. It is safer to have pure O2 as the driving gas because the FiO2 will be reduced if there was a leak in the bellows. A leak in the bellows can transmit high gas pressure from the external circuit to the patient (3.5 bar), potentially causing pulmonary barotrauma, but the gas delivered to the patient will be enriched with O2. This problem can be detected by the O2 analyzer where an FiO2 higher than that adjusted will be present. Some ventilators have a built-in drive gas regulator that reduces the driving gas pressure to 1.7 bar for safety. A free breathing valve is incorporated into the external circuit to allow outside air to enter and the bellows to collapse if the patient generates negative pressure by taking spontaneous breaths during mechanical ventilation. (To prevent negative pressure pulmonary edema). The amount of O2 consumed to power the ventilator is at a rate at least equal to minute ventilation. Thus if O2 FGF is 2 L/min and the ventilator is delivering MV = 6 L/min, a total of at least 8 L/min of O2 is being consumed. This should be kept in mind if cylinder gas is being consumed (to keep in mind how long the cylinder will last). Some machines reduce O2 consumption by incorporating a Venturi device that draws in room air to provide O2-air pneumatic power (= injector device). 11 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Additional components in the ventilator 1) Bag/ventilator selector switch: When the switch is turned to “ventilator”, the breathing bag and APL valve are excluded from the breathing circuit. In such ventilators it is not necessary to close the APL valve during mechanical ventilation. When the switch is turned to “bag” the ventilator is excluded and spontaneous/ manual ventilation is possible. 2) Ventilator spill valve: Vents excess waste gas (patient expiration) from the ventilator into the scavenging system. During inspiration the valve is closed so that positive pressure can be generated. During expiration the valve is open and excess gas is vented out into the scavenging system. Sticking of this valve results in abnormally elevated airway pressure during expiration → barotrauma. Valve incompetence results in inadequate airway pressure during inspiration → hypoventilation. The scavenging connections must connect the exhalation port of the spill valve to the scavenging system. The spill valve has a minimum opening pressure of 2-4 cm H2O to enable the bellows to fill during expiration. This amount of PEEP is inevitably applied to the breathing system. 3) Ventilator exhaust valve: vents driving gas to the atmosphere. 4) Safety-relief valve: is built into a ventilator to limit the pressure in the bellows. It is usually preset to 65-80 cm H2O since pressures beyond those may cause serious barotrauma. Safety relief valves may function in either of 2 ways: When the pressure exceeds the safe limit the lungs are held inflated at the set pressure until the end of the inspiratory phase (inspiratory time). With the second type once the pressure limit is reached the inspiratory phase is immediately terminated and expiratory phase is started. Interaction between the ventilator and the breathing circuit: 2 factors can cause a difference between the ventilators preset tidal volume and the actual tidal volume actually delivered to the patient. Actual delivered VT = [preset VT] – [volume lost] + [volume added] Factors which decrease VT delivered: (Volume lost) 1) Breathing circuit compliance: this is the volume lost as the corrugated tubing distends/expands. Breathing circuits have a compliance of about 9 ml/cm H2O. It is calculated as: [PIP-PEEP] x [circuit compliance]. (Eg. PIP= 22 cmH2O, PEEP= 2 cmH2O [22-2] x 9 = 180 ml of the tidal volume will be lost due to tube expansion. 2) Gas compression: is about 3% so if the tidal volume is about 600 ml about 18 ml of the preset VT will be lost. Some new ventilators (gera7it atfal) during the initial electronic self checkout, measure the system compliance and use this measurement to make adjustments to compensate for the loss in tidal volume. 