Lantoom Rubble Cladding Specification

advertisement

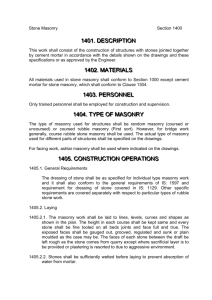

Disclaimer: These specifications address generally accepted methods and details for installation of rubble stone cladding. To the best of our knowledge, it is correct and up to date. However, this information is designed only as a guide; and it is not intended for any specific construction project. Lantoom Quarry makes no express or implied warranty or guarantee of the techniques, construction methods or materials identifed herein. It is understood that there are alternative means or methods that might be required and/or recommended based on project conditions, manufacturer’s recommendations, or product characteristics. To be clear, the following specifications are for builders, architects, designers, masons, installers and other construction professionals. The following specifications illustrate typical applications of rubble stone cladding. It is the responsibility of all architectural and construction professionals to determine the applicability and appropriate application of any detail to any specific project. Lantoom Rubble Cladding Specification • Manufacturer: Lantoom Quarry - Web: http://www.lantoom.co.uk/ - Tel: +44 (0)1579 308 234 - Product reference: Natural Rubble Cladding • Size: [300 x 300 mm]. [??? x ??? mm]. • Thickness: [90 mm]. [?? mm]. • Colour: [????]. [????]. . • Surface finish: [Flamed ] [Honed]. External Stone Walls. - Rubble Build the external walls of rubble from the Lantoom quarries. To be laid random, with hammerdressed joints, and the outside face split so that the projection shall not exceed 2 inches. The stones to be laid on their natural bed, with good vertical bond, and to be one through stone in every .9 M2 of wall. All stones showing on the exterior to be selected from the largest in the pile, and as few spalls to be used as possible. Every stone to be well bedded in mortar, made of 1 part cement and 2 parts clean, sharp sand, and all joints and chinks filled solid with mortar and spalls. All inside joints to be smoothly pointed with the trowel as the wall is built. After the wall is built the joints on the outside are to be raked out and filled with cement mortar, and a false joint of red Portland cement mortar run with a jointer and straight-edge, in imitation of broken ashlar. Specification for Coursed Rubble Stone Material Specification Stone shall be hard, sound, free from decay and weathering. Stones with porous matter or with boulder skin shall be rejected. The size of stones shall not be less than 7cm in any direction.Cement and sand for cement mortar or lime and surkhi for lime mortar shall be of standard specification. Laying Technique specified All the stones shall be thoroughly wetted before laying. Every course of stone shall be hammer dressed and laid truly horizontal and every vertical joint shall be truly vertical. Faces shall be accurately squared and each face joint shall be dressed at right angles. The face stones shall be laid in alternate headers and stretchers fashion. The masonry shall be carried up regularly and true to plumb. The thickness of joints shall not exceed 12mm. Bond or through stones The stones going through in the walls shall be well distributed by arranging them in a staggered fashion in successive courses. The intervals of through stones shall not be less than 1.5m in each course. For walls up to 60cm thickness, a through stone shall extend from one face of the wall to the other. Laying of Quoins Corner stones or quoins shall be dressed to correct angle. The short bed of the stone shall be at least equal to height. The quoins shall be laid with header and stretcher in alternate layers. Curing Method The work shall be protected from rain or sun while it is curing. At the end of the day’s work, the top surface of the walls shall be kept wet so that it acquires the required strength. The masonry shall be kept moist on all the faces for at least 8 days. NBS Specification F20 NATURAL STONE RUBBLE WALLING GENERAL Cross-reference General: Read with A90 General technical requirements. Mortar: Read with Z21 Mortars. PRODUCTS Stone Quality: Thoroughly seasoned and free from cracks, vents, fissures or other defects deleterious to strength, durability or appearance. EXECUTION Adverse weather General: Do not use frozen materials or lay on frozen surfaces. Air temperature: Do not lay stones: • In cement gauged mortars: At or below 3°C and falling or unless it is at least 1°C and rising. • In hydraulic lime:sand mortars: At or below 5°C and falling or unless it is at least 3°C and rising. Temperature of walling during curing: Above freezing until mortar hardened. Newly erected walling: Protect at all times from: • Rain and snow. • Drying out too rapidly in hot conditions and in drying winds. Laying Absorbent stones: Dampen in warm weather to reduce suction. Do not soak. Mortar joints: • Laying: Full bed of mortar with all joints and voids filled. • Appearance: Neat and consistent. • Brushed finish to joints: After the initial set has taken place, brush joints to remove laitance/ excess fines and give a coarse texture. Orientation for natural bed of stones: • In plain walling: Horizontal. • Coping and projecting stones: Vertical and at right angles to wall face. • Arches: Perpendicular to line of thrust. Appearance and bonding: Consistent overall appearance and good bond. Distribute different shapes, sizes and colours evenly throughout the face of the wall. • Random walling: Distribute different shapes, sizes and colours evenly throughout the face of the wall. Avoid long continuous vertical joints. Accuracy: • Walling generally: Plumb, unless specified otherwise. • Setting out: Achieve satisfactory junctions and joints with adjoining or built-in elements and components. • Coursed work: Courses true to line and level. Cleanliness: Keep facework clean. Rubbing and other abrasive or chemical cleaning methods to remove marks and stains not permitted. Ground level Extent of facework below finished level of adjoining ground or external works (minimum): 150 mm. Putlog scaffolding Use: Not permitted in facework. Cavity walls Regularity: Dress stones to give consistent leaf thickness and maintain full cavity width. Quoins and jambs Selection of stones: Large stones, dressed to a regular shape. Laying: In advance of main body of walling. Bonders for walls faced both sides Bonding stones: • Length: Two thirds the thickness of the wall. • Height: Not less than one third of length. • Distribution: One to every square metre of each side of wall and staggered.