hydraulic fracturing tests on sand at high stress

advertisement

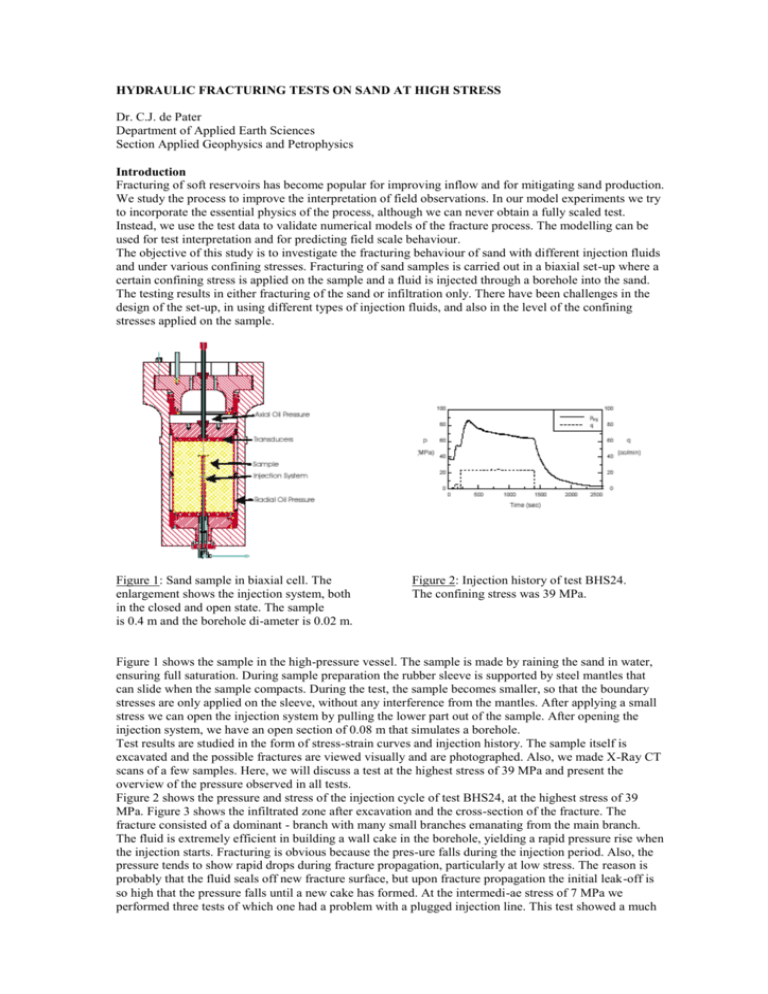

HYDRAULIC FRACTURING TESTS ON SAND AT HIGH STRESS Dr. C.J. de Pater Department of Applied Earth Sciences Section Applied Geophysics and Petrophysics Introduction Fracturing of soft reservoirs has become popular for improving inflow and for mitigating sand production. We study the process to improve the interpretation of field observations. In our model experiments we try to incorporate the essential physics of the process, although we can never obtain a fully scaled test. Instead, we use the test data to validate numerical models of the fracture process. The modelling can be used for test interpretation and for predicting field scale behaviour. The objective of this study is to investigate the fracturing behaviour of sand with different injection fluids and under various confining stresses. Fracturing of sand samples is carried out in a biaxial set-up where a certain confining stress is applied on the sample and a fluid is injected through a borehole into the sand. The testing results in either fracturing of the sand or infiltration only. There have been challenges in the design of the set-up, in using different types of injection fluids, and also in the level of the confining stresses applied on the sample. Figure 1: Sand sample in biaxial cell. The enlargement shows the injection system, both in the closed and open state. The sample is 0.4 m and the borehole di-ameter is 0.02 m. Figure 2: Injection history of test BHS24. The confining stress was 39 MPa. Figure 1 shows the sample in the high-pressure vessel. The sample is made by raining the sand in water, ensuring full saturation. During sample preparation the rubber sleeve is supported by steel mantles that can slide when the sample compacts. During the test, the sample becomes smaller, so that the boundary stresses are only applied on the sleeve, without any interference from the mantles. After applying a small stress we can open the injection system by pulling the lower part out of the sample. After opening the injection system, we have an open section of 0.08 m that simulates a borehole. Test results are studied in the form of stress-strain curves and injection history. The sample itself is excavated and the possible fractures are viewed visually and are photographed. Also, we made X-Ray CT scans of a few samples. Here, we will discuss a test at the highest stress of 39 MPa and present the overview of the pressure observed in all tests. Figure 2 shows the pressure and stress of the injection cycle of test BHS24, at the highest stress of 39 MPa. Figure 3 shows the infiltrated zone after excavation and the cross-section of the fracture. The fracture consisted of a dominant - branch with many small branches emanating from the main branch. The fluid is extremely efficient in building a wall cake in the borehole, yielding a rapid pressure rise when the injection starts. Fracturing is obvious because the pres-ure falls during the injection period. Also, the pressure tends to show rapid drops during fracture propagation, particularly at low stress. The reason is probably that the fluid seals off new fracture surface, but upon fracture propagation the initial leak-off is so high that the