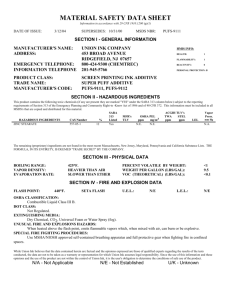

evaporation rate: slower than ether voc

advertisement

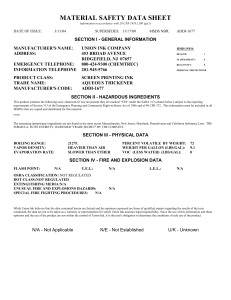

MATERIAL SAFETY DATA SHEET Information in accordance with 29 CFR 1910.1200 (g)(1) DATE OF ISSUE: 3/11/04 SUPERSEDES: 11/16/98 MSDS NBR: ADDI-2559 SECTION I - GENERAL INFORMATION MANUFACTURER'S NAME: ADDRESS: EMERGENCY TELEPHONE: INFORMATION TELEPHONE UNION INK COMPANY 453 BROAD AVENUE RIDGEFIELD, NJ 07657 800-424-9300 (CHEMTREC) 201-945-5766 PRODUCT CLASS: TRADE NAME: MANUFACTURER'S CODE: SCREEN INK ADDITIVE FINE ALUMINUM PASTE ADDI-2559 HMIS INFO: HEALTH: 2 FLAMMABILITY: 2 REACTIVITY: O PERSONAL PROTECTION: E SECTION II - HAZARDOUS INGREDIENTS This product contains the following toxic chemicals (if any are present they are marked "YES" under the SARA 313 column below) subject to the reporting requirements of Section 313 of the Emergency Planning and Community Right-to -Know Act of 1986 and of 40 CFR 372. This information must be included in all MSDS's that are copied and distributed for this material. HAZARDOUS INGREDIENTS ALUMINUM DUST ONLY AS DUST OR FUME STODDARD SOLVENT CAS Number 7429-90-5 8052-41-3 % 65 SARA 313 Listed Yes No MFR's TLV OSHA PEL ppm mg/m3 N.E. N.E. 2900 ACGIH TLV's TWA STEL ppm ppm 100 Vapor Press. LEL N/E 0.9 mm Hg N.E. 10 The remaining (proprietary) ingredients are not found in the most recent Massachusetts, New Jersey, Maryland, Pennsylvania and California Substance Lists. THE FORMULA, IN ITS ENTIRETY, IS DEEMED "TRADE SECRET" BY THE COMPANY. SECTION III - PHYSICAL DATA BOILING RANGE: VAPOR DENSITY: EVAPORATION RATE: N/E HEAVIER THAN AIR SLOWER THAN ETHER PERCENT VOLATILE BY WEIGHT: WEIGHT PER GALLON (LBS/GAL): VOC (THEORETICAL) (LBS/GAL): 35 12.5 4.4 SECTION IV - FIRE AND EXPLOSION DATA FLASH POINT: 116 F. C.O.C. U.E.L.: N/E L.E.L.: 0.9 OSHA CLASSIFICATION: Combustible, Class 2 DOT CLASS: Not Regulated. Ground – Flammable – Air / Ship EXTINGUISHING MEDIA: Foam, Dry Chemical. Use Class B extinguisher, inert granular material like sand, Class D extinguisher with low velocity nozzle. Do not use a water hose stream. UNUSUAL FIRE AND EXPLOSIONS HAZARDS: When closed containers are exposed to excessive heat, there is the possibility of pressure build-up inside the container. SPECIAL FIRE FIGHTING PROCEDURES: DO NOT USE A WATER STREAM. DO NOT USE HALOGENATED EXTINGUISHING AGENTS, LIKE HALON OR CARBON TETRACHLORIDE. Aluminum particles suspended in air may form an explosive mixture; avoid any disturbance which could cause a dust cloud, such as directing water streams or gas propelled fire extinguishers into the burning material. Direct the dry chemical extinguishing agent, above the fire, to rain down on the burning material. Care should be used when applying a dry chemical extinguishing agent because some agents can accelerate a fire where most of the solvent in the pigment has been consumed and the aluminum flake has started to burn. If the extinguishing agent is carefully applied, it will be very evident if it accelerates the fire. If it does, or if the fire at some point has the appearance of metal burning with a bright, whitish glow, do not attempt to extinguish it. Isolate the fire by forming a ring with a dry, inert granular material, or Class D extinguishing agent, then let it alone. Allow the material to become cold before disposal, because if the metal