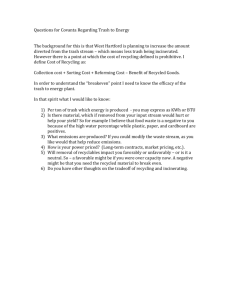

Concept:Energy Generation at Sugarcane Mills Using Trash

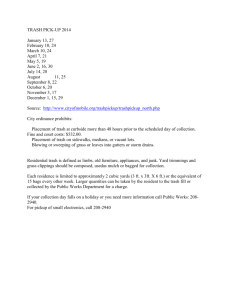

advertisement