Chilled water discharge plan - Facilities Planning and Management

advertisement

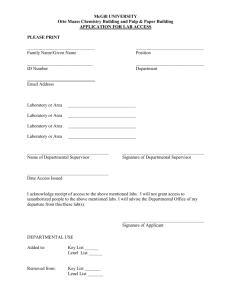

Revised November 2013 G:\Facilities Services (Miller)\Bldg Maint\Chilled Water Discharge (Utilities -do not delete)\June 2005 Draft Chilled water discharge plan Utilities.doc Operating Procedure - ISU Utilities Central Chilled Water System Discharge Identification and Correction To be updated by Steve Mayberry Purpose To identify and minimize discharges from the central chilled water system. Primary Authority / Coordinator The Power Plant Shift Supervisor(phone 294-4926) will be the primary authority coordinating activities until a discharge (leak) is found and corrected. The Power Plant control room will act as the message center to receive and provide information to the personnel responding to locate the discharge. Searches to locate the point of discharge shall be continued until new direction is given from the Power Plant Shift Supervisor. If needed, the Power Plant Shift Supervisor may arrange a meeting in the Power Plant with the Departmental Contacts (see table in this document). Background The chilled water system is chemically treated. Molybdate had been the corrosion inhibitor maintained in the system at concentrations near 5 PPM (3 -PPM molybdenum). Molybdenum concentration in the university sanitary outfall is limited to 0.250 PPM by the University / City of Ames Domestic Water Pretreatment Agreement. Therefore, chilled water discharges into the sanitary sewer system needs to be managed to prevent violations and fines. The Utilities Department manages the Domestic Water Pretreatment Agreement for the University. The current chemical treatment program no longer uses molybdate as the corrosion inhibitor; this treatment program eliminates chemical loading concerns with the Ames treatment facility. Page 1 of 11 Approval of Discharges & Filling of the System Within Each Building Unavoidable discharges of chilled water shall be coordinated with Mike Murray (2948751). Randy Larabee (520-1503) is the backup coordinator. Approval of intentional chilled water discharges may be granted provided discharge times, flow rates, and quantities are pre-planned. Actual discharge information shall also be provided to the coordinator when the discharge is completed. Approval of Filling of the System Within Each Building An organization planning an activity, which will cause chilled water make-up to occur, shall contact the Power Plant Shift Supervisor (phone 294-4926) to notify when the activity is to start and finish. This reduces the chance of having the Power Plant staff misinterpret the planned maintenance activity as a leak. Page 2 of 11 System Maintenance Chilled water piping and coils are to be inspected regularly for leaks as part of routine maintenance schedules. Maintenance personnel shall correct any detected leaks at the time of the inspection. Un-repairable leaks shall be reported to the Power Plant Shift Supervisor who will maintain an on-going file of current issues. The file will include approximate flow rates and the expected repair date. Once repaired, the Power Plant Shift Supervisor shall be notified. Training All ISU employees associated with the chilled water system shall be familiar with the contents of this procedure. Departments should review this document as needed to maintain familiarization. Chilled Water Make-up Monitoring The chilled water make-up is monitored by a metering installation in the Power Plant. Chilled water make-up to the system should occur only in the Power Plant. Otherwise, erroneous measured make-up quantities will occur. Potential make-up from other sources shall be identified and removed. If makeup rates occur outside of established parameters, the appropriate action plan listed within this document shall be followed. Action Plan When Unplanned Losses Are Recognized The action plan is based upon the flow rate magnitude as listed in the sections below. The Power Plant Operator (phone 294-4926) will provide email instructions / updates. The Power Plant Operator will communicate directly to the Departmental Contacts across campus as shown in the table below. Communication and coordination within the department will be the responsibility of the Departmental Contact. Information provided by the Power Plant Operator shall include when the situation started average flow rate (gpm) expected action including the urgency (dependant on flow rate) when feedback is needed provide web link to this written procedure at http://www.fpm.iastate.edu/utilities/chw_system_discharge/ Page 3 of 11 Helpful Tips to Assist in Locating a Leak 1) Process cooling loops sometimes have lines going to drains. These locations are suspects and should be included in specific building inspection checklists. 2) Locations where recent system modifications / construction have occurred tend to increase the probability of a discharge. 3) Piping & coils exposed to extreme cold air conditions are suspect and should be included in the specific building checklists. Examples include air handlers with cooling coils that have outside air dampers. Accumulated chilled water typically is present inside the air handler casing. 