3) Gas sampling for capnography (sidestream) and anesthetic gas measurement (analysis) represent additional loss unless the sampled gas is returned to the breathing circuit as in some machines (~ 200 mL/min) Factors which increase VT delivered: (Volume added) FGF contributes to the tidal volume delivered to the patient. An increase in FGF from the anesthetic machine increases the delivered VT. All gas enters the breathing circuit 12 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal whether from the ventilator bellows or from the flowmeter. The volume of gas dispensed from the anesthetic machine during inspiratory cycle depends on the inspiratory time (TI) and the fresh gas flow rate (FGFR). It is calculated as: TI x FGFR (eg. TI = 1.5 sec, FGF= 8L/min = 133 ml/sec so 133 x 1.5 = 200 ml added to the tidal volume). Modern ventilators have mechanisms to compensate for changes in FGF: fresh gas flow decoupling where excess tidal volume is vented to the reservoir bag during the inspiratory phase (Dragger: Cicero, Fabius, Primus). [see p.19 & 20] Monitoring during mechanical ventilation: 1. Clinical observation of the pt: colour and chest inflation. Sound of the ventilator. 2. Disconnection and leakage alarms: low peak inspiratory pressure (low airway pr alarm), low exhaled VT (VTE). 3. Airway pressure: low, high, continuously elevated, subatmospheric. 4. Measurement of inspired and expired VT by flow sensor (spirometer). 5. Measurement of FiO2 by O2 sensor (analyzer). 6. Pulse oximetry & plethysmography. Hemodynamic monitoring. 7. Capnography & ETCO2. 8. Measurement of O2 supply pressures: by Bourdon gauge. If it is low, visual and audible alarms should be activated: O2 supply failure alarm (O2 whistle alarm). Safety features for ventilators: 1) 2) 3) 4) 5) Ascending bellows safer than descending to detect leakage and disconnections. Driving gas: pure O2 is safer than a mixture of O2 and air. A bag/ventilator switch to avoid problems of APL valve. Presence of alarms. O2 pressure supply to the anesthetic machine by Bourdon gauge should not be below 4 bar (otherwise O2 fail safe alarm must be activated giving audible and visual alarms: O2 whistle alarm). 6) The use of the O2 flush valve during the inspiratory cycle of the ventilator must NEVER be done because the pressure will be transmitted to the patients lungs resulting in barotrauma. Checklist for the Anesthesia Machine 1- Ventilator check: check for full re-expansion of the bellows at high O2 flow. Then reduce O2 flow to 1 L/min & ensure full re-expansion. Check VT, and RR (ventilator settings). 2- Leak check for the Anesthetic Machine: a) Open flowmeter. b) Occlude FGF outlet. c) This should create a backpressure indicated by a drop in the flowmeter bobbins. When the FGF outlet is released the bobbins briskly rebound and return to their original height. d) If the bobbins do not drop this indicates a substantial leakage within the anesthesia machine. e) The site of leakage can be detected by sound or by a soap solution that will create bubbles!! (like 3agalaty). 3- Leak check for the Breathing Circuit and Bag: a) Open flowmeter. b) Attach reservoir bag to its position on the breathing circuit. Close APL valve. c) Occlude Y piece (the end of the breathing circuit = patient limb). d) Pressurize breathing circuit to about 30 cm H2O with O2 flush. e) Ensure that pressure remains fixed for at least 10 seconds & there is no source of leakage. 13 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal 4- Leak check for the Vaporizer: a) Open flowmeter. b) Switch vaporizer ON. c) Occlude FGF outlet. d) This should create a backpressure indicated by a drop in the flowmeter bobbins. e) When the FGF outlet is released the bobbins briskly rebound and return to their original height. f) If there is a substantial leak from the vaporizer, the bobbins will not drop. (6) Scavenging systems Sources of OR pollution: 1) Exhaled gases from the APL valve (spontaneously breathing patient). 2) Exhaled gases from the ventilator exhaust (mechanically ventilated patient). 3) Leaks from equipment: cylinders, pipelines, flowmeters, vaporizers, breathing circuits. 4) Spillage during filling of vaporizers. Importance of the scavenging system: Risks to OR personnel of chronic exposure to trace quantities of anesthetic agents: 1. Increased risk of spontaneous abortion. 2. Increased risk of congenital anomalies (teratogenicity). 3. Cancer. 4. Hepatic disease as serum hepatitis. 5. Renal disease. 6. Neurological disease from exposure to N2O. Methods of reducing OR pollution: 2. Scavenging system. 3. Closed circuit (circle system). 