pressure falls until a new cake has formed. At the intermedi-ae stress of 7 MPa we performed three tests of which one had a problem with a plugged injection line. This test showed a much Figure 3: Several vertical fractures initiated from the injection pipe, test BHS24. A cross section of the main fracture shows many small branches. Figure 4: Normalised maximum pressure for all tests versus stress. smaller maximum pressure (but it was still rising at shut-in). The other two tests showed the same maximum pressure. The difference between these tests was the boundary condition at the ends of the open section. PVC end jackets were fitted over the steel injection tube to mitigate shear band formation when the borehole expands. The pressure turned out almost the same, but the fracture was closer to the middle of the open section. Tests at higher stress showed a lower relative pressure, although the decrease was fairly small. The fluctuations also became smaller at high stress. This can be caused by the change in leak-off at high stress, since it will be more difficult to build an effective filter cake. Also, there is more energy stored in the compressed fluid, so that the pressure does not drop suddenly when the fracture propagates. Figure 4 shows the normalised maximum pressure versus stress, for different injection fluids. Most tests showed a d-crease with stress that is in line with numerical simulations. Only the tests with bentonite slurry at low stress deviated strongly from the general trend. The tests show that fluid rheology is of vital importance for achieving efficient fractures. Good wallbuilding capability will yield a dominant fracture, which is important for well stimulation. On the other hand, the fluid rheology maybe used for avoiding fractures in drilling operations. References Pater, C.J. de, T.P. Lhomme, F. Henry, B. Bohloli, L.J. Beugelsdijk, A. Bezuije; Geometry of hydraulic fractures - Progress Report 18, TUD Report, 10 p., 2002. Pater, C.J. de, T.P. Lhomme, F. Henry, L.J. Beugelsdijk, A. Bezuije; Geometry of hydraulic fractures Progress Report 19, TUD Report, 14 p., 2002. Dong, C., C.J. de Pater, Numerical modeling of crack reorientation and link-up, Advances in engineering software, Vol. 33, p 577-587, 2002. Lhomme, T.P., C.J. de Pater; Experimental study of hydraulic fracture initiation incolton sandstone, SPE Paper 78187, Proc. SPE/ISRM Rock Mechanics Conference, Irving TX, 20-23 Oct. 2002. Minner, W.A., C.A. Wright, G.R. Stanley, C.J. de Pater, T.L. Gorham, L.D. Eckerfield, K.A. Hejl; Waterflood and production-induced stress changes dramatically affect hydraulic fracture behavior in lost hills infill wells, SPE Paper 77536, Proc. SPE Annual Conf. & Exhib., San Antonio, 29 Sept-2 Oct. 2002. Dam, D.B. van, P. Papanastasiou, C.J. de Pater; Impact of rock plasticity on hydraulic fracture propagation and closure, SPE P&F, August 2002, p. 149, SPE Paper 78812. Bezuijen, A., J.P. Pruiksma, C.J. de Pater; Maximum pressures in tunnelling limited by hydraulic fractures, Proc ITA Conference Amsterdam, 2002. Henry, F., J.T. Fokkema, C.J. de Pater; Experiments on Stoneley wave propagation in a borehole intersected by a finite horizontal fracture, Extended abstract P143, 64th EAGE Conference & Technical Exhibition, Florence, Italy.