4) Gasketed joints in direct buried piping are subject to corrosion. The joints are typically at hot tap valves. Removing the lids on direct buried valves can sometimes show standing water that may be associated with an underground leak. A final update will be sent out to inform everyone that the situation has been corrected along with information detailing what was found. Departmental Contact Call List Department Primary Contact (phone) Alternative Contact (phone) Residence Randy Monthei (1) After hour Manager On- Randy cell (290-5504) Call pager 24 Hr Help Desk (294-3322) (515) 239-2801 6:00am to 7:00pm M-F 6:00 am to 4:30 pm Sat-Sun (2) Randy Monthei (8263425) cell (290-5504) (3) Richard Garrey Work phone 294-6836 Home 515-382-8733 Page 4 of 11 Ames Lab Mark Grootveld (1)Mike Valcav (294-7891) Guard Desk 24/7 (294-3483) (2) Mark Grootveld (2947895) Soil Tilth Jerry Hatfield (294-5723) After hours (1) xxxxx(xxx-xxxx) (2) Ron Cochran (294-7515) Memorial Union Ken Umbaugh (294-1147) (1) Mark Turner (4-1449) Ken Umbaugh Cell (460- Turner cell (450-0401) 6800) (2) After Hours Main Desk (294-1031) for call-in list Ron Home (597-2372) (1)Kenny Bollenbaugh(4608533) (2) Don Hoffmann (733- Service Center (294-5100) 4437) FP&M General University Ron Cochran Building Maintenance Ron cell (460-8531) Hoffman cell (460-8534) FP&M General University Mike Murray (294-8751) Mike Murray ( 296-1015) Utilities Mechanical Randy Larabee (520-1503) Distribution After Hour Call (294-5100) FP&M General University Mike McGraw (294-8333) Jeff Witt (294-8286) Utility Production FP&M General University Dean McCormick (294-0563) After Hours Service Center Construction (294-5100) Administration Ron Cochran (597-2372) Page 5 of 11 Actions will be taken based up the makeup flow rate as shown in the sections below. O GPM Makeup (unintentional) Make-up average over the a day is essentially 0 GPM and this condition is sustained for two consecutive days. The condition would suggest that unintentional / un-metered make-up is occurring. A) Departmental Contact: a. Initial Contact: Power Plant Operator (phone 294-4926) will email departmental contacts to have each department inspect their buildings / systems within next two business days. b. Departmental Action: The departmental contact shall reply by email to the Power Plant Operator indicating receipt of the email message as soon they receive it and follow up with any questions that they may have. The departmental contact will distribute the information with the appropriate departmental staff members. The departmental contact shall maintain an internal check-off list of building systems and tasks to complete. c. Departmental Response: The completed task list shall be emailed back to the Power Plant Operator within two days after being notified. The task list should indicate what actions were taken and describe anything out of the ordinary. B) Set Up Meeting: If the unintended make-up is not located within 4 business days of being observed, the Power Plant Operator (phone 294-4926) will arrange a meeting with the Departmental contacts to discuss what additional actions can be taken. During the meeting, potential resolution of the situation will be discussed. Potential actions may include: a. Shutting down individual buildings while monitoring the makeup b. Shutting down sections of the distribution piping while monitoring the makeup c. Recalibrate / test makeup meter. Page 6 of 11 0.2 -2 GPM Makeup This is the expected make-up to the system under normal operating conditions. No action is required. 2-10 GPM Makeup Make-up average over the day is greater than 2 gpm and less than 10 GPM and the makeup is sustained for two consecutive days. A) Departmental Contact: a. Initial Contact: Power Plant Operator (phone 294-4926) will email departmental contacts to have each department inspect their buildings / systems within next two business days. b. Departmental Action: The departmental contact shall reply by email to the Power Plant Operator indicating receipt of the email message as soon they receive it and follow up with any questions that they may have. The departmental contact will distribute the information with the appropriate departmental staff members. The departmental contact shall maintain an internal check-off list of building systems and tasks to complete. c. Departmental Response: The completed task list shall be emailed back to the Power Plant Operator within two business days after being notified. The task list should indicate what actions were taken and describe anything out of the ordinary. Specifically, actions taken that result in an increase or decrease in the system make-up should be clearly noted in detail. B) Utility Operations Actions a. Main Plant 1. Check the evaporator vents and drains on chillers 1,2,3 & 4 for any indication of leakage. 2. Check the primary pumps 1,2,3 & 4 and associated piping for any indication of leakage. 3. Check the supply and return header piping for any indication of leakage. 4. Check the filter, filter pump and associated piping for any indication of leakage. Page 7 of 11 5. Check the makeup controller and confirm set point 75 psi and note controlled variable. 6. Check the 1 inch makeup valve and insure proper operation b. North Campus Chiller Plant 1. Check all chilled water piping for any indication of leakage. 2. Check the evaporator vents and drains for any indication of leakage. 