4. Filling of vaporizers by agent-specific connections to reduce spillage. 5. Efficient non-recirculating air conditioning to allow efficient OR ventilation: 15 changes per hr. Recommended upper limit for traces of anesthetic gases in OR: N2O: 25 ppm (part per million). Halogenated agents without N2O: 2 ppm. Halogenated agents without N2O: 0.5 ppm. There are 3 methods of gas disposal: a) Active disposal system: withdraws waste gases to the outside by creating –ve pressure (suction or vacuum). This system should contain a positive pressure relief valve to vent excess waste gases to the atmosphere if the system pressure exceeds +5 cm H2O, and a negative pressure relief valve to entrain room air if the system pressure falls below -0.5 cm H2O to prevent negative pressure pulmonary edema. b) Passive disposal system: conducts waste gases through wide bore tubes to avoid the presence of resistance against the pts expiration. Contains a positive pressure relief valve only, to prevent build up of positive pressure in the breathing system above +5 cm H2O if an obstruction occurs in the disposal system. c) Assisted passive disposal system: (Ta7’assusi) uses non-recirculating air conditioning system of the OR for elimination of waste gases where the gas disposal tubing is connected to exit (suction) of the non-recirculating central air conditioning system. 14 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Safety features of scavenging systems: 1) Tubing should have a colour code of yellow bands to distinguish them from the breathing system tubing. 2) All connections of the scavenging system should be 30 mm in diameter to: (1) avoid misconnections and (2) decrease resistance against expiration of the patient. (N.B. anesthetic breathing system connections are standard: 15 mm and 22 mm in diameter). 3) Active disposal system should include: positive and negative pressure relief valves. 4) Passive disposal system should include: a positive pressure relief valve only. Other safety measures of the anesthesia machine: (A) Safety measures against disconnection: locking connector (locks the breathing circuit to the common gas outlet), pressure disconnection alarms, and volume disconnection alarms. (B) Airway pressure monitoring: low, high, continuously elevated, subatmospheric. (C) Gas analysis: O2, CO2, anesthetic gases (N2O), volatile agents, carbon monoxide. (D) Miscellaneous: internal battery in case of electrical power failure, or flow-driven ventilators. (E) Electrical safety in OR. Electrical Safety in OR Electrical hazards: (A) Electric shock. (B) Diathermy: burns, electric shock, pacemaker dysfunction. (C) Fires and explosions. (A) Electric shock: a) Macroshock: produces VF when a current of 100-200 mA is applied to the skin and passes to the heart. b) Microshock: produces VF when a current of 50-100 μA is applied directly to the heart while the patient is earthed (eg: through 1- intracardiac pacemaker, 2saline-filled central venous line, 3- cautery in open heart surgery, 4- esophageal temp probe). The electric current may be produced due to: 1) Defective insulation in the device circuit even with very small current. 2) Leakage current which is a small current occurring in all electrical equipment. These small currents (50-100 μA) are not capable of producing gross electric shock (macroshock), but may cause microshock if directly applied to the heart as above. The RULE is: to GROUND/EARTH all electrical equipment and to ISOLATE the patient. EVERYTHING in OR should be grounded EXCEPT the PATIENT who should be isolated NOT earthed. Although earthed equipment is protective, patients are still at risk of developing electric shock when the patient is earthed in the following conditions: 1. When the feet/arms of the patient are touching the stem of a portable lamp or metal stand or the OR table which is earthed. (This is avoided by the wheels of metal stands are made of insulating material). 2. When the patient lies on an electrical warming blanket which is earthed. 3. When the patient is connected to a monitor through ECG electrodes which are earthed. 4. When the anesthesiologist is in contact simultaneously with the earthed casing of the device and with the patient. 