has ignited, it may continue to burn under a crust without flames. For further information, see NFPA 651, Aluminum and Magnesium Powder - 1980 While Union Ink believes that the data contained herein are factual and the opinions expressed are those of qualified experts regarding the results of the tests conducted, the data are not to be taken as a warranty or representation for which Union Ink assumes legal responsibility. Since the use of this information and these opinions and the use of the product are not within the control of Union Ink, it is the user's obligation to determine the conditions of safe use of the product. N/A - Not Applicable N/E - Not Established U/K - Unknown Page 2 - ADDI-2559 SECTION V - HEALTH HAZARD DATA PRIMARY ROUTE OF ENTRY: Skin, Eyes MEDICAL CONDITIONS WHICH MIGHT BE AGGRAVATED: None Known OVEREXPOSURE TO VAPOR MAY CAUSE: (ACUTE) Overexposure is unlikely at ambient temperature. Excessive high temperatures may produce irritating vapors. REPEATED OVEREXPOSURE TO VAPOR MAY CAUSE: (CHRONIC) None Known EMERGENCY AND FIRST AID PROCEDURES: Eyes - Flush with plenty of water for 15 minutes to remove irritant. Consult a physician. Skin - Wash with mild soap and water. Inhalation - Remove to fresh air. SECTION VI - REACTIVITY DATA STABILITY: Stable CONDITIONS TO AVOID: Avoid smoking, open flames, sparks and contact with water. INCOMPATIBILITY: Water, acids, caustics, chlorinated hydrocarbons and oxidizers. ALUMINUM - See NFPA 401 M, Manual of Hazardous Chemical Reactions, Aluminum. To prevent possible chemical reactions, keep dry and isolate from acids caustics, chlorinated hydrocarbons and oxidizers. Reacts with water, some acids and caustic solutions to produce hydrogen gas. HAZARDOUS DECOMPOSITION PRODUCTS: Combustion may produce smoke, CO and/or CO2 and aluminum oxide. Reaction with other chemicals may produce hydrogen. HAZARDOUS POLYMERIZATION: Will not occur. SECTION VII - SPILL OR LEAK PROCEDURES STEPS TO BE TAKEN IN CASE MATERIAL IS RELEASED OR SPILLED: Remove all sparks and flames from the area and allow hot surfaces in the area to cool. Use non-sparking tools to repack UNCONTAMINATED pigment in a dry, tightly sealed container. Check for quality. Dispose of contaminated material or waste. WASTE DISPOSAL METHOD: Sanitary landfill in accordance with local, state and federal regulations. SECTION VIII - SPECIAL PROTECTION INFORMATION VENTILATION: General dilution type adequate to keep dust levels below TLV in Section II. RESPIRATORY PROTECTION: None should be needed unless dust levels are high, then use a NIOSH approved dust respirator. PROTECTIVE GLOVES: Use chemical resistant gloves. EYE PROTECTION: Use eye protection appropriate for splash hazard. OTHER PROTECTIVE EQUIPMENT: Not required. SECTION IX - SPECIAL PRECAUTIONS PRECAUTIONS TO BE TAKEN IN HANDLING AND STORING: Avoid spillage and the creation of airborne dust. Vehicles in the same area should have non-sparking wheels. Store and use in areas free of excess water vapor, contaminating vapors or gases. Do not store in the same area as oxidizing agents or combustible material. OTHER PRECAUTIONS: Do not take internally. Use non-sparking metal tools for transfer. All equipment should be well grounded. FOR INDUSTRIAL USE ONLY KEEP OUT OF THE REACH OF CHILDREN DO NOT USE UNTIL MANUFACTURER'S SAFETY PRECAUTIONS HAVE BEEN READ AND UNDERSTOOD