3. Check the primary pump and associated piping for any indication of leakage. C) Mechanical Distribution System Actions: a. Sewer Sampling: Utility Mechanical Distribution staff will take a grab sample from the sanitary sewer manhole SA11D10 (City # 739) located at the intersection of Beach Avenue and Lincolnway within one business days after being notified. The sample(s) shall be retained for testing to identify molybdate levels should the sustained make-up present a sewer effluent violation potential based upon discussions with the City of Ames Water Pollution Staff (see external notification section). b. Surface Check: The Mechanical Distribution staff will also survey the ground surface over buried distribution piping to locate water that may be coming out the ground. c. Valve Box Check: After the initial surface review, each valve box shall be check within two business days after being notified to see if water is accumulating in the box. Accumulated water shall be tested in the Power Plant water lab to verify if molybdate is present which would tend to indicated a chilled water leak. D) Set Up Meeting: If the leak is not located within 4 business days of being observed, the Power Plant Operator will arrange a meeting with the Departmental contacts to discuss what additional actions can be taken. During the meeting, potential resolution of the situation will be discussed. Potential actions may include: a. Shutting down individual buildings while monitoring the makeup Page 8 of 11 b. Shutting down sections of the distribution piping while monitoring the makeup c. Monitoring the storm and sanitary sewer effluent to measure molybdenum concentrations in trunk lines across campus that potentially could focus the search to specific locations on campus. d. Recalibrate / test makeup meter. In Excess of 10 GPM Makeup Make-up average over a four hour period is greater than 10 GPM. Each department shall maintain their staff on-site looking for the leak unless the Power Plant Operator provides different instructions. A) Departmental Contact: a. Initial Contact: Power Plant Operator (phone 294-4926) will call the departmental contacts to have each department inspect their buildings / systems after the four hour period. After hour call in lists will be utilized by the Power Plant Operator if needed to personally contact each departmental contact. The Power Plant Operator will also send out an email to document relevant information. b. Departmental Action: The departmental contact will distribute the information with the appropriate departmental staff members. The departmental contact shall maintain an internal check-off list of building systems and tasks to complete. c. Departmental Response: The departmental contacts shall email the task list back to the Power Plant Operator within 4 hours after being notified and follow-up with an email. The task list should indicate what actions were taken and describe anything out of the ordinary. Specifically, actions taken that result in an increase or decrease in the system makeup should be clearly noted in detail. B) Utility Operations Actions a. Main Plant Page 9 of 11 i. Check the evaporator vents and drains on chillers 1,2,3 & 4 for any indication of leakage. ii. Check the primary pumps 1,2,3 & 4 and associated piping for any indication of leakage. iii. Check the supply and return header piping for any indication of leakage. iv. Check the filter, filter pump and associated piping for any indication of leakage. v. Check the makeup controller and confirm set point 75 psi and note controlled variable. vi. Check the 1 inch makeup valve and insure proper operation b. North Campus Chiller Plant i. Check all chilled water piping for any indication of leakage. ii. Check the evaporator vents and drains for any indication of leakage. iii. Check the primary pump and associated piping for any indication of leakage. C) Distribution System Actions: a. Sewer Sampling: Utility Mechanical Distribution staff will take a grab sample from the sanitary sewer manhole SA11D10 (City # 739) located at the intersection of Beach Avenue and Lincolnway within 4 hours after being notified. The sample(s) shall be retained for testing to identify molybdate levels should the sustained make-up present a sewer effluent violation potential based upon discussions with the City of Ames Water Pollution Staff (see external notification section). b. Surface Check: The Mechanical Distribution staff will also survey the ground surface over buried distribution piping within 4 hours after being notified and follow-up with an email to locate water that may be coming out the ground. c. Valve Box Check: After the initial surface review, each valve box shall be checked within 4 hours after being notified to see if water is accumulating in the box. Accumulated water shall be tested in the Power Plant water lab to verify if molybdate is present which would tend to indicated a chilled water leak. Page 10 of 11 d. Confirming Task Completion: Upon completion of the sewer sampling, surface check, and valve box check; an email shall be sent to the Power Plant Operator. D) Set Up Meeting: If the leak is not located within 4 hours, the Power Plant Operator (phone 294-4926) will arrange a meeting with the Departmental contacts to discuss what additional actions can be taken. This meeting would be set up even if this search is occurring outside the normal working hours. During the meeting, potential resolution of the situation will be discussed. Potential actions may include: a. Shutting down individual buildings while monitoring the makeup b. Shutting down sections of the distribution piping while monitoring the makeup c. Monitoring the storm and sanitary sewer effluent to measure molybdenum concentrations in trunk lines across campus that potentially could focus the search to specific locations on campus. d. Recalibrate / test makeup meter. E) External Notification: If the discharge exceeds 10 gpm for 15 hours, External Notification procedures will be followed. Mike Murray (alternate – Randy Larabee) will be responsible for notifying the City of Ames Water Pollution Control Facility of planned and accidental chilled water discharges. If directed by the City of Ames Water Pollution Control Facility, a continuous wastewater sampler may be needed at sanitary sewer manhole SA11D10 (City # 739) located at the intersection of Beach Avenue and Lincolnway. Page 11 of 11