15 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Timing of the current flow through the heart: if the current passes through the heart during the vulnerable period = the repolarization of the muscle cells (during the downstroke of R wave and early T wave of the ECG) the risk of VF will be greatest. Safety measures for protection of electrical equipment: 1) Earthed equipment: device is connected to an earth wire: the third wire in the mains supply socket. 2) Fuse (circuit breaker): is included in the circuit so that if a short circuit occurs the high current will melt the fuse and the circuit will be interrupted before a fire or electrocution occurs. 3) Double insulated: protected by 2 layers of insulation or a single layer of reinforced insulation. 4) Monitoring equipment: Isolated patient circuits: (eg. ECG, temp probe) use an isolated pt circuit (floating circuit) that connects the patient to a secondary circuit away from the mains supply. The electric current of the equipment is divided into 2 parts: mains part, and isolated part (which is not earthed and is separated by an electrical barrier). (B) Diathermy (Electrocautery): Definition: is a device that uses electrical current to cut and coagulate the tissues by generating very high frequency currents VHF (0.5-2 MHz). When an electric current enters the body it causes an electric burn at the inlet and exit and if the current passes through the heart VF may occur. VHF currents do not cause VF (ventricular fibrillation) as they have low tissue penetration and do not excite cardiac muscle cells. (Heart responds to 50 Hz = domestic electric current). Electric current enters the device from the mains power supply as 50 Hz and is converted into 0.5-2 MHz. Any fault in the device which fails to convert to high frequency current may cause VF. Precaution: an isolating capacitor is placed in the return plate which breaks the circuit and prevents passage of 50 Hz current. Types: a) Unipolar: has one active electrode and one return electrode. The active electrode used by the surgeon has a very small area at its tip. The return electrode (patients plate) has a large surface area and returns the current from the patient to the surgical diathermy unit. It is a large metal plate covered with a pad which must be well gelled by a conducting gel and must be applied to a well perfused, nonhairy (hair → ↓ conduction. Must be shaved.) large skin area of the patient (eg. buttocks, thigh, calf). The large surface area in contact with the patient produces a low current density so that it dissipates the heat and does not produce burns. b) Bipolar: has 2 active electrodes like 2 arms of a forceps. When applied to the surgical area, the electric current flowing through the tissues is confined to the few millimetres between the 2 electrodes. Therefore it has no return electrode/plate as the current passes between the 2 electrodes and not through the patient. It is safer than unipolar diathermy. Hazards of diathermy: 1. Diathermy burns: A burn is liable to occur with unipolar diathermy under the following conditions: a) If the pad covering the plate becomes dry, or the gel is off. b) If the plate has a small surface area in contact with the skin. c) If the plate is not well applied to the skin or if applied to a hairy area. 16 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal 2. 3. 4. 5. d) If the wire connecting the return plate to the surgical diathermy unit is broken or disconnected. In these cases the current will find another pathway to return to the surgical diathermy such as ECG electrode, or metal parts of the OR table in contact with the patient, thus resulting in a cautery burn. Pacemaker dysfunction (see precautions). Fires and explosions (rare nowadays with the use of non-flamable anesthetics). Electric shock. Interference with electronic monitoring equipment: ECG, pulse oximeter. (C) Fires and Explosions: In order for a fire to occur 3 elements must come together at the same time: fire triad: 1-fuel 2-spark (source of ignition or heat) 3-oxidizing gas. 1) Fuel: (flammable materials) they are organic materials that contain carbon atoms such as: flammable anesthetic agents: cyclopropane and ether which are no longer used in anesthetic practice. Ethyl alcohol used for sterilization. Ethyl chloride local anesthetic spray. 2) Spark: (source of ignition or heat): includes a) Heat: open flame, cautery, hot bulbs, laser beam, heat from soda lime (CO2 interaction with soda lime → exothermic reaction). b) Sparks: from diathermy, switches, electric equipment. c) Static electricity: generated from synthetic non-conducting materials as rubber, wool, nylon, plastic. 3) Oxidizer: (supporting atmosphere: must contain oxygen): O2, N2O, or air act as oxidizing gas in the OR which support combustion. Types of OR fires: 1. LASER fires of upper and lower airway. 2. During tonsillectomy: in children uncuffed ETT are used which allow leakage of O2 and N2O around the tube. When cautery is used fire may occur. Precautions: (1) use O2-air mixture, (2) wet oral packs around the tube by the surgeon. 3. During tracheostomy: if cautery is used ignition of ETT may occur. Precautions: (1) Use O2-air (2) dissection is more preferred than cautery. 4. Laparoscopy: after 30 mins of O2-N2O anethesia N2O diffuses into the abdominal cavity. If the gut was injured methane and hydrogen gases (fuel) escape into the abdominal cavity so when cautery is used combustion may occur. This becomes severe if N2O was used as an insufflating gas. (CO2 does not support combustion). 5. Skin sterilization using alcohol. (*V.Imp: alcohol + cautery = fire). Safety precautions to prevent fires and explosions: 1) AVOID the use of flammable anesthetic agents: ether, cyclopropane. All modern volatile agents are non-flammable, non-explosive (halothane, iso, sevo, des, enflurane). O2 and N2O are not flammable but support combustion. 2) Prevention of electric sparks: periodic checking of electrical equipment ( ص يان ة (دوري ةspark-proof switches. 3) Prevention of static electricity: antistatic measures/ materials: contain carbon (hence the black colour of anesthetic breathing bags, circuits, masks, & wheels of tables. Nowadays due to the use of non-flammable anesthetics different colours are now present). Antistatic floors, clothes (cotton) avoid synthetic materials and wool, wheels of OR tables, anesthetic machines, fluid supports, antistatic rubber shoes for OR staff. Humidity of OR should not be less than 50%. Earthing of 17 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal electrical equipment to conduct static charges to earth. (Most of these recommendations are disregarded in modern anesthetic practice). 4) Fire-extinguishing equipment: Halon, CO2, pressurized water. 5) Special precautions during: LASER, tonsillectomy, tracheostomy, laparoscopy. Hazards of Anesthesia and OR Equipment (A) Medical gas supplies (pipelines & cylinders): O2 failure, malfunction of pr reducing valves → damage anesthetic machine, misfilling of cylinders, over-filling, explosions, entonox → hypoxic mixture. (B) Flowmeter: leakage, hypoxic mixture. (C) O2 flush valve: accidental locking → barotrauma, awareness. (D) Vaporizer: miscalibration, underdosing → awareness, overdosing → toxicity & delayed recovery, misfilling by wrong agent, leakage from selectatic mounting system, tipping → overdosing, malignant hyperthermia from leakage of trace anesthetic agents. (E) Ventilator: (hazards of mechanical ventilation) hypoventilation, hyperventilation, hypoxia, hypercapnia, barotrauma, + hazards & complications of intubation. Obstruction of spill valve → barotrauma, driving gas leak → hypoventilation, tear in bellows → barotrauma, hypoventilation. (F) Breathing circuit: disconnections, leakage, kinks, closed circuit (low flow): rebreathing, incompetent unidirectional valve → rebreathing, stuck unidirectional valve → barotrauma, soda lime: compound A, carbon monoxide, fires & explosions, exhausted → hypercapnia. (G) Scavenging system: excessive +ve pressure or –ve pressure barotrauma. (H) Electrical hazards: electric shock, diathermy (burns, pacemaker dysfunction, fires), fires & explosions. (I) Hazards of anesthetic drugs. Alarms of the Anesthesia Machine: causes & management RULE: NEVER ignore an alarm by the anesthesia machine/ventilator!! (A) Low airway pr: disconnection, leakage, disconnection of pressure line. Perform leakage test to search for disconnection or leakage in the breathing circuit or ventilator. (B) High airway pr: a) High peak + high plateau pr = ↓compliance: restrictive airway disease (problem with lung parenchyma, pleura, chest wall): (pulmonary edema, ARDS, endobronchial intubation, pneumothorax, obesity, kyphoscoliosis). b) High peak + normal plateau pr = ↑ resistance: obstructive airway disease (problem with the airways): (bronchospasm, kinked ETT, mucus plug). (C) Continuously elevated airway pr: Def: airway pr > 18 cmH2O for more than 10 seconds. Causes: obstruction of ventilator spill valve, scavenging system malfunction. Disconnect patient immediately otherwise barotrauma will occur and use Ambu bag. (D) Negative/ subatmospheric airway pr: spontaneous breathing, scavenging system. May result in negative pressure pulmonary edema. (E) Low VTE: expired tidal volume less than adjusted tidal volume: search for leakage. (F) Apnea alarm: disconnection, ventilator switched off, ventilator malfunction, pt on bag. (G) O2 sensor failure: (unfortunately common in many of our ventilators). (H) Flow sensor failure: (unfortunately common in many of our ventilators). ********* Thank You ********* 18 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Ventilators contd. In traditional ventilators (which are not fresh gas decoupled), the delivered tidal volume is the sum of the adjusted volume delivered from the ventilator bellows, and the fresh gas flow delivered during the inspiratory phase of each breath cycle. Thus, delivered tidal volume may change as FGF is changed. Modern ventilators can compensate the delivered tidal volume for changes in fresh gas flow (FGF). There are two approaches to dealing with this problem: fresh gas flow compensation and fresh gas flow decoupling (FGD). The first approach is fresh gas compensation. The volume and flow sensors provide feedback which allows the ventilator to adjust the delivered tidal volume so that it matches the set tidal volume, in spite of changes in the total fresh gas flow. The second approach is fresh gas decoupling (FGD) used in piston ventilators. Fresh Gas Decoupling: means to prevent the fresh gas flow from affecting the tidal volume by isolating (decoupling) the fresh gas flow so that it does not enter the breathing system during inspiration. The ventilator decouples fresh gas flow from tidal volume. Piston ventilators Piston ventilators use an electric motor to compress gas in the breathing circuit, creating the motive force for mechanical ventilation. The motor's force compresses the gas within the piston, raising the pressure within it, which causes gas to flow into the patient's lungs. Thus a piston ventilator uses no driving gas, and may be used without depleting the oxygen cylinder in case of oxygen pipeline failure. During the inspiratory phase fresh gas is diverted to the manual breathing bag by a decoupling valve and is thus not added to the delivered tidal volume. This decoupling is achieved by storing fresh gas in the reservoir bag during the time when the piston is pushing inspiration. As fresh gas is stored during inspiration the reservoir bag expands and fills. During the expiratory phase piston retraction draws in expired gas from the lungs and fresh gas accumulated in the reservoir bag. Thus fresh gas decoupling helps ensure that the set and delivered tidal volumes are equal. The piston ventilator has positive and negative pressure relief valves built in. If the pressure within the piston exceeds 75 + 5 cm H2O, the positive pressure relief valve opens protecting the patient from barotrauma. Movement of the piston (retraction) in the expiratory phase may create negative pressure in the system. If the pressure within the piston declines to -8 cm H2O, the negative pressure relief valve (NPR) opens, and room air is drawn into the piston, protecting the patient from NEEP (negative endexpiratory pressure). Implications of “Decoupling” Reservoir bag is included in the circuit during ventilation (not excluded from the circuit as in double circuit ventilators). With fresh gas decoupling, if there is a disconnection, the manual breathing bag rapidly deflates, since piston retraction draws gas from it. Removal or damage or disconnection of the reservoir bag (from poor fit on the bag mount or a bag perforation) during mechanical ventilation, results in a significant leak. Room air may enter the breathing circuit as the ventilator piston unit refills during the expiratory phase. This could result in dilution of the inhaled anesthetic agent concentration resulting in intraoperative awareness, as well as dilution of the enriched oxygen mixture resulting in hypoxemia. This type of a disruption could also lead to significant 19 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal pollution of the operating room with anesthetic agents escaping into the atmosphere as fresh gas is diverted to the damaged breathing bag during inspiration. Double circuit ventilators Driving force Driving gas: O2. (electrically powered). Bellows Bellows present. End expiratory PEEP is created during pressure expiration necessary for inflation of the bellows. NPR valve Not necessary. FGD No FGD (some ventilators use fresh gas compensation). Breathing Bag Isolated from the circuit during mechanical ventilation. 20 Piston ventilators Mechanically & electrically driven by a piston. Piston (cannot utilise bellows). NEEP is created during expiration by piston movement. Must be incorporated. FGD present. Included in the circuit during mechanical ventilation. What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Figures for Anesthetic Machine Components of the anesthesia machine. 21 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Model & diagrammatic representation of the anesthesia machine. (1) Medical gas supplies O2 N2O CO2 Air Entonox Homework: colour and label the above cylinders. Dip tube for Entonox cylinders. Manifold of O2 cylinders. 22 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal PISS (cylinder yoke at the back of machine). DISS (diameter index safety system) for pipelines. PISS code. PISS (pin index safety system) for cylinders. (2) Flowmeters Diagram of the flowmeter. (2-tube O2 flowmeter). 23 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Arrangement sequence of flowmeters (flow leaks). O2:N2O proportionator/ ratio controller: chain link. Correct sequence: O2 downstream (USA), or upstream through a separate channel (UK). Hypoxic guard (25% O2 minimum). 200 cc/min minimum O2 basal flow preset. Anti-hypoxic device. 24 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Digital flowmeters. (3) Vaporizers Diagram of the vaporizer. Diagram of the Desflurane vaporizer. (x2 temp= 39oC, x2 pressure= 1500 mmHg). Back bar of the anesthesia machine selectatic system. 25 Agent specific connector. What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Leak test: After fitting vaporizer check for leaks with it turned ON. T switch (for transport/ tilting) (4) Breathing Circuits Mapleson classification of breathing circuits. Mapleson F:Jackson-Rees modification of Ayres T-piece (+ valve and closed ended bag). Mapleson D and its coaxial modification (Bain Circuit). 26 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal APL valve. APL safety limit: (Bain= 60 cm H2O) (Pediatric Jackson Rees= 35 cmH2O). The closed circuit (circle system) with CO2 absorber and unidirectional valves. Silicon (left) and plastic (right) circuits. Unidirectional valve (closed circuit) Bourdon pressure gauge. Green shaded safe zone (2.5-6 bar). Injector component of the ventilator. For pipeline & cylinder pressure. 27 What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal (5) Ventilators Parts of a ventilator (2 circuits). Descending bellows. Dr.Olla &Dr.Zeer 4got the APL valve closed !! Airway pr doesnt exceed 40 cmH2O. (6) Scavenging system (Hanging bellows) Difference between VT (adjusted tidal volume) and VTE (expired) Why?? 28 Scavenging system outport. What do we Need to Know about the Anesthesia Machine? A Practical Guide. By Doaa Kamal Electricity Hazards of Closed Circuits & Low Flow Anesthesia: 1. Hypoxia → O2 analyzer is essential (for inspired & expired O2 concentrations). 2. Hypercapnia (exhausted soda lime) → capnography is essential. 3. Awareness/light anesthesia → gas analysis is essential. 4. Low FGF cannot produce rapid changes in concentration & depth of anesthesia. High FGF must used during induction & recovery. 5. Accumulation of toxic gases eg. carbon monoxide, haloalkene toxins (from interaction of volatile agents + soda lime). Unipolar diathermy/cautery. Unipolar diathermy/cautery (monopolar). Bipolar diathermy/cautery. Value of analysis: Anesthetic Gas 1. Calibration of the vaporizer (to monitor whether the vaporizer is giving the correct concentration). 2. Detection of vaporizer misfilling by wrong agent. 3. Detection of traces of volatile agent before anesthesia for malignant hyperthermia. 4. Measurement of trace anesthetic gas concentrations causing OR pollution. 5. Detection of N2 in expired gas = pulmonary air embolism. 6. Detection of CO poisoning. 7. Indicator of the degree of depth of anesthesia